Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "No secondary treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

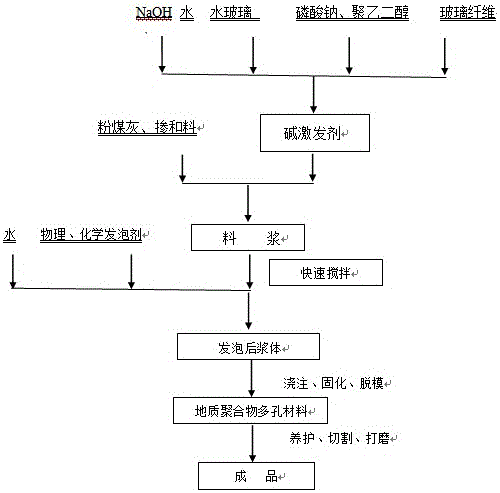

Flyash geopolymer based porous material and preparation process thereof

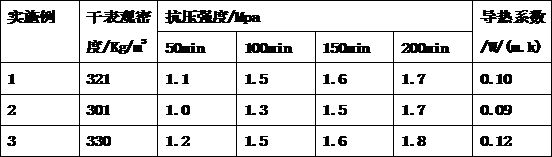

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

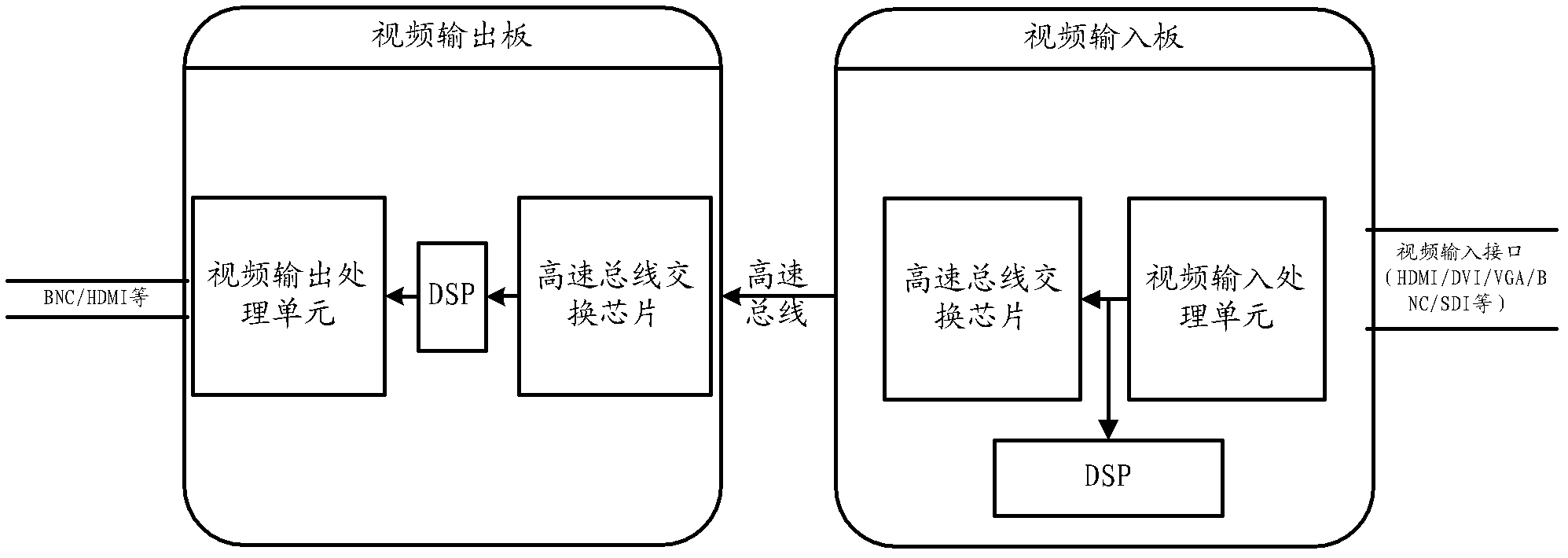

Surveillance video matrix system, network and cascade switch and band width adjustment methods of surveillance video matrix system

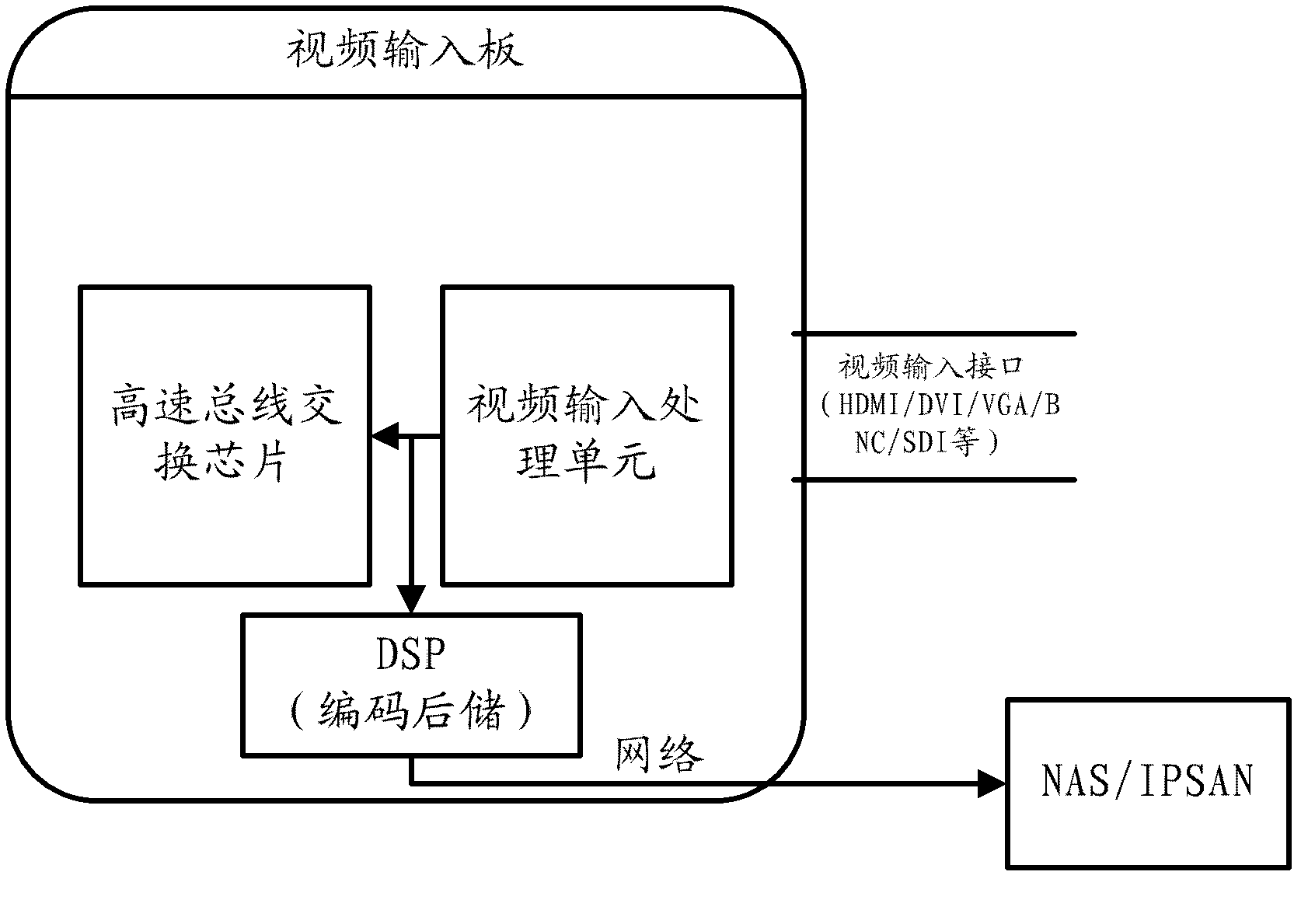

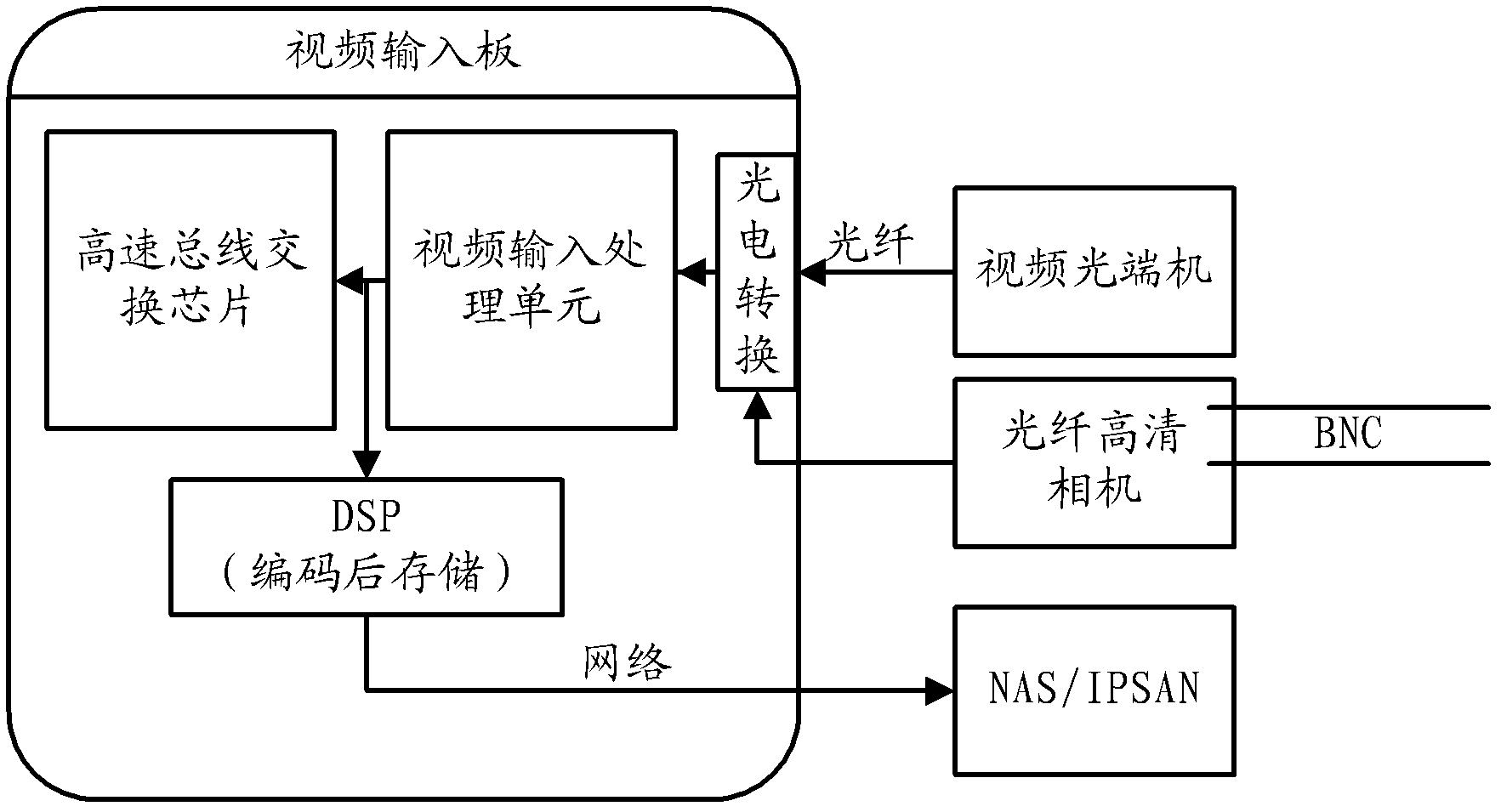

ActiveCN103037170ARealize centralized storageEasy retrievalTelevision system detailsPulse modulation television signal transmissionTransfer procedureTransducer

The invention relates to the field of security and protection and surveillance video, and discloses a surveillance video matrix system, a network and cascade switch and band width adjustment methods of the surveillance video matrix system. The surveillance video matrix system comprises a high-speed bus and a processor, wherein video picture signals are directly converted into high-speed bus signals, encoding and decoding are not carried out, low latency is realized, data are not damaged or compressed in the transmission process, picture quality is high, video edition can be directly carried out, and secondary processing is needless. The surveillance video matrix system further comprises a photoelectric transducer, optical signals are converted into electric signals, input and output of various ports are supported, and seamless joint of anolog signals and digital signals is realized. As extension of the surveillance video matrix system, two optical fiber cascade panels are connected through optical fiber backbones, the optical fiber transmission advantages of large communication capacity and long transmission distance can be fully played, and transmission of any video can be achieved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

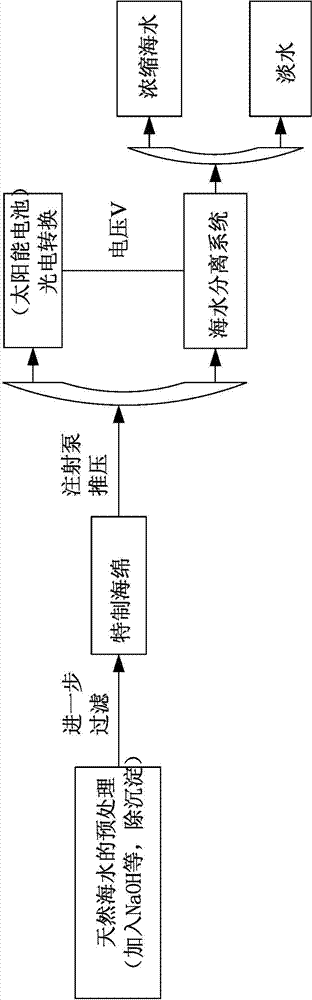

Seawater desalination system and seawater desalination method

ActiveCN104773796AHigh purityNo pollutionSeawater treatmentWater/sewage treatment by magnetic/electric fieldsEngineeringFresh water

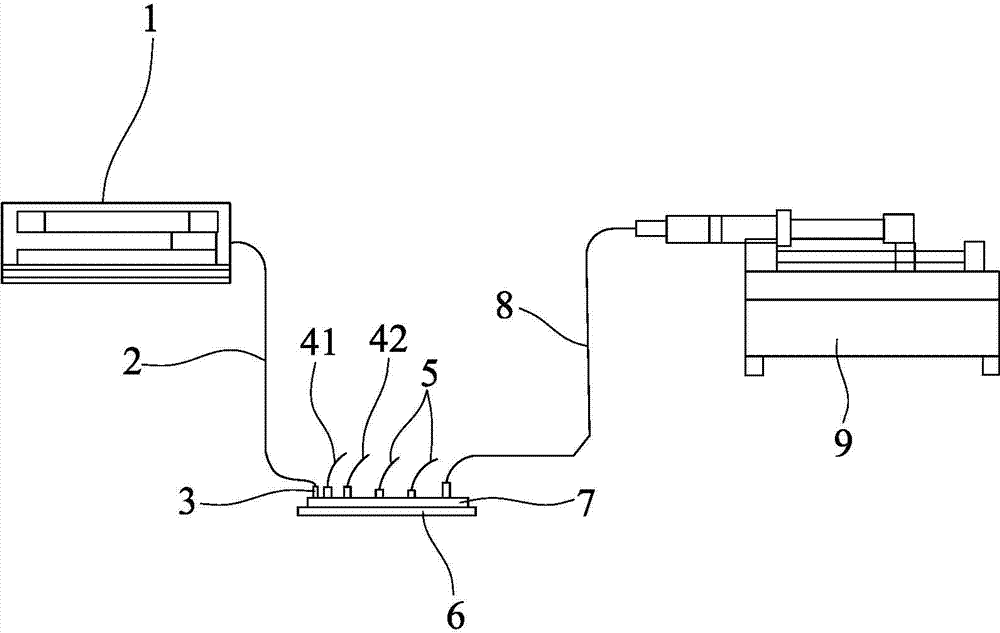

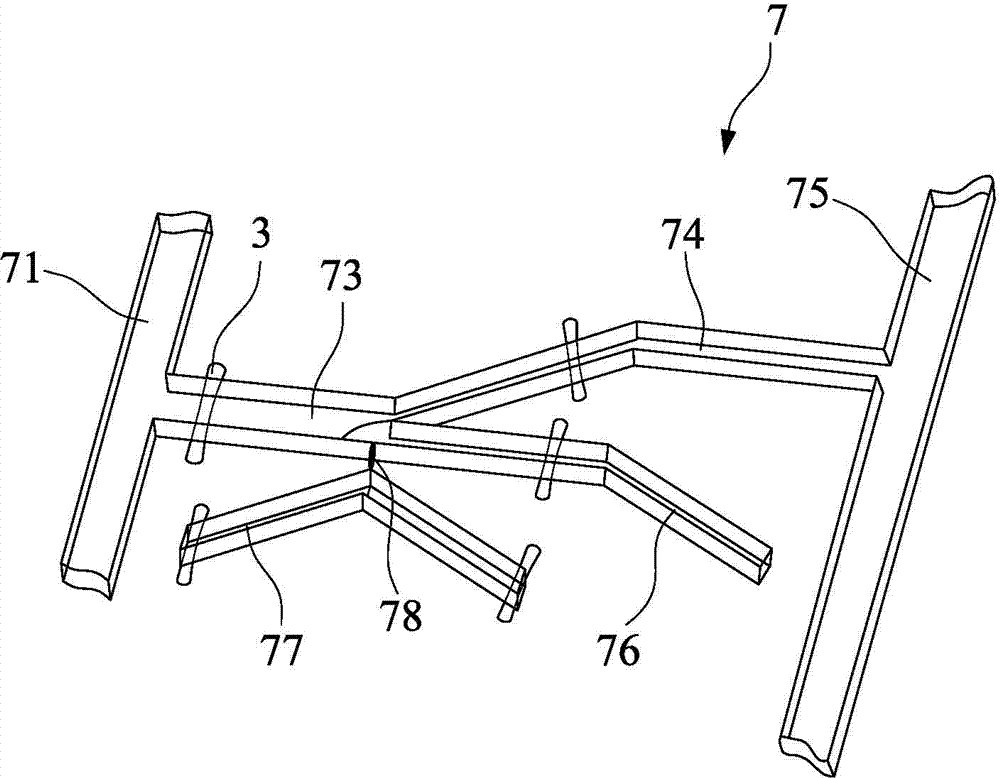

The invention discloses a seawater desalination system and a seawater desalination method. The system includes a DC current source, a metal lead, electrodes, a plurality of microfluidic chips composed of a glass sheet and a PDMS chip, a liquid inlet pipe, an injection pump, and a fresh water outlet pipe, a concentrated seawater outlet pipe and two liquid conveying pipes that are connected to the microfluidic chips. The DC current source is in connection with the electrodes at all microchannel ports of the microfluidic chips through the metal lead. The fresh water outlet pipe and the concentrated seawater outlet pipe are respectively connected to a respective collecting groove. According to the method and the system provided by the invention, the ion concentration polarization phenomena occurs to impurity particles in seawater under the action of an electric field, and then under an outside pressure on seawater, the impurity particles and fresh water are separated. The system has the characteristics of low manufacturing cost and small volume, and can realize portability and other effects.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Photovoltaic module recycling method and system

ActiveCN110571306AWon't happenThe realization of the productionWaste processingFinal product manufactureElectrical batteryResource recovery

The invention discloses a photovoltaic module recycling method and system. The method comprises the following steps: removing a frame, a junction box and a glass panel on a photovoltaic module to obtain primarily-separated materials; shearing the primarily-separated materials to obtain primarily-separated material fragments; placing the primarily-separated material fragments in a stripping deviceprovided with a rotary striking mechanism and performing stripping to obtain a mixture of EVA film fragments, backplane fragments, bus-bar fragments, solder strip fragments and silicon powder; and sorting out silicon powder, EVA film fragments, backplane fragments, bus-bar fragments and solder strip fragments through a sorting device. The method for disassembling and recycling the backplane, EVA,battery cells and complete glass has the advantages of high disassembling and recycling efficiency, low energy consumption, no environmental pollution and the like. Resource waste and waste dischargeare greatly reduced, and the recycling cost is reduced. The method is an environment-friendly resource recycling method.

Owner:YINGLI ENERGY CHINA +1

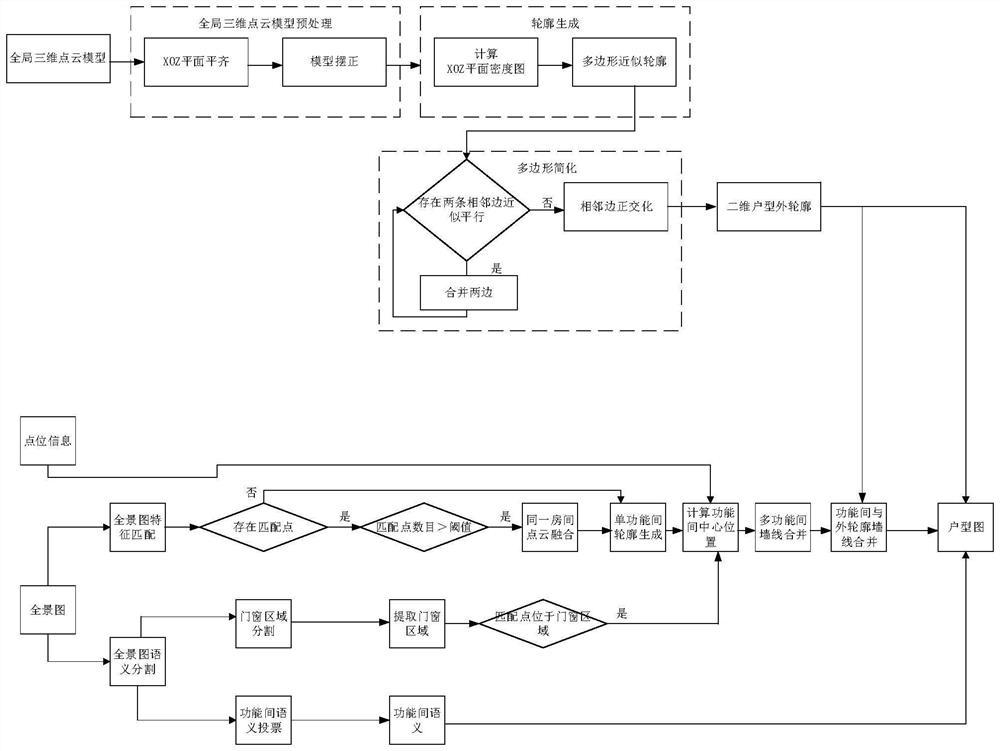

House plan generation method and device, equipment and medium

PendingCN113823001AHigh precisionAvoid interferenceImage enhancementImage analysisGeneration processPoint cloud

The embodiment of the invention discloses a house plan generation method and device, a storage medium and electronic equipment. The method comprises the following steps: acquiring a panorama of a house, fusing point cloud data corresponding to the same function based on the panorama, and determining a function room contour of each data based on a function room point cloud model obtained by fusion; obtaining a house point cloud model of the house, and determining the outer contour of the house based on the house point cloud model; and generating a house plan of the house based on the contour of the function room and the outer contour of the house. The house plan obtained based on the combination of the contours of all the function rooms and the outer contour of the house avoids the interference of objects in the house on the contours of the function rooms, and the precision is high. In the generation process of the contours of the function rooms and the outer contour of the house, the contours of the function rooms is generated by extracting the outer contours of the function rooms, the outer contour of the house is generated by extracting the outer contour of the house, the situation that the contour is discontinuous does not exist, secondary processing is not needed, and the generation process of the house plan is simplified.

Owner:BEIJING YOUZHUJU NETWORK TECH CO LTD

Method for reducing wear by metal surface micro-texture auxiliary friction induction film formation

The invention discloses a method for reducing wear by metal surface micro-texture auxiliary friction induction film formation. The method mainly comprises the steps of metal surface micro-texture, lubrication condition control, friction process control and the like. According to the method for reducing wear by the metal surface micro-texture auxiliary friction induction film formation, three aspects of a micro-texture state, a lubrication condition and a friction process are organically combined, so that a friction reaction film can be rapidly formed on the metal surface through the micro-texture auxiliary friction induction, and a good anti-wear effect is achieved. The preparation process of the method for reducing wear by the metal surface micro-texture auxiliary friction induction filmformation is simple and controllable, is easy to realize, and has wide application prospect in the fields of improving wear resistance of various metal friction and the like.

Owner:HEFEI UNIV OF TECH

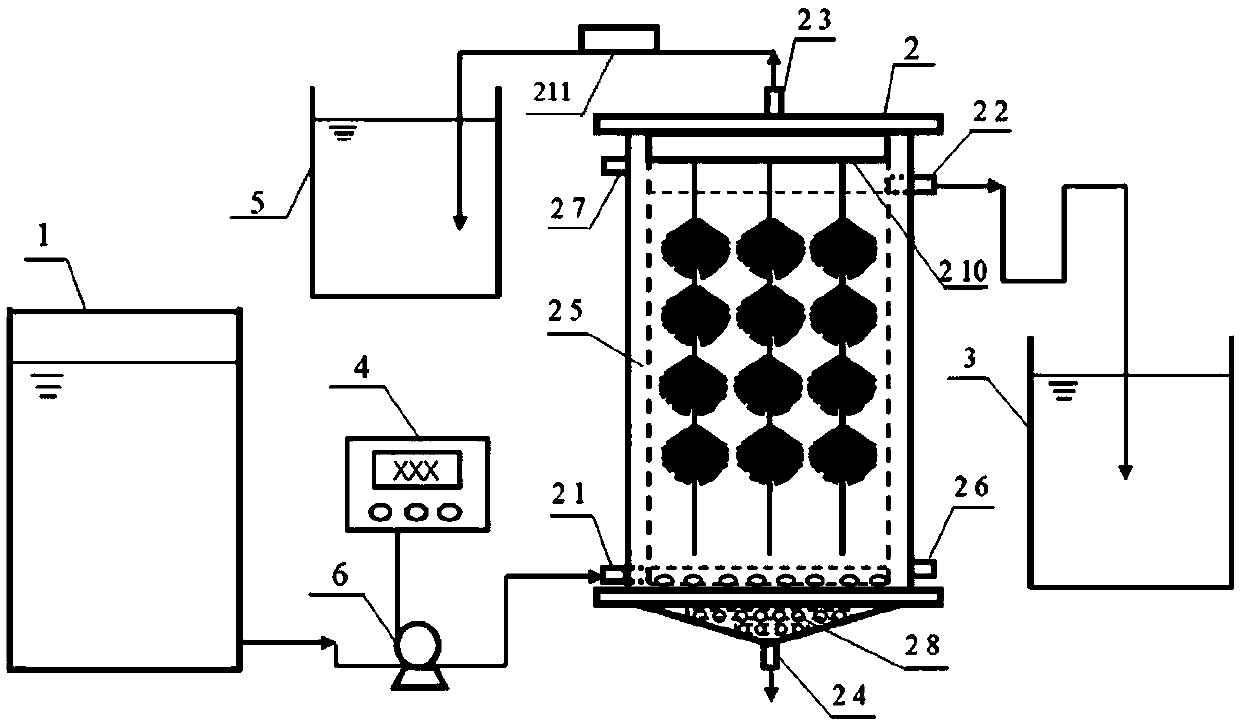

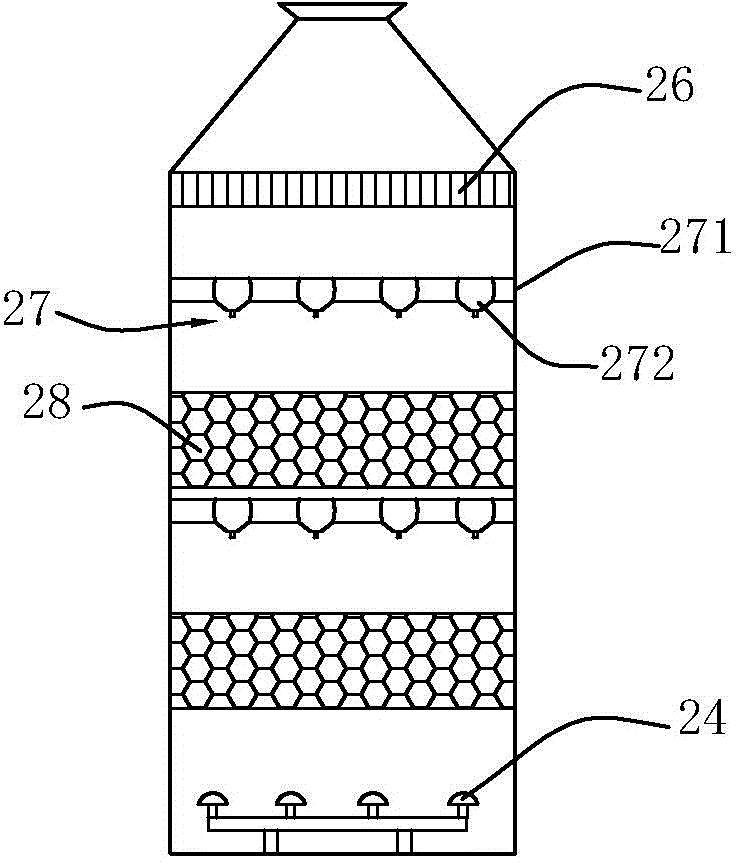

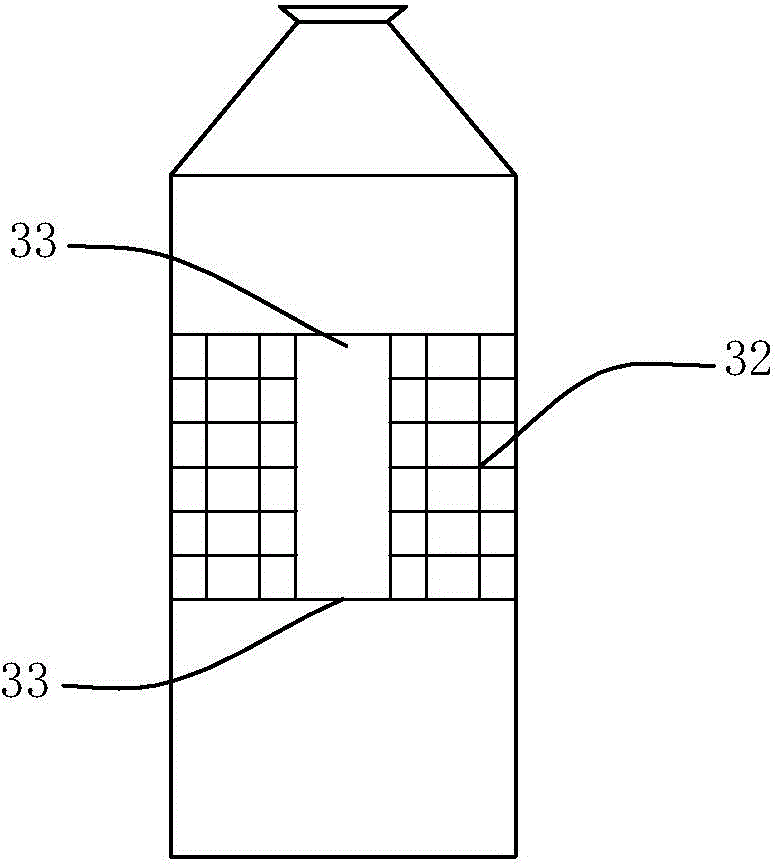

Method and device for enriching anaerobic ammonium oxidizing bacteria based on modified basalt fiber filler

ActiveCN109593685AShort generation cycleSave matrix feedBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeSewage

The invention discloses a method and a device for enriching anaerobic ammonium oxidizing bacteria based on modified basalt fiber filler, and belongs to the technical field of sewage biological treatment. The method is characterized by comprising the following steps: S1, starting a system, mixing nitrified sludge with anaerobic ammonium oxidized sludge, then adding the mixed sludge into a reactor filled with modified basalt fibers, and mixing the sludge thoroughly; S2, in an initial stage of culturing, sending matrix raw water into the reactor; at the same time, turning on circulating water forcircular flow; and S3, in a logarithmic growth phase, controlling the water inlet speed of the raw water matrix for continuous rapid enrichment culturing of the anaerobic ammonium oxidizing bacteria.By adopting the method for enriching the anaerobic ammonium oxidizing bacteria provided by the invention, the generation cycle of the anaerobic ammonium oxidizing bacteria can be effectively shortened, high-activity proliferation in a short time can be realized, effective enrichment culturing of the anaerobic ammonium oxidizing bacteria can be implemented, and a foundation is laid for the engineering application of the novel biological denitrification technology.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

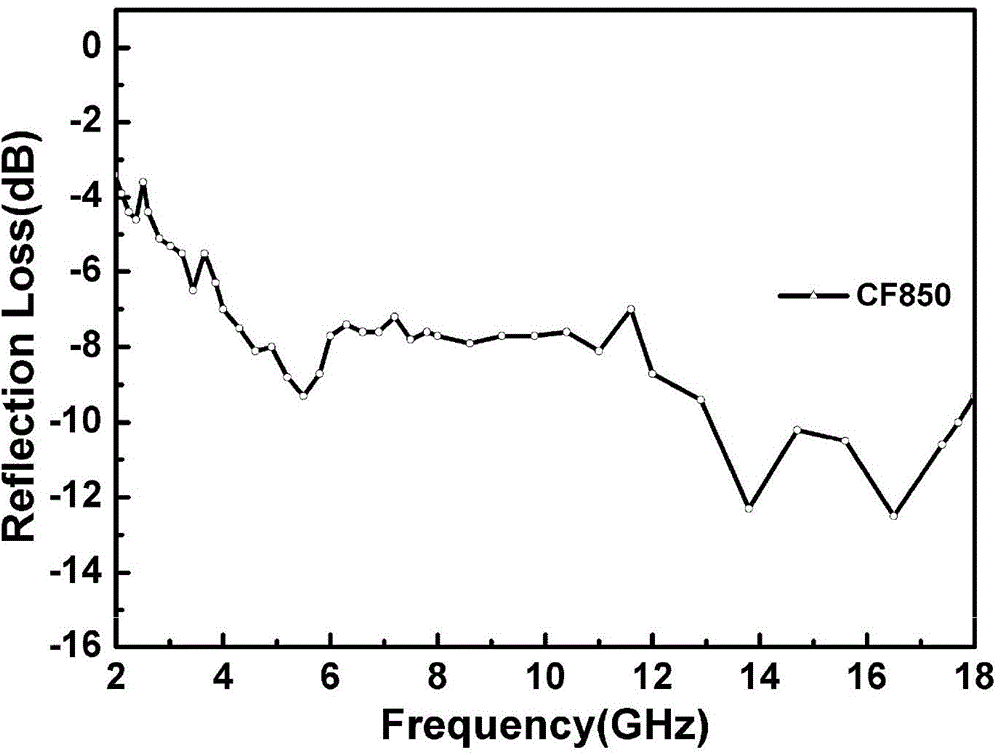

Method for preparing structural type wave-absorbing material

InactiveCN104804708ASimple preparation processLow equipment requirementsOther chemical processesMaterials science and technologyCarbon source

The invention relates to the technical fields of inorganic non-metallic material science and technology, branched carbon material science and technology and wave-absorbing materials. According to the method for preparing the structural type wave-absorbing material, the structural type wave-absorbing material is prepared with direct coal liquefaction residues as a carbon source and metal salt and halogen-family elementary substances as auxiliary agents. The method has the advantages as follows: (1), a preparation process is simple, the requirement for equipment is not high, process parameters are easy to control, and enlarging or shrinking can be performed as required; (2), raw materials used for preparation are wastes of the coal liquefaction process, are low is cost, do not require secondary treatment and can be directly applied, the utilization value of the raw materials is increased, and the economic benefits are increased; (3), the prepared material has the advantages of wide wave-absorption frequency band, high absorption strength, broad application field and the like.

Owner:DALIAN UNIV OF TECH

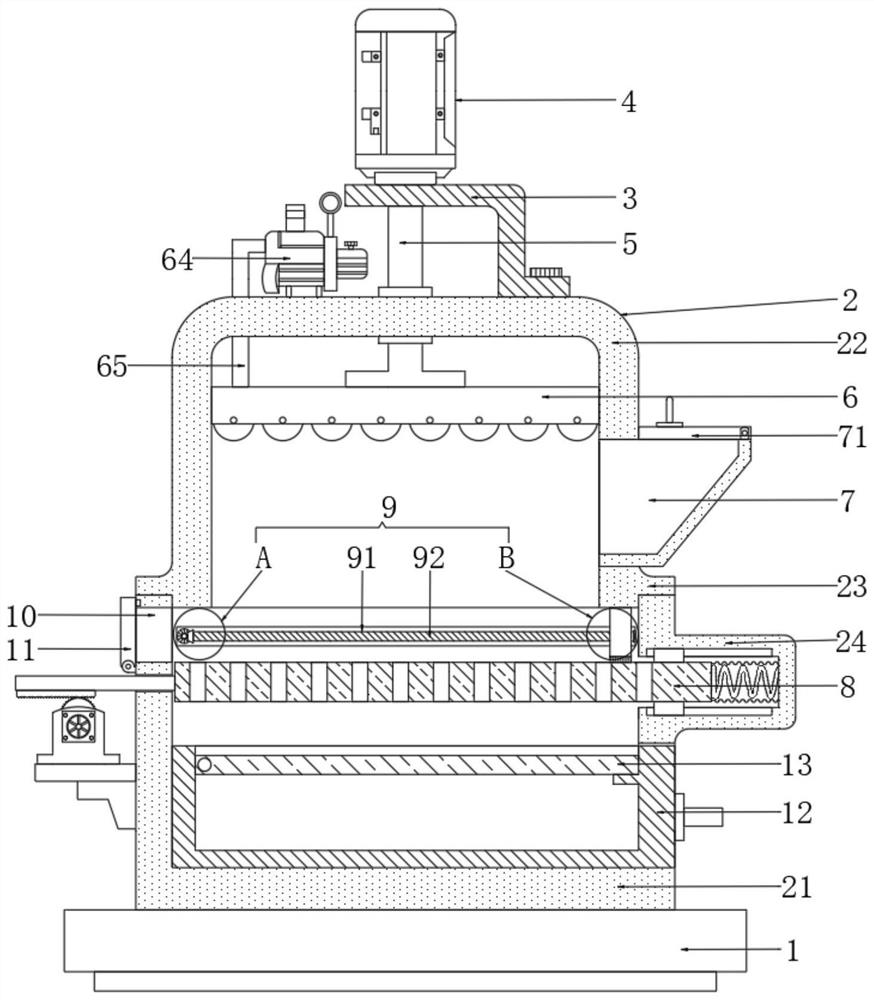

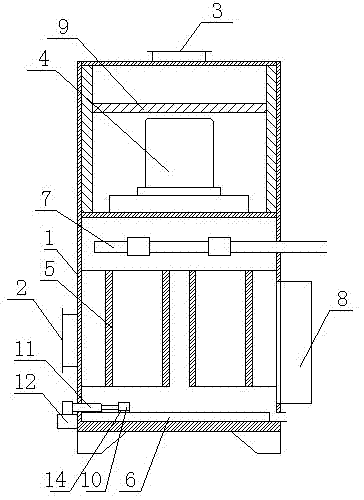

Garbage treatment box facilitating garbage solid-liquid separation and treatment method

PendingCN111791523AUniform compressionDry evenlyPressesStationary filtering element filtersThermodynamicsElectric machine

The invention discloses a garbage treatment box facilitating garbage solid-liquid separation, and belongs to the technical field of garbage treatment boxes. The garbage treatment box comprises a base.A treatment box body is fixedly arranged at the top of the base and comprises a bottom box fixed to the top of the base, and a dewatering and drying part is movably arranged in an inner cavity of a top box. A compression supporting plate mechanism matched with the dewatering and drying part is arranged at the top of an inner cavity of the bottom box, and a cleaning pushing structure matched withthe compression supporting plate mechanism is arranged on the inner wall of the rear side of the bottom box. According to the garbage treatment box, under pressing of a pressing roller, part of liquidin garbage is separated out. Through a driving motor, a rotating wheel, an incomplete tooth section, a rack, a movable column, a stress spring and a rubber corrugated pipe, the pressing roller rollsto achieve uniform compression of the garbage, and residual liquid continues to be compressed out. After compression, through an air blower, a heating element, a telescopic hose, a hollow shell and anozzle, the treatment efficiency and quality are greatly improved, secondary treatment is not needed, and the energy consumption and the cost are reduced.

Owner:赵兴寿

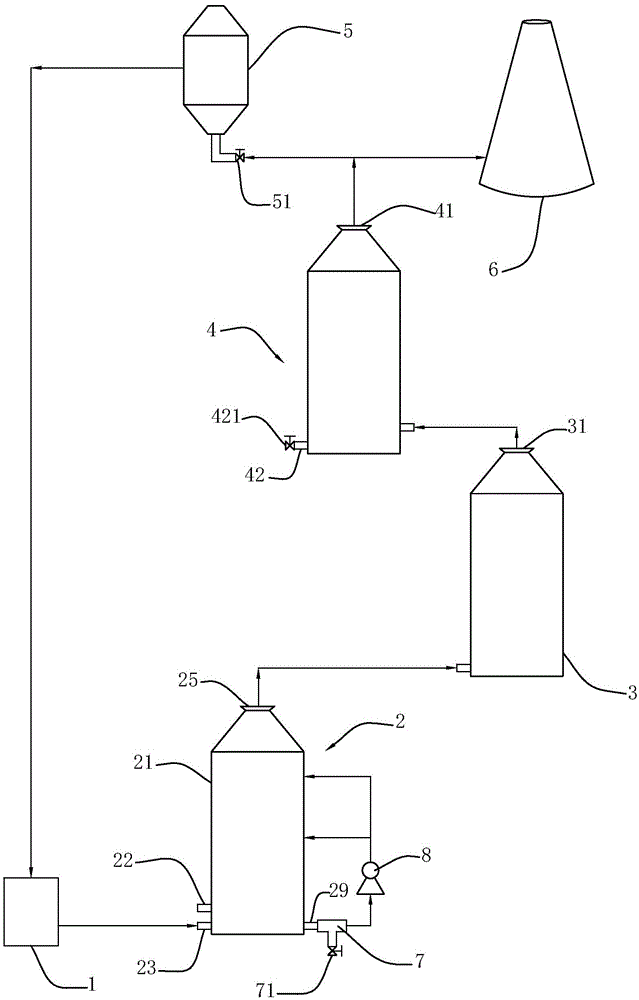

Organic waste gas processing method and processing device

InactiveCN104815536AEnsure self-sufficiencyReduce processing costsDispersed particle separationOzone generatorElectricity

The invention belongs to the technical field of waste gas processing, in particular to an organic waste gas processing method and processing device. The processing method includes steps of (1) spray oxidation, (2) catalytic oxidation, (3) acid-base neutralization and (4) recycling or emission; the processing device comprises an ozone generator, an advanced oxidation tower, a catalytic oxidation tower, an acid-base neutralization tower, an oxygen recycling tank and a chimney. According to the organic waste gas processing method, the ozone oxidation ability is 10 times of the individual ozone oxidation ability by means of oxidation accelerator, the ozone can generate a lot of hydroxyl radical, the ozone use ratio is more than 90%, the organic waste gas degradation rate is 40-50% higher than that of the individual ozone oxidation, and moreover, the processing device is low in energy consumption, the processing device only consumes electricity and water, the cost is low, the use is safe, the degradation is complete, secondary pollution is avoided, and secondary treatment is not needed.

Owner:SHANDONG GREEN TESTING

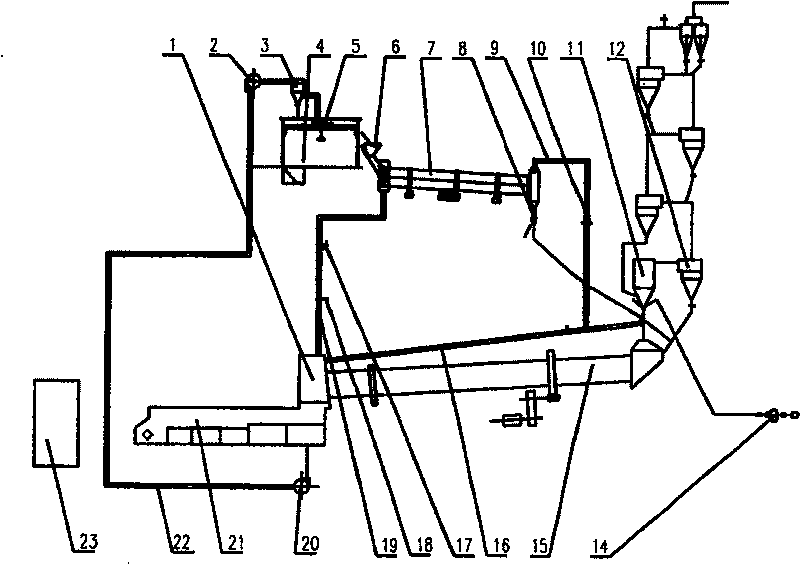

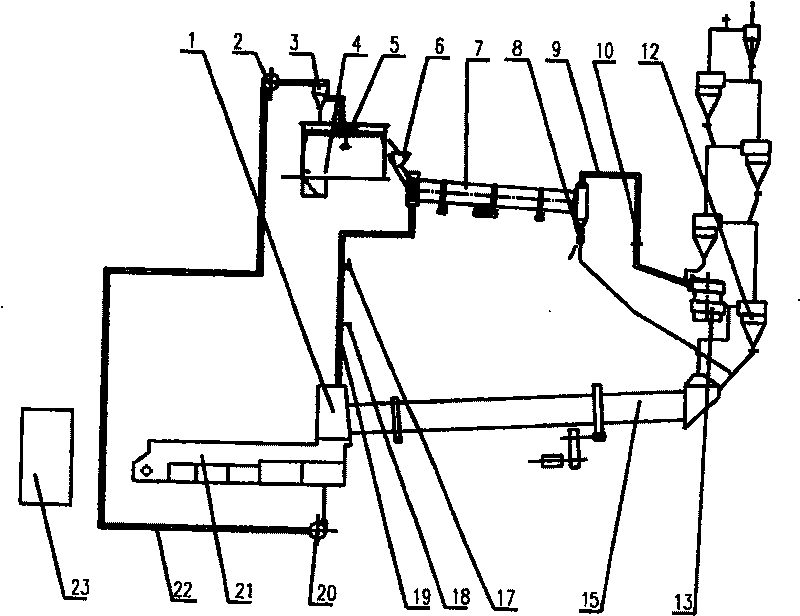

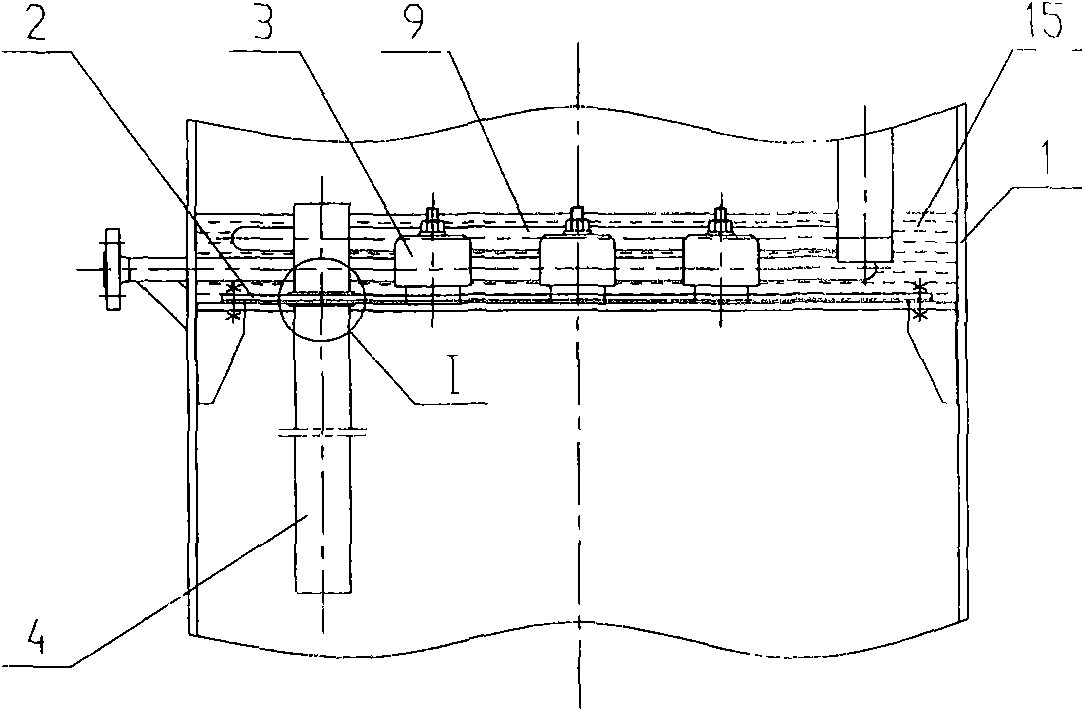

Cement rotary kiln and incinerator combined treatment system for urban domestic refuse

InactiveCN1844747BImprove heat utilizationReduce processing costsSolid waste managementRotary drum furnacesThermal energySlag

The invention discloses a system for using cement rotary kiln and incinerator to process life waste of city. It comprises a waste incinerator, a cement generator, a controller and several channels. Itis characterized in that: said waste incinerator comprises rotary waste incinerator (7), waste feeder (6), waste tank (4), bag deduster (3) and wind discharger (2); said cement generator comprises acement rotary kiln (15) whose head is connected to a material cooling device (21) and end is connected to a preheat device (12); said waste incinerator, cement generator and several channels form a closed system. The invention can be used to treat city life waste, while its heat and slag can be utilized, with lower pollution discharge and lower cost, without secondary treatment.

Owner:HEFEI CEMENT RES DESIGN INST

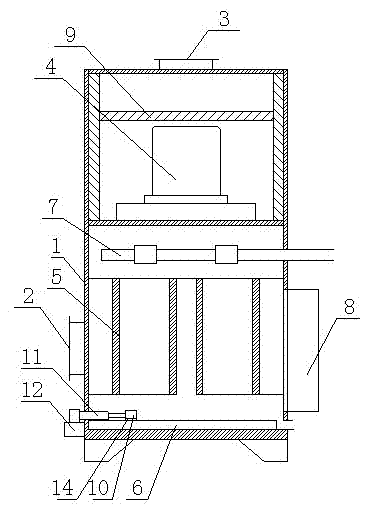

Filtering cylinder type pulse deduster

InactiveCN102366692AImprove efficiencyShorten the timeDispersed particle filtrationPneumatic pressureHigh pressure

The invention discloses a filtering cylinder type pulse deduster. The filtering cylinder type pulse deduster is characterized in that: the filtering cylinder type pulse deduster comprises a housing, an air inlet arranged on one side of the housing, an air outlet arranged on the top of the housing, a high pressure fan arranged in the housing, and filtering cylinders arranged in the housing; a dust container is arranged under the filtering cylinders; a pulse dedusting apparatus is arranged between the high pressure fan and the filtering cylinders; the bottom of the housing is provided with an access door; a silencer is arranged above the top of the high pressure fan; the dust container is provided with a dust scraping plate which is fixed on the bottom of the housing through a pneumatic tank; the pneumatic tank is connected with a pneumatic pump; and the side wall at the bottom of the housing is provided with a dust outlet opposite to the dust scraping plate. The filtering cylinder type pulse deduster of the invention has the advantages of simple structure, good dedusting effect, and convenient and fast processing of accumulated dusts.

Owner:南通市升昊暖通设备有限公司

Release agent for concrete member

The invention discloses a release agent for a concrete member, comprising the following raw materials in parts by weight: 12-20 parts of saturated fatty acid, 9-15 parts of oleic acid, 22-28 parts of linseed oil, 18-22 parts of emulsified oil, 8-14 parts of sodium nitrite, 10-12 parts of bauxite, 10-20 parts of a fatty acid waterproofing agent and the balance of a water solvent. Due to the release agent for the concrete member, the surface of the concrete member is antirust, heat-resisting and rain wash-resisting, is smooth and has no air holes, and the edges of the concrete member are tidy and are not needed secondary treatment, so that the project cost is reduced. The release agent for the concrete member is applicable to a wide range.

Owner:桑达化工(南通)有限公司

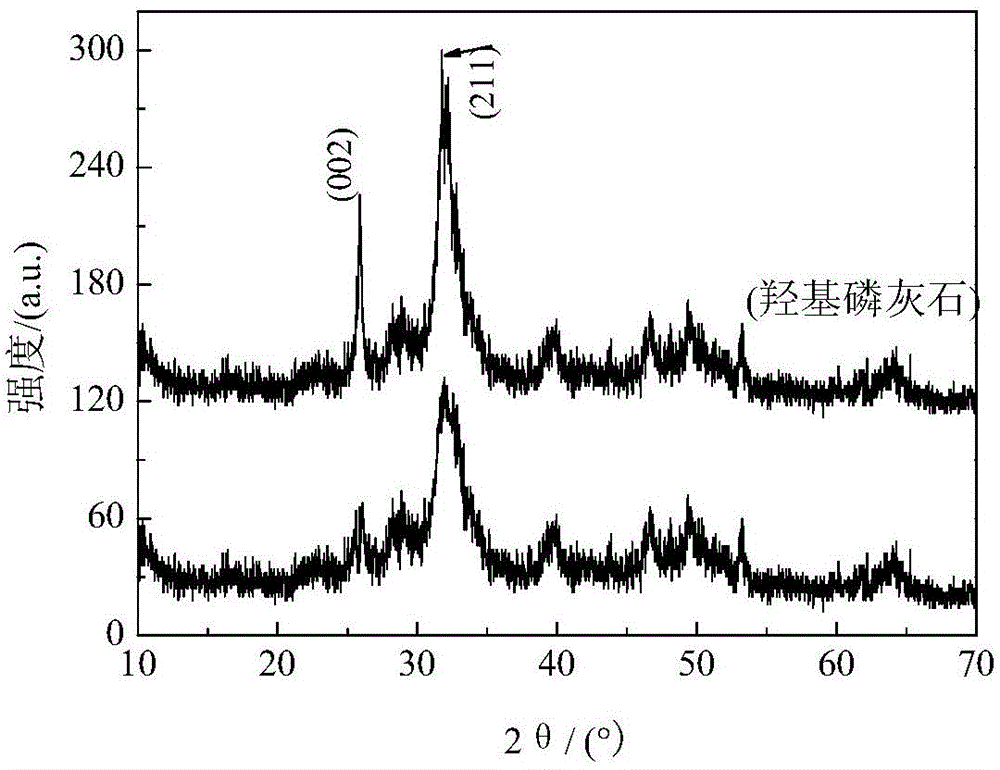

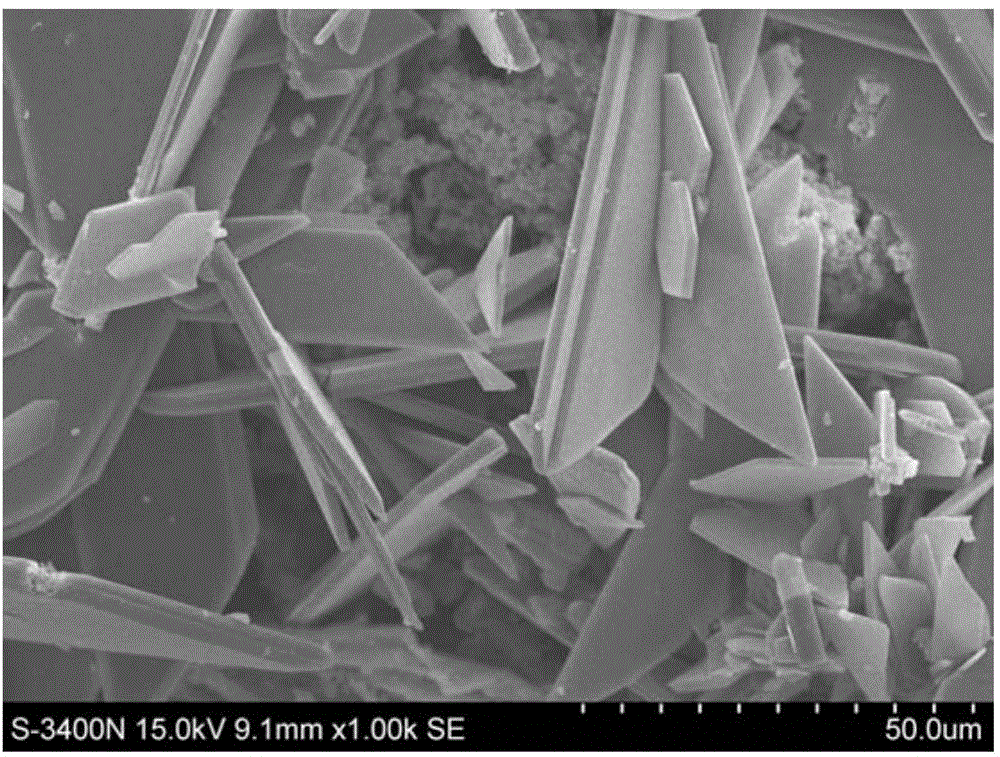

Method for recovering phosphorus from fosfomycin-containing wastewater

ActiveCN104591336APromote rapid formationEfficient degradationWater/sewage treatment by irradiationWater contaminantsFertilizerTobermorite

The embodiment of the invention discloses a method for recovering phosphorus from fosfomycin-containing wastewater. The method comprises the following steps: using a method of cooperating photoelectro-catalytic oxidation with hydroxyl calcium phosphate deposition; connecting a graphite anode and a stainless steel cathode into a photoelectro-catalytic reaction device, and taking an ultraviolet lamp as a light source, and an aqueous solution of NaCl as an electrolyte; and enabling the fosfomycin-containing wastewater to enter the reaction device while stirring, and pouring porous tobermorite into the reaction device, controlling a reaction voltage, temperature and time, monitoring water quality indexes in real time, and collecting a phosphorus recovery product after the reaction is finished. The process of recovering phosphorus disclosed by the invention is low in energy consumption and free from secondary pollution; moreover, the product after phosphorus recovery, namely hydroxyl calcium phosphate, can be used as a phosphatic fertilizer or a phosphorus-containing mineral for being used, thus realizing effective recovery for phosphorus resources while treating a polluted water quality.

Owner:CHONGQING UNIV OF ARTS & SCI

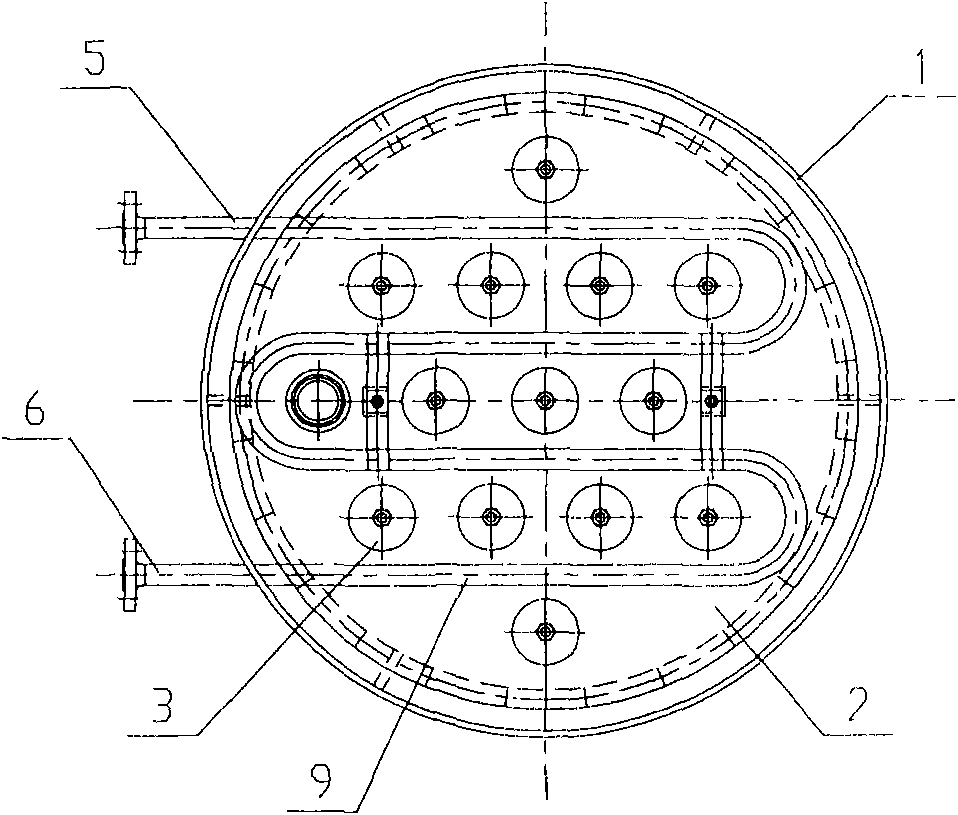

Nitric acid gas absorber

InactiveCN101569824ASimple processEasy to operateDispersed particle separationCooling coilEngineering

The invention relates to a nitric acid gas absorber. The top of a housing (1) is provided with a gas outlet (8), and the upper part is provided with a water inlet (7); a bubbling hood (3) in the middle of the housing (1) and a cooling coil (9) are fixed to tower trays (2); downflow spouts (4) are fixed to the tower trays (2) and communicate every two tower trays (2); the outlet of the downflow spout (4) at the lower part of the housing (1) is communicated with a nitric acid room (12) at the bottom of the housing (1); the lower part of the housing (1) is a nitric acid gas room (11); the housing (1) at the upper part of the nitric acid gas room (11) is provided with a nitric acid gas inlet (10); the bottom of the housing (1) is connected with a skirt support (14); and the bottom of the nitric acid room (12) is provided with a nitric acid outlet (13) that is communicated with the skirt support (14).The invention has the advantages of simple structure, easy and convenient operation and low cost. The treated nitric acid gas meets the environmental protection index specified in GB 16297.

Owner:SEDIN ENG

Rust-resistant concrete mold release agent and preparation method thereof

InactiveCN104479843AExcellent anti-rustImprove high temperature resistanceLubricant compositionMaterials scienceTert-butyl acrylate

The invention discloses a rust-resistant concrete mold release agent and a preparation method thereof. The rust-resistant concrete mold release agent comprises the following components as raw materials in parts by weight: 50-55 parts of modified glycerin, 25-30 parts of coconut acid monoethanolamide, 0.3-0.5 part of zinc dialkyl dithiophosphate, 8-10 parts of rosin resin, 0.4-0.6 part of t-butyl acrylate, 2-3 parts of sodium tripolyphosphate, 1.5-1.8 parts of lauryl diethanolamide, 6-8 parts of purified benzene emulsion, 0.3-0.5 part of sodium tripolyphosphate, 0.1-0.2 part of sodium benzoate and 300-330 parts of deionized water. By adopting modified glycerin as main base oil, the difficulty of emulsification is decreased; the rust-resistant agent and multiple additives are added, so that the rust-resistant concrete mold release agent has good rust resistance, high temperature resistance and the like on the surface of a concrete member and the concrete member has smooth surface, the secondary treatment is not needed and the construction cost is decreased.

Owner:蒙城县科技创业服务中心

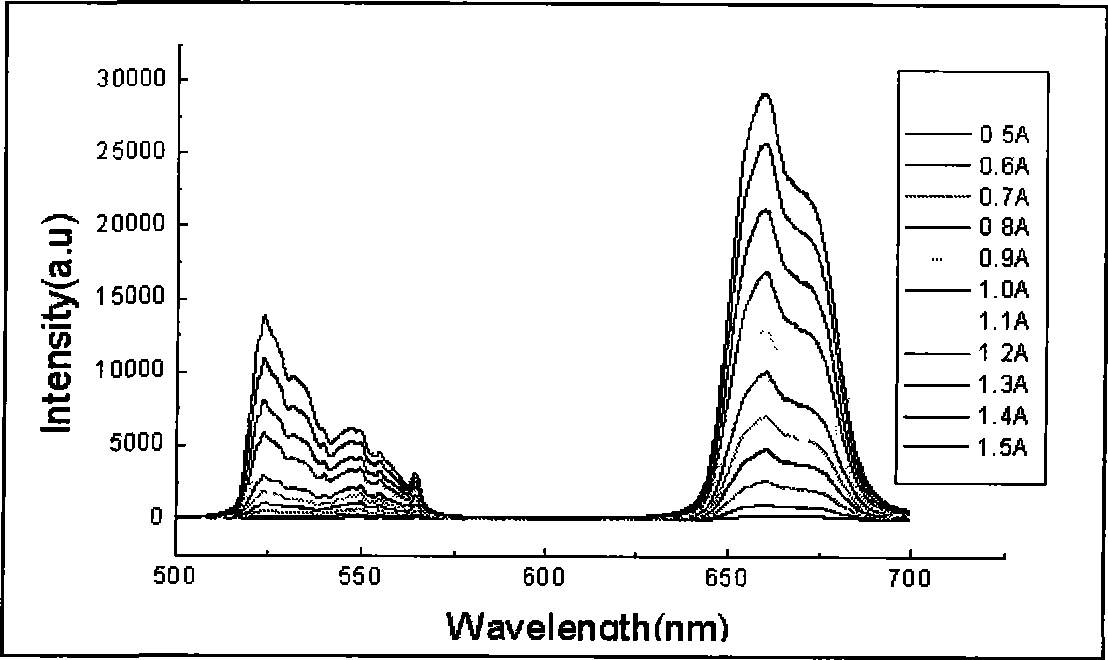

Synthesis and surface decorating method of rare-earth nanometer compound material

InactiveCN101518545AThe material synthesis method is simpleVarious preparation techniquesAntibacterial agentsHeavy metal active ingredientsRare-earth elementMaterial synthesis

The invention belongs to the technical field of material chemistry and material physics, and in particular relates to a synthesis and surface decorating method of rare-earth nanometer compound materials. The invention prepares the rare-earth nanometer compound materials by the steps of the hydrolysis of butyl titanate, the mixing of element solutions, surface decoration, high-temperature calcination, and the like and using a mixing and surface decorating technology of rare-earth elements and transitional metal elements. Under the irradiating illumination of near infrared lights or visible lights, and the rare-earth elements generate upconversion luminescence to excite titanium oxide to achieve anti-bacterium and anti-tumor functions. The invention has the characteristics of simple material synthesis method, multiple preparation technologies, easy-controlled combination, low cost, good modified effect on titanium oxide, and the like, does not pollute or harm the human and the environment, can directly kill bacteria and tumors and decompose the endotoxin generated by the bacteria and the tumors, and does not need secondary processing.

Owner:NORTHEAST NORMAL UNIVERSITY

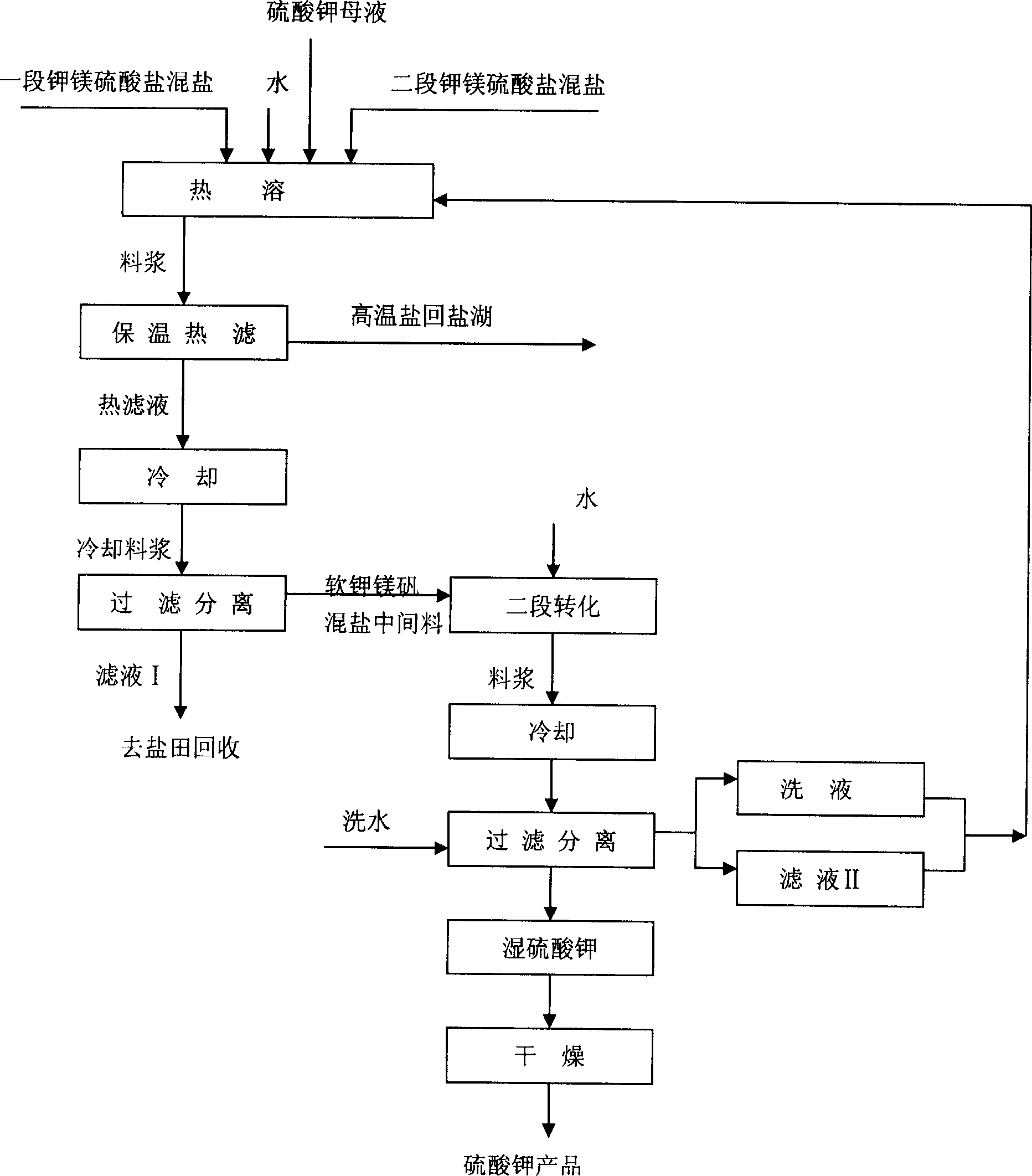

Method for extracting potassium sulphate by magnesium sulfate sub-type potassium-containing salt lake brine water

InactiveCN1789129AReduce manufacturing costNo pollution in the processAlkali metal sulfite/sulfate purificationEcological environmentResource utilization

The invention provides a method for preparing kalium sulphuricum by employing potassium and magnesium sulfate mixed ores got from solarizing the sulfuric acid magnesium salt lake containing potassium saline water salt-field as raw material, which comprises: solarizing the saline water containing potassium from sulfuric acid magnesium salt lake, getting one-stage potassium and magnesium sulfate mixed ores and two-stage potassium and magnesium sulfate mixed ores, proportioning the two ores, kalium sulphuricum mother liquid and water according to a certain propotion, proceeding thermal conversion in a certain temperature range, thermal filtering to remove sodium, cooling for crystallization to evole out medium raw material, adding water into the medium raw material, then disintegrating and conversing directly, cooling, separating, washing, and drying under a certain temperature range, and getting the kalium sulphuricum. The inventioin is characterized by the following aspects: adding no extra potassium chloride, low producing cost, high quality of the product which can be directly used as industrial raw material; employing no floating agent, removing the grinding and float choosing process, simple process, convenient operation, high benefit, no pollution to the ecological environment, increasing the utilization coefficient of the salt lake resource and realizing the resource utilization stratege of circulating economy.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Nuclear power plant radioactive-waste treatment system

InactiveCN107887047ASolve the problem of long-term storageEmission reductionRadioactive decontaminationNuclear plantLiquid waste

The invention discloses a nuclear power plant radioactive-waste treatment system. The nuclear power plant radioactive-waste treatment system comprises a mixed gas delivery device, a fluidized bed, a filter and an oxidizer, wherein the fluidized bed, the filter and the oxidizer are sequentially and serially connected at the downstream of the mixed gas delivery device through pipes, a fluidized bedinlet is also connected with an additive supply device through a pipe. Compared with prior art, the nuclear power plant radioactive-waste treatment system is simple in structure, low in manufacturingcost, small in radioactive leakage risk, small in waste discharging amount and capable of treating waste resin and organic liquid wastes simultaneously and has a very good market application prospect.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +2

Method for manufacturing microtexture friction surface through photoetching

The invention discloses a method for manufacturing a microtexture friction surface through photoetching. The friction performance of the surface can be significantly improved. The method comprises the steps of preheating, photoresist coating, predrying, masking, exposing, baking, developing, hard baking, etching, photoresist removal and the like. According to the method, no large equipment is needed, the process is easy and convenient, patterns are easy to control, and the method has important applications in the field of friction-reducing lubricating materials and the like.

Owner:HEFEI UNIV OF TECH

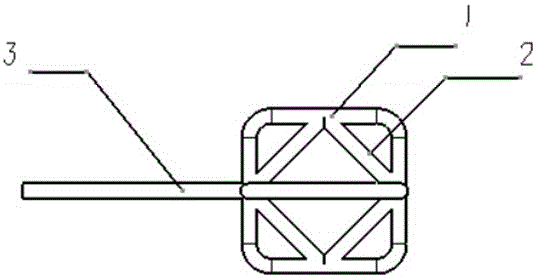

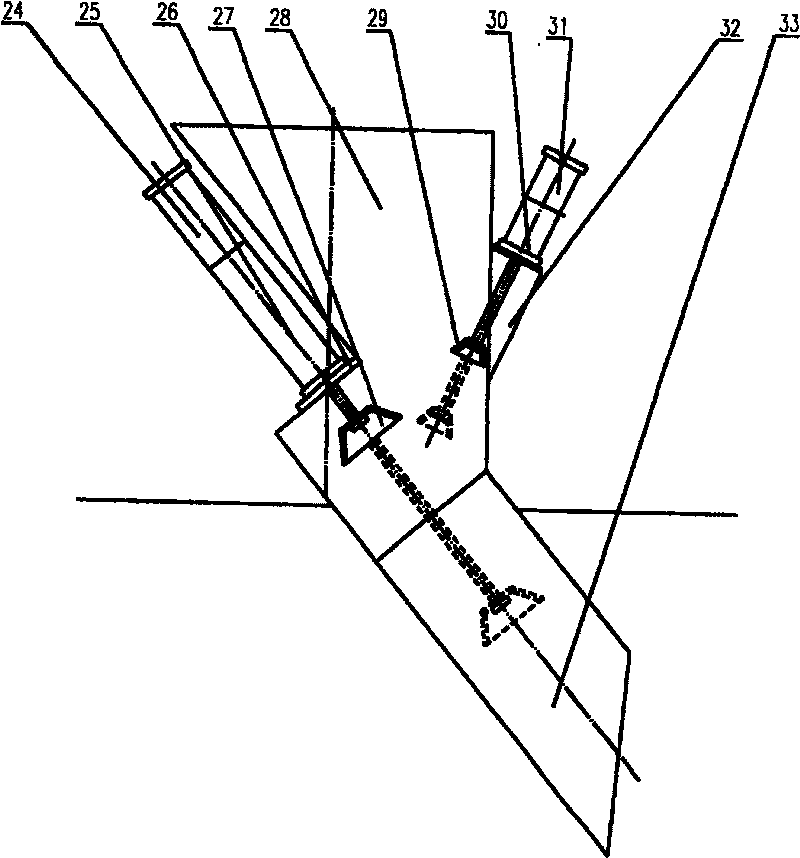

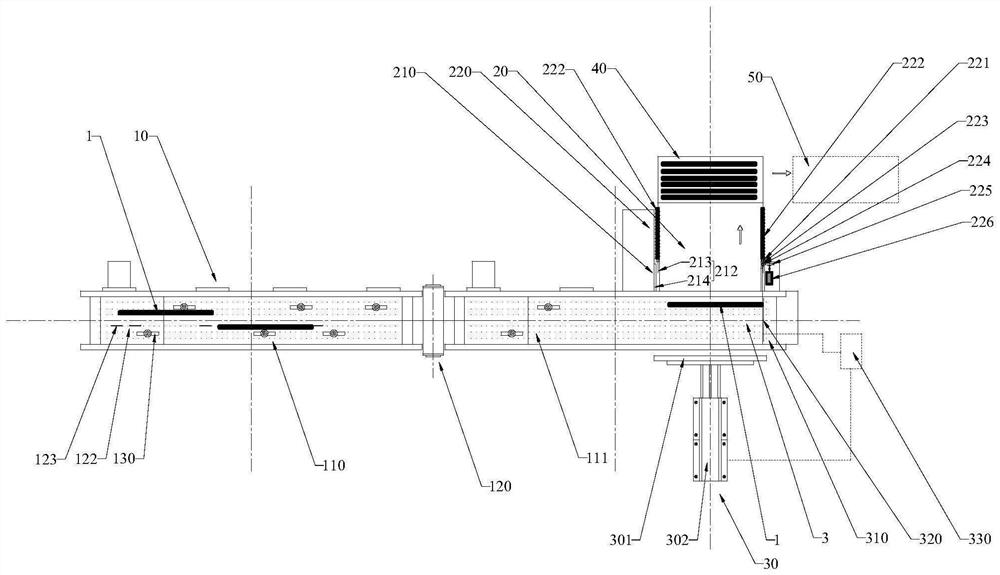

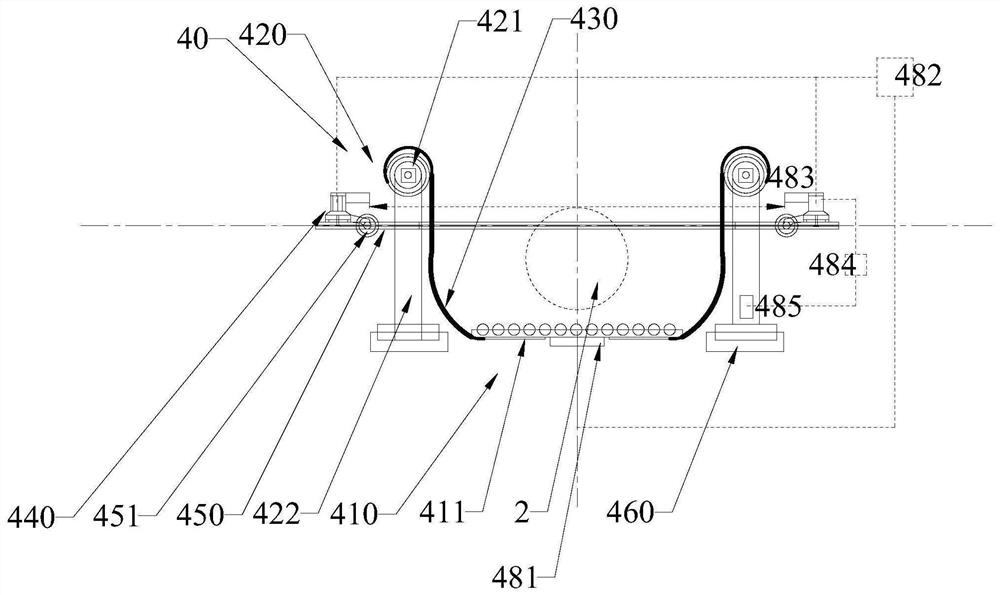

Online automatic packaging device for metal pipes

ActiveCN113022922AReduce the probability of sliding to escapeNo secondary treatmentBinding material applicationBundling machine detailsStructural engineeringMoving parts

The invention provides an online automatic packaging device for metal pipes. The online automatic packaging device comprises a conveying mechanism, a pre-tightening assembly and a packaging assembly, wherein the pre-tightening assembly comprises pre-tightening belts and pre-tightening moving parts, the two pre-tightening belts are tensioned on the two sides of the conveying mechanism, the two pre-tightening belts and the conveying mechanism define a containing space for a plurality of metal pipes, the pre-tightening moving parts are located on the sides, away from the conveying mechanism, of the pre-tightening belts, and the two pre-tightening moving parts move relatively to extrude the two pre-tightening belts to be attached. The packaging assembly is located on the downstream of the pre-tightening assembly and comprises a main rotating ring capable of rotating, a packaging wheel is rotationally connected to the main rotating ring, and a packaging belt is wound around the packaging wheel. According to the online automatic packaging device for the metal pipes, the packaging belt is adopted for packaging a metal bundling body, the probability that the metal pipes slide and escape is reduced through overall packaging, and meanwhile secondary treatment such as welding is not needed after packaging.

Owner:佛山市三三得钢业有限公司

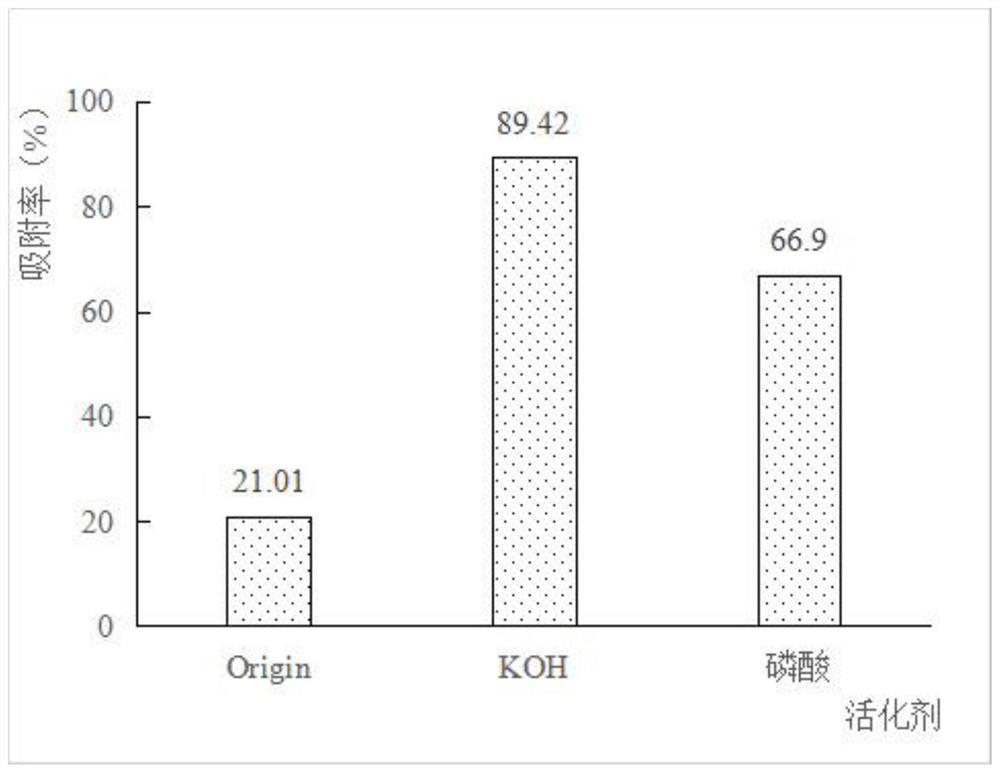

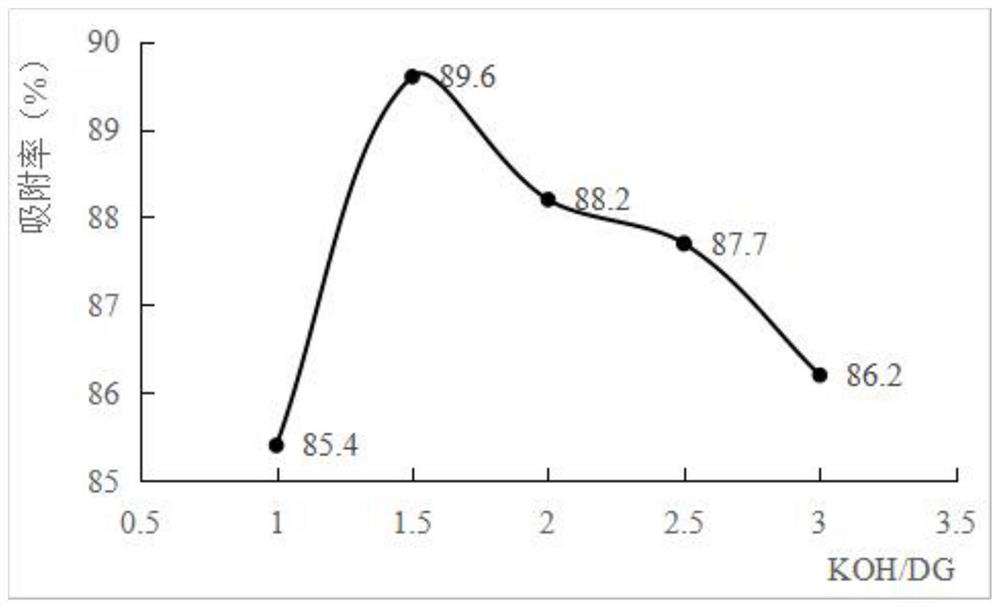

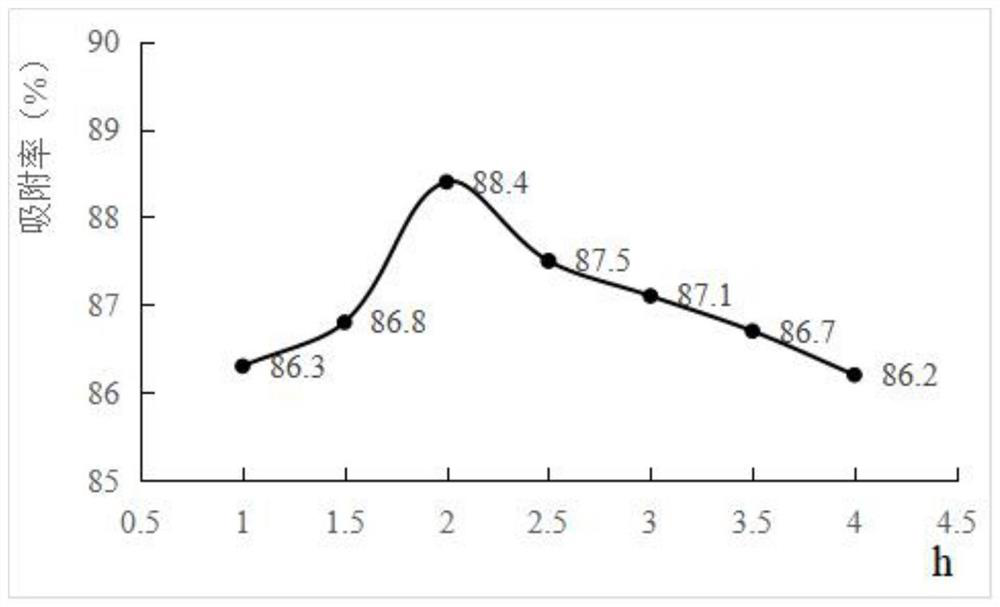

Adsorption and degradation dual-function soil remediation material, preparation and application thereof

PendingCN113943580AGood removal effectRealize resourcesChemical industryContaminated soil reclamationPorous carbonBifunctional

The invention discloses an adsorption and degradation dual-function soil remediation material, preparation and application thereof. The adsorption and degradation dual-function soil remediation material comprises modified vinasse-based porous carbon, wherein the modified vinasse-based porous carbon is embedded and loaded with a microbial strain capable of being used for degrading polycyclic aromatic hydrocarbons, and the modified vinasse-based porous carbon is a material which is prepared by taking vinasse as a raw material and modifying with potassium hydroxide and has the performance of adsorbing polycyclic aromatic hydrocarbons. According to the invention, the immobilized microbial adsorption material is an adsorption and degradation bifunctional vinasse adsorption material, and achieves the technical purpose of adsorbing and degrading PAHs synchronously; and when the adsorption and degradation dual-function soil remediation material is used for soil remediation, waste vinasse can be recycled, waste is treated with waste, the pressure of the waste vinasse on the environment is relieved, the purpose of saving energy is achieved, PAHs can be directly degraded, secondary treatment is not needed, harm is directly eliminated, the purpose of reducing emission is achieved, and the environmental protection concept of treating waste with waste and saving energy and reducing emission is met.

Owner:SHAANXI UNIV OF SCI & TECH

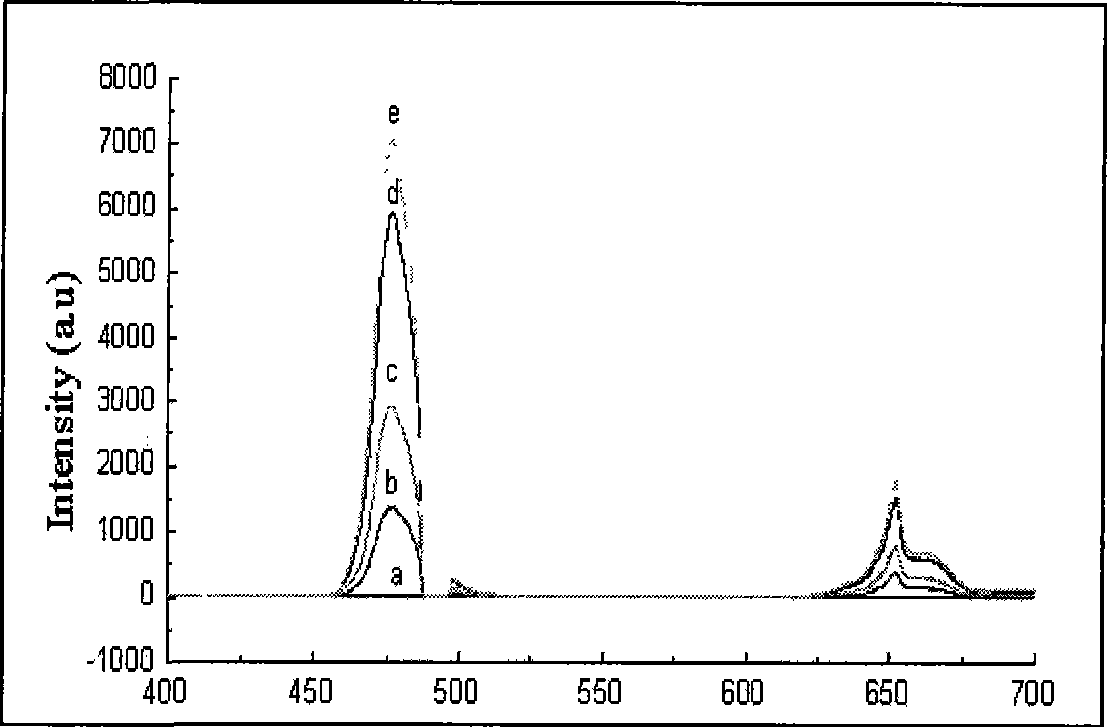

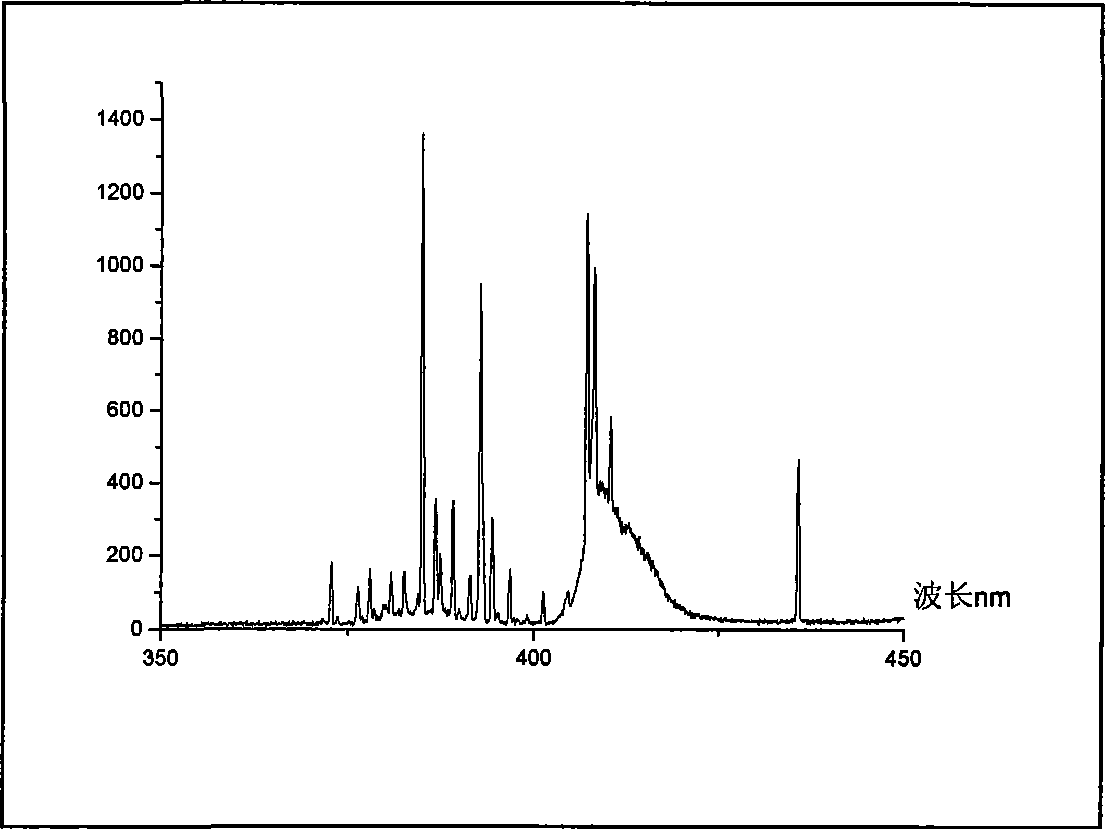

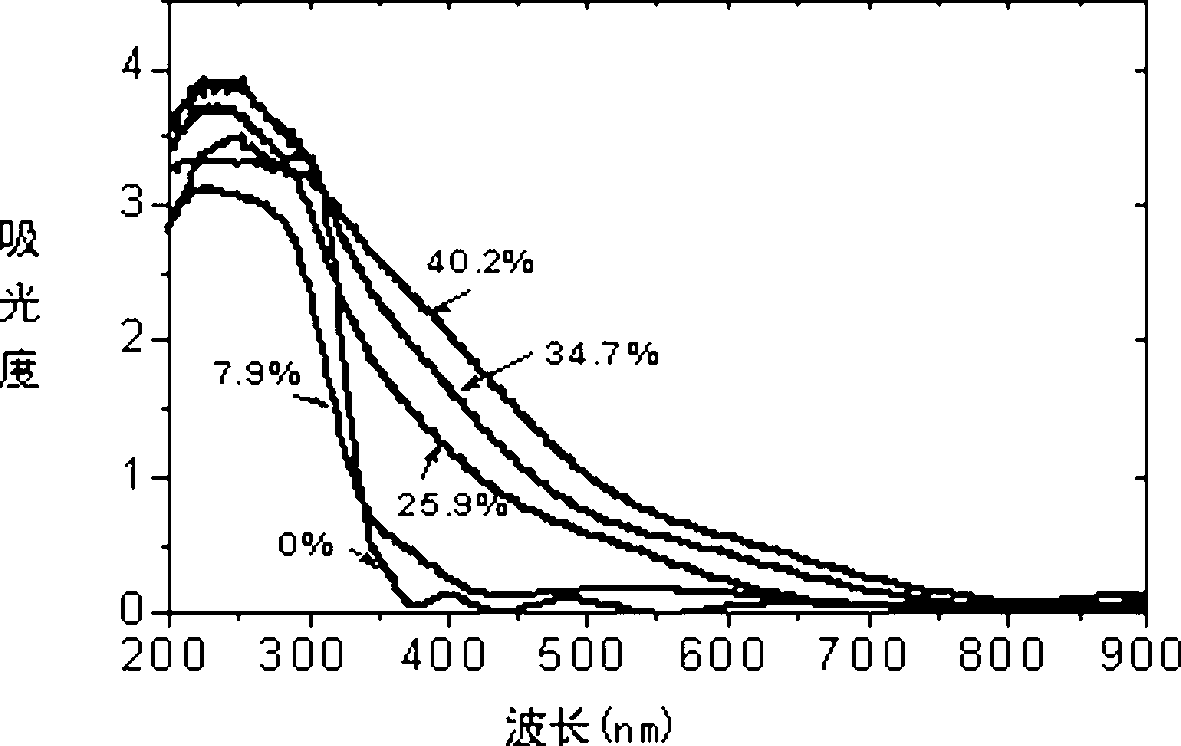

Preparation method of manganese-doped titanium dioxide film for strengthening photoelectric response of visible light

InactiveCN103280488AImprove electrical performanceCompact structureFinal product manufactureSemiconductor devicesElectronic transmissionReaction temperature

The invention provides a preparation method of a manganese-doped titanium dioxide film for strengthening photoelectric response of visible light. The preparation method comprises the following steps: with a magnetic control cosputtering method of direct-current radio-frequency reaction, taking a silicon chip, a quartz plate, FTO (Fluorine-doped Tin Oxide), or ITO (Indium-Tin Oxide) material as a substrate; taking a high-purity Ti target as a magnetic control direct-current sputtering cathode, taking an Mn metal target as the cathode of a reaction magnetic control sputtering radio-frequency end, taking the substrate as the anode of the reaction magnetic control sputtering radio-frequency end, taking O2 as reaction gas, taking Ar as sputtering gas, and controlling relative contents of Ti and Mn and the thickness of the film by adjusting parameters such as reaction temperature, direct-current and radio-frequency end power, oxygen flow and reaction time. The preparation method is simple, easy to operate, high in controllability and high in film forming quality; the prepared manganese-doped titanium dioxide film can realize absorption of a visible light region, and the electrical property is greatly improved; and the manganese-doped titanium dioxide film can be widely applied to the fields of photocatalysis and photovoltaic energy, and can be used as an optical absorption layer or an electronic transmission layer of a solar cell.

Owner:HUBEI UNIV

Assembled frame-type horizontal warehouse, prefabricated wallboard mould and construction method of horizontal warehouse

PendingCN110259237ALong construction periodBuild fastWallsMouldsSupporting systemReinforced concrete

The invention discloses an assembled frame-type horizontal warehouse, a prefabricated wallboard mould and a construction method of a horizontal warehouse. In recent years, steel plate silos develop rapidly due to the characteristics of the high construction speed, the short construction period, the low cost and the like, however, the fatal weakness of the steel plate silos is that the silo wall is thin, the temperature is greatly affected by the outside world, grain and other items which have strict requirements for the temperature and moisture are prone to mildewing, decaying and other phenomena in the storage process, it is difficult to store the grain for a long time, and the service life of the steel plate silos is short. The assembled frame-type horizontal warehouse comprises a frame-type warehouse body (1), the frame-type warehouse body is connected with a foundation (11) and a warehouse top (12), the frame-type warehouse body comprises a group of reinforced concrete stand columns (2) located at the four walls of a wall body, reinforced concrete connecting beams (3) are arranged between the reinforced concrete stand columns to form a supporting system of the warehouse top, and the reinforced concrete stand columns (2) and the reinforced concrete connecting beams (3) are connected with a reinforced concrete prefabricated wallboard (4). The assembled frame-type horizontal warehouse is used for horizontal warehouse construction.

Owner:刘全义

Magnesium phosphate-based foam concrete thermal insulation material

ActiveCN113493340AHigh foaming ratioLower free energySolid waste managementCeramicwareMagnesium orthophosphateThermal insulation

The invention provides a magnesium phosphate-based foam concrete thermal insulation material. The magnesium phosphate-based foam concrete thermal insulation material is prepared from the following raw materials in parts by weight: 60-90 parts of magnesium compound, 1-8 parts of active foaming agent, 0.1-0.3 part of dense air entraining agent, 20-35 parts of mineral admixture, 0.5-1 part of high-efficiency water reducing agent, 5-15 parts of composite retarder, 20-30 parts of phosphate, 75-125 parts of quartz sand, 0.5-2 parts of water-resistant agent and 5-8 parts of pH stabilizer. The invention also provides a preparation method of the magnesium phosphate-based foam concrete thermal insulation material. The magnesium phosphate-based foam concrete thermal insulation material has the characteristics of high early strength, good fluidity, uniform pores, excellent thermal resistance, easy construction, low toxicity, non-flammability, environmental protection and energy saving.

Owner:山东坊能新动能科学研究院有限公司

Raw bamboo batch bending treatment process and application thereof

InactiveCN110253698AEvenly heatedNo secondary treatmentWood treatment detailsCane mechanical workingCombustionWater vapor

The invention relates to a raw bamboo batch bending treatment process and application thereof. The treatment process comprises the following steps of manufacturing a high-temperature steam tank, introducing steam containing an improved raw bamboo treating agent into the high-temperature steam tank, setting the steam temperature as 100 DEG C-145 DEG C and recovering steam condensate at the bottom of the tail end of a tank body; putting a plurality of raw bamboos into the high-temperature steam tank to be subjected to normal-pressure treatment; putting the raw bamboos onto a raw bamboo batch bending shaping device to be subjected to bending treatment to reach the preset radian, fixing the two ends of the batch bending raw bamboos and the two ends of a bending radian mold through steel wire locks and rope tensioners at the radian, opening a bending device frame, taking down the batch bending raw bamboos and the bending radian mold and then conducting natural cooling shaping to obtain the batch raw bamboos with the preset bending radian. The raw bamboo batch bending treatment process provided by the invention is clean and free of pollution to the atmosphere, wastewater discharge and combustion smoke dust and has quite good commercial prospects, and only electric energy is adopted.

Owner:安吉悦腾竹文化发展有限公司

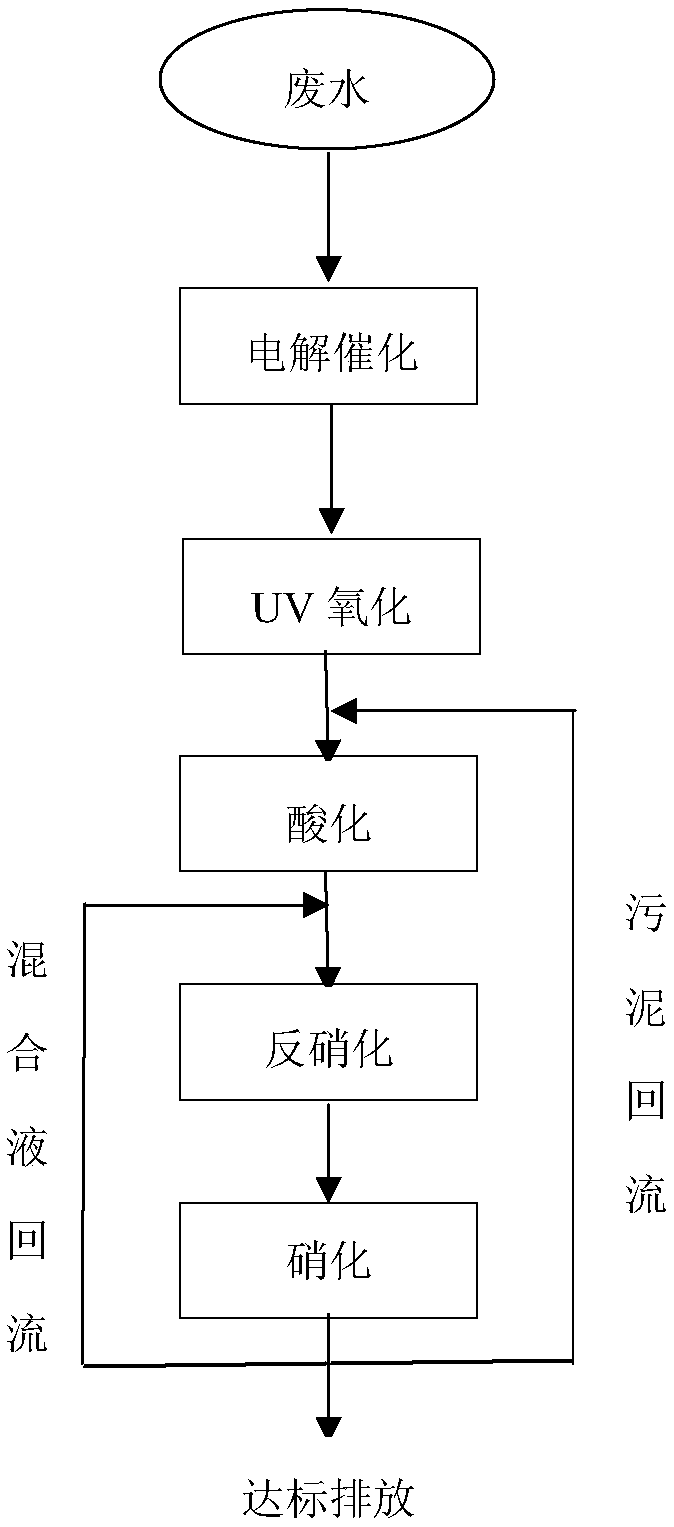

Treatment method of benzene-containing wastewater

InactiveCN109626726ALow costImprove oxidation efficiencyWater/sewage treatment by irradiationWater contaminantsBenzeneElectrolysis

The invention belongs to the technical field of wastewater treatment, and specifically discloses a treatment method for benzene-containing wastewater. The method includes the following steps of 1, electrolytic catalysis, 2, UV oxidation, 3, anaerobic acidification, 4, anoxic denitrification and 5, aerobic nitrification. The treatment method has the thorough degradation effect, no elements difficult to treat are introduced in the treatment process, the wastewater can be thoroughly degraded into small molecular substances such as H2O, CO2 and N2, the biodegradability of the benzene-containing wastewater treated by the method can be significantly improved, and pollutant factors such as nitrobenzene, aniline, ammonia nitrogen and COD in the wastewater can be greatly reduced. Compared with theprior art, the cost is low, operation is convenient, pollutant factors can be completely eliminated, and the method has strong industrial application prospects.

Owner:ZHEJIANG DIBANG CHEM

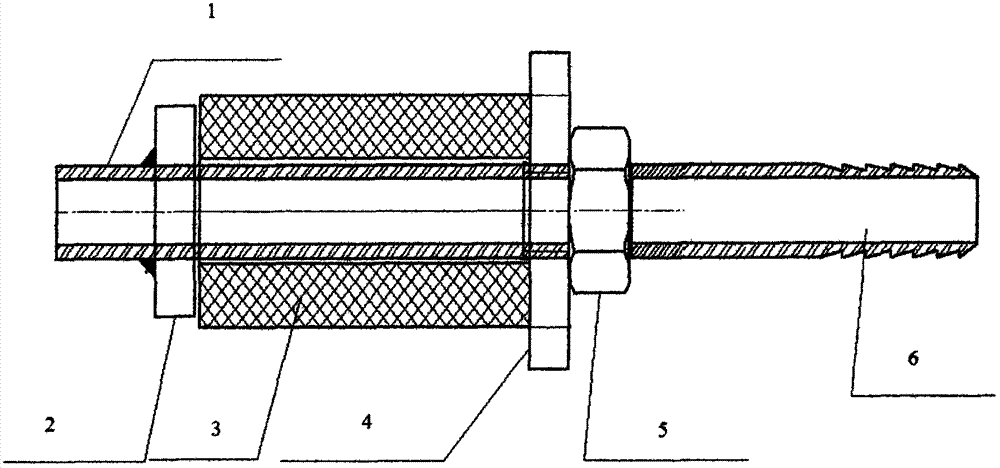

Single body pressure testing tool, single body pressure testing tool combination and pressure testing method for blast furnace cooling equipment

The invention relates to a single body pressure testing tool, a single body pressure testing tool combination and a pressure testing method for blast furnace cooling equipment. According to the technical scheme, the single body pressure testing tool for the blast furnace cooling equipment comprises a screw and a rubber hose sleeved outside the screw, and a nut is arranged at one end of the rubber hose and is in threaded connection with the screw which can enable the nut to press the rubber hose if the screw rotates. The single body pressure testing tool combination for the blast furnace cooling equipment is characterized in that two single bodies are connected together through the pressure testing hose. A method for testing pressure of a cooling wall single body is characterized by comprising the following steps of: filling water in the cooling wall single body; sealing in a series-connection manner; exhausting; closing an exhaust opening; and boosting pressure to detect leakage. By the technical scheme, the single body pressure testing tool for the blast furnace cooling equipment has the advantages that welding is not required, connection speed is high, the single body pressure testing tool can be detached after pressure testing is finished and can be used repeatedly, the rubber hose can be replaced after the single body pressure testing tool is used for 30 times, a cooling wall can be provided with tubes normally after the single body pressure testing tool is detached, ports are not required to be re-treated, cost is saved, and construction period is short.

Owner:NO 9 METALLURGICAL CONSTR

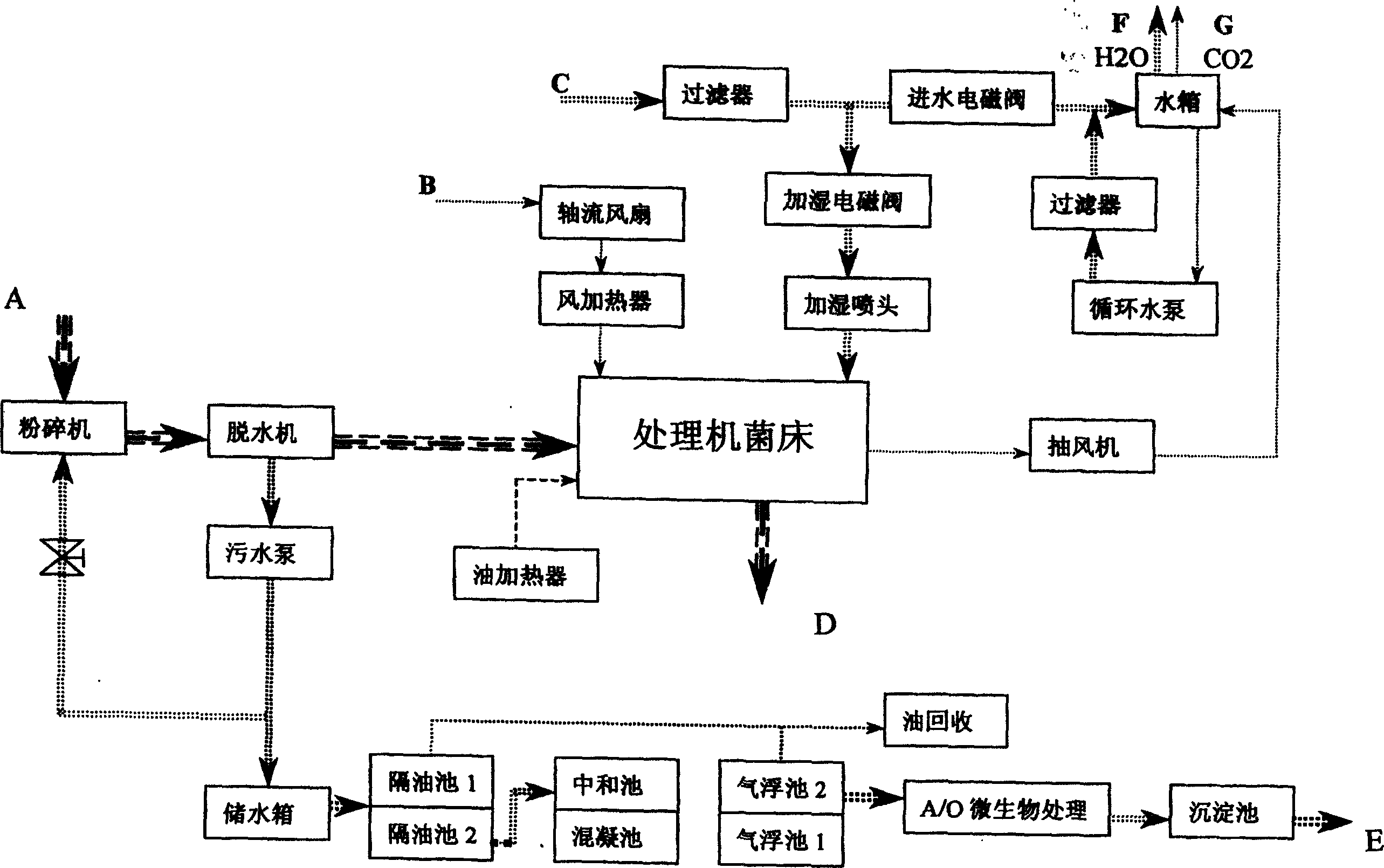

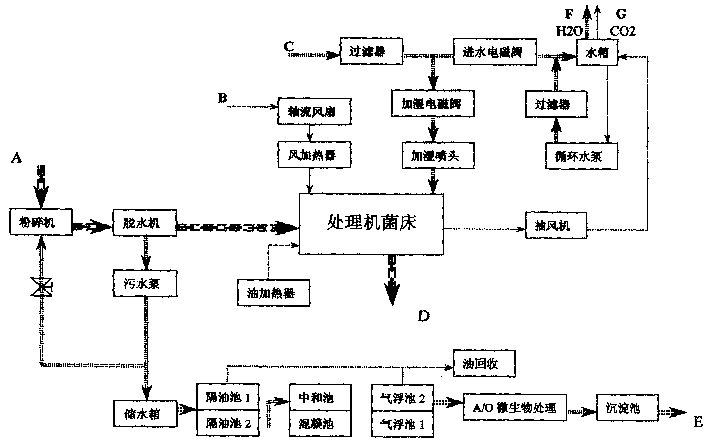

Biological treatment for organic garbage from dining room and kitchen

InactiveCN1187140CIncrease microbial throughputIncrease throughputSludge treatmentWaste processingSewageOil water

A biologic process for treating the organic garbage coming from kitchen includes breaking, dewatering, microbial treating, processing tail gas to generate Co2, separating oil from water, and treating sewage. Its advantages are high effect and no secondary pollution.

Owner:陈建乐

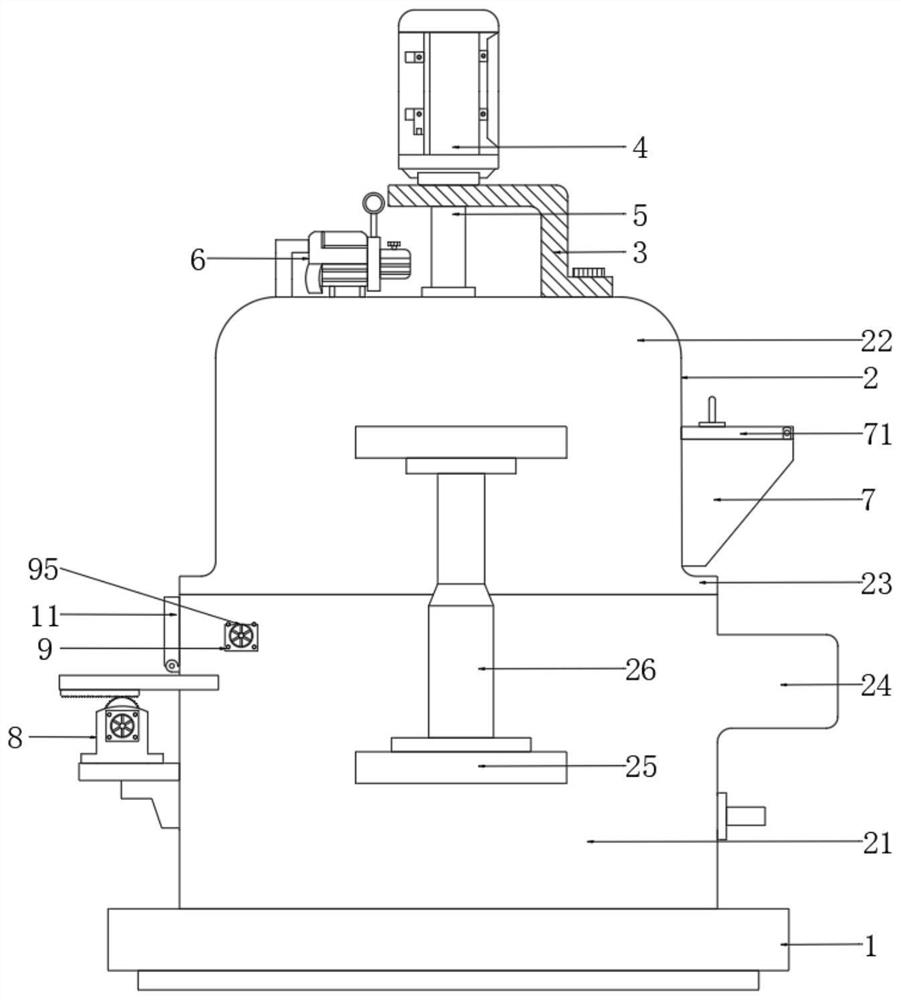

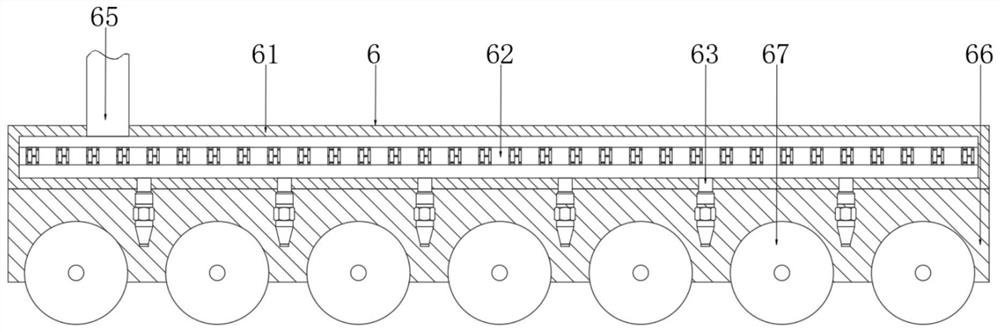

Method and system for recycling photovoltaic modules

ActiveCN110571306BWon't happenThe realization of the productionWaste processingSolid waste disposalResource recoveryBusbar

The invention discloses a method and system for recycling photovoltaic components. The method includes the following steps: removing the frame, the junction box and the glass panel on the photovoltaic module to obtain the preliminary material; cutting the preliminary material to obtain the preliminary material fragment; placing the preliminary material fragment in the Stripping is carried out in a peeling device equipped with a rotary hitting mechanism to obtain a mixture of EVA film fragments, backplane fragments, bus bar fragments, welding ribbon fragments and silicon powder; Board fragments, busbar fragments, and ribbon fragments. The method for dismantling and recycling backplanes, EVA, battery sheets and complete glass of the present invention has the advantages of high dismantling and recycling efficiency, low energy consumption, no environmental pollution, etc., greatly reduces resource waste and waste discharge, and reduces recycling cost, is an environmentally friendly resource recovery method.

Owner:YINGLI ENERGY CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com