Vaporization power generation method for liquid nitrogen power regeneration recycling and power generation equipment for liquid nitrogen power regeneration recycling

A technology for power generation equipment and equipment, applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of dim prospects for sustainable development, high cost of wind farms, and difficulty in large-scale application, and achieve good sustainable development. The effect of enhancing production efficiency and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

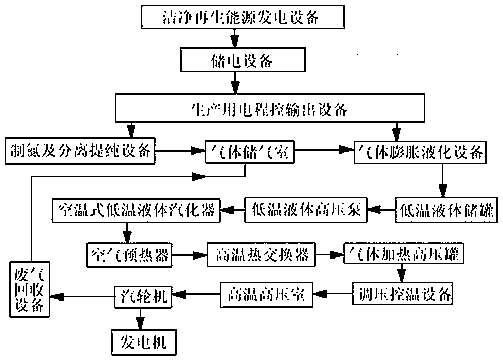

[0012] Embodiment 1: as figure 1 As shown, including clean renewable energy power generation equipment, power storage equipment, program-controlled output equipment for production electricity, nitrogen production and separation and purification equipment, gas storage chambers, gas expansion liquefaction equipment, cryogenic liquid storage tanks, cryogenic liquid high-pressure pumps, air temperature type low-temperature liquid vaporizer, air preheater, high-temperature heat exchanger, gas heating and high-pressure tank, pressure regulation and temperature control equipment, high-temperature and high-pressure chamber, exhaust gas recovery equipment, steam turbine and generator, and the clean renewable energy power generation equipment can be photovoltaic Any one or a combination of two or more of power generation equipment, wind power generation equipment, geomagnetic power generation equipment, tidal power generation equipment or solar power generation equipment. The clean rene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com