Solid electrolyte SO2 gas sensor and manufacturing method thereof

A solid electrolyte and gas sensor technology, which is applied in semiconductor/solid-state device components, piezoelectric/electrostrictive/magnetostrictive devices, televisions, etc., can solve problems such as cumbersome production methods, poor performance parameters, and complexity. Achieve the effects of controllable electrode specific surface area, simple structure and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

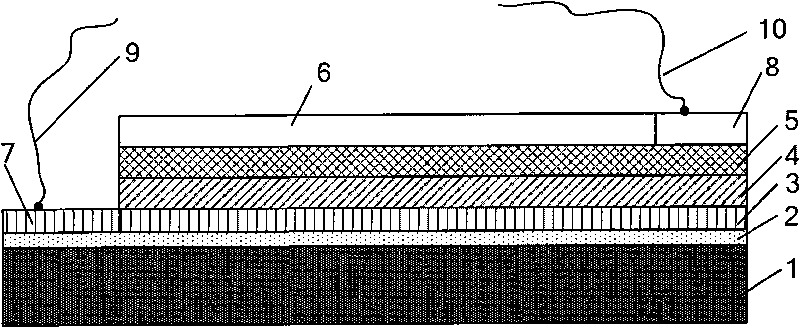

[0021] refer to figure 1 , is a kind of solid electrolyte SO of the present invention 2 The gas sensor has a silicon substrate 1, and SiO 1 is sequentially arranged on the silicon substrate 1. 2 Insulation layer 2, conductive film 3, Sn / SnF 2 Film 4, LaF 3 The solid electrolyte film 5 and the Pt net 6, the conductive film 2 is connected to the first lead wiring board 7, the Pt net 6 is connected to the second lead wiring board 8, and the first lead 9 and the second lead 10 are respectively pasted by conductive glue Connect out and connect to the measurement signal processing circuit.

[0022] SiO on silicon substrate 1 2 Insulation layer 2 is obtained by thermal oxidation of silicon wafers, in SiO 2 Metal Al is deposited on the insulating layer 2 by ion sputtering to form a connected conductive film 3 and the first lead wiring pad 7, and Sn / SnF is deposited on the conductive film 3 by ion sputtering. 2 Film 4, LaF 3 Solid electrolyte film 5, in LaF 3 The solid electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com