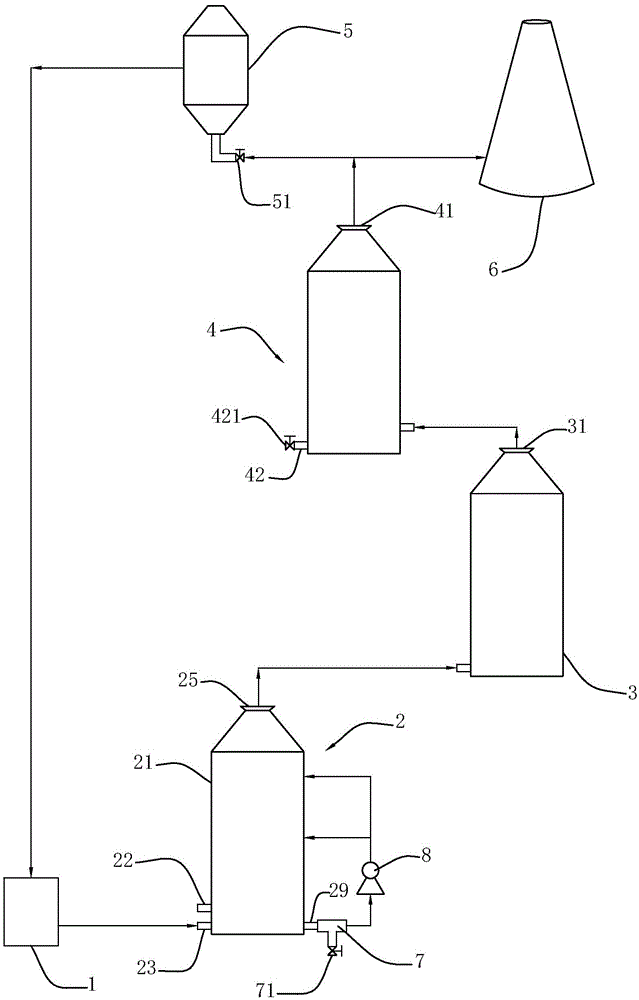

Organic waste gas processing method and processing device

A technology for organic waste gas and treatment methods, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as insufficient degradation of organic matter, incomplete mineralization of organic matter, and limitations of ozone oxidation technology to achieve complete degradation, Low cost, effect of reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

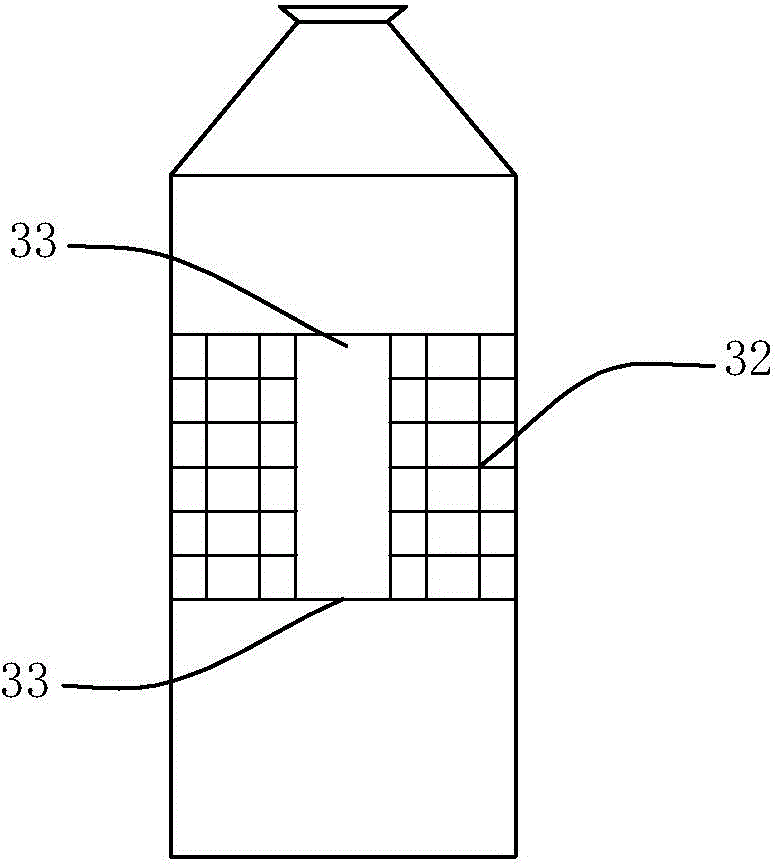

[0058] Use the above treatment device to treat organic waste gas

[0059] (1) Spray oxidation:

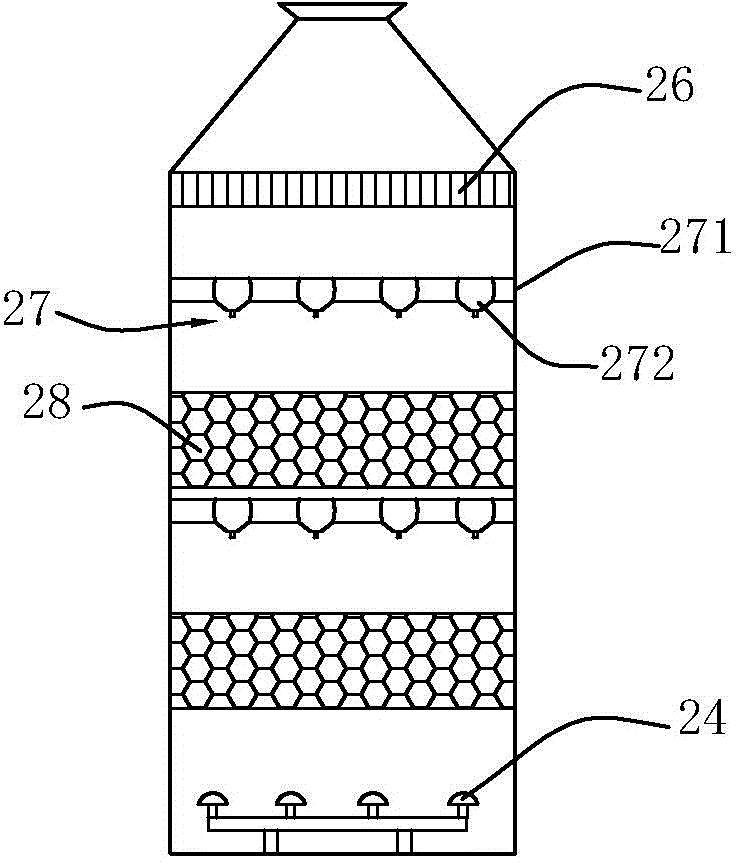

[0060] a. Enter the organic waste gas into the advanced oxidation tower from the waste gas inlet, the feed rate of the organic waste gas is 2kg / h, the ozone generated by the ozone generator enters the aeration tray at the bottom of the advanced oxidation tower through the ozone inlet, and the feed rate of the ozone is 1kg / h, dispersed into the advanced oxidation tower through the aeration tray, and the organic waste gas and ozone are evenly distributed into the advanced oxidation tower through the packing layer;

[0061] b. Add an oxidation accelerator (preferably titanium dioxide) into water to form a spraying liquid, the molar ratio of titanium dioxide to water is 0.2:1, the spraying liquid is distributed to each nozzle through the distribution main pipe of the spraying device, and the spraying liquid is sprayed through the nozzle Liquid atomization, the spray liquid is disperse...

Embodiment 2

[0067] Use the above treatment device to treat organic waste gas

[0068] (1) Spray oxidation:

[0069] a. Enter the organic waste gas into the advanced oxidation tower from the waste gas inlet, the feed rate of the organic waste gas is 3kg / h, the ozone generated by the ozone generator enters the aeration tray at the bottom of the advanced oxidation tower through the ozone inlet, and the feed rate of the ozone is 3kg / h, dispersed into the advanced oxidation tower through the aeration tray, and the organic waste gas and ozone are evenly distributed into the advanced oxidation tower through the packing layer;

[0070] b. adding an oxidation accelerator (preferably titanium dioxide) into water to form a spray, the molar ratio of titanium dioxide to water is 0.5:1, then add sodium hydroxide to the spray to adjust the pH of the spray to 8, spray The spray liquid is distributed to each nozzle through the distribution main pipe of the spray device, and the spray liquid is atomized t...

Embodiment 3

[0076] Use the above treatment device to treat organic waste gas

[0077] (1) Spray oxidation:

[0078] a. Enter the organic waste gas into the advanced oxidation tower from the waste gas inlet. The feed rate of the organic waste gas is 1.5kg / h. The ozone generated by the ozone generator enters the aeration tray at the bottom of the advanced oxidation tower through the ozone inlet. The feed rate of the ozone is It is 3kg / h, dispersed into the advanced oxidation tower through the aeration tray, and the organic waste gas and ozone are evenly distributed into the advanced oxidation tower through the packing layer;

[0079] b. adding an oxidation accelerator (preferably titanium dioxide) into water to form a spray, the molar ratio of titanium dioxide to water is 1:1, and then adding potassium hydroxide in the spray to adjust the pH of the spray to 12, spray The spray liquid is distributed to each nozzle through the distribution main pipe of the spray device, and the spray liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com