Green preparation process of zirconia-based metal ceramic material for optical fiber

A ceramic material and preparation process technology, applied in the field of ceramic materials, can solve the problems of residual stress, easy deformation of products, harmful phase changes, etc., and achieve the effects of reducing the generation of cracks, excellent anti-aging performance, and stabilizing the temperature of ball milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A green preparation process for optical fiber using zirconia-based cermet materials, including:

[0039] S1. Weigh magnesium nitrate, cerium nitrate, scandium nitrate, calcium nitrate, and lanthanum nitrate according to the mass ratio of 1:2:2:0.5:1, then add deionized water, mix evenly, and configure 25% nitrate mixture solution;

[0040] S2, add 10% citric acid solution to the mixed nitrate solution, and stir evenly;

[0041] S3. Raise the temperature of the mixed solution to 75°C, and at the same time slowly add ammonia water with a concentration of 30% with a peristaltic pump, and keep stirring until a gel precipitate is formed, and the obtained gel precipitate is repeatedly washed to remove excess residual water-soluble ions, and then dried;

[0042] S4. Take the designed amount of metal powder and alumina-based ceramic powder and place them in a high-speed ball mill for mixing and grinding for 3 hours. The speed of the high-speed ball mill is 450 rad / min, and then...

Embodiment 2

[0053] A green preparation process for optical fiber using zirconia-based cermet materials, including:

[0054] S1. Weigh magnesium nitrate, cerium nitrate, scandium nitrate, calcium nitrate, and lanthanum nitrate according to the mass ratio of 1:2:2:0.5:1, then add deionized water, mix evenly, and configure 25% nitrate mixture solution;

[0055] S2, add 10% citric acid solution to the mixed nitrate solution, and stir evenly;

[0056] S3. Raise the temperature of the mixed solution to 75°C, and at the same time slowly add ammonia water with a concentration of 30% with a peristaltic pump, and keep stirring until a gel precipitate is formed, and the obtained gel precipitate is repeatedly washed to remove excess residual water-soluble ions, and then dried;

[0057] S4. Take the designed amount of metal powder and alumina-based ceramic powder and place them in a high-speed ball mill for mixing and grinding for 5 hours. The speed of the high-speed ball mill is 450 rad / min, and th...

Embodiment 3

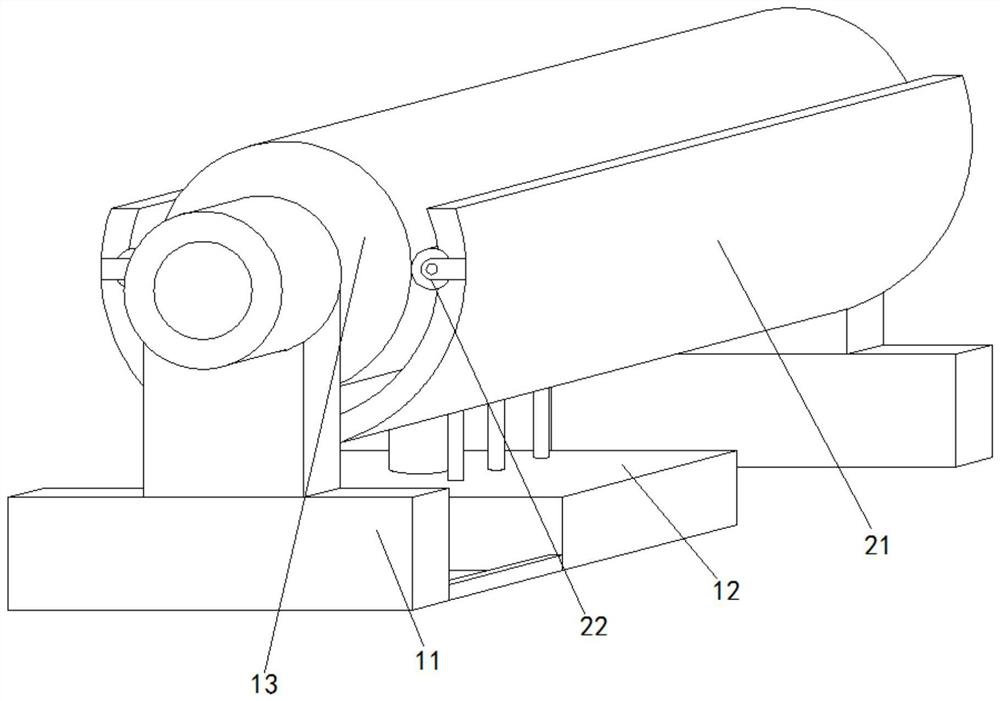

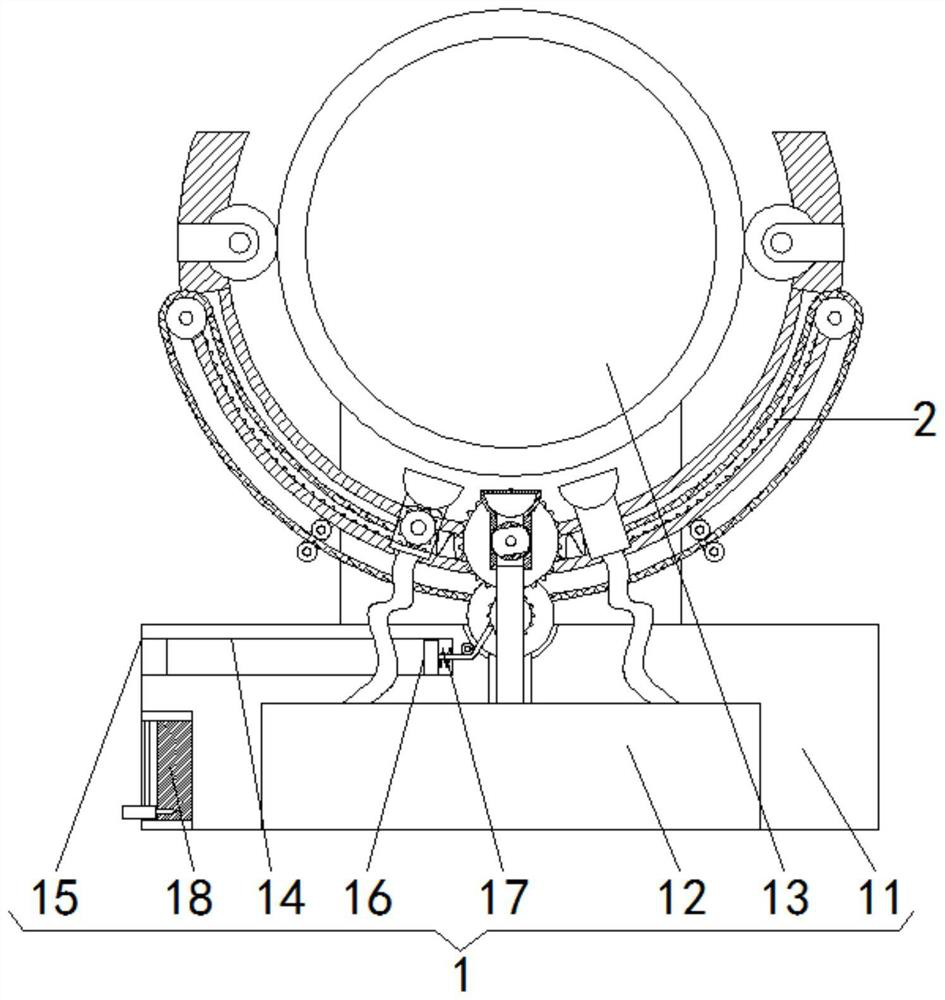

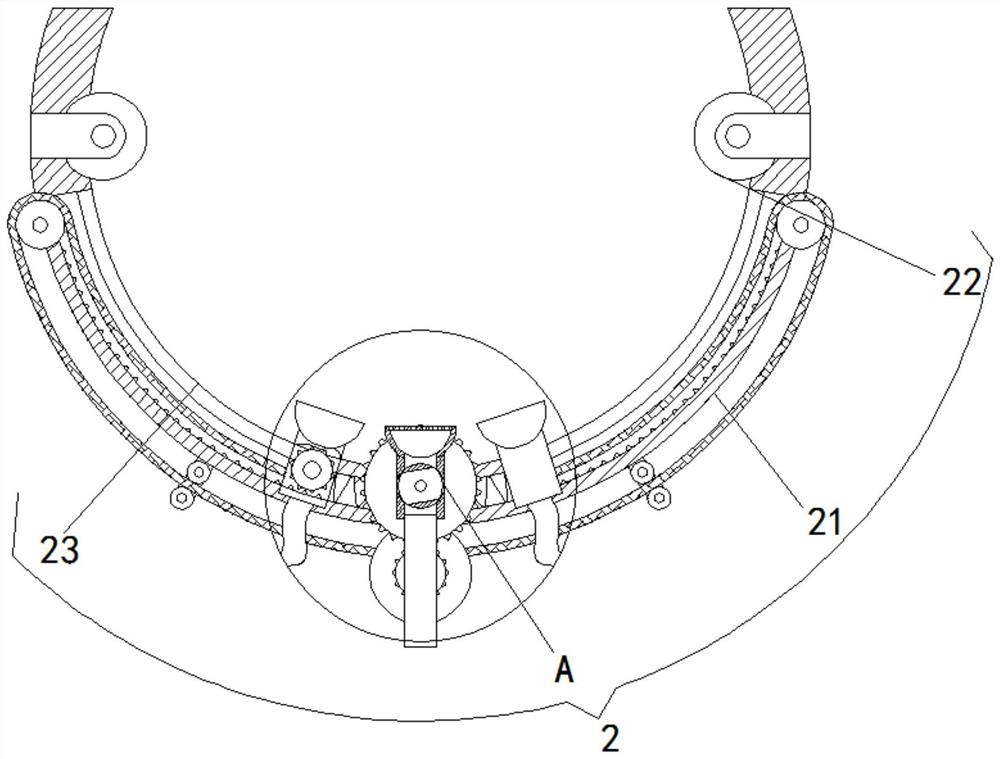

[0068] see Figure 1-Figure 5 , a green preparation process for optical fiber using zirconia-based cermet materials, including:

[0069] S1. Weigh magnesium nitrate, cerium nitrate, scandium nitrate, calcium nitrate, and lanthanum nitrate according to the mass ratio of 1:2:2:0.5:1, then add deionized water, mix evenly, and configure 25% nitrate mixture solution;

[0070] S2, add 10% citric acid solution to the mixed nitrate solution, and stir evenly;

[0071] S3. Raise the temperature of the mixed solution to 75°C, and at the same time slowly add ammonia water with a concentration of 30% with a peristaltic pump, and keep stirring until a gel precipitate is formed, and the obtained gel precipitate is repeatedly washed to remove excess residual water-soluble ions, and then dried;

[0072] S4. Take the designed amount of metal powder and alumina-based ceramic powder and place them in a high-speed ball mill for mixing and grinding for 3-5 hours. The speed of the high-speed ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com