Aluminum frame pneumatic engaging device for solar module

An occlusal device, aluminum frame technology, applied in electrical components, semiconductor devices, climate sustainability, etc., can solve problems such as easy cracks, short aluminum frame and long aluminum frame cracks, corner codes and long and short frames easy to loosen, etc. Achieve the effect of reducing cracks, improving sealing performance and connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

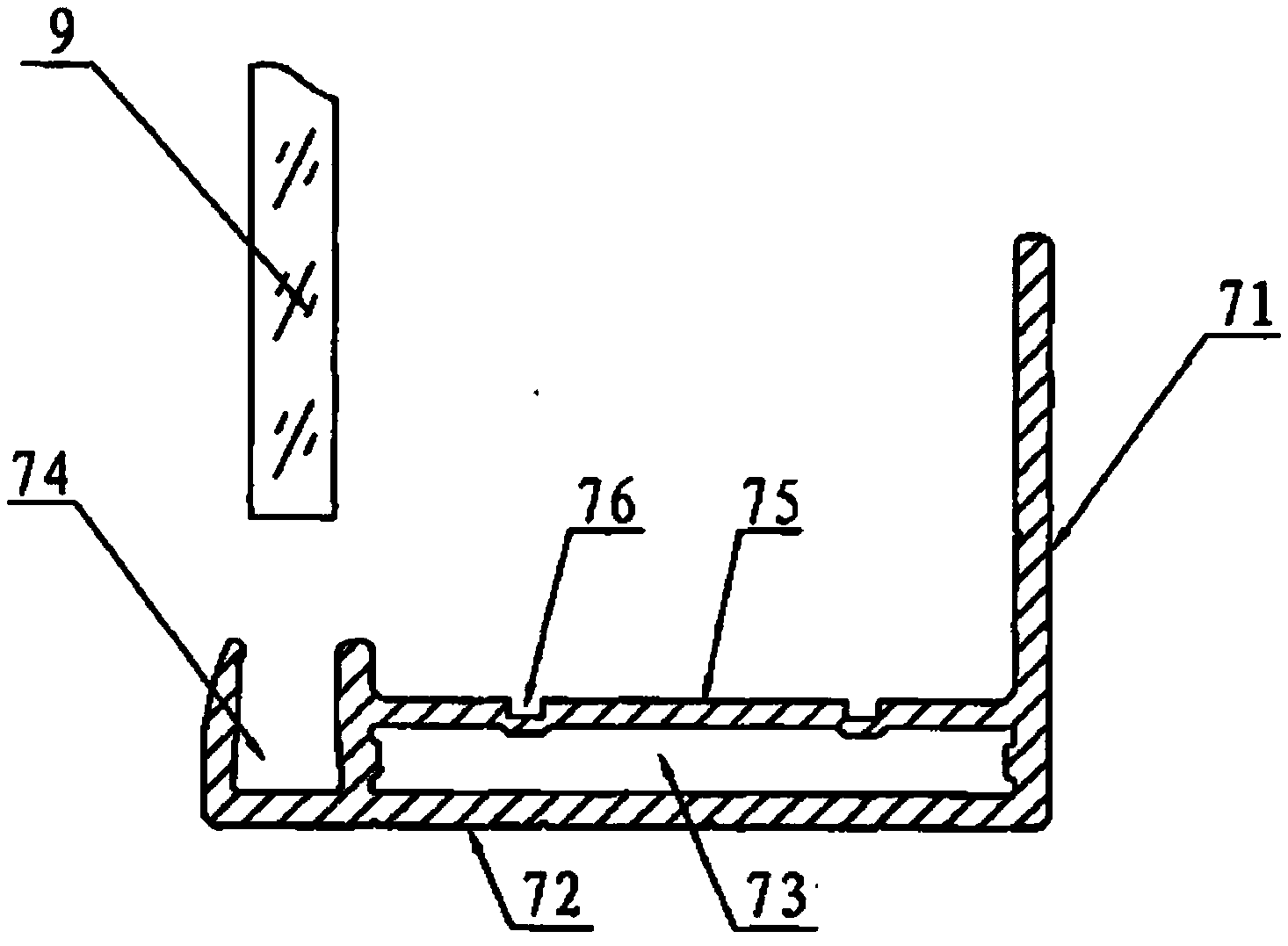

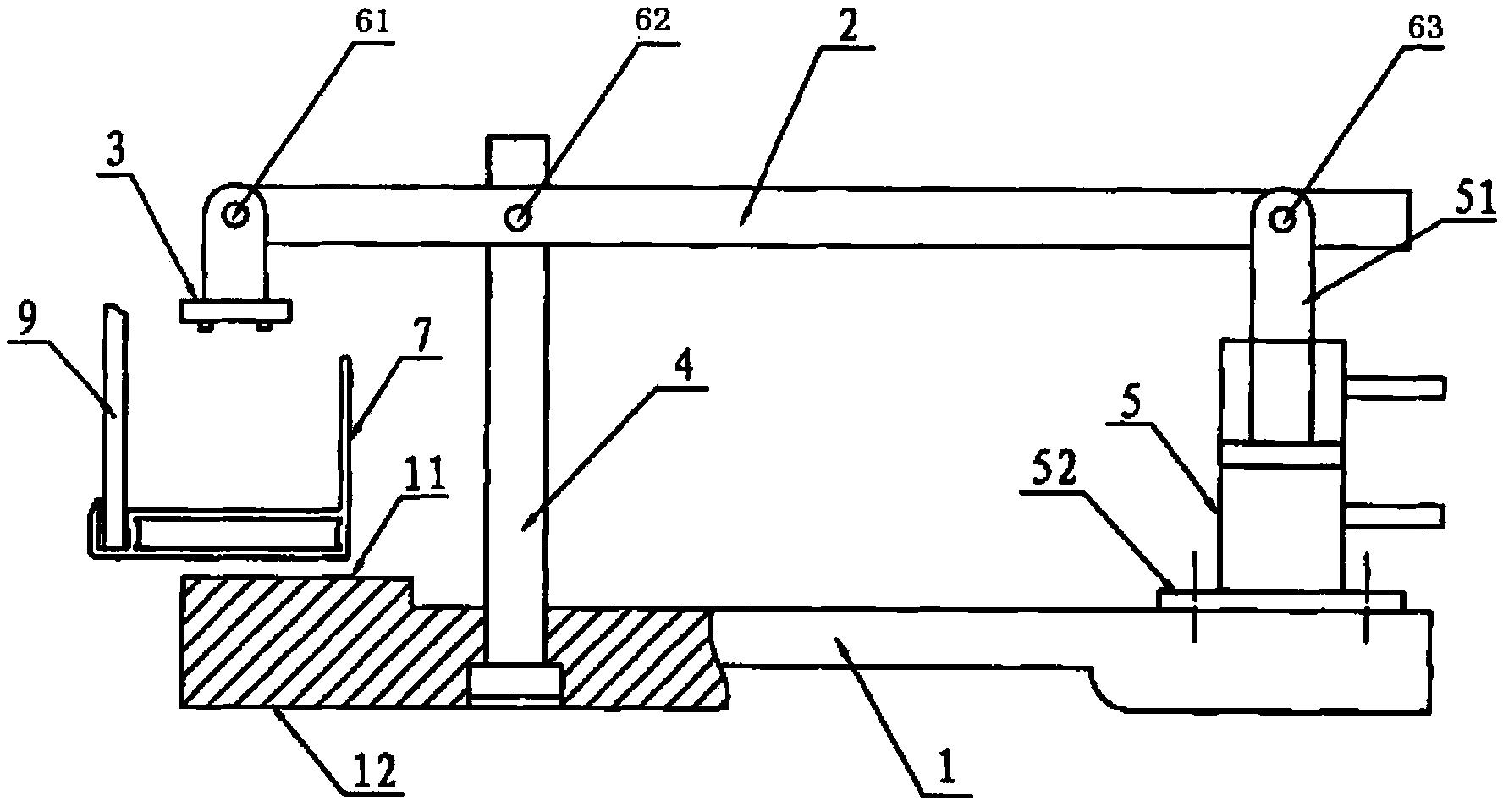

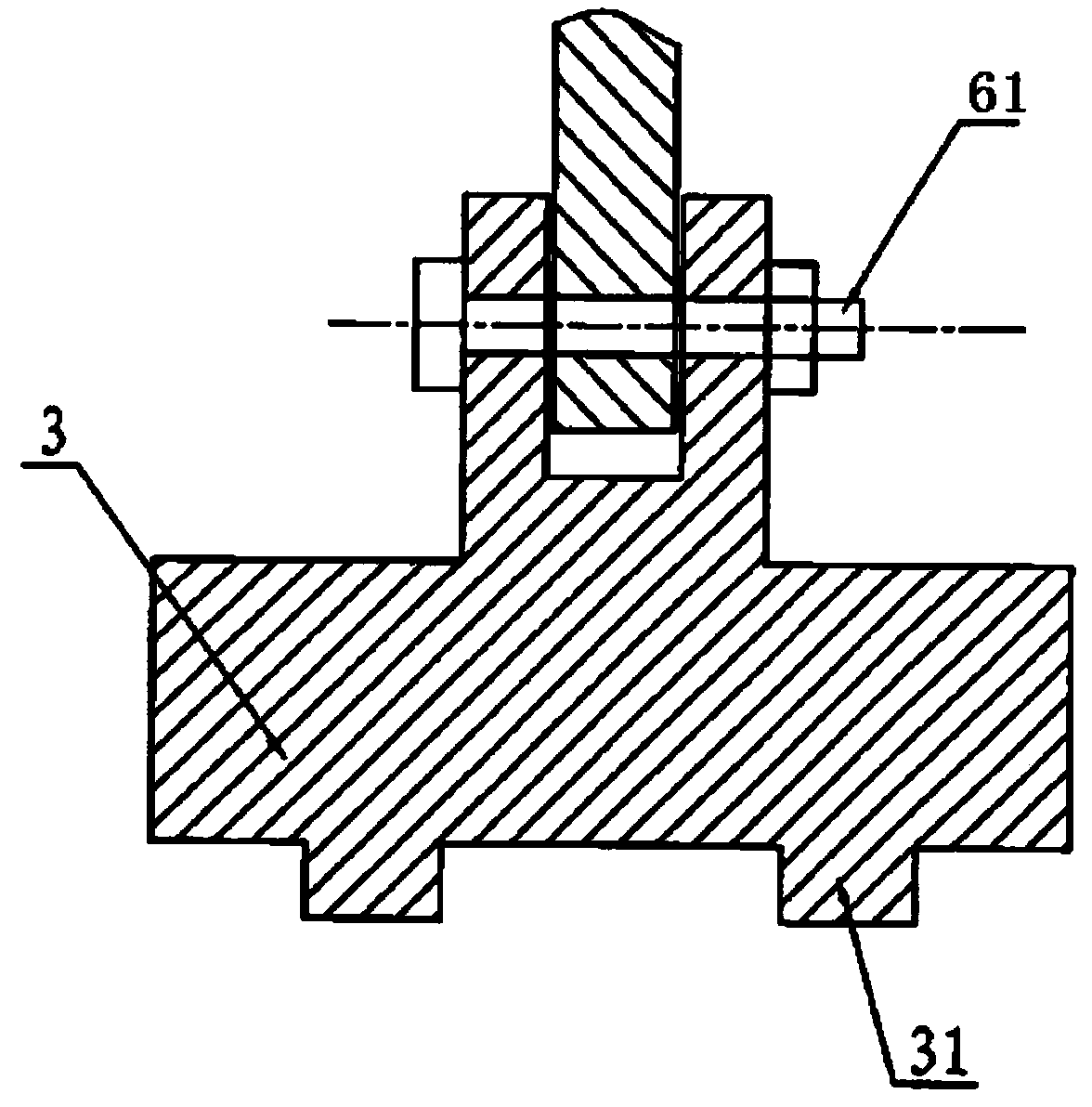

[0016] The aluminum frame of the solar cell module is pneumatically punched and engaged, such as figure 1 , figure 2 As shown, it includes a base plate 1, a lever 2, a stamping die head 3, a pressure bearing column 4 and a pressure cylinder 5, the pressure bearing column 4 is fixed on the base plate 1, and the stamping die head 3 is hinged through a first pin shaft 61 On the left end of the lever 2, a pressure bearing platform 11 is arranged on the left end 12 of the base plate. The width of the pressure bearing platform 11 is equivalent to the width of the outer surface 72 of the aluminum frame 7. The pin 62 is hinged, the piston rod 51 of the pressure cylinder 5 is hinged with the right end of the lever 2 through the third pin 63, the cylinder body 52 of the pressure cylinder 5 is fixed on the base plate 1, and the pressure cylinder 5 is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com