A temperature control system for mems devices

A temperature control system and device technology, applied in the field of sensors, can solve the problems that the temperature sensor cannot accurately measure the temperature of the device, cannot reflect the temperature difference between the upper substrate and the lower substrate, and the temperature performance temperature of the MEMS device, so as to improve the temperature performance and reduce the cost. , the effect of controllable structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

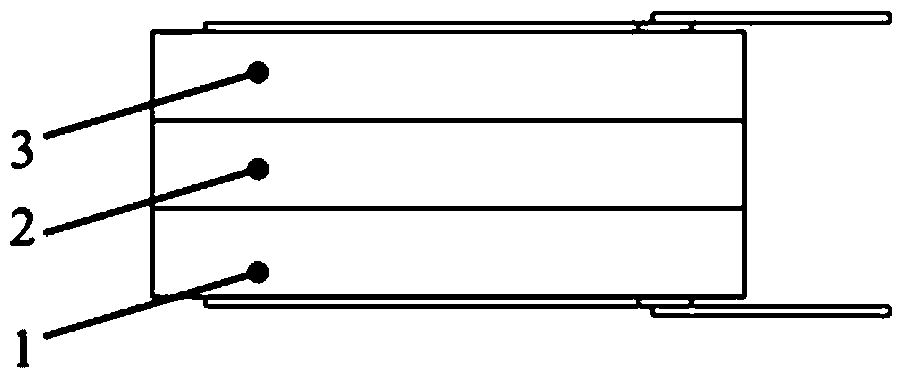

[0017] Such as figure 1 As shown, the MEMS device structure of the present invention includes a sensitive layer structure 2, an upper substrate 3 and a lower substrate 1, and the sensitive layer structure is a movable structure prepared by wet etching or dry etching, and the structure can be Due to external acceleration, rotation, and pressure, a certain change in motion state occurs. This structure is the core structure for detecting the object to be measured. The above three-layer structure is prepared as a whole by bonding technology.

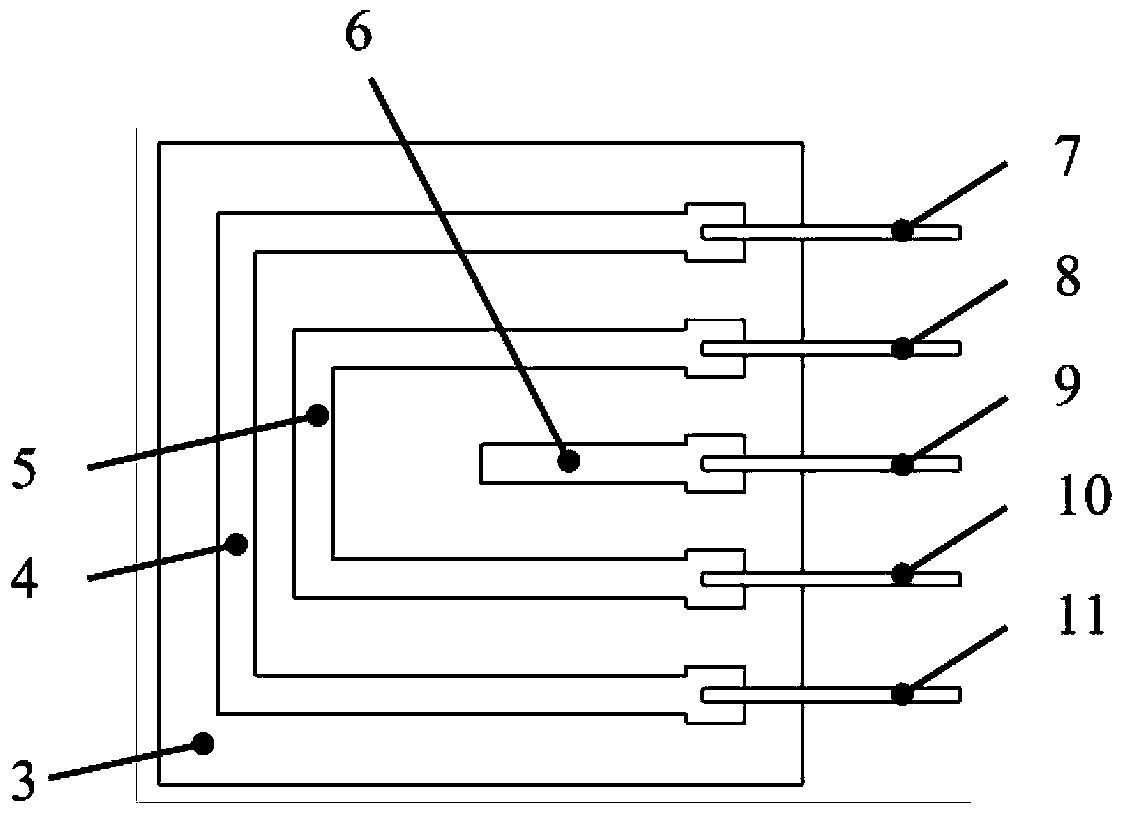

[0018] The upper substrate and the lower substrate of the MEMS device of the present invention all adopt MEMS process to prepare temperature detection electrodes, heating electrodes and signal detection electrodes, the temperature detection electrodes on the substrate are used to test the temperature of the substrate, and the heating electrodes are used to heat the substrate , the signal detection electrode is used for testing to obtain elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com