Method for preparing styrene-butadiene latex with low film formation temperature

A technology of styrene-butadiene latex and film-forming temperature, which is applied in the field of preparation of styrene-butadiene latex, can solve the problems of delaying film-forming time of styrene-butadiene latex, affecting the performance and appearance of finished products, and prolonging production time, so as to save costs and water resources, Effect of reducing cracks and lowering film forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

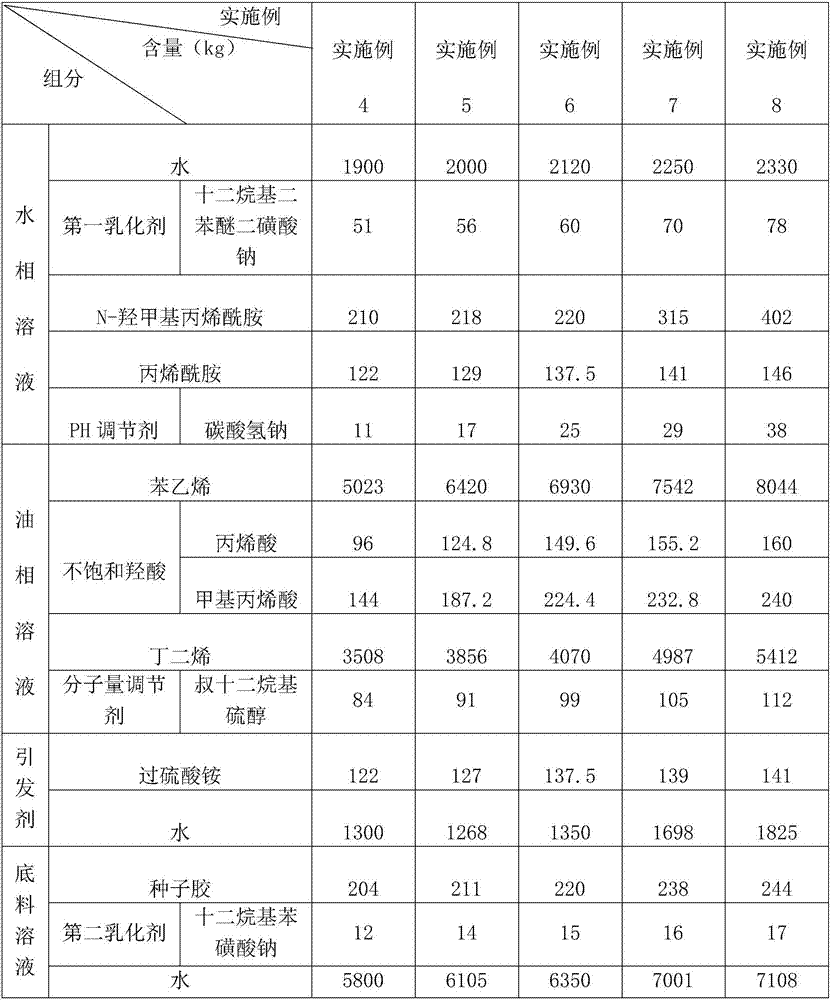

Examples

Embodiment 1

[0065] Embodiment 1: a kind of preparation method of seed glue, adopts following steps to make:

[0066] Step Y, the preparation of reaction solution: the styrene of 82kg, the 3rd emulsifier of 5.2kg and the water of 30kg are mixed uniformly, obtain reaction solution;

[0067] Step Z, preparation of seed glue: vacuumize the seed glue kettle, add 70kg of water and 25kg of the fourth emulsifier and mix evenly, stir and heat up to 85°C, simultaneously and continuously add the reaction solution prepared in step Y to react, react The temperature is controlled at 90°C, and the feeding time is 2h; after the addition is completed, keep warm for 1.5h and continue to stir the reaction; then cool to 35-38°C, and discharge; record it as N1.

[0068] Wherein the third emulsifier is the same as the fourth emulsifier and is C10 fatty alcohol polyoxyethylene ether.

Embodiment 2

[0069] Embodiment 2: a kind of preparation method of seed glue, adopt following steps to make:

[0070] Step Y, the preparation of reaction solution: mix the styrene of 76kg, the 3rd emulsifier of 5.8kg and the water of 30kg uniformly, obtain reaction solution;

[0071] Step Z, preparation of seed glue: vacuumize the seed glue kettle, add 70kg of water and 22kg of the fourth emulsifier, mix evenly, stir and heat up to 80°C, and simultaneously and continuously add the substrate solution prepared in step Y to react, The reaction temperature is controlled at 87°C, and the feeding time is 2h; after the addition is completed, keep warm for 1.5h and continue to stir the reaction; then cool to 35-38°C, and discharge; record it as N2.

[0072] Wherein the third emulsifier is the same as the fourth emulsifier and is C10 fatty alcohol polyoxyethylene ether.

Embodiment 3

[0073] Embodiment 3: a kind of preparation method of seed glue, adopt following steps to make:

[0074] Step Y, the preparation of reaction solution: the styrene of 79kg, the 3rd emulsifier of 5.5kg and the water of 30kg are mixed uniformly, obtain reaction solution;

[0075] Step Z, preparation of seed glue: vacuumize the seed glue kettle, add 70kg of water and 24kg of the fourth emulsifier and mix evenly, stir and heat up to 80°C, and simultaneously and continuously add the substrate solution prepared in step Y to react, The reaction temperature is controlled at 87°C, and the feeding time is 2h; after the addition is completed, keep warm for 1.5h and continue to stir the reaction; then cool to 35-38°C, and discharge; record it as N3.

[0076] Wherein the third emulsifier is the same as the fourth emulsifier and is C10 fatty alcohol polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com