Bamboo veneer semi-finished product dryer

A technology of semi-finished products and dryers, applied in the direction of dryers, drying, progressive dryers, etc., can solve the problems of limited contact area, chain link damage failure rate, etc., and achieve the effect of balanced operation and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

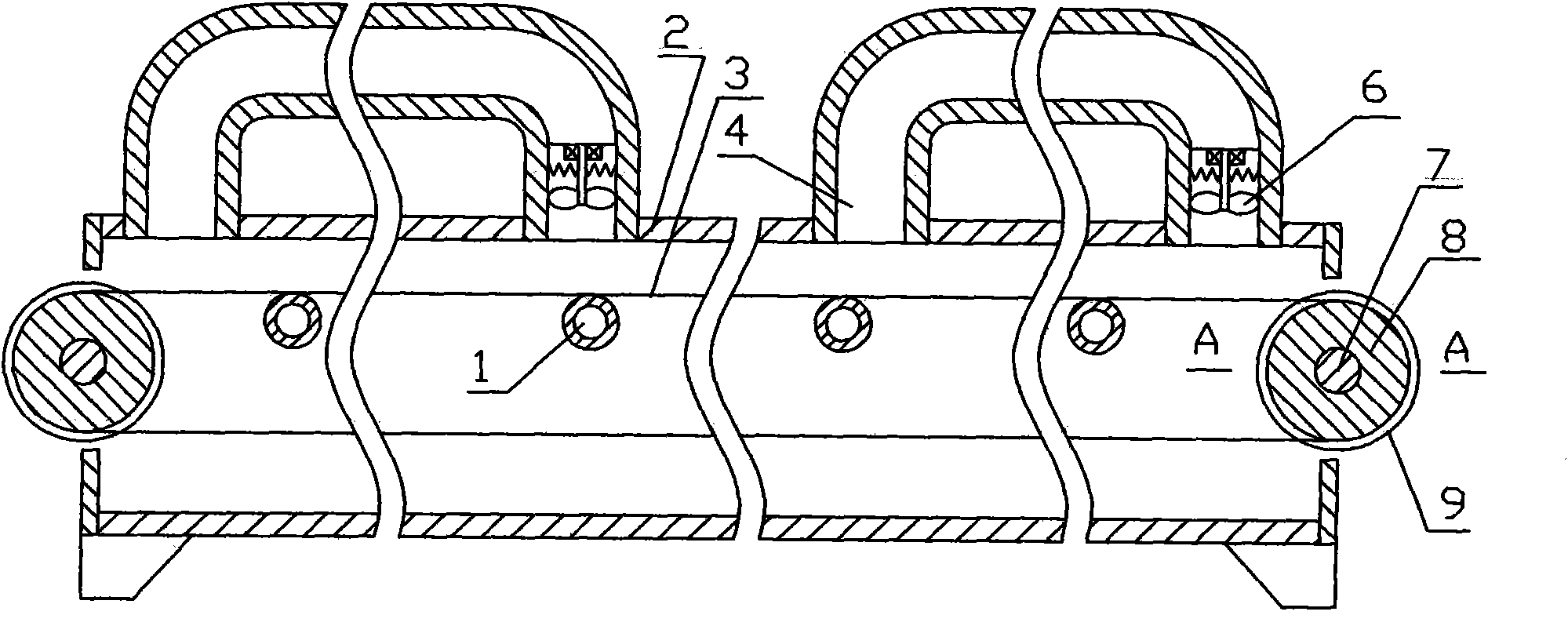

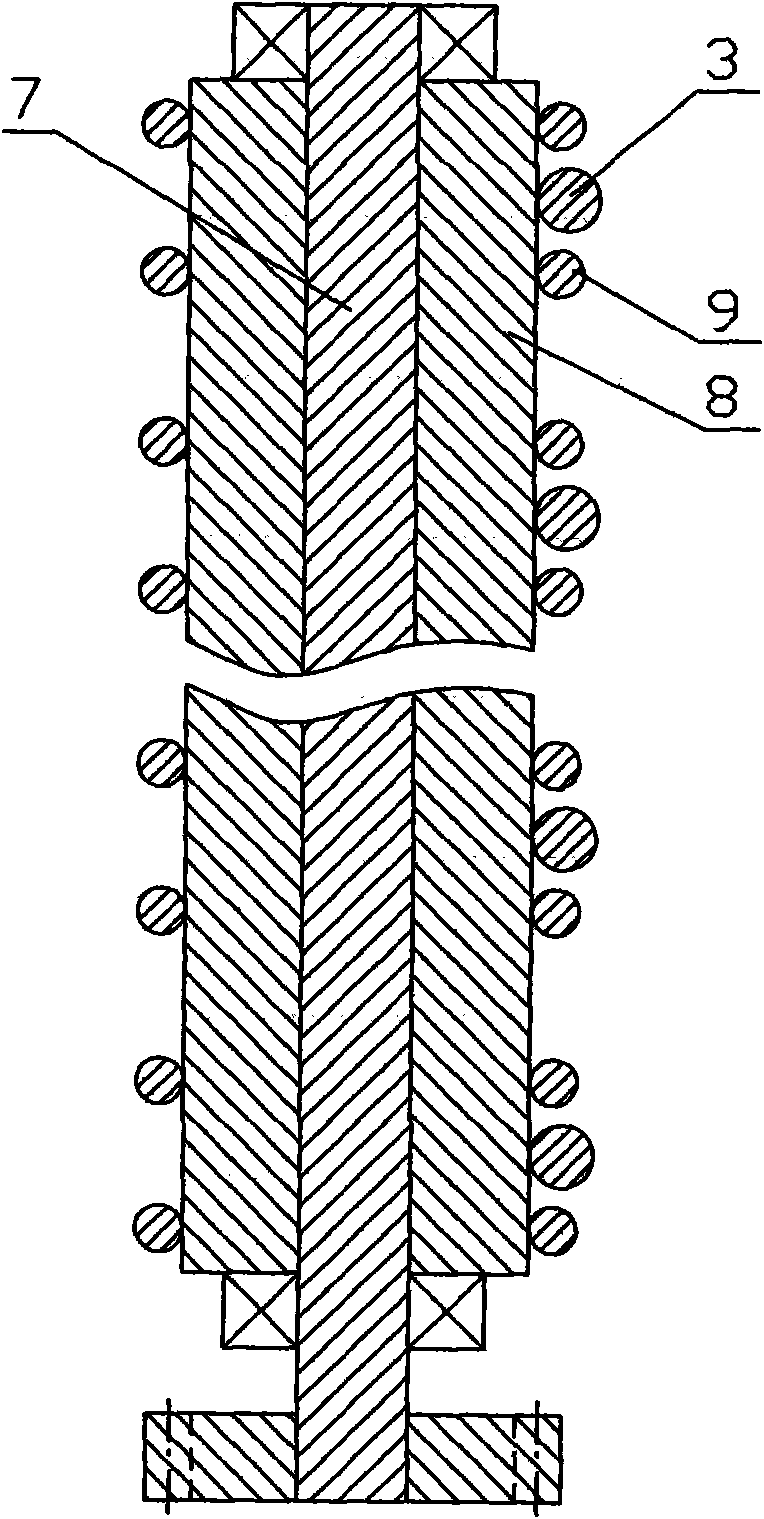

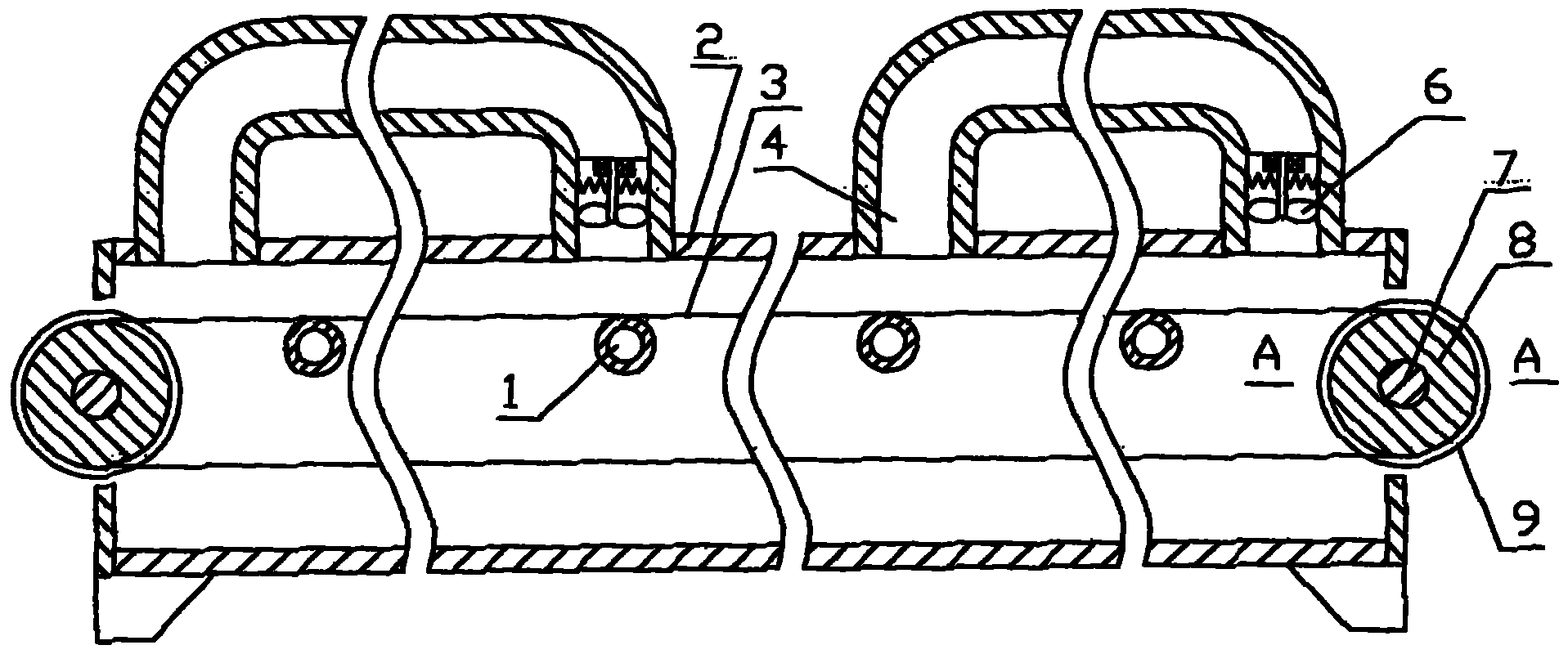

[0010] The structure of the present invention is composed of a motor, a transmission mechanism, a transmission mechanism, a box-shaped enclosure body outside of the transmission mechanism 2, a steam input pipe 6 installed on the enclosure body 2, a steam output pipe, and a heat sink in the enclosure body 2. The mechanism includes a driving shaft 7, a driven shaft, a bearing seat, and a conveyor belt tensioning mechanism. It is characterized in that: a plurality of axial fans 6 are fixed on the upper surface of the enclosure body 2, and each axial fan 6 is in the forward direction of the conveyor belt. The enclosure body 2 has an opening and fixes an exhaust pipe 4, and the air outlet of the exhaust pipe 4 is connected with the air inlet of the axial flow fan 6 through a pipeline; the driving shaft 7 and the driven shaft of the transmission mechanism are respectively fixed and sleeved with a rotating drum 8. Fix and weld several pairs of steel rims 9 on the outer circle of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com