Production method for boron-containing cold heading steel

A production method and technology for cold heading steel, which are applied in the production field of 10.9 grade boron-containing cold heading steel, can solve the problems of insignificant yield strength of cold heading steel, unfavorable stability of wire product quality, low silicon content, etc., and achieve less cracks. , low cost, low strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

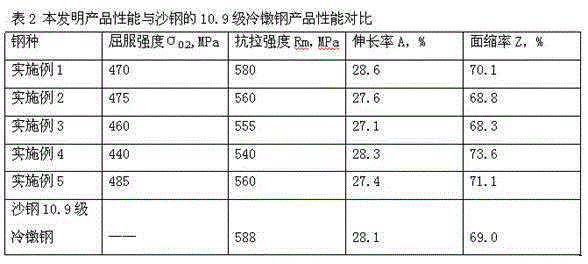

Embodiment 1

[0039] The components and weight percentages of grade 10.9 boron-containing non-spheroidizing annealed cold pier steel in this example are: C: 0.21%; Si: 0.19%; Mn: 1.33%; P: 0.0017%; S: 0.006%; Al: 0.029%; Ti: 0.051%; B: 0.0019%, the rest is iron and unavoidable impurity elements. The diameter of the wire rod is 20mm, and its production process is: converter smelting, out-of-furnace refining, continuous casting of 150mm*150mm billet, high-speed wire-controlled rolling, and Stelmo wire-controlled cooling. The key control parameters are: (1) The tapping temperature is 1635°C, the carbon content of tapping is 0.07%, and the phosphorus content of tapping is 0.014%; (2) In the refining process, the refining in-place temperature is 1536°C, The temperature is at 1569°C. In the steelmaking and refining station, aluminum alloy, titanium alloy, and boron alloy are added at the end of refining, and the order of addition is: aluminum alloy is added first, then titanium alloy is added, t...

Embodiment 2

[0041] The components and weight percentages of grade 10.9 boron-containing non-spheroidizing annealed cold pier steel in this example are: C: 0.20%; Si: 0.21%; Mn: 1.36%; P: 0.020%; S: 0.008%; Al: 0.030%; Ti: 0.046%; B: 0.0017%, the rest is iron and unavoidable impurity elements. The diameter of the wire rod is 20mm, and its production process is: converter smelting, out-of-furnace refining, continuous casting of 150mm*150mm billet, high-speed wire-controlled rolling, and Stelmo wire-controlled cooling. The key control parameters are: (1) The tapping temperature is 1640°C, the carbon content of tapping is 0.08%, and the phosphorus content of tapping is 0.016%; (2) In the refining process, the refining in-place temperature is 1563°C, The temperature is at 1588°C. In the steelmaking and refining station, aluminum alloy, titanium alloy, and boron alloy are added at the end of refining, and the order of addition is: aluminum alloy is added first, then titanium alloy is added, th...

Embodiment 3

[0043] The components and weight percentages of grade 10.9 boron-containing non-spheroidizing annealed cold pier steel in this example are: C: 0.19%; Si: 0.25%; Mn: 1.38%; P: 0.019%; S: 0.008%; Al: 0.031%; Ti: 0.049%; B: 0.0018%, the rest is iron and unavoidable impurity elements. The diameter of the wire rod is 20mm, and its production process is: converter smelting, out-of-furnace refining, continuous casting of 150mm*150mm billet, high-speed wire-controlled rolling, and Stelmo wire-controlled cooling. The key control parameters are: (1) The tapping temperature is 1655°C, the carbon content of tapping is 0.09%, and the phosphorus content of tapping is 0.015%; (2) In the refining process, the refining in-place temperature is 1571°C, The temperature is 1588°C. In the steelmaking and refining station, aluminum alloy, titanium alloy, and boron alloy are added at the end of refining, and the order of addition is: aluminum alloy is added first, then titanium alloy is added, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com