Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die steel forging production method

The invention discloses a die steel forging production method. The method includes the following steps that A, a forging die is preheated; B, a die steel ingot is manufactured; C, primary firing is conducted, a large platform is upset, and drawing is conducted through the WHF method; D, secondary firing is conducted, flatting is conducted first and then forging is conducted, side faces are trimmed, and the erecting and upsetting are conducted; E, tertiary firing and quartus firing are conducted, drawing, flatting and forging continue, and large faces and side faces are produced alternately. Large face pressing and side face trimming are conducted alternately. Metal plasticity is improved through recovery recrystallization, and corner cracks are prevented. The forging mode is optimized, ends enter an anvil and are pressed downwards and flatted reversely, axial tensile stress is reduced, and pull cracks of anvil connection portions are prevented.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Al-Ni alloy electroplating method in low-temperature salt melting system

The invention relates to an electroplating method, in particular to an Al-Ni alloy electroplating method in a low-temperature salt melting system. The Al-Ni alloy electroplating method in the low-temperature salt melting system is characterized in that in a pre- electrolyzing process, both a negative pole and a positive pole adopt aluminium sheets with the purity of 99 percent; and in an electroplating process, a mild steel sheet with the thickness of 1mm is taken as the negative pole, a pure aluminium material with the purity of more than 99 percent is taken as the positive pole, and an NiCl2+RClX+AlCl3+NaCl+KCl mixture is added into an electrolysis bath and is heated and melted into an electrolyte for electroplating. The invention has the advantages that aluminium and nickel chlorides are adopted as raw materials, and an additive is added, so that aluminium ions and nickel ions are electrolyzed and deposit together on negative-pole materials to generate a uniform and dense Al-Ni alloy plating; and through the adoption of the Al-Ni alloy electroplating method provided by the invention, low heat energy is required for producing the plating, the oxidation loss of the alloy metal is small, and the production cost is low.

Owner:淄博鸿润新材料有限公司

High-strength aluminium alloy

The invention discloses a high-strength aluminium alloy. The high-strength aluminium alloy comprises the following components in percentage by weight: 0.4-0.8% of Si, less than or equal to 0.7% of Fe, 0.15-0.4% of Cu, less than or equal to 0.15% of Mn, 0.8-1.2% of Mg, 0.04-0.14% of Cr, less than or equal to 0.25% of Zn, less than or equal to 0.15% of Ti, 0.2-0.4% of Pb, 0.4-0.8% of Bi and the balance of Al and inevitable impurities. The surface of an insert manufactured by using the high-strength aluminium alloy disclosed by the invention has few cold shut and cracks, the tensile strength of the insert reaches 290Mpa-360Mpa, the Rp of the insert reaches 240-330Mpa, the percentage elongation after fracture of the insert is 4%, and the Brinell hardness of the insert reaches 85-100HBW.

Owner:EC PRECISION TECHJIANGSUCORP

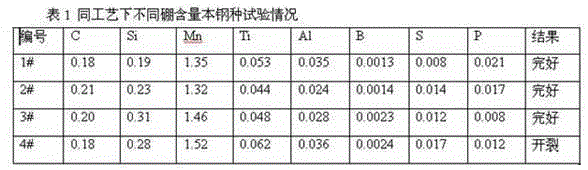

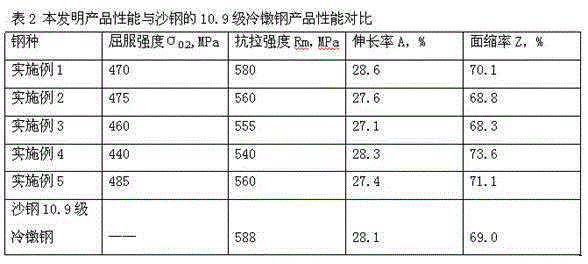

Production method for boron-containing cold heading steel

The invention relates to a production method for boron-containing cold heading steel and belongs to the field of metal materials produced in the metallurgical industry. The boron-containing cold heading steel comprises C, Si, Mn, Ti, Al, P, S, B and the balance Fe and inevitable impurities. According to the production method, the content of C, the content of Si and the content of B in the components are controlled, and metal such as Cr and V is not contained in the components. The product manufactured through the method is low in cost, few cracks are generated during production, and the performance of the steel subjected to heat treatment by users is stable; in addition, the purpose of high strength can be achieved after heat treatment, the high-strength cold heading steel has an obvious sigma 0.2 yield strength step in the using process, and thus the use safety of the cold heading steel is facilitated.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

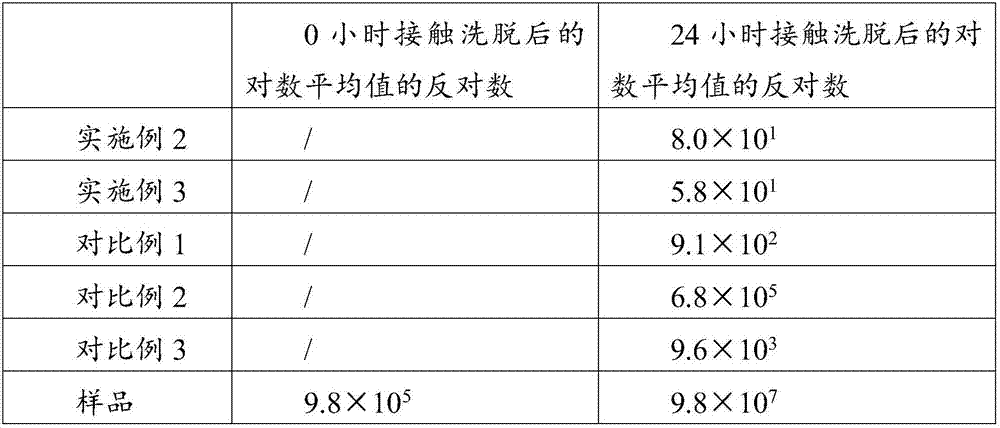

Mold-proof anti-microbial tile joint mixture and preparation method thereof

InactiveCN106927718AImprove caulk strengthReduce cracksBiocideDead animal preservationChemistryMagnesium

The invention discloses a mold-proof anti-microbial tile joint mixture and a preparation method thereof. The method comprises the following steps: taking easily acquired and low-cost nanometer magnesium oxide and chitosan as raw materials; performing chemical preparation, modifying treatment, water-bath heating compound, ice water cooling, centrifugal separation and vacuum freeze drying, thereby acquiring a nanometer magnesium oxide modified chitosan compound antibacterial agent; using the nanometer magnesium oxide modified chitosan compound antibacterial agent for preparing a tile joint mixture. The tile joint mixture prepared according to the invention has the advantages of low cost and good sterilizing effect. The color of the nanometer magnesium oxide modified chitosan is light when the nanometer magnesium oxide modified chitosan is applied to the joint mixture, so that the color of the joint mixture is not influenced.

Owner:FOSHAN LANRUI OUTE INFORMATION SERVICES CO LTD

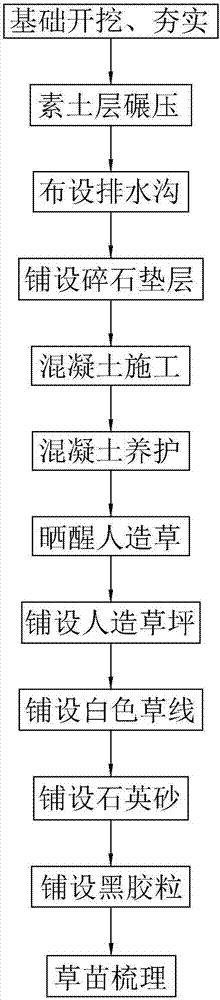

Construction method of plastic sports field

Owner:NANJING HANWEI SPORT ENG IND

Production method of 32Cr3Mo1V continuous casting large round billet for roller shell

The invention relates to the technical field of continuous casting large round billet production and specifically discloses a production method of a 32Cr3Mo1V continuous casting large round billet forroller shell. The production method of the 32Cr3Mo1V continuous casting large round billet for roller shell is provided for mainly solving the technical problems that a continuous casting large roundbillet in the prior art has large defects in the center of the large section and cannot be used as a major billet raw material for producing a 32Cr3Mo1V roller shell. The production method of the 32Cr3Mo1V continuous casting large round billet for the roller shell comprises the steps of molten steel smelting, wherein molten iron with the low impurity element content is adopted as the molten steelsmelting, and the impurity elements include less than or equal to 0.002% of Pb, less than or equal to 0.01% As, less than or equal to 0.002% of Sn, less than or equal to 0.003% of Sb and less than orequal to 0.002% of Bi; continuous casting, specifically, conducting protective casting in the whole continuous casting process, conducting constant-drawing-speed production, utilizing a crystallizer,conducting flow casting and end electromagnetic stirring to cooperate with weak secondary cooling water; and conducting heating, forging and pressing, low-temperature furnace charging, heating, upsetting, punching, drawing-out and broaching. The continuous casting large round billet produced through the production method has qualified chemical components. The low-power quality and the center quality of the continuous casting large round billet meet the requirements for forging the roller shell. The 32Cr3Mo1V continuous casting large round billet can be used for producing the 32Cr3Mo1V rollershell instead of steel ingots and has the good development prospects.

Owner:JIANGSU LIANFENG ENERGY EQUIP

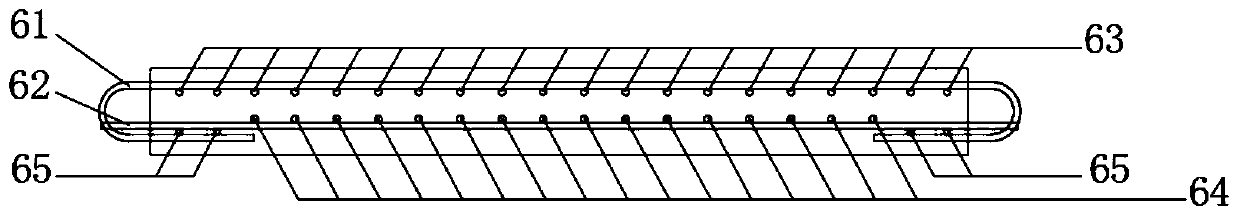

Pantograph carbon slide plate and preparation process thereof

The invention discloses a pantograph carbon slide plate. The pantograph carbon slide plate comprises the following raw materials in percentage by mass: 50 to 70 percent of graphite powder, 50 to 70 parts of corundum, 10 to 15 parts of carbon fiber, 20 to 30 parts of petroleum coke coarse powder, 20 to 30 parts of petroleum coke fine powder, 10 to 15 parts of high bauxite, 10 to 15 parts of asphaltadhesive, 5 to 10 parts of coal tar asphalt, 5 to 10 parts of copper powder and 5 to 10 parts of aedelforsite powder. The aedelforsite powder is added to the raw materials of the carbon slide plate,and the own characteristics of the aedelforsite powder are utilized, so that the surface expansion performance of the carbon slide plate is enhanced, cracks are reduced, the corrosion resistance, thedurability and the weather resistance are enhanced, and the structural shrinkage rate of the carbon slide plate during work is effectively reduced; the corundum material is adopted, so that the wear resistance of the carbon slide plate surface is guaranteed and the own thermal expansion rate of the carbon slide plate is reduced; the process is simple, low in requirement on equipment and high in operability, and has good social popularization application.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

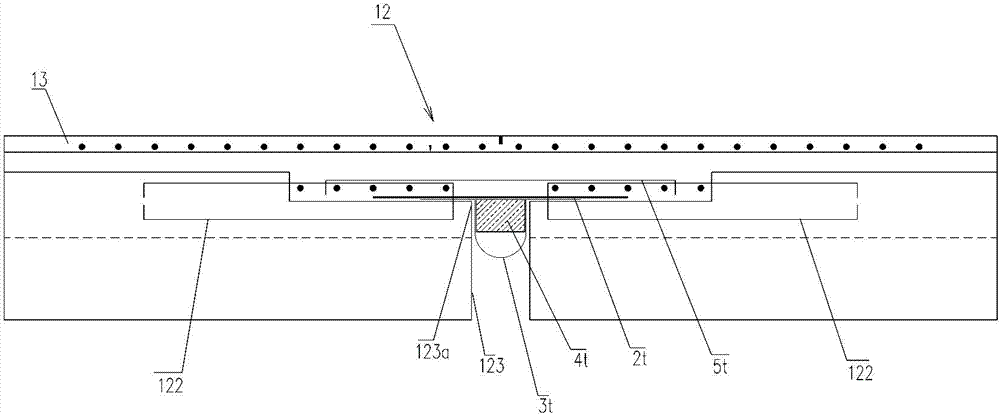

Touch panel and preparation method thereof

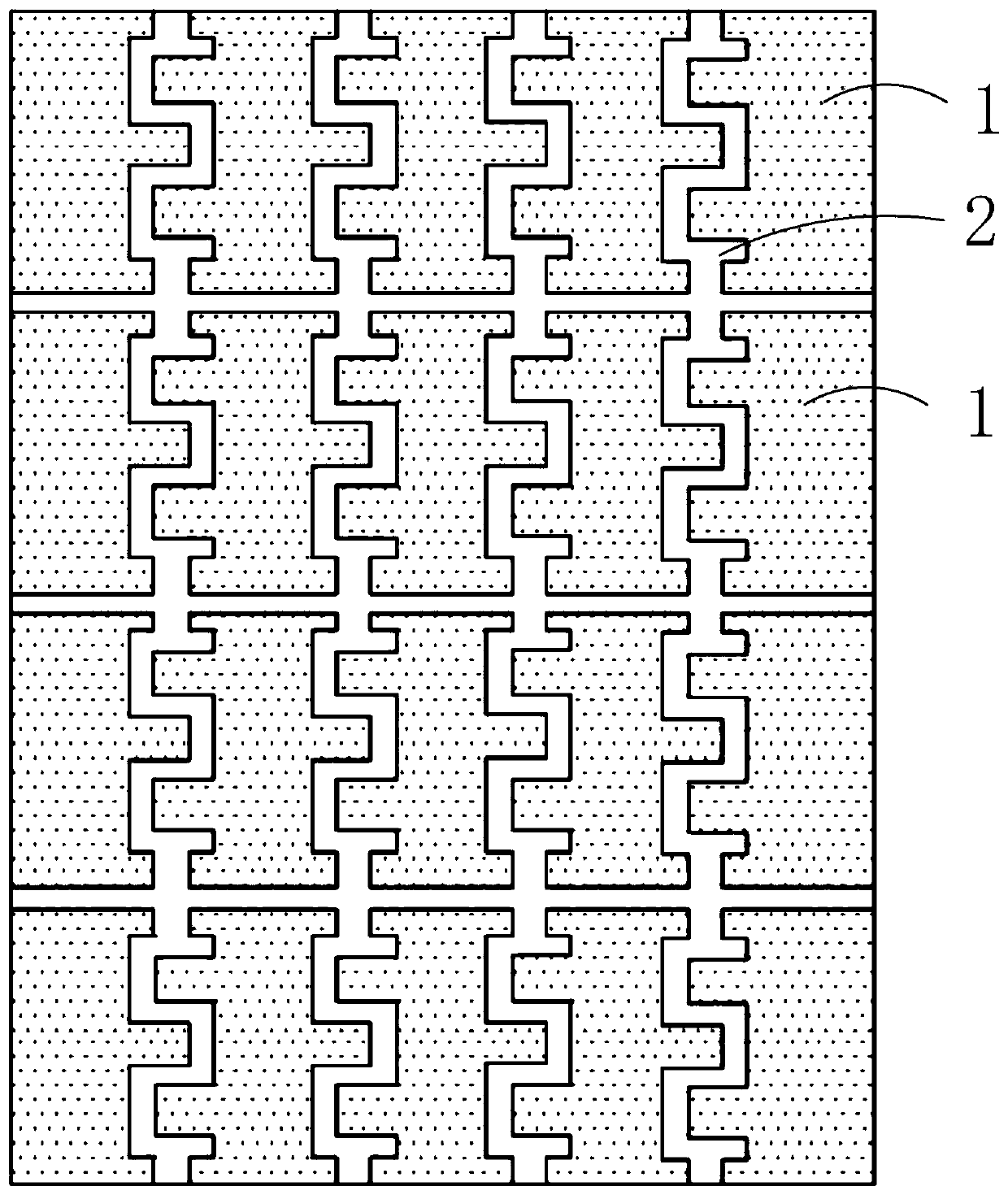

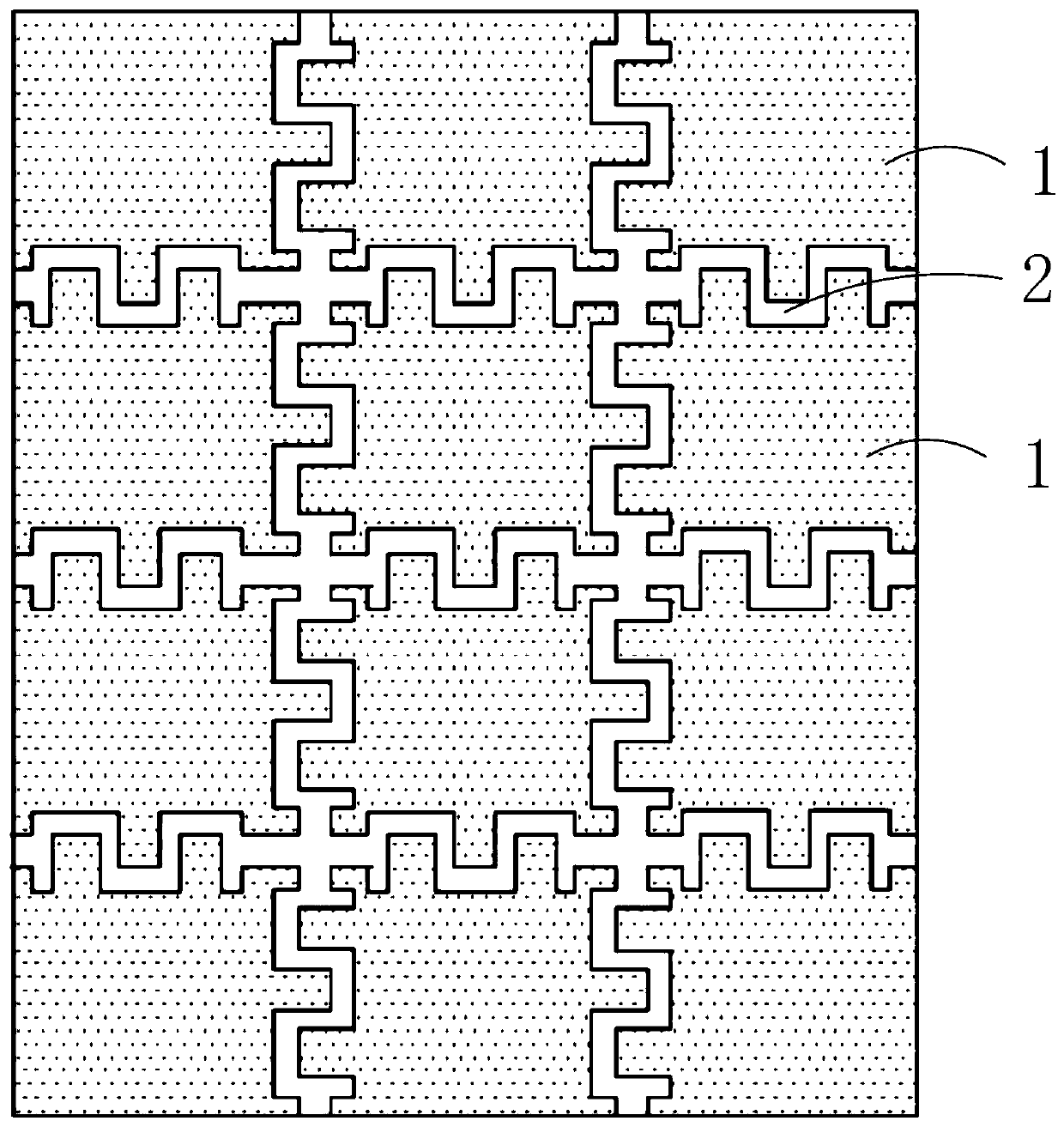

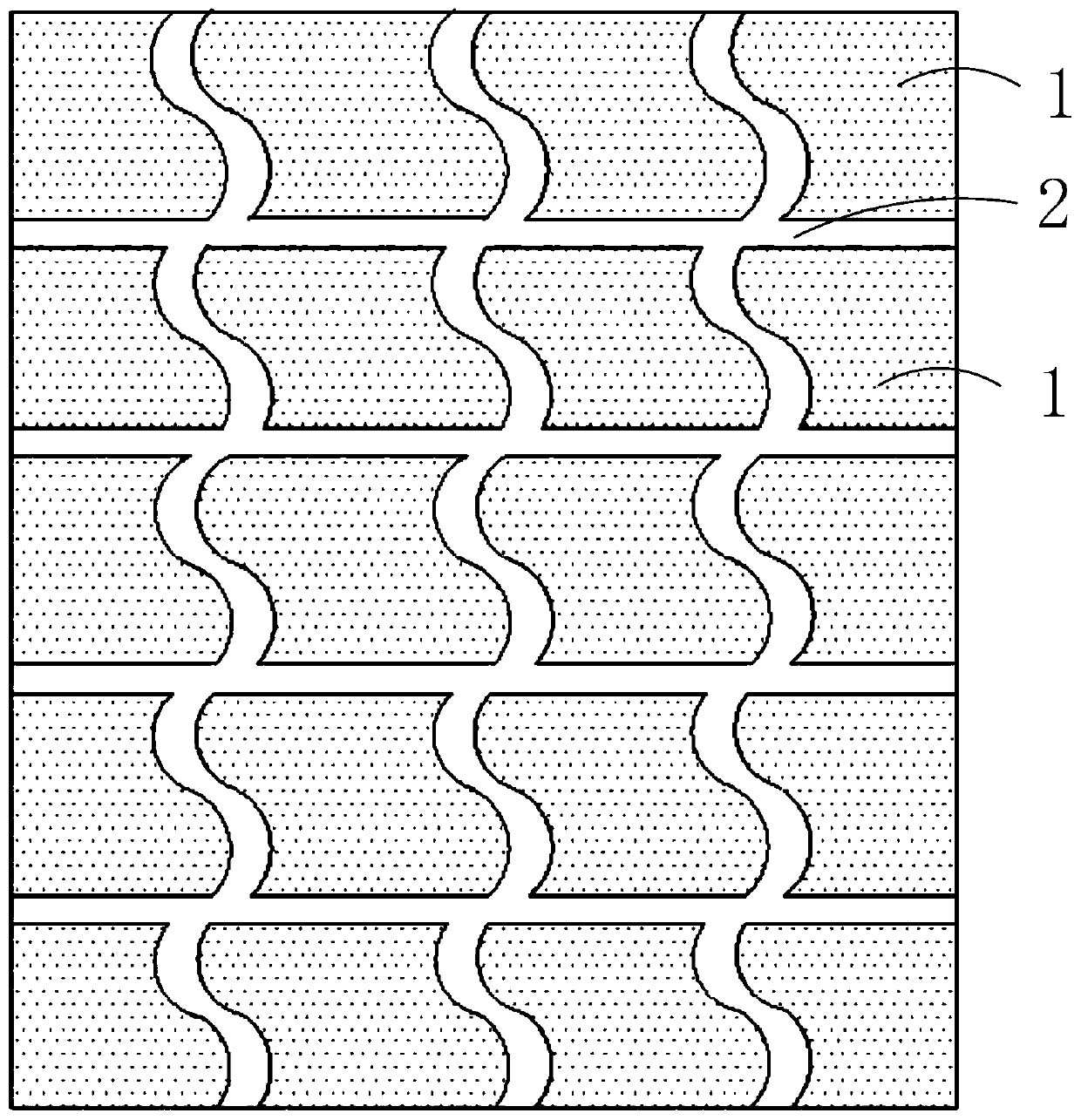

InactiveCN110045887AReduce delay effectReduce cracksSolid-state devicesNon-linear opticsTouch panelResistance capacitance

The invention provides a touch panel which comprises a substrate and a touch layer located on the substrate, the touch layer comprises a plurality of touch units arranged at intervals, an area betweenevery two adjacent touch units forms a lead area, and the lead areas are filled with lead materials;the edge of each touch unit is engaged with the edge of at least one adjacent touch unit, the touchpanel has the advantages that the graph of the touch unit inside the touch panel is made into a matched shape, the resistance-capacitance delay effect of the touch panel is reduced, and then the situation that the touch panel cracks is relieved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Ceramic self-cleaning glaze

The invention discloses a ceramic self-cleaning glaze. A ground glaze consists of 33 parts of an ultrafine quartz powder, 20 parts of feldspar, 10 parts of wollastonite, 5.5 parts of calcite, 4 parts of dolomite, 3.5 parts of bahrain soil, 6.5 parts of a calcined alumina powder, 2 parts of calcined zinc oxide, 4.5 parts of frit and 13 parts of an ultrafine zirconium silicate powder; an overglaze consists of the components in parts by weight; 38 parts of the ultrafine quartz powder, 24 parts of feldspar, 13 parts of wollastonite, 4 parts of calcite, 3 parts of dolomite, 4.5 parts of bahrain soil, 7 parts of a calcined alumina powder, 1.5 parts of calcined zinc oxide and 4.5 parts of frit; the particle size of the ground glaze is 1-10 microns, and the ground glaze is 0.8-1.2mm in thickness; the particle size of the overglaze is not greater than 10 microns, and the overglaze is 0.2-0.3mm thick; the ground glaze and the overglaze are calcined independently; the start temperature is 145 DEG C, the highest temperature is 1,298 DEG C, and the glazes are cooled to 70-80 DEG C; the calcining time is 12-22 hours. The number of needle holes and the number of cracks on the surface of the ground glaze are small, so that a product is uniform in texture, the surface is fine and bright, and dirt is unlikely to attach.

Owner:南安市荣兴专利技术转移中心有限公司

Large-span suspension bridge GFRP rib prefabricated slab composite beam bridge deck system and construction method thereof

PendingCN111472258AReduce cracksIncreased durabilitySuspension bridgeBridge structural detailsRebarLap joint

The invention discloses a large-span suspension bridge GFRP rib prefabricated slab composite beam bridge deck system, which comprises steel longitudinal beams, transverse tie beams, prefabricated bridge deck slabs and cast-in-place concrete joints, wherein the plurality of steel longitudinal beams are arranged in parallel at intervals, the two ends of the steel longitudinal beams are fixedly connected through the transverse tie beams, stud shear keys are arranged at the top ends of the steel longitudinal beams, the prefabricated bridge deck slab is erected above the two adjacent steel longitudinal beams, every two adjacent prefabricated bridge deck slabs are connected through the cast-in-place concrete joint, GFRP ribs are arranged in the prefabricated bridge deck slabs, the ends of the GFRP ribs protrude out of the prefabricated bridge deck slabs, and the reserved GFRP ribs at the ends of the prefabricated bridge deck slabs are embedded between the stud shear keys and connected with the GFRP ribs in the cast-in-place concrete joint in a binding and lap joint mode. According to the large-span suspension bridge GFRP rib prefabricated slab composite beam bridge deck system and the construction method thereof, cracks of the concrete slabs can be effectively reduced, and the durability problem of the bridge deck system due to the fact that cracked steel bars are exposed in a chlorine salt environment can be solved.

Owner:WUHAN UNIV OF TECH

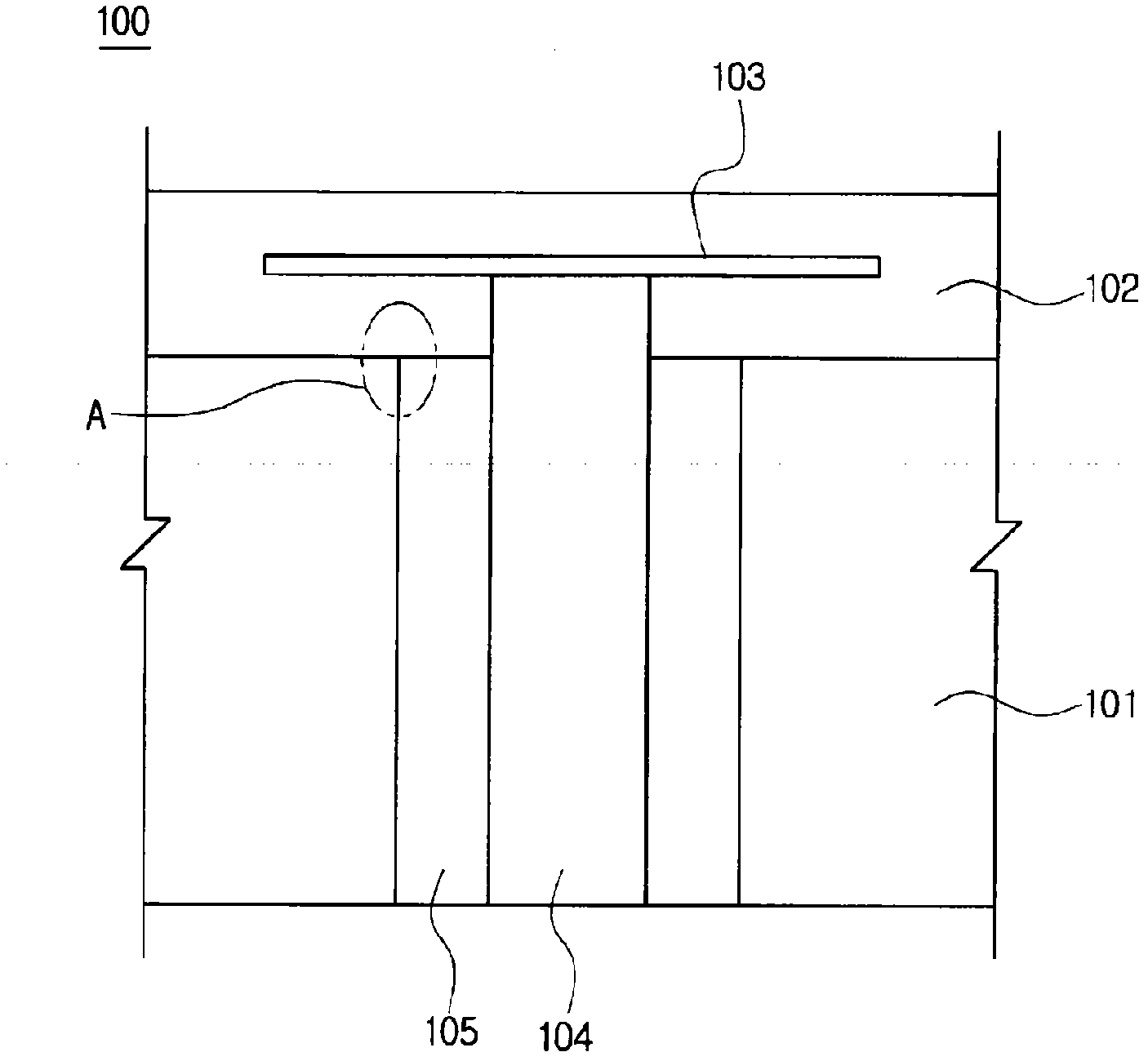

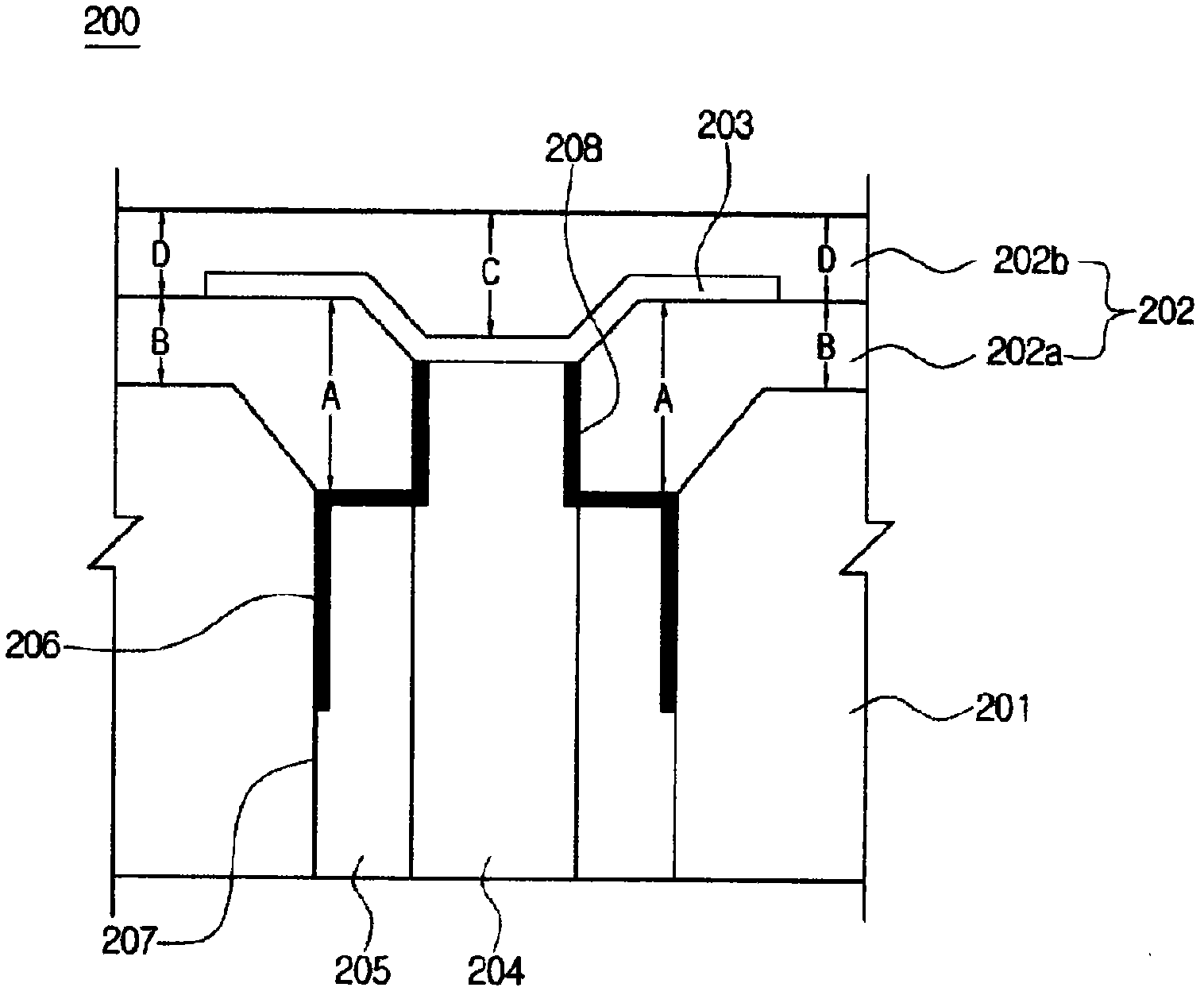

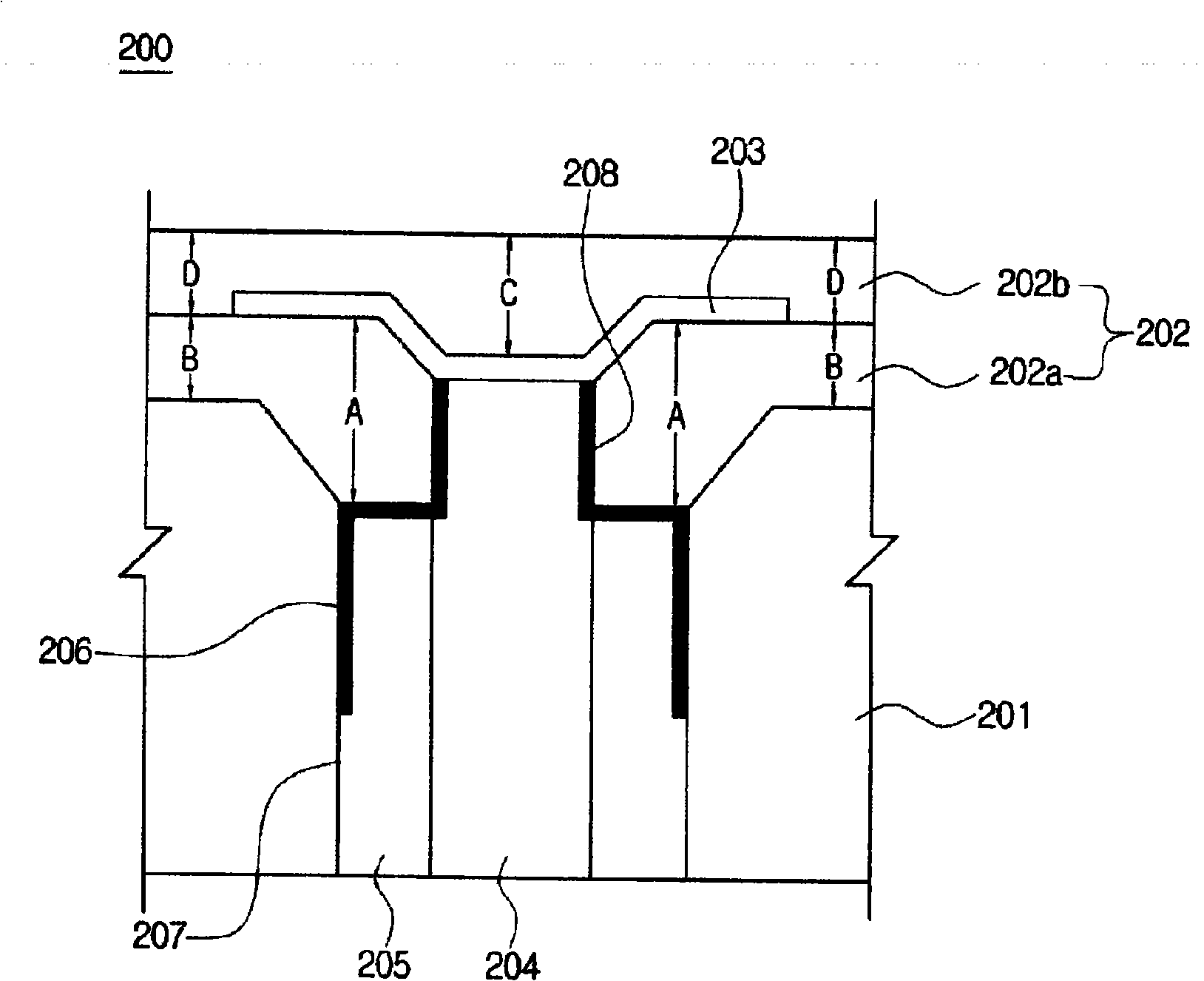

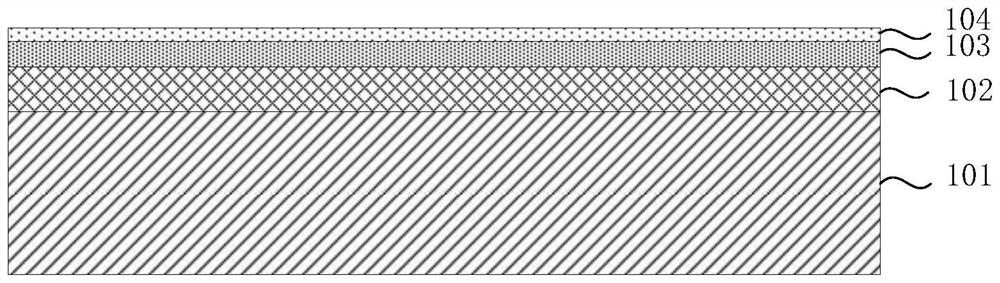

Electrostatic chuck (esc) comprising a double buffer layer (dbl) to reduce thermal stress

ActiveCN102150233AReduce cracksIncreased Durability LifeSemiconductor/solid-state device manufacturingElectrostatic holding devicesEngineeringTerminal unit

Disclosed is an electrostatic chuck comprising a buffer layer to absorb thermal stress. The electrostatic chuck comprises: a main body having transverse holes; a base plate disposed on the upper side of said main body and including insertion holes corresponding to said transverse holes, and an electrode layer partially exposed through said insertion holes, to secure an object to be held by the electrostatic energy of said electrode layer; a terminal unit having a contact terminal connected to said electrode layer through said transverse holes and said insertion holes; and a buffer layer disposed at at least one boundary between said contact terminal, said main body, and said base plate so as to be able to absorb thermal stress from said main body.; According to the present invention, the buffer layer of the electrostatic chuck absorbs thermal stress, thereby minimising cracks due to thermal stress and extending the life of the chuck.

Owner:KOMICO

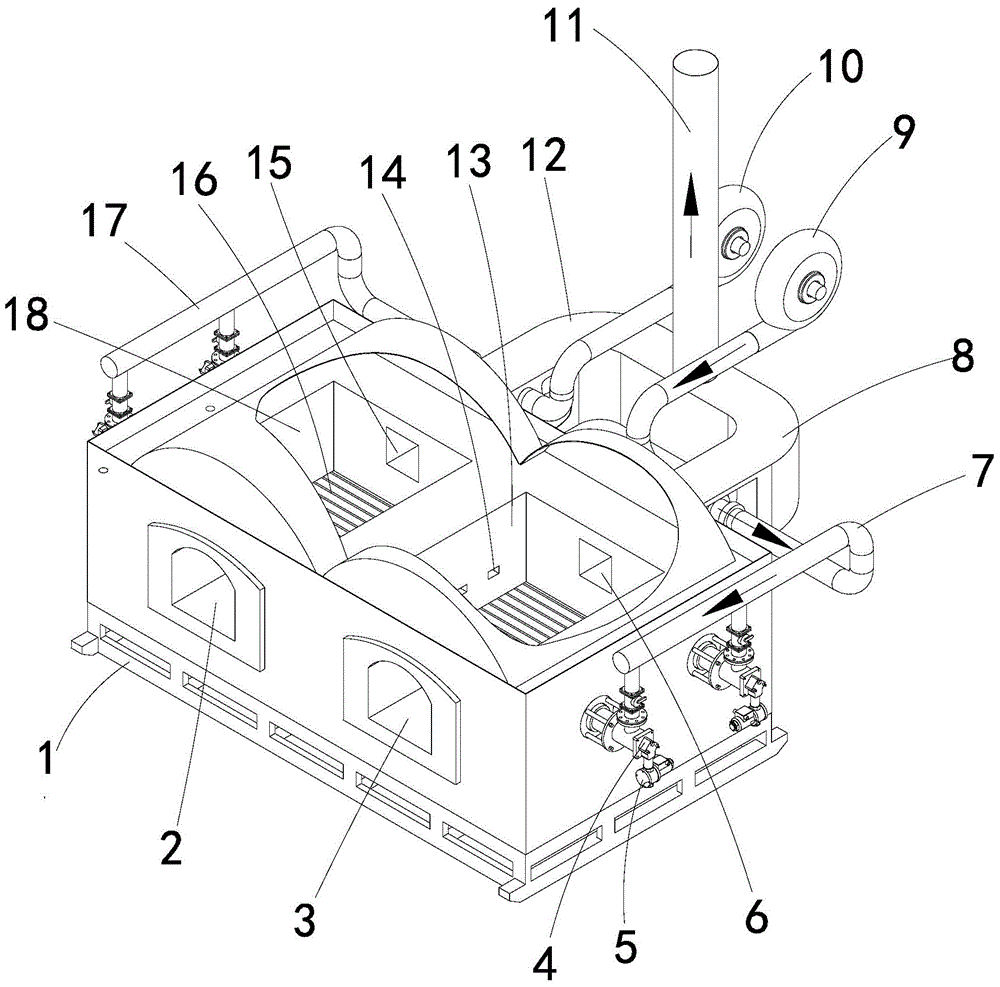

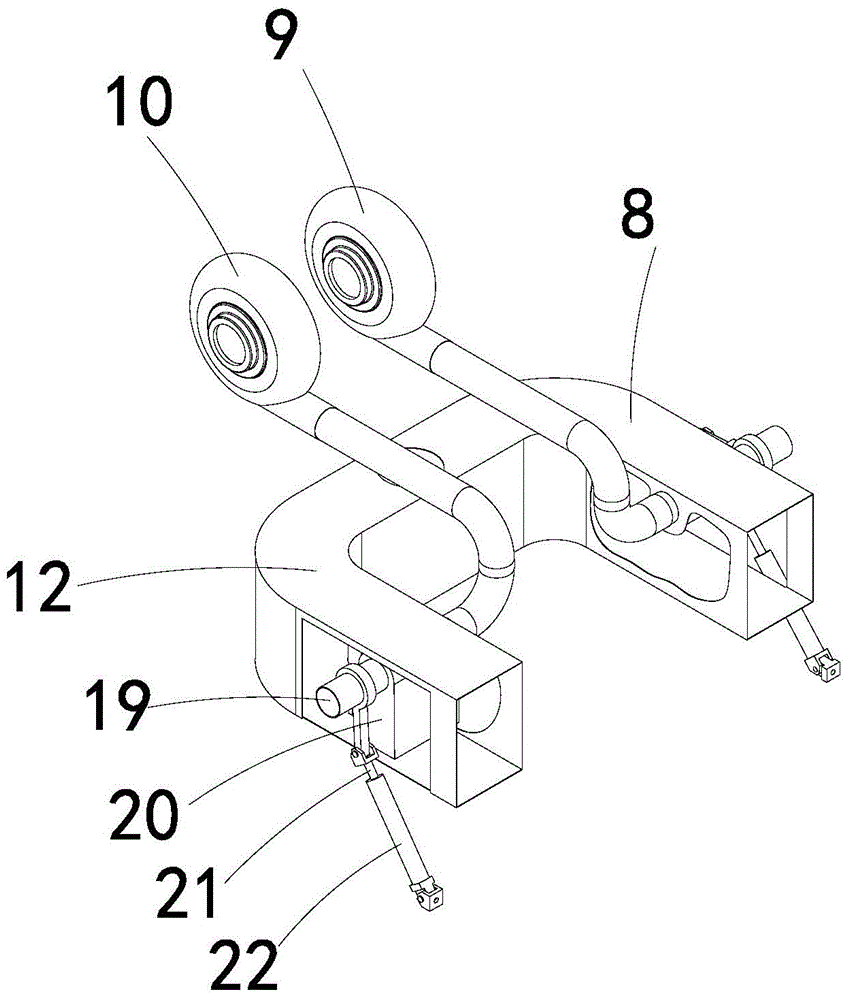

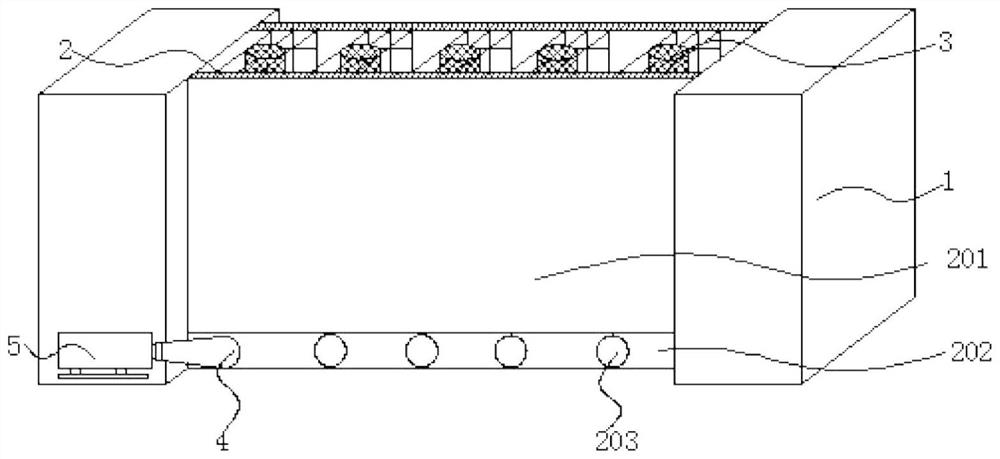

Sintering furnace

InactiveCN104374190AReduce cracksTo achieve the warm-up effectFurnace typesWaste heat treatmentFlueEngineering

The invention discloses a sintering furnace. The sintering furnace comprises a base, a first hearth and a second hearth, wherein the first hearth and the second hearth are arranged on the base, a first fuel nozzle is arranged on the left side of the first hearth, a second fuel nozzle is arranged on the right side of the second hearth, a first flue is arranged on the back side of the first hearth, a second flue is arranged on the back side of the second hearth, one end of the first flue is communicated with the first hearth, one end of the second flue is communicated with the second hearth, a first flue switch device is arranged on the first flue, a second flue switch device is arranged on the second flue, the first hearth is connected with the second hearth through a channel device, a first air inlet device is arranged on the first fuel nozzle, and a second air inlet device is arranged on the second fuel nozzle. According to the sintering furnace, waste heat is brought into the second hearth through the channel device when sintering is conducted in the first hearth, so that a shell mold of the second hearth is preheated, in this way, cracks caused by direct high-temperature sintering can be reduced, and heat energy can be fully utilized to achieve energy saving.

Owner:ZHONGSHAN CITY DONGSHENG TOWN ZHUYOU EQUIP MFG PLANT

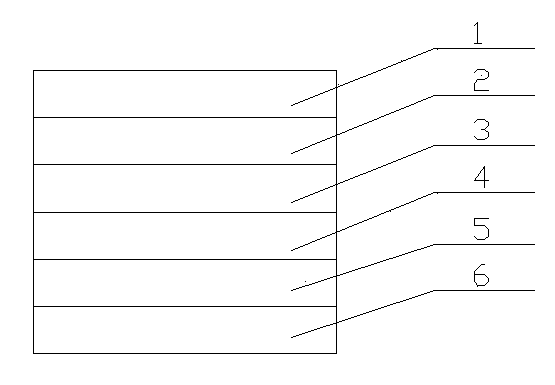

Composite decorating water-proof plate

InactiveCN103572925AGood waterproof performanceReduce cracksCovering/liningsEngineeringSurface layer

The invention relates to a composite decorating water-proof plate which is of a multi-layer integrated structure. The composite decorating water-proof plate is characterized by at least comprising a water-proof roll layer, a flexible putty layer, an alkali-resistant primer layer and a coating surface layer, and all the layers are sequentially connected integrally. The composite decorating water-proof plate is good in water-proof performance, resistant to cracks, flexible, stable in product quality, small in construction cost, short in period and high in efficiency, reduces wet construction on site and can be machined on site.

Owner:江苏百代节能建材有限公司

Manufacturing method of novel environment-friendly concrete

InactiveCN113800874AReduce cracksImprove adhesionSolid waste managementCeramicwareProcess engineeringEnvironmental geology

The invention discloses a manufacturing method of novel environment-friendly concrete. The manufacturing method comprises the following steps: 1, selecting the following raw materials according to a weight ratio: wastewater, zeolite powder, cement, fly ash, mica powder, latex powder, wood fibers, ferrovanadium slag, gypsum powder, a water reducing agent and a foaming agent; 2, mixing and stirring a foaming agent and wastewater according to a ratio of 1: 45 to obtain a mixture A; 3, mixing and stirring fly ash, mica powder, zeolite powder, ferrovanadium slag, gypsum powder and cement for 10-15 minutes, then adding residual wastewater, and continuously carrying out stirring for 20-25 minutes to obtain a mixture B; 4, mixing and stirring the obtained mixture A and the mixture B for 60-70 minutes to obtain a mixture C; 5, adding latex powder, wood fibers and a water reducing agent into the mixture C, and continuously carrying out stirring for 40-50 minutes to obtain the concrete. The method for manufacturing the environment-friendly concrete conforms to the concept of environmental protection, and the resource utilization rate is increased.

Owner:贵州磐石高科新材有限公司

Electrostatic attraction resistant coating material

The invention discloses an electrostatic attraction resistant coating material, which is prepared from the following raw materials (by weight): 13-15 parts of glass glaze, 67-80 parts of silicon nitride ceramic powder, 3-3.5 parts of zirconium carbide, 2-2.5 parts of tantalum nitride, 4-5 parts of chromium boride, 1.2-1.4 parts of indium-doped tin oxide, 0.4-0.5 part of zinc oxide, 0.8-1.2 parts of titanium dioxide, 0.3-0.4 part of a silane coupling agent kh560, 2-3 parts of sodium alginate, 0.3-0.4 part of sodium hexametaphosphate, 1-2 parts of white latex powder, 3.6-4 parts of polythiophene, 9-12 parts of an acrylic emulsion, 40-46 parts of isopropanol and a proper amount of anhydrous ethanol. By addition of processed glass glaze, structural defects of the coating are effectively improved, and binding ability of the coating and a matrix is raised. The prepared coating has compact surface and good continuity. A ceramic coating material with excellent comprehensive performance, good electrostatic attraction resistance and strong practicability is formed.

Owner:MAANSHAN JINSHENG IND DESIGN

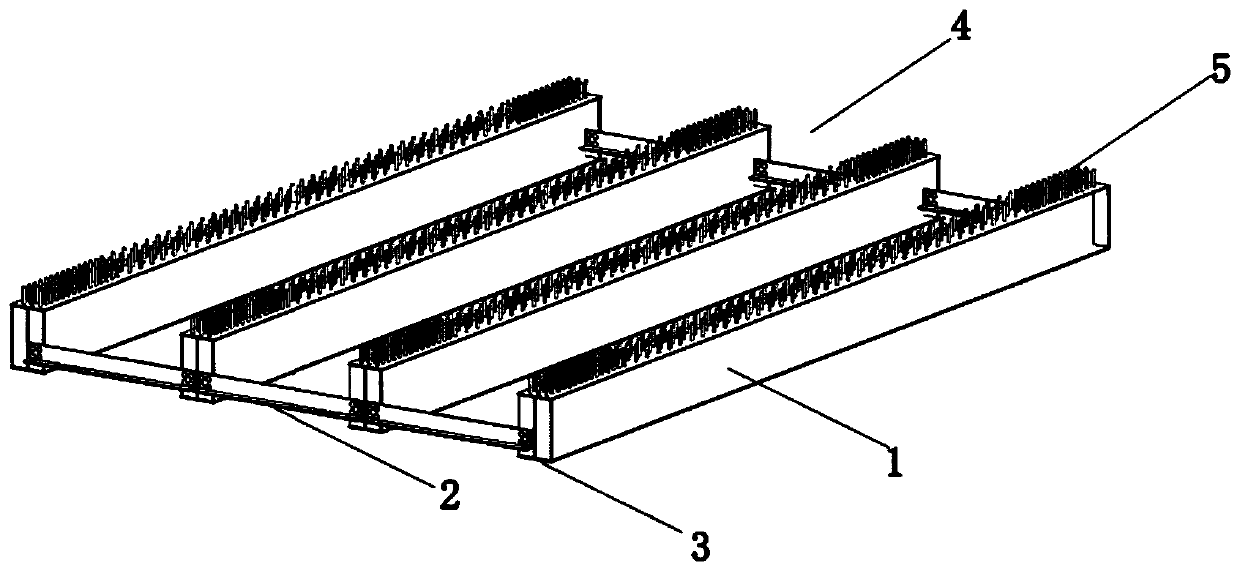

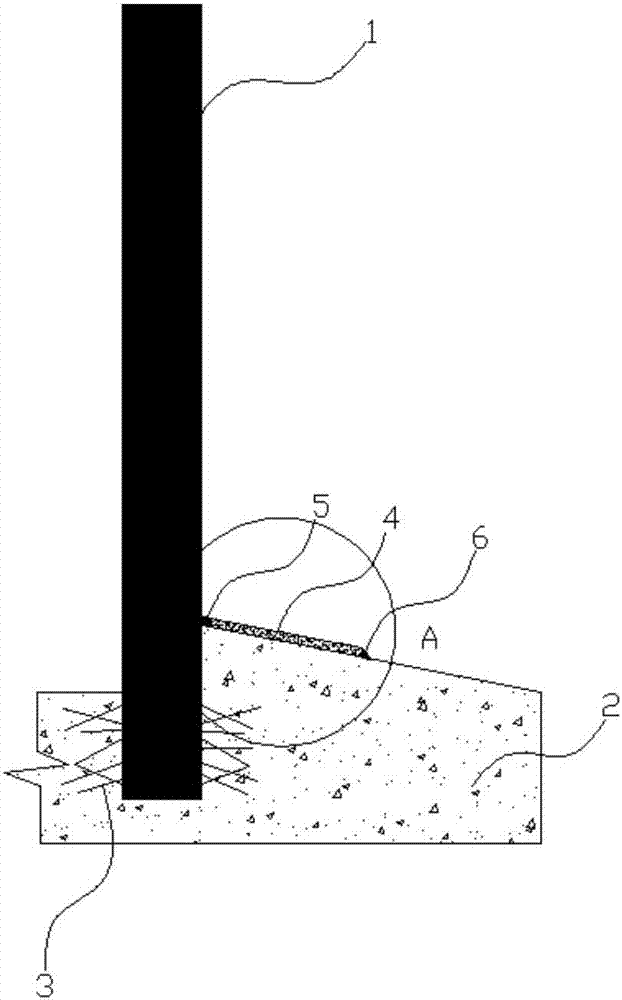

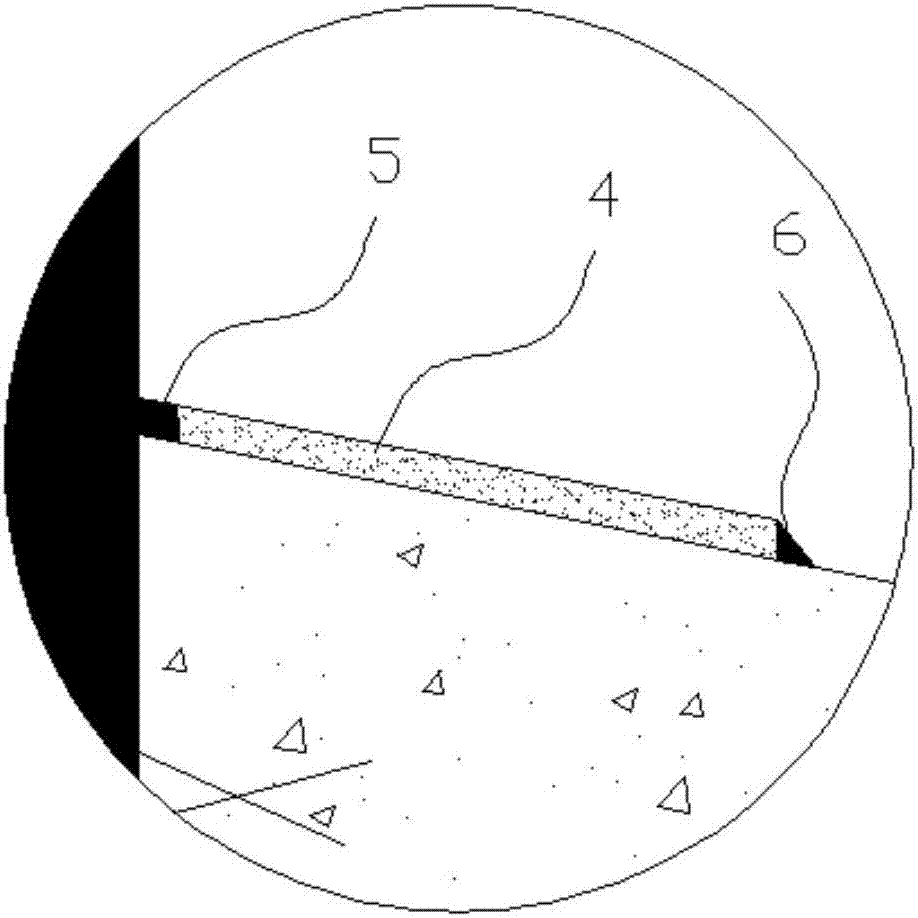

Steel-concrete-composite-bridge durability improving construction and construction method

PendingCN107237253AReduce cracksReduce crack developmentBridge structural detailsBridge erection/assemblyRebarReinforced concrete

The invention discloses a steel-concrete-composite-bridge durability improving construction and a construction method. The steel-concrete-composite-bridge durability improving construction comprises steel and reinforced concrete fixedly connected with the steel; a plurality of steel needles are arranged at the position, connected with the reinforced concrete, on the steel and used for increasing the contact area of the steel and the reinforced concrete. By means of the steel-concrete-composite-bridge durability improving construction and the construction method, generation of a crack of the contact face of a steel-concrete composite structure can be reduced, and meanwhile it is prevented that rainwater enters the crack of the contact face; a certain quantity of the steel needles are welded on the steel for being capable of increasing the contact area of the steel and the reinforced concrete, and the possibility of crack developing is reduced; a slope of 5% is set on the upper surface of the reinforced concrete, and rainwater can conveniently and rapidly flows down from the surface of the reinforced concrete; rubber has the certain elasticity, the rubber, the steel and a waterproof face brick can be firmly bonded, and therefore it can be guaranteed that a gap does not exist between the waterproof face brick and the steel when the crank exists between the reinforced concrete and the steel.

Owner:JSTI GRP CO LTD +1

Production process for autoclaved aerated concrete blocks

ActiveCN111923225AReduce cracksSmall and few cracksSolid waste managementCeramic shaping apparatusProcess engineeringAutoclaved aerated concrete

The invention discloses a production process for autoclaved aerated concrete blocks, and relates to the technical field of autoclaved aerated concrete blocks. According to the technical scheme, the production process for the autoclaved aerated concrete blocks comprises the following steps of: S1, weighing, wherein raw materials are weighed according to raw material ratios; S2, pulping, wherein theraw materials are put into a stirrer, a proper amount of water is added, and the mixture is stirred to obtain slurry; S3, feeding into a mold, wherein the slurry is poured into the mold; S4, cutting,wherein the autoclaved aerated concrete blocks are subjected to demolding after standing for a period of time, and then are cut into a required size; S5, steam curing, wherein the cut autoclaved aerated concrete blocks are put into a steam curing car to be subjected to steam curing; and S6, stacking, wherein the finished autoclaved aerated concrete blocks are stacked and stored. In the step S3, before the slurry is poured into the mold, pre-stretched elastic fiber lines are arranged in the mold firstly, and then the slurry is poured, so that the elastic fiber lines exist in the slurry. The structure is reasonable, and the number of cracks on the autoclaved aerated concrete blocks can be effectively reduced.

Owner:SHANGHAI NUANFENG INSULATION MATERIAL

Forming method of integral wallboard

InactiveCN112554390AReduce cracksMolding stabilityWallsForms/shuttering/falseworksWall plateManufacturing engineering

The invention discloses a forming method of an integral wallboard. The forming method comprises the steps of step 1, arranging a supporting mold, and forming the outer contour of a wall body; step 2,embedding an air belt from the bottom of the supporting mold, and inflating the air belt by utilizing an air pump; step 3, pouring cement mortar; step 4, waiting for solidification of the cement mortar; and step 5, deflating the air belt, and dismounting the mold. By means of the forming method, the integral wallboard can be manufactured, unit wall bodies do not need to be used for splicing, and therefore, cracks occurring between seams of the unit wall bodies are greatly reduced; the integral wallboard manufactured through the forming method is more stable, simpler and more convenient to form, and meanwhile, a large number of punching and splicing processes are reduced, so a large amount of time and labor can be saved; and the forming method can be specifically implemented according to terrain and space of a site, higher applicability is achieved, the embarrassing situation that the unit wall bodies need to be cut is avoided, and the working efficiency is indirectly improved.

Owner:扬州市邗江汊河甘来水泥制品厂

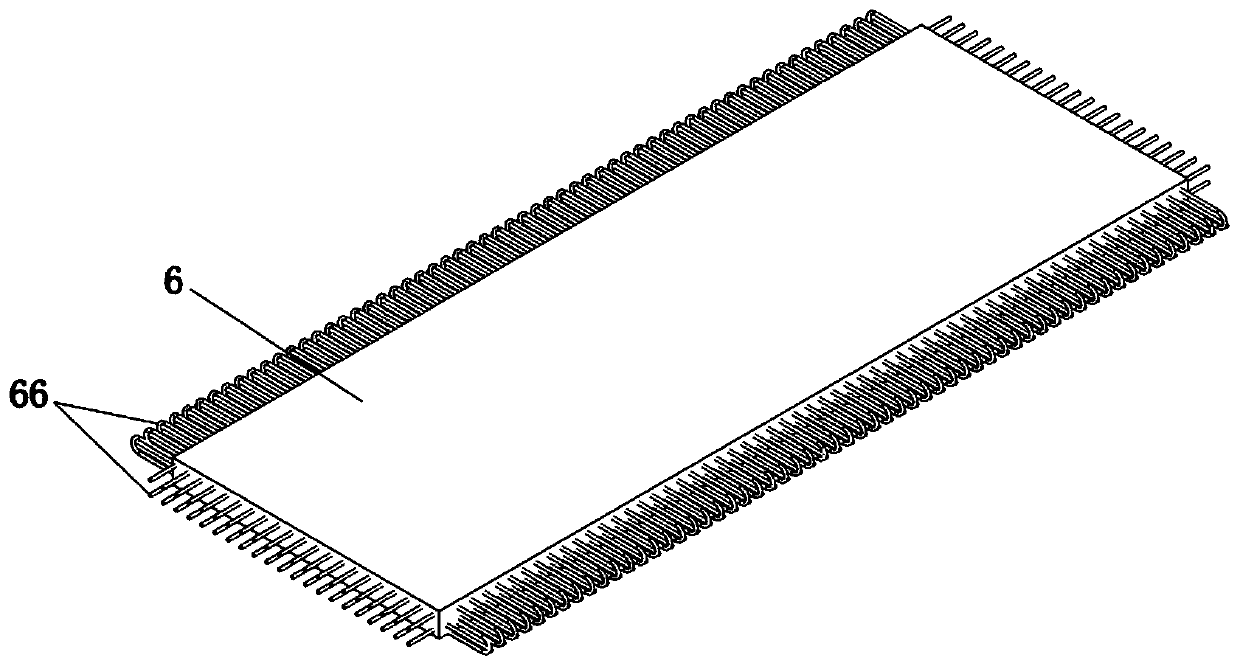

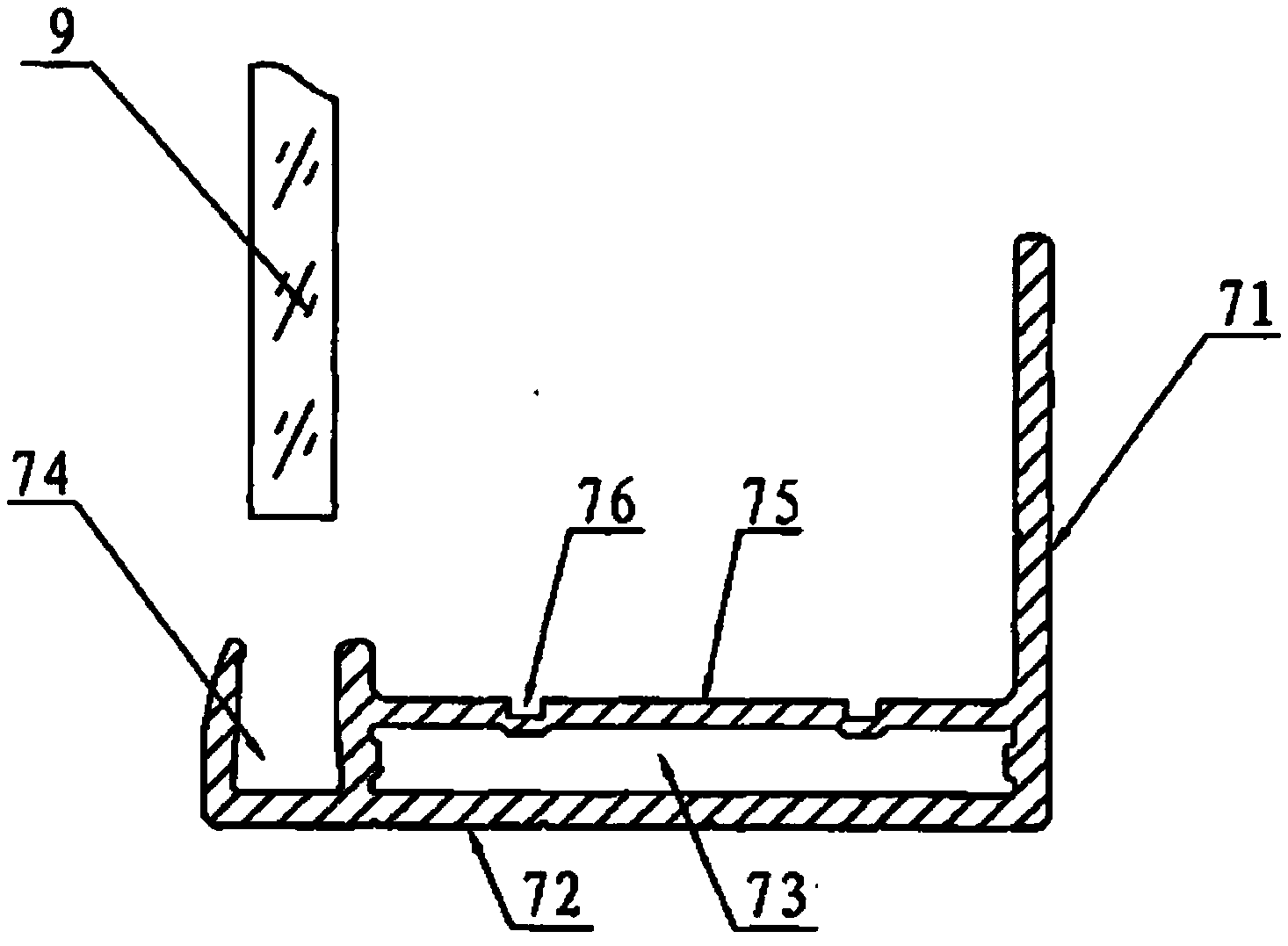

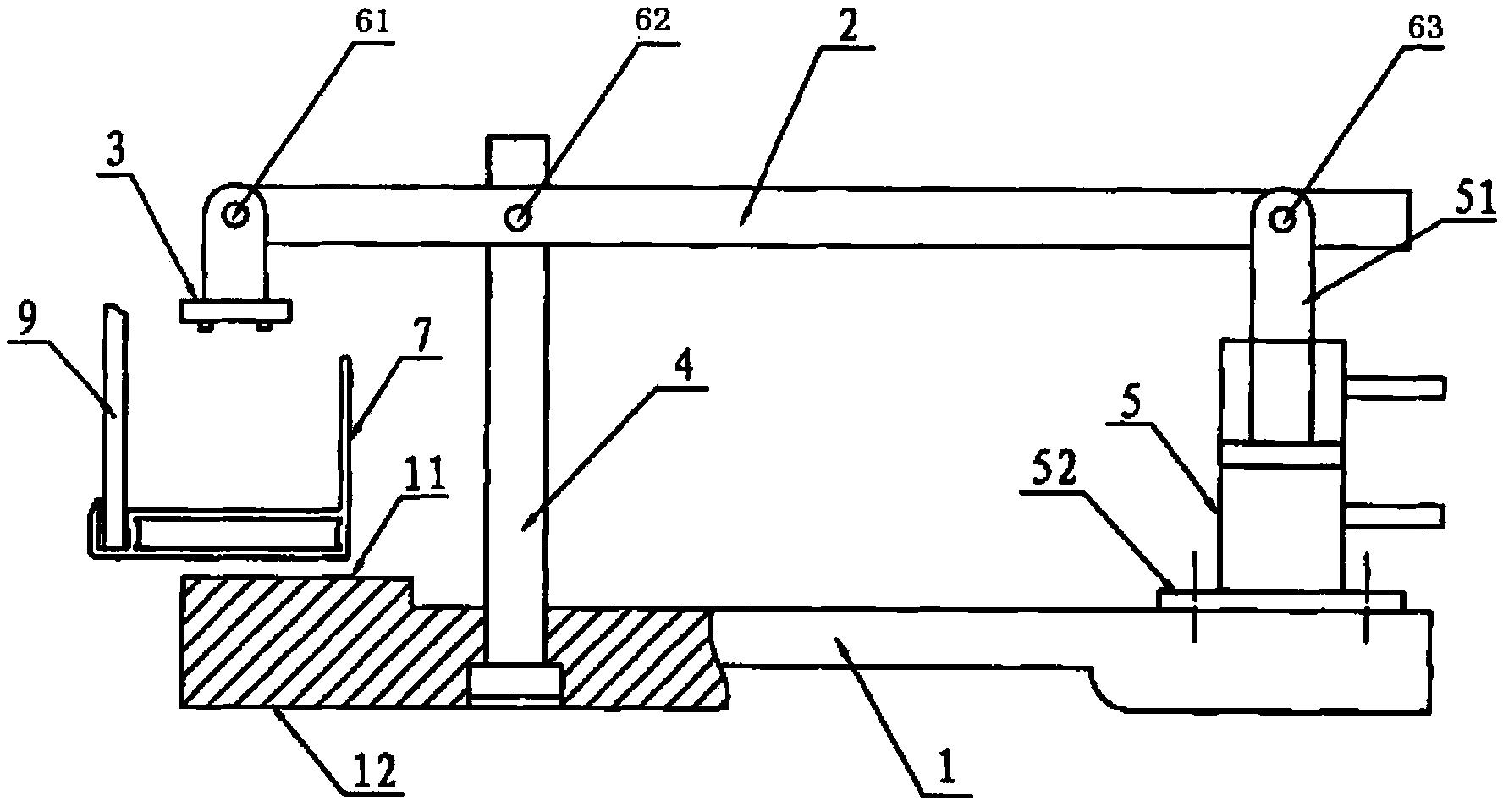

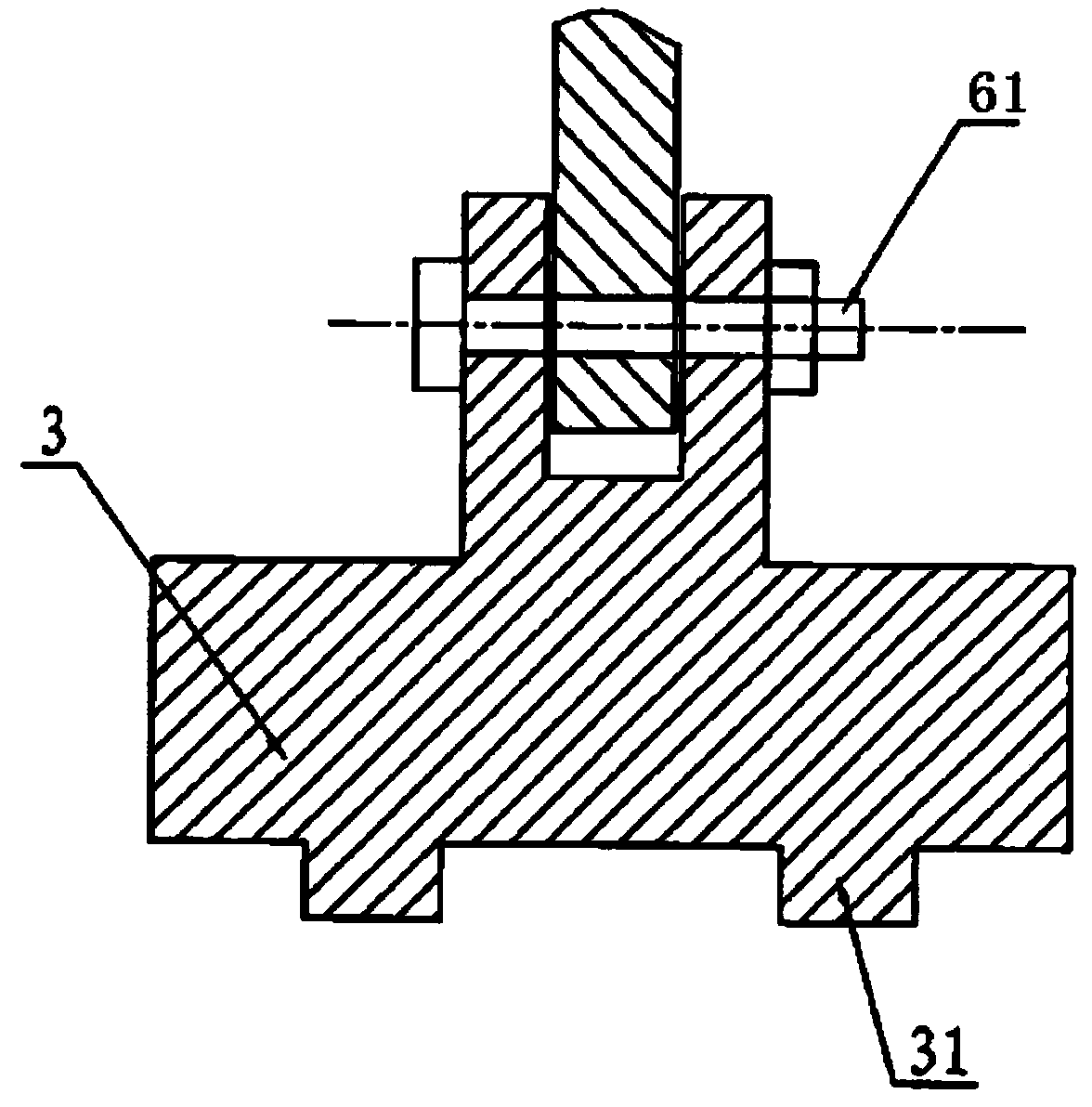

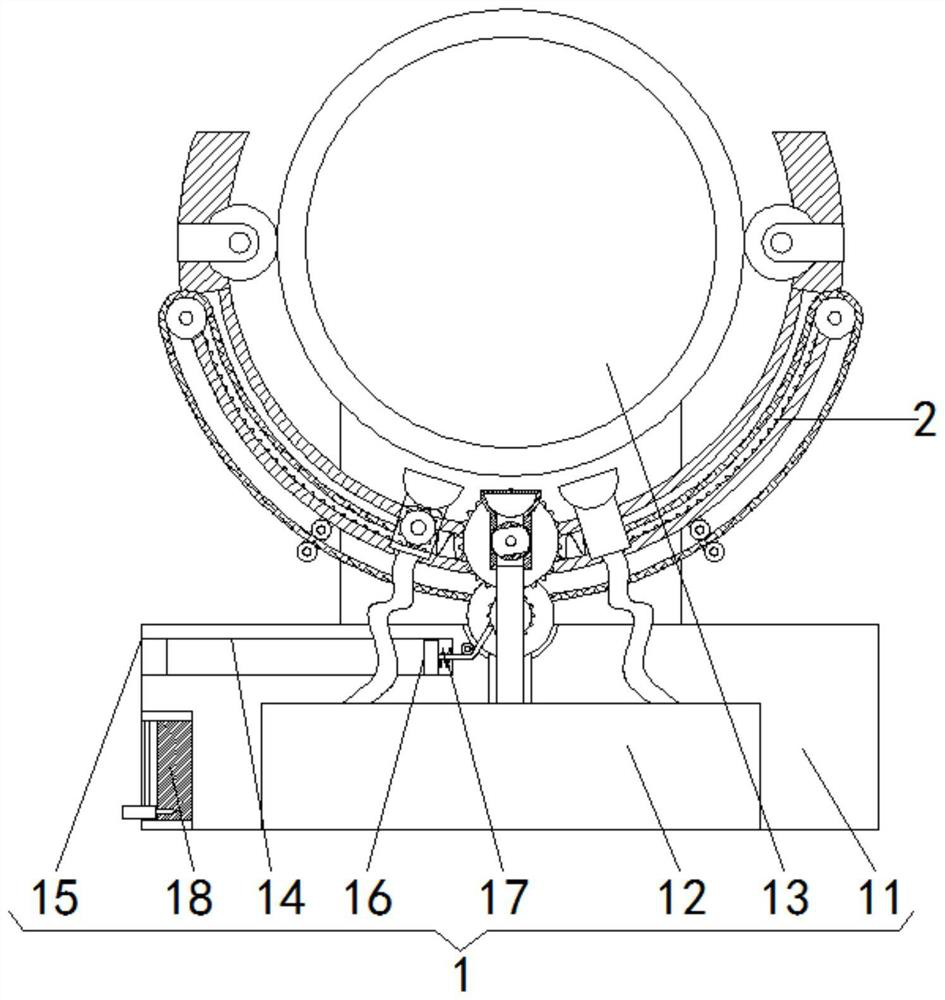

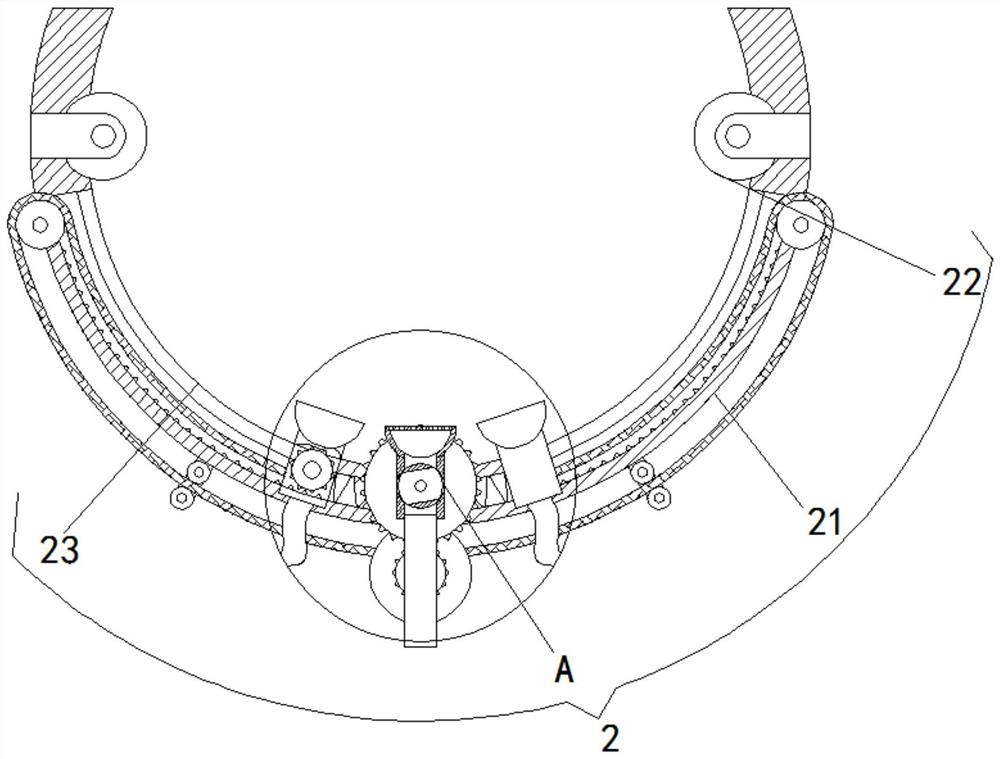

Aluminum frame pneumatic engaging device for solar module

ActiveCN101872810BReduce cracksImprove sealing performance and connection firmnessFinal product manufactureSemiconductor devicesAluminiumEngineering

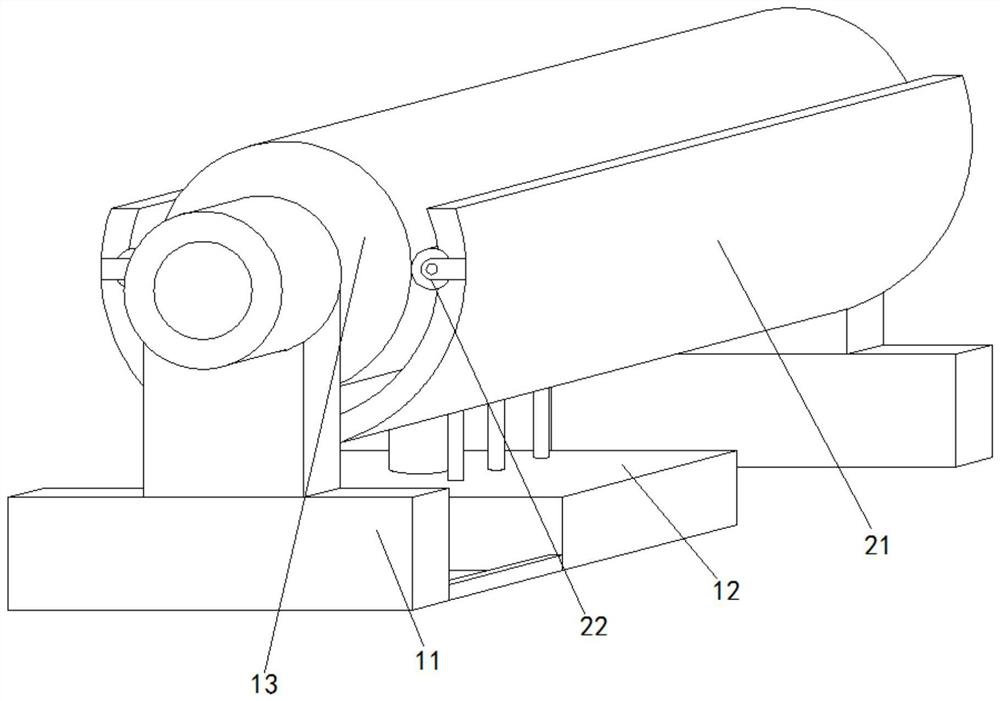

The invention provides an aluminum frame pneumatic engaging device for a solar module. The device comprises a base plate, a lever, a stamping head, a loaded column and a pressurizing cylinder, wherein the stamping head is hinged with the left end of the lever; the lever is hinged with the upper end of the loaded column; a piston rod of the pressurizing cylinder is hinged with the right end of the lever; the body of the pressurizing cylinder is fixed on the base plate; the pressurizing cylinder is controlled by the pneumatic control device to act; and a convex body structure is arranged on the lower end surface of the stamping head. After the solar cell module is encapsulated with adhesive, the long aluminum frame is subjected to tightening and engaging treatment by the module, so that the long aluminum frame and the short aluminum frame are both firmly engaged with zigzag angles to form a whole, which can greatly reduce the phenomenon that cracks are generated among aluminum frames after the solar cell module is used outdoor for long time, and improve the sealing performance and connecting firmness of the solar cell module.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

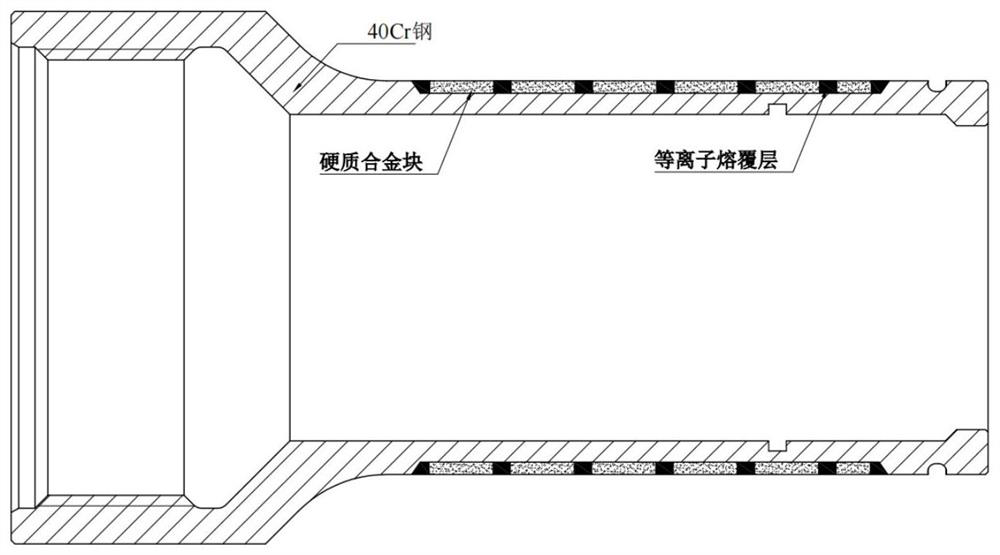

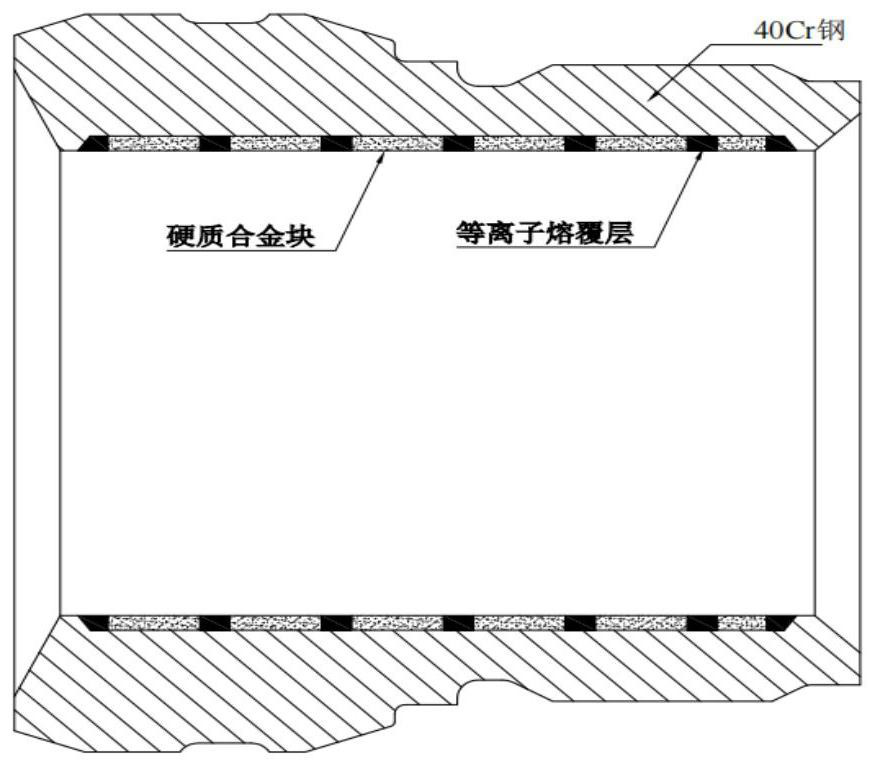

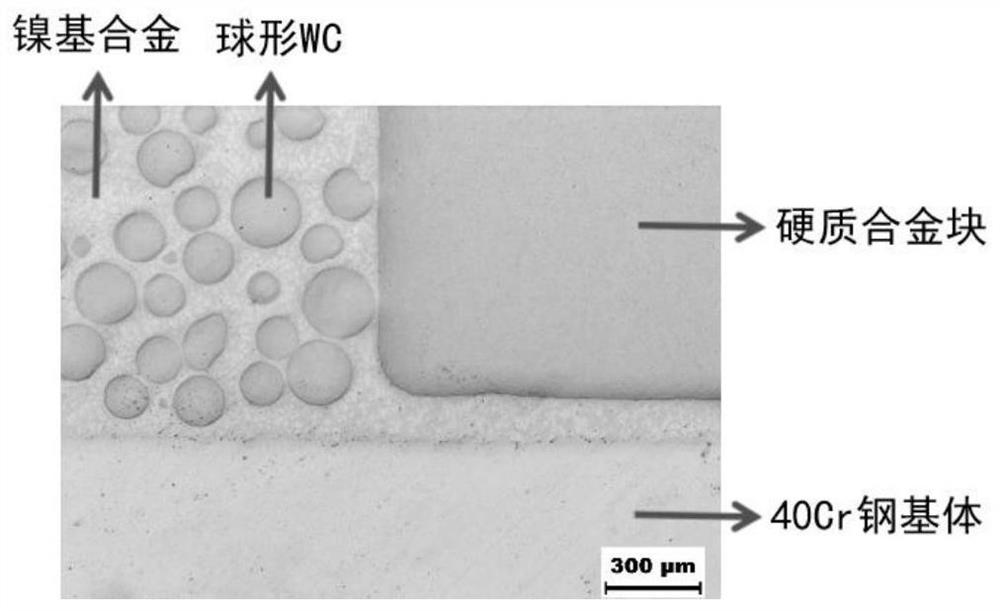

Preparation method of composite hard material

The invention discloses a preparation method of a composite hard material, and belongs to the technical field of composite materials. The method comprises the following steps: spraying a nickel-based alloy coating on the surface of a metal matrix by flame; fixing a hard alloy block and the metal matrix through fusion welding; and cladding a metal ceramic material in gaps among the hard alloy blocks by adopting a plasma transferred arc cladding technology to obtain the composite hard material. According to the invention, the plasma transferred arc cladding technology is adopted to clad the metal ceramic material in the gaps between the hard alloy blocks, and the hard alloy blocks and the metal base material form metallurgical bonding, so that the compounding of the metal base material, the hard alloy, the nickel-based alloy and the tungsten carbide ceramic particles is realized. The obtained composite hard material has the advantages of lower porosity, fewer cracks, higher bonding strength between the plasma transferred arc cladding layer and the hard alloy block and between the plasma transferred arc cladding layer and the metal base material, and excellent wear resistance and impact resistance.

Owner:湖南威盾新材料技术有限责任公司

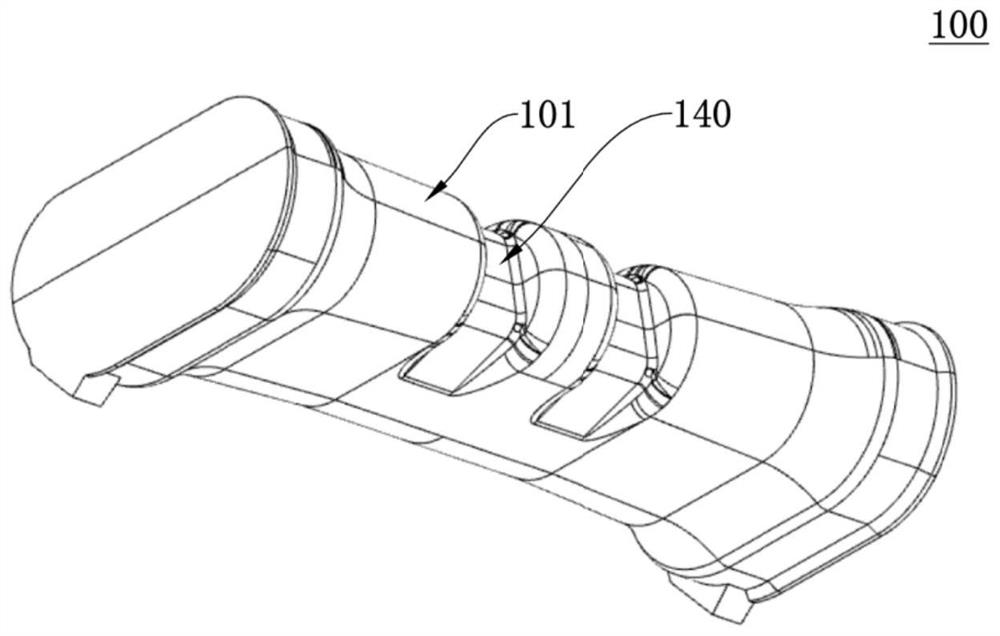

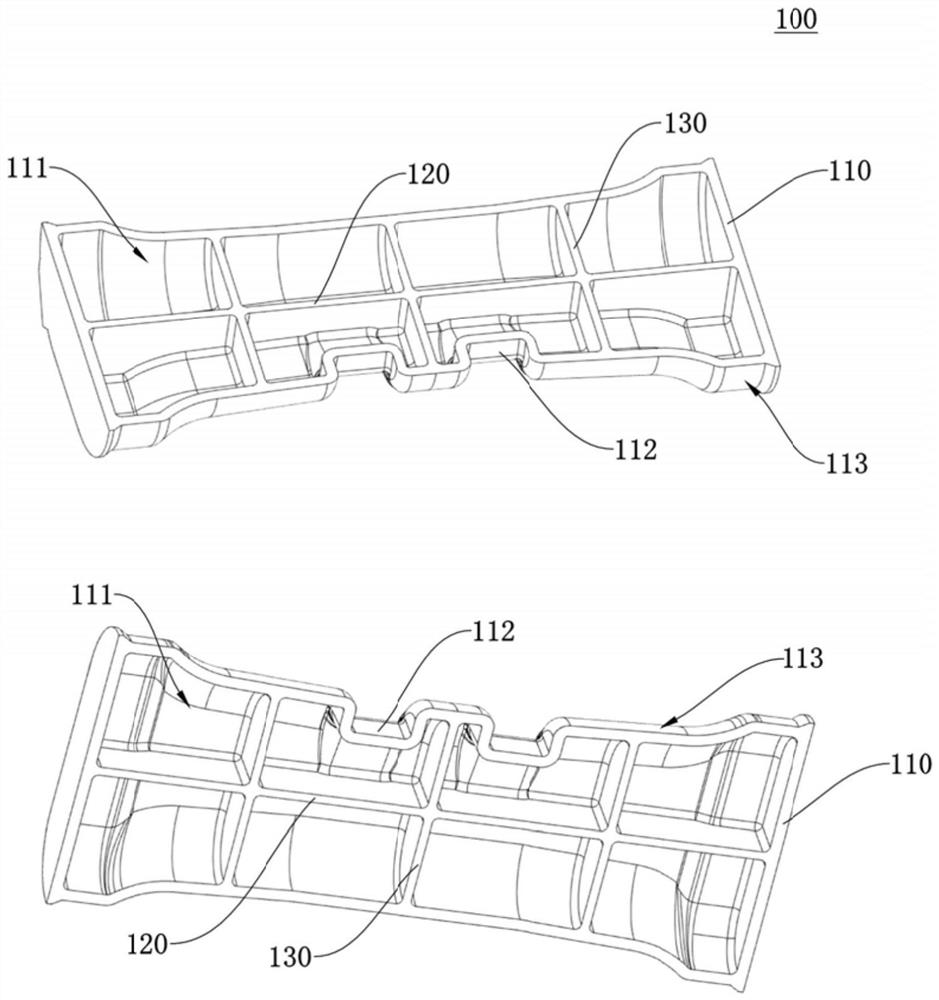

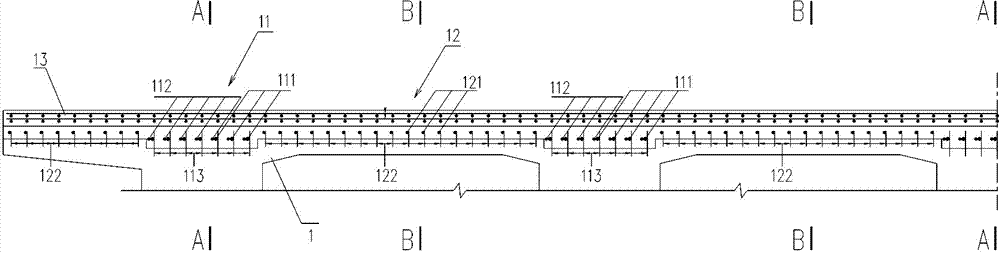

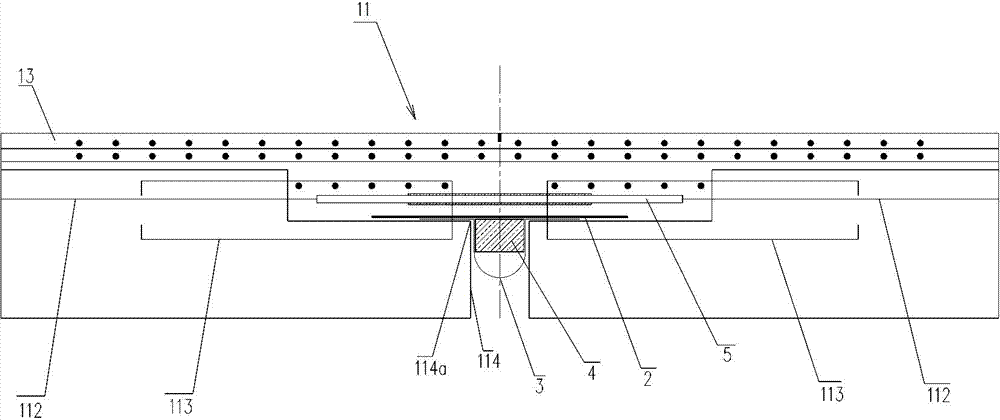

Pipe core, preparation method of pipe core, preparation method of cross beam pipe and cross beam pipe

PendingCN112846096AReduce cracksReduce the effects of shrinkageFoundry mouldsFoundry coresCrazingMagnetic powder

The invention discloses a pipe core, a preparation method of the pipe core, a preparation method of a cross beam pipe and the cross beam pipe, and relates to the technical field of casting manufacturing. The pipe core comprises two half core shells which are connected with each other in a matched mode, and the materials of the half core shells comprise ceramsite, warm core box resin and a curing agent. The wall thickness of each half core shell is uniform and unchanged. Therefore, the ceramsite, the warm core box resin and the curing agent are used for manufacturing a beam pipe core, in the process that the beam pipe core is used for manufacturing the cross beam pipe, under the effect of pouring high-temperature molten steel, the warm core box resin in the beam pipe core continuously generates character changes, in the contraction cooling stage of a cross beam pipe casting, the beam pipe core can be automatically collapsed, so that the influence of the beam pipe core on the shrinkage of a cross beam pipe can be reduced, the generation of cracks is reduced, and even, the beam pipe core has no chance to generate stress which hinders the shrinkage, so that the inner cavity of a produced cross beam pipe casting is attractive, and the crack defect is completely avoided through overall magnetic powder detection.

Owner:NINGBO JINHUI PRECISION CASTING

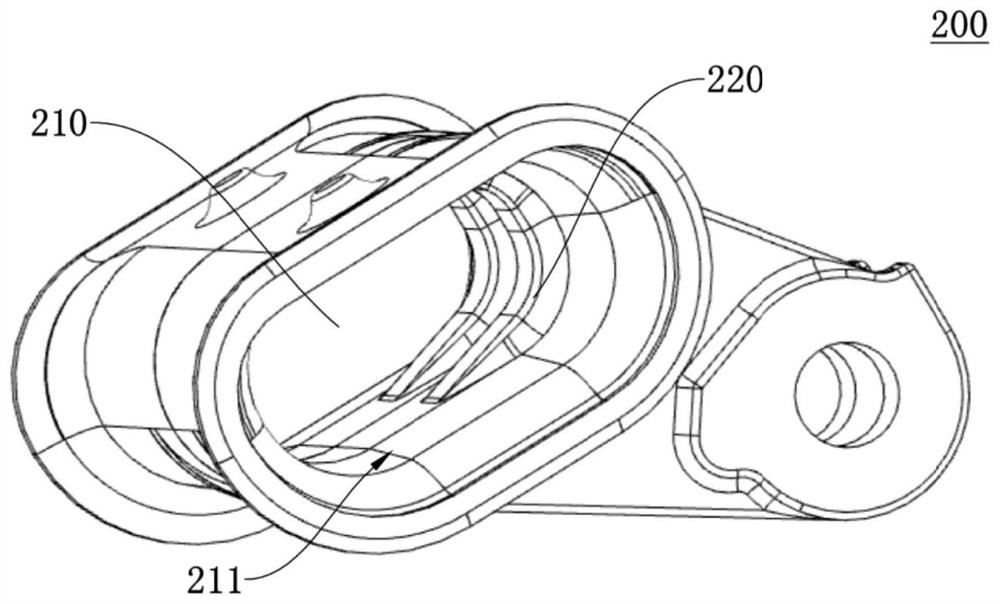

Plasma composite surfacing process

PendingCN113695723AEnhance the surfacing effectReduce cracksPlasma welding apparatusManufacturing engineeringMechanical engineering

The invention relates to a plasma composite surfacing process, which comprises the following steps: S1, cleaning a workpiece; S2, surfacing preparation; S3, surfacing position confirmation; S4, carrying out surfacing work; and S5, composite surfacing. The plasma composite surfacing process provided by the invention has the advantage of improving the plasma welding surfacing effect.

Owner:郑州雷姆自动化科技有限公司

Large-span prefabricated bridge structure

ActiveCN104711922AHigh tensile strengthReduce cracksBridge structural detailsBridge materialsWater seepageStructural engineering

The invention discloses a large-span prefabricated bridge structure. The large-span prefabricated bridge structure comprises a beam body, wherein the beam body is sequentially provided with a beam rib area and a beam wing plate area which are connected in the longitudinal direction of the beam body. Bridge floor cast-in-place layers are arranged on the tops of the beam rib area and the beam wing plate area. The beam rib area is provided with a plurality of first cross-joint force-bearing assemblies which are arranged at intervals and a plurality of first buried assemblies arranged at intervals. The first cross-joint force-bearing assemblies and the first embedded assemblies are welded and connected. The beam wing plate area is provided with a plurality of second cross-joint force-bearing assemblies which are arranged at intervals and a plurality of second buried assemblies arranged at intervals. The second cross-joint force-bearing assemblies and the second buried assemblies are arranged in the transverse direction of a large-span prefabricated bridge. The second cross-joint force-bearing assemblies and the second buried assemblies are welded and connected. By means of the large-span prefabricated bridge structure, the tensile strength of breaking joint positions is improved, and therefore cracks at end joints are reduced, the influences of water seepage caused after a bridge floor cracks on the beam body are reduced, and the durability of the bridge is improved.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

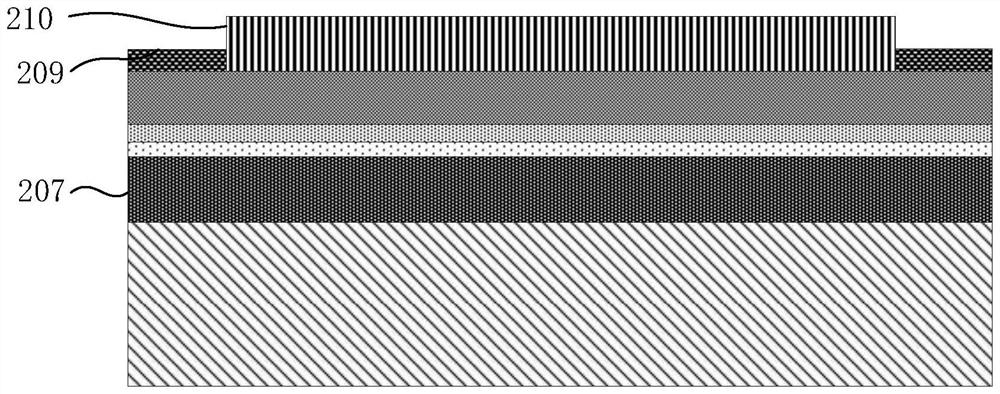

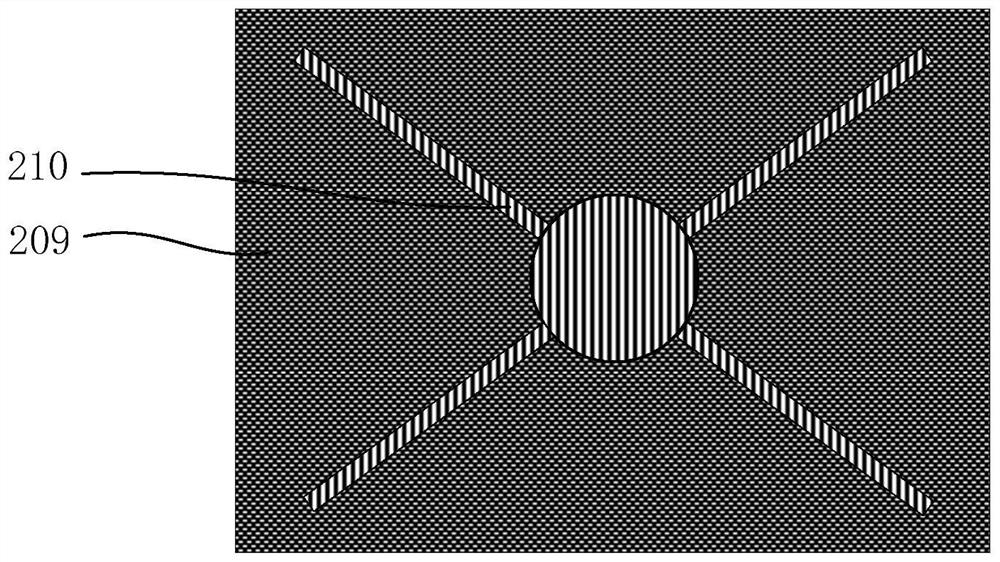

Vertical LED chip structure and preparation method thereof

The invention provides a vertical LED chip structure and a preparation method thereof. The preparation method comprises the steps of providing a growth substrate and forming an epitaxial layer; forming a plurality of first grooves distributed at intervals in the epitaxial layer; forming first N electrode metal layers in the first grooves; forming an N electrode insulating layer; forming a P electrode metal layer to cover the P-type GaN layer and the N electrode insulating layer; bonding the P electrode metal layer with the supporting substrate; removing the growth substrate; forming a surface insulating layer on the surface of the N-type GaN layer; forming a plurality of second grooves distributed at intervals in the surface insulating layer, wherein the N-type GaN layer is exposed out of the second grooves, and the first grooves and the second grooves correspond to each other up and down; and forming second N electrode metal layers, wherein the second grooves are filled with the second N electrode metal layers, and the second N electrode metal layers in the second grooves are electrically connected with one another. According to the invention, the chip breakdown phenomenon can be effectively reduced, the cracking phenomenon of the insulating layer can be reduced, the electric leakage phenomenon of the chip can be obviously reduced, and the stability and reliability of the chip can be improved.

Owner:SHANGHAI XINYUANJI SEMICON TECH

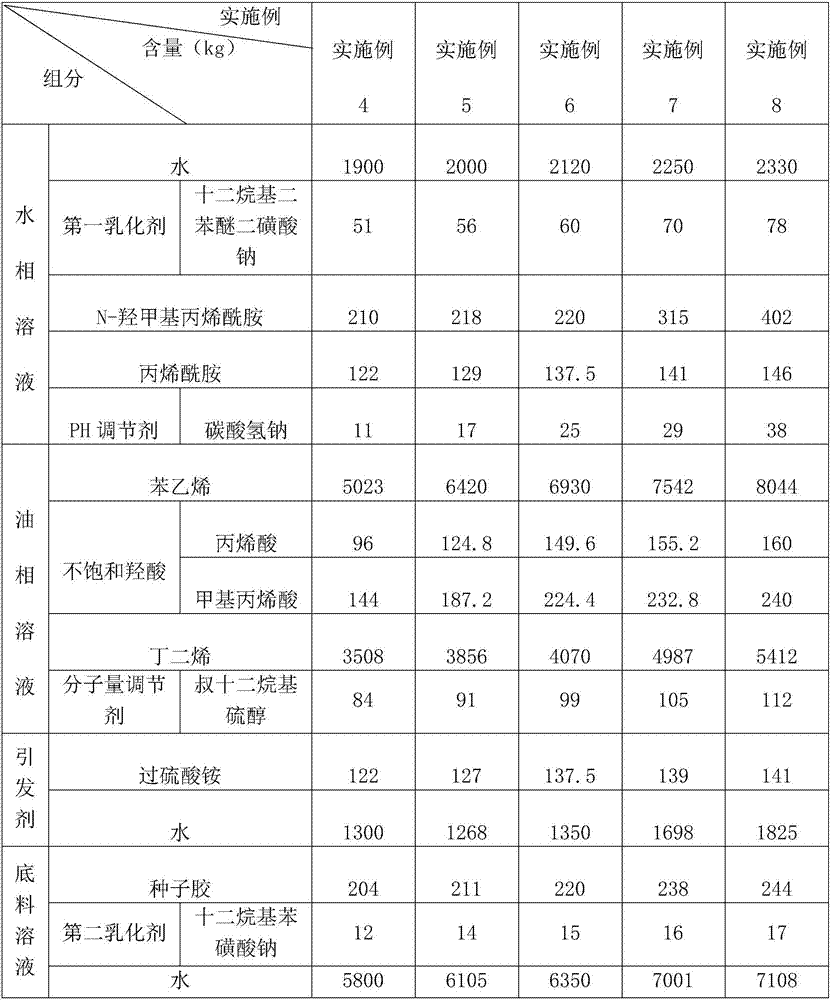

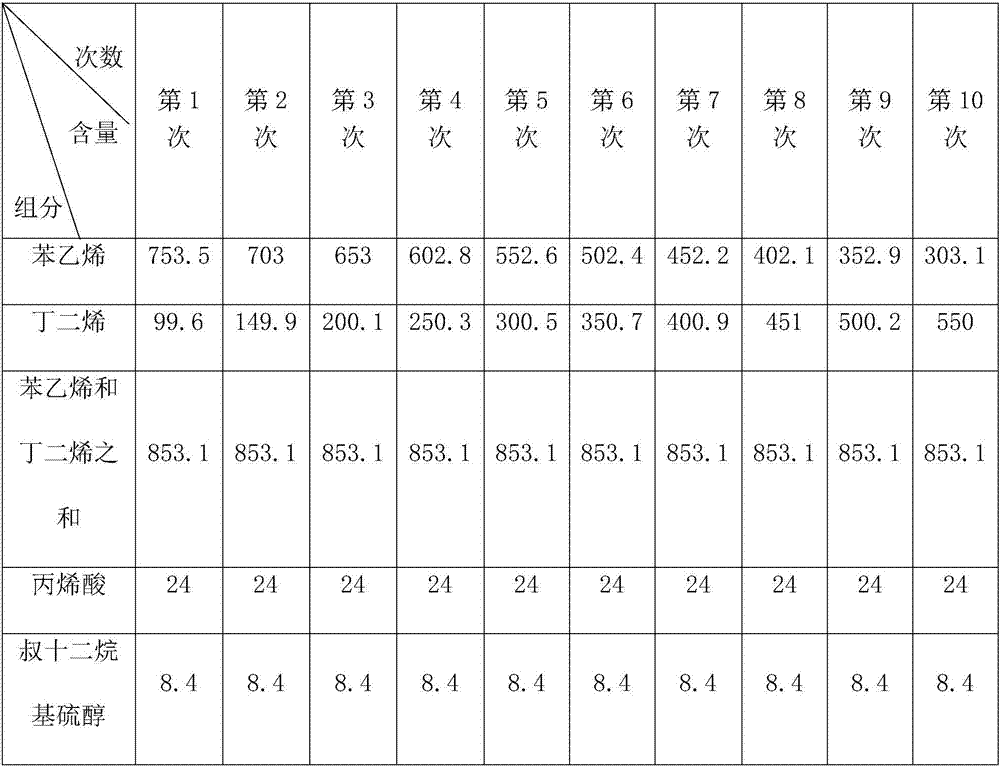

Method for preparing styrene-butadiene latex with low film formation temperature

InactiveCN107987204ALow film forming temperatureReduce cracksConjugated diene hydrocarbon coatingsChemistryButadiene-styrene rubber

The invention discloses a method for preparing styrene-butadiene latex with a low film formation temperature. The method is characterized by comprising the following steps: preparing an aqueous phasesolution for later use; preparing an oil phase solution for later use; preparing an initiator for later use; preparing a base material solution for later use; preparing the styrene-butadiene latex; S6, carrying out aftertreatment. In the process of preparing the oil phase solution, the oil phase solution is prepared by adding materials for multiple times and stirring, the materials are independently and continuously fed into a reaction kettle to participate in a reaction every time, and the weight percent, which the sum of the weights of butadiene and styrene in the material added every time accounts for, in the weight of the material added every time is the same as the weight percent, which the sum of the weights of all butadiene and styrene accounts for, in the overall weight of the oilphase solution; furthermore, the weight of the butadiene in the materials added for a plurality of times is progressively increased or decreased. The method has the effects of reducing the film formation temperature, reducing the cracks generated during film formation of the finished product, and improving the quality of the styrene-butadiene latex finished product.

Owner:杭州龙驹合成材料有限公司

Green preparation process of zirconia-based metal ceramic material for optical fiber

PendingCN114367666AReduce cracksExtended service lifeTransportation and packagingMetal-working apparatusLanthanum nitrateZirconia ceramic

The invention relates to the technical field of ceramic materials, and discloses a green preparation process of a zirconia-based metal ceramic material for optical fibers, which comprises the following steps: weighing magnesium nitrate, cerium nitrate, scandium nitrate, calcium nitrate and lanthanum nitrate according to a mass ratio of 1: 2: 2: 0.5: 1, then adding deionized water, and uniformly mixing to prepare a 25% nitrate mixed solution; the metal powder and the alumina-based ceramic powder with the designed amount are taken and placed in a high-speed ball mill to be mixed and ground for 3-5 h, the metal powder and the alumina-based ceramic powder are evenly mixed in a high-speed mixer, and a primary mixture is obtained; according to the green preparation process of the zirconia-based metal ceramic material for the optical fiber, through mixed use of the metal powder and the alumina-based ceramic powder and reasonable control over the pre-sintering heating rate, cracks are reduced, the service life of the optical fiber is prolonged, the grain size of zirconia ceramic is refined through accompanying use of gel precipitation, and the service life of the optical fiber is prolonged. Therefore, the effects of low price, high mechanical strength and excellent anti-aging performance are achieved.

Owner:江苏文宸知识产权运营有限公司

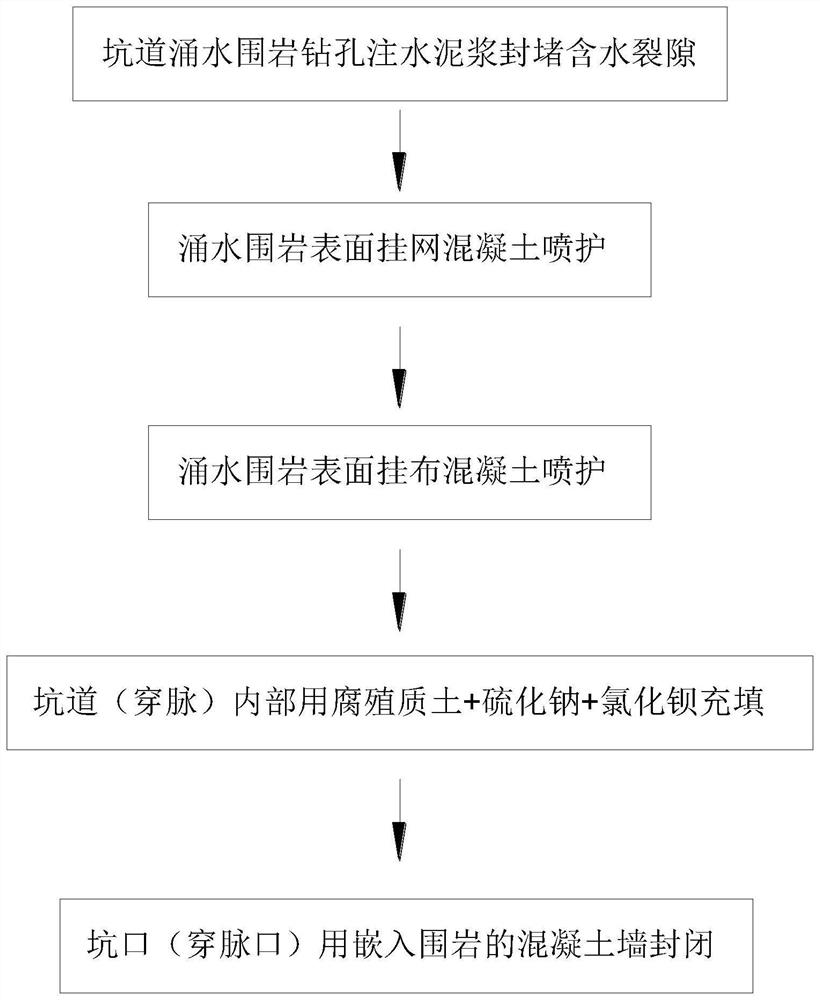

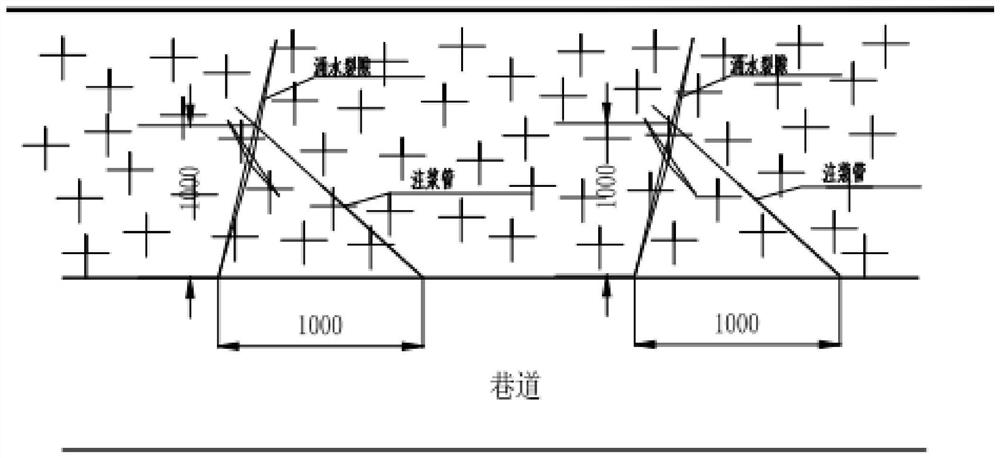

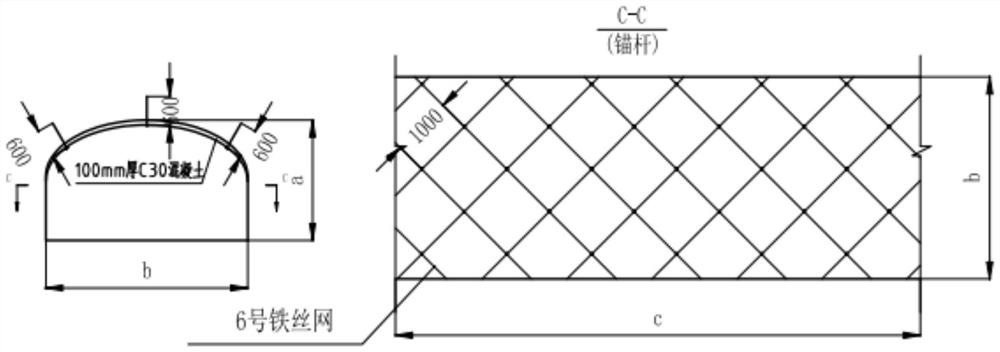

Uranium-exceeding tunnel water treatment process

PendingCN113530598AReduce cracksReduce outflowUnderground chambersDrainageEnvironmental chemistrySoil science

The invention discloses a uranium-exceeding tunnel water treatment process. The uranium-exceeding tunnel water treatment process comprises the following steps that holes are drilled in tunnel water gushing surrounding rock and water-containing cracks are plugged by cement paste; hanging net concrete spraying protection is carried out on the surface of the water gushing surrounding rock; hanging concrete spraying protection is carried out on the surface of the water gushing surrounding rock; and the interior of a tunnel (transverse drift) is filled with humus soil, sodium sulfide and barium chloride, and a pit opening (transverse drift opening) is sealed with a concrete wall embedded into the surrounding rock. The uranium-exceeding tunnel water treatment process is simple in construction, firstly, cracks of the water gushing surrounding rock are plugged, then the surrounding rock is reinforced through a steel wire mesh and the concrete, then the surrounding rock is reinforced again through the composite waterproof cloth and the concrete, so that the occurrence of cracks of the tunnel surrounding rock is greatly reduced, even if the tunnel surrounding rock generates tiny cracks again, the composite waterproof cloth further ensures that tunnel water cannot penetrate through cracks to enter underground water, the discovering situation that the tunnel water of the closed-pit uranium mine flows out of the cracks is greatly reduced, humus soil, sodium sulfide and barium chloride are adopted for filling, the target of one-time standard treatment is achieved, and the economical efficiency is superior to that of an adsorption process and a precipitation process.

Owner:中陕核工业集团二一八大队有限公司

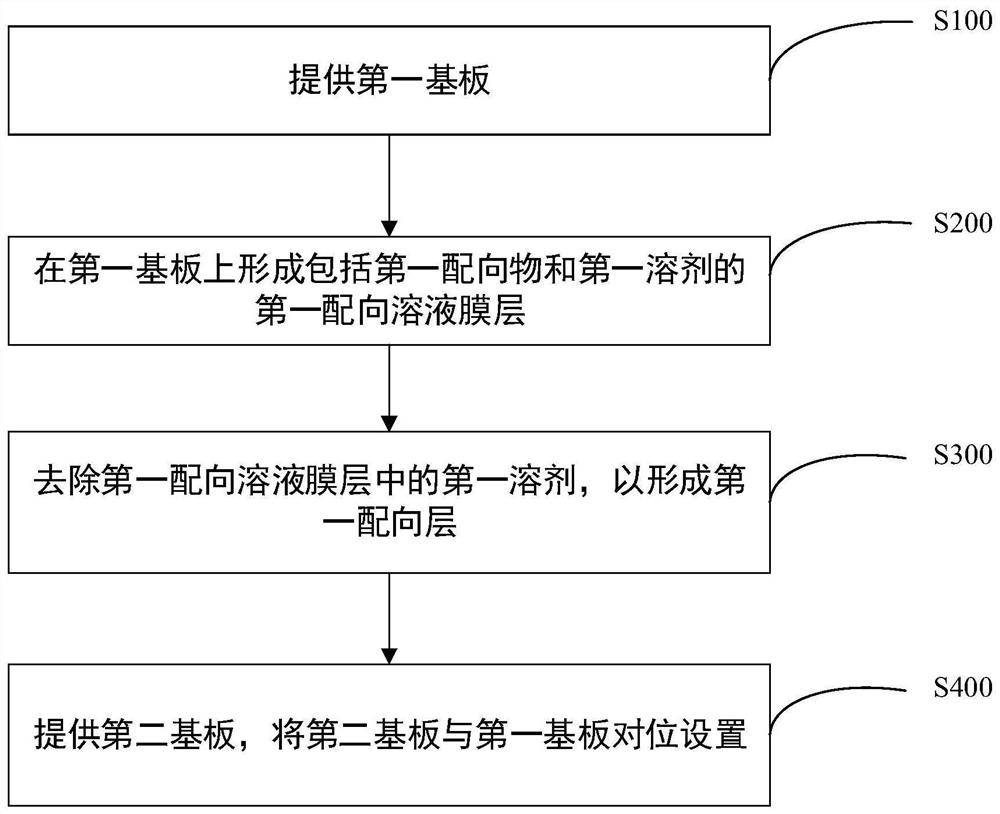

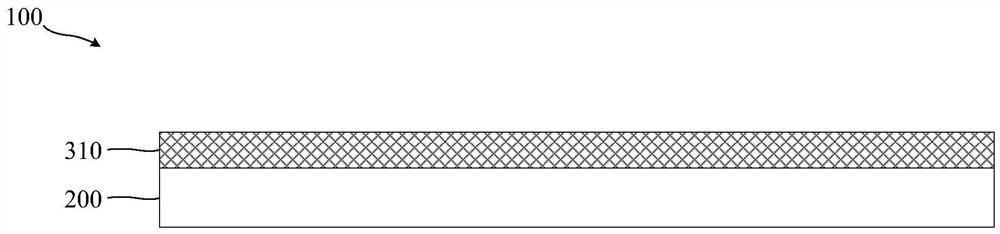

Manufacturing method of display panel

PendingCN113419382AAvoid high temperature curing stepsReduce cracksNon-linear opticsPhysicsChemistry

The embodiment of the invention discloses a manufacturing method of a display panel. The manufacturing method of the display panel comprises the following steps: providing a first substrate; forming a first alignment solution film layer comprising a first alignment object and a first solvent on the first substrate; removing the first solvent in the first alignment solution film layer to form a first alignment layer; and providing a second substrate, and aligning the second substrate with the first substrate, wherein the boiling point temperature of the first solvent is lower than the curing synthesis temperature of the precursor of the first alignment object. According to the embodiment of the invention, the alignment substance is dissolved in the solvent with a lower boiling point to form the solution, the alignment solution film layer is formed on the substrate, the solvent is removed through evaporation, and the alignment substance film layer is formed, so that a high-temperature curing step required by a precursor is avoided, cracks of the film layer of the display panel are reduced, and the stability of the display panel is enhanced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Corrosion-resistant aluminum alloy

The invention provides corrosion-resistant aluminum alloy. The corrosion-resistant aluminum alloy comprises, by weight percentage, 14%-35% of silicon, 12%-25% of magnesium, 17%-25% of copper, 25%-30%of titanium, 17%-19% of chromium, 11%-23% of cerium, 16%-32% of strontium and 13%-45% of aluminum. The corrosion-resistant aluminum alloy has the advantages that the number of cold shuts and cracks onthe surface is reduced, the elongation is high, and the elongation and the impact toughness are improved.

Owner:NANTONG DISONG TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com