Hard-shell encapsulation structure of lithium-ion battery and processing method of hard-shell encapsulation structure

A lithium-ion battery and packaging structure technology, which is applied to structural parts, battery pack parts, battery boxes/coats, etc., can solve the problems of cumbersome hard shell packaging steps and time-consuming operations, and achieve the goal of being suitable for large-scale production and saving energy. The effect of high man-hours and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

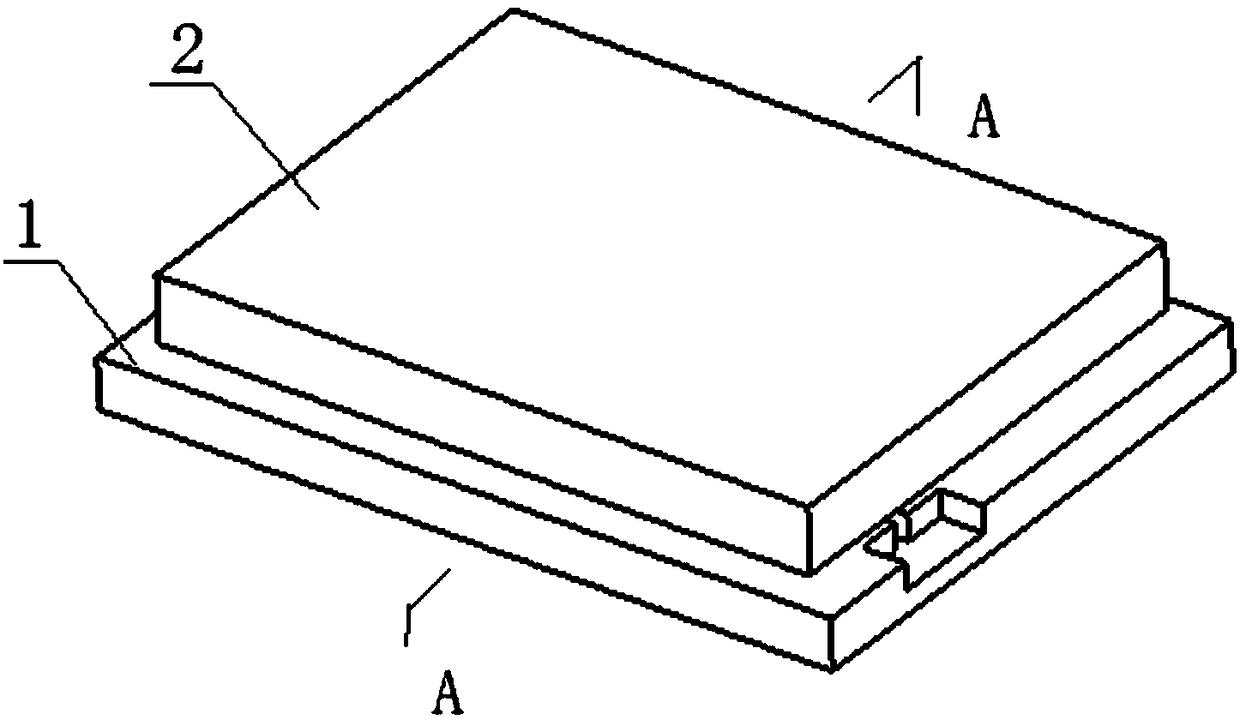

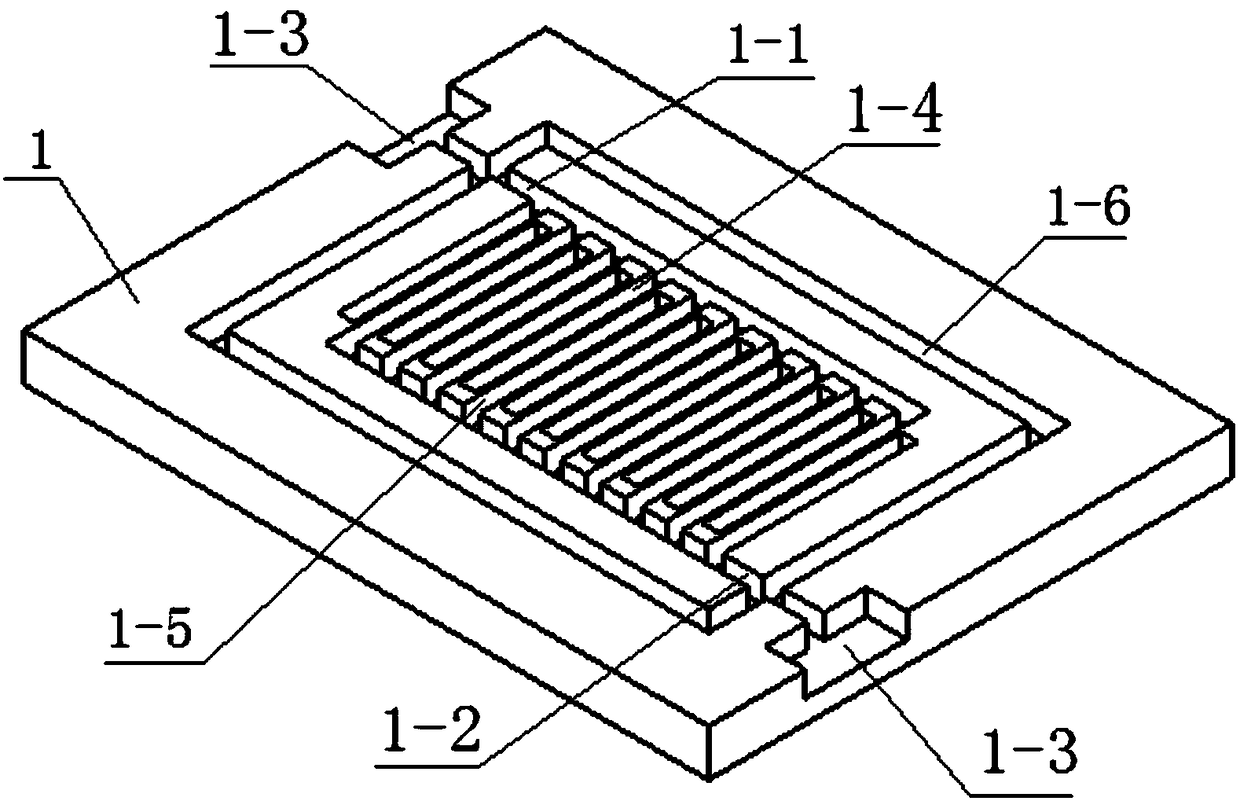

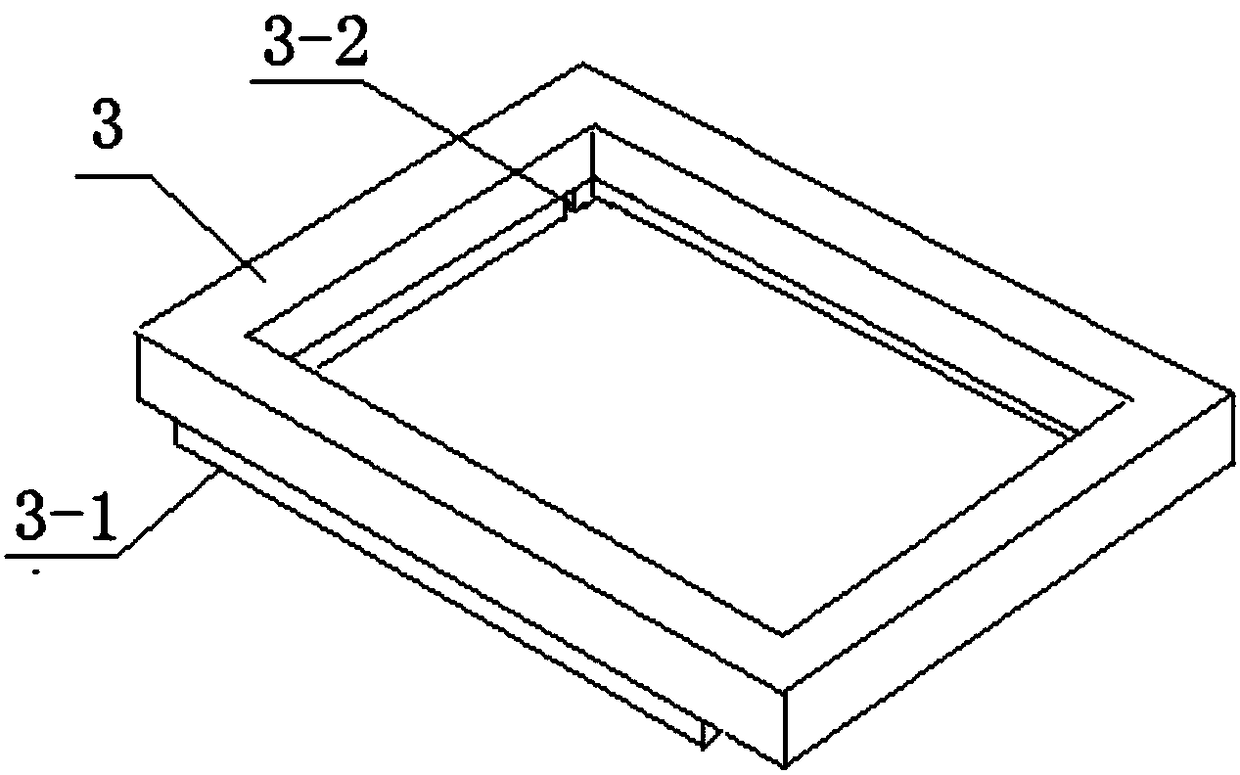

[0016] Such as figure 1 , 2 , 3, and 4 show the embodiment of lithium-ion battery hard shell packaging structure, which is composed of a substrate 1, an enclosure 3 and a buckle cover 2. The substrate 1 is provided with a longitudinal positive tab lead-out groove 1-1 and a negative pole tab lead-out recess. The slots 1-2 and the extended grooves 1-3 at their lead ends, and the extended grooves 1-3 of the lead-out grooves of the positive and negative tabs are located at opposite ends of the substrate 1, respectively. The expanded grooves 1-3 with increased area facilitate the measurement of electrochemical performance.

[0017] The substrate 1 between the lead-out grooves of the two tabs is provided with two sets of radial grooves at equal intervals embedded in the positive and negative electrode collectors, namely the positive electrode collector groove group 1-4 and the negative electrode collector groove group 1-5, wherein the positive electrode current collector groove gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com