Preparation method of composite hard material

A technology of composite hard materials and hard alloy blocks, which is applied in the direction of metal material coating process, coating, fusion spraying, etc. Performance degradation and other problems, to achieve the effect of omitting mold engraving and layout time, simple and fast production process, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

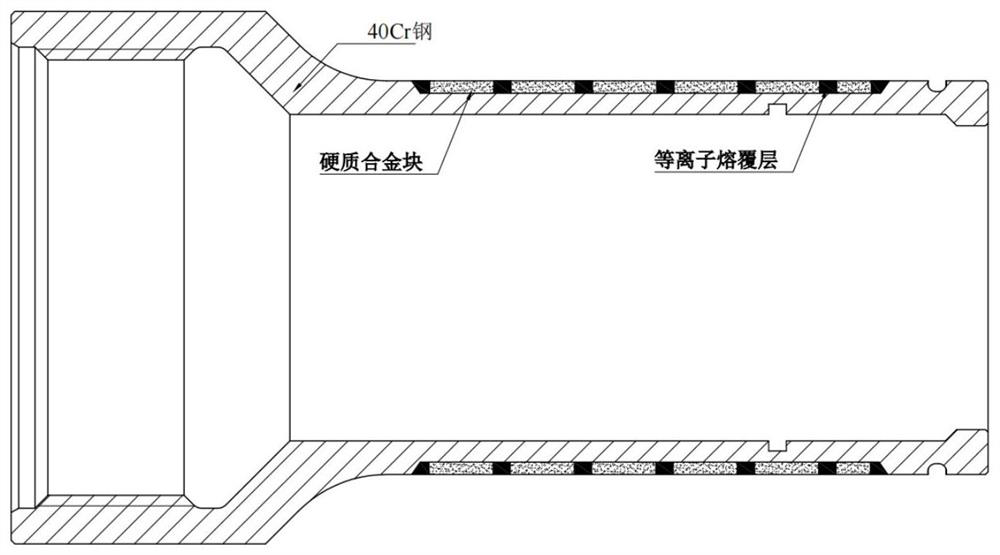

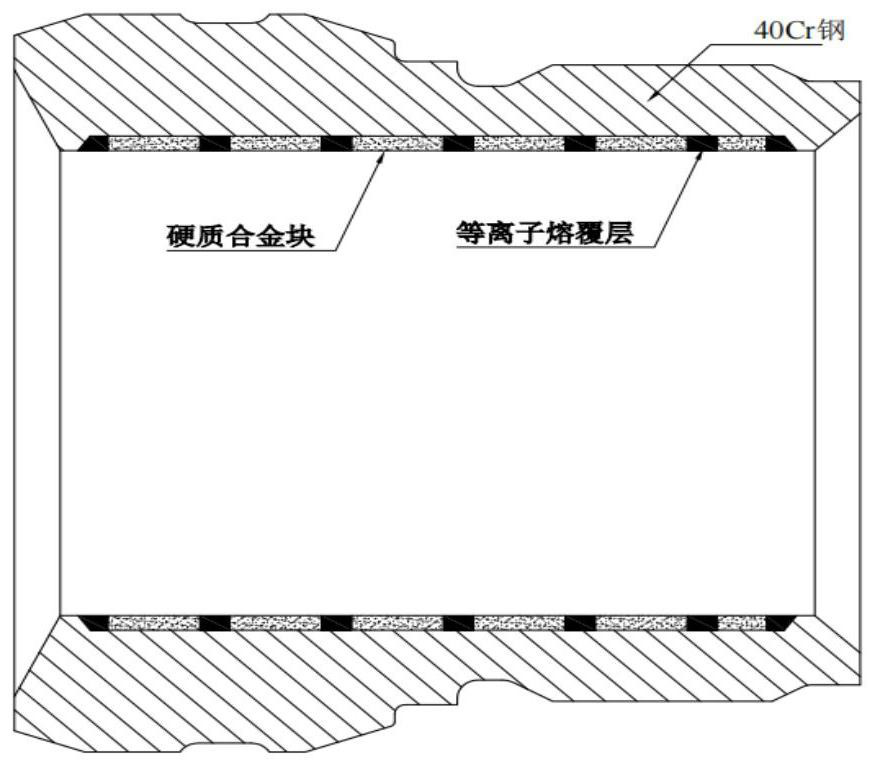

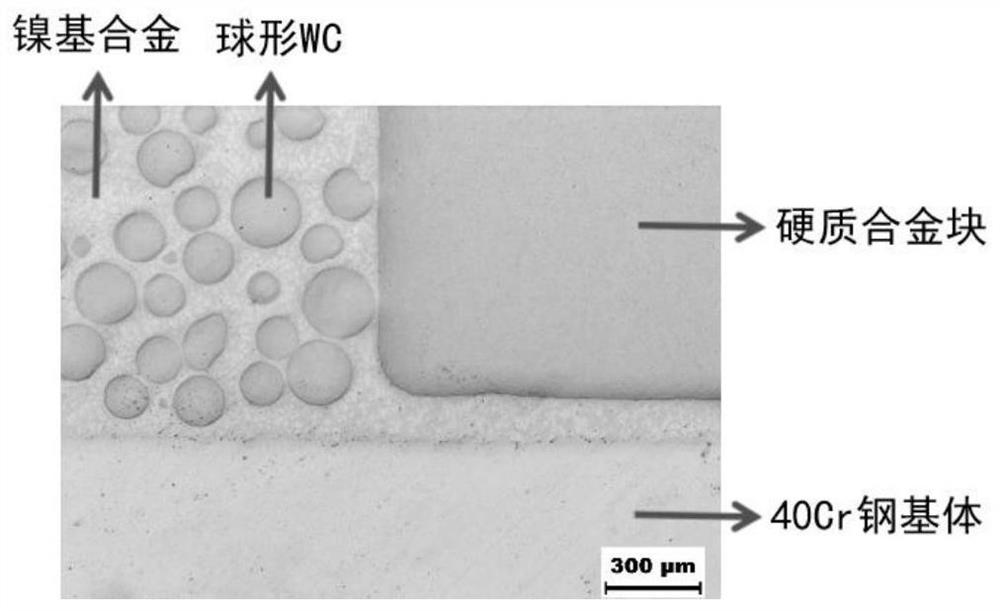

[0034] According to a general technical idea of the present invention, such as Figure 1-3 As shown, a kind of preparation method of composite hard material is provided, comprising the following steps:

[0035] According to the design requirements, the metal substrate can be made of steel, and the grade, performance, shape, size and distribution of the hard alloy block on the surface of the steel should be selected properly. The shape of the steel can be flat or curved;

[0036] Apply a layer of nickel-based alloy coating on the steel surface by means of flame spraying;

[0037] Using custom-made automated "quick discharge" equipment, the hard alloy block is placed on the surface of the above-mentioned nickel-based alloy coating, and then a large current is applied instantaneously to make the hard alloy block and the nickel-based alloy coating instantly heat up, and the temperature is higher than The melting point of nickel-based alloy coating is lower than the liquidus poi...

Embodiment 1

[0048] On the outer surface of the tubular 40Cr substrate whose size is Φ120mm outer diameter*Φ260mm inner diameter*70mm long, use powdered nickel-based powder as raw material, and use flame spraying method to coat a layer of nickel-based alloy coating, the thickness of which is controlled at 0.08mm .

[0049] The above-mentioned 40Cr substrate coated with the nickel-based alloy coating on the surface is placed on the fixture of the automatic rapid discharge equipment. The automatic rapid discharge equipment is equipped with an automatic conveying and holding device for cemented carbide blocks. The cemented carbide blocks are WD11C grades provided by Weidun New Material Technology Co., Ltd., and the size is 12mm long*5mm wide*3mm thick. According to the customer's requirements, combined with the outer diameter and length of the substrate, determine the horizontal and vertical spacing between the cemented carbide blocks as 3.3mm and 2.5mm respectively, and set them in the PLC p...

Embodiment 2

[0057] On the surface of the inner wall of the tubular 40Cr matrix with a size of Φ150mm outer diameter*Φ70mm inner diameter*165mm long, a layer of nickel-based alloy coating is coated with powdered nickel-based powder as raw material by flame spraying, and its thickness is controlled at 0.1mm.

[0058] The above-mentioned 40Cr substrate coated with the nickel-based alloy coating on the surface is placed on the fixture of the automatic rapid discharge equipment. The automatic rapid discharge equipment is equipped with an automatic conveying and holding device for cemented carbide blocks. The cemented carbide blocks are WD11C grades provided by Weidun New Material Technology Co., Ltd., and the size is 12mm long*5mm wide*3mm thick. According to the customer's requirements, combined with the outer diameter and length of the substrate, determine the horizontal and vertical spacing between the cemented carbide blocks as 3.5mm and 3mm respectively, and set them in the PLC program on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com