Preparation method of acrylic acid organic silicon soap-free copolymerization emulsion

A technology of copolymerization emulsion and silicone, which is applied in the field of polymer emulsion preparation, can solve the problems of reduced polymer film compactness, reduced polymer performance, and low polymer purity, and achieves reduced water absorption, improved water resistance, and low Effect of Film Formation Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

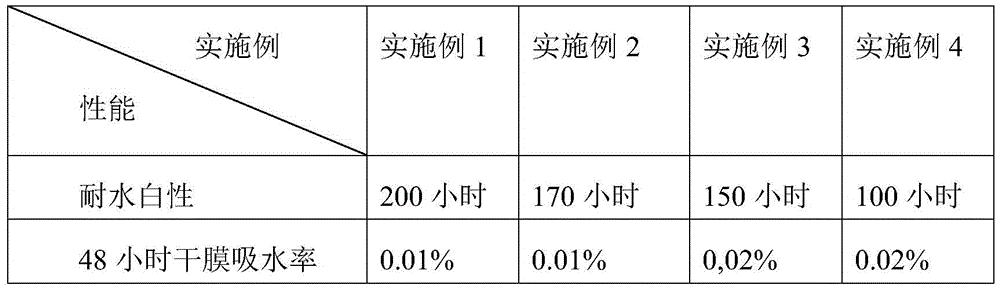

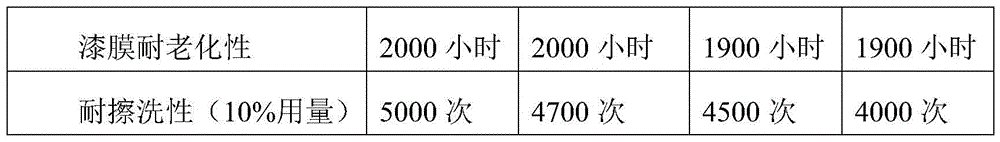

Examples

Embodiment 1

[0031] Add 120kg deionized water, 10.8kg allyl alkyl alcohol ether sulfate SR-1025, 2kg acrylamide into the pre-emulsification tank (A), then add 2.4kg methacrylic acid (AA), 55kg butyl acrylate (BA ), 130kg methyl methacrylate (MMA) were dispersed at a high speed to obtain pre-emulsion A.

[0032] Add 48.5kg deionized water, 2.34kg allyl alkyl alcohol ether sulfate SR-1025, 1.04kg methacrylamide isopropyl sulfonate AMPS-2404, 1.2kg diacetone acrylamide into the emulsification tank (B) (DAAM), 72.1kg isooctyl acrylate (2-EHA), 31.2kg methyl methacrylate (MMA), 0.78 methacrylic acid, 5.72kg γ-methacryloxypropyltrimethoxysilane (A- 174), the shell layer pre-emulsion (B) was obtained.

[0033] Add 304.2kg of deionized water and 4.2kg of SR-1025 into the reaction kettle, and then heat it to 82-84°C. Prepare 12.5kg of pre-emulsion (A) and 0.44kg of initiator potassium persulfate (KPS) + 8.3kg The deionized water solution is added into the reaction kettle, the reaction temperature...

Embodiment 2

[0039] Add 120kg deionized water, 10.8kg allyl alkyl alcohol ether sulfate SR-1025, 2kg acrylamide into the pre-emulsification tank (A), then add 2.4kg methacrylic acid (AA), 55kg butyl acrylate (BA ), 130kg methyl methacrylate (MMA) were dispersed at a high speed to obtain pre-emulsion A.

[0040] Add 48.5kg deionized water, 2.34kg allyl alkyl alcohol ether sulfate SR-1025, 1.04kg methacrylamide isopropyl sulfonate AMPS-2404, 1.2kg diacetone acrylamide into the emulsification tank (B) (DAAM), 72.1 kg isooctyl acrylate (2-EHA), 31.2 kg methyl methacrylate (MMA), 0.78 methacrylic acid, 5.72 kg vinyltrimethoxysilane (A-171) to prepare the shell Pre-emulsion (B).

[0041] Add 304.2kg of deionized water and 4.2kg of SR-1025 into the reaction kettle, and then heat it to 82-84°C. Prepare 12.5kg of pre-emulsion (A) and 0.44kg of initiator potassium persulfate (KPS) + 8.3kg The deionized water solution is added into the reaction kettle, the reaction temperature is kept at 84-86° C.,...

Embodiment 3

[0047] Add 120kg deionized water, 10.8kg allyl alkyl sulfosuccinate M-12S, 2kg acrylamide to the pre-emulsification tank (A), then add 2.4kg methacrylic acid (AA), 55kg butyl acrylate (BA), 130kg methyl methacrylate (MMA) carry out high-speed dispersion, make pre-emulsion A.

[0048] Add 48.5kg deionized water, 2.34kg allyl alkyl sulfosuccinate M-12S, 1.04kg methacrylamide isopropyl sulfonic acid AMPS-2404, 1.2kg diacetone to the emulsification tank (B) Acrylamide (DAAM), 72.1kg isooctyl acrylate (2-EHA), 31.2kg methyl methacrylate (MMA), 0.78 methacrylic acid, 5.72kg γ-methacryloxypropyltrimethoxysilane ( A-174), make the shell layer pre-emulsion (B).

[0049] Add 304.2kg of deionized water and 4.2kg of allyl alkyl sulfosuccinate M-12S into the reaction kettle, then heat to 82-84°C, prepare 12.5kg of pre-emulsion (A) and 0.44 Add kg initiator sodium persulfate + 8.3kg deionized aqueous solution into the reactor, keep the reaction temperature at 84-86°C, and control the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com