Preparation method of manganese-doped titanium dioxide film for strengthening photoelectric response of visible light

A titanium oxide thin film, photoelectric response technology, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problem of not preparing Mn-doped titanium oxide thin film, and achieve the effect of improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

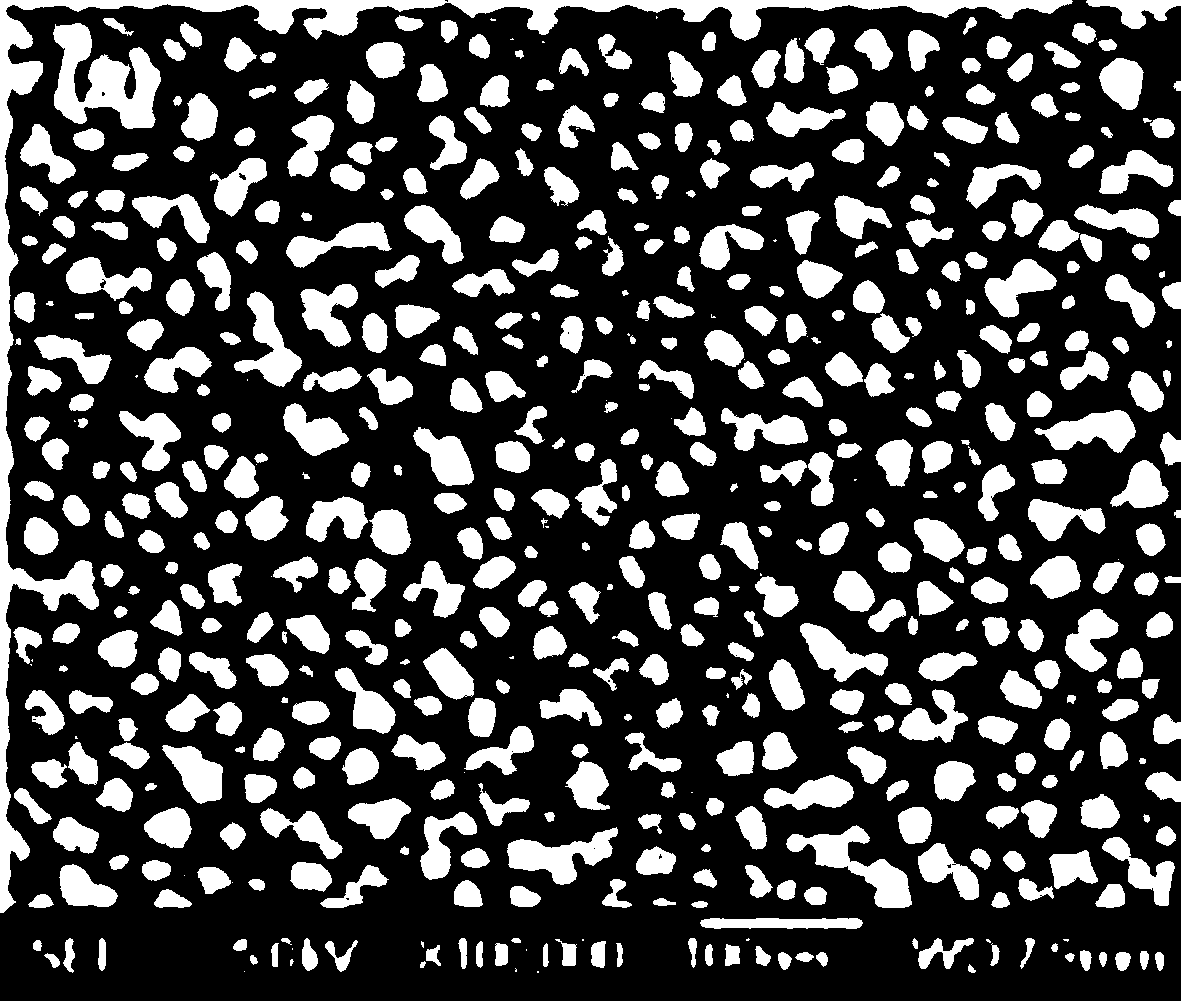

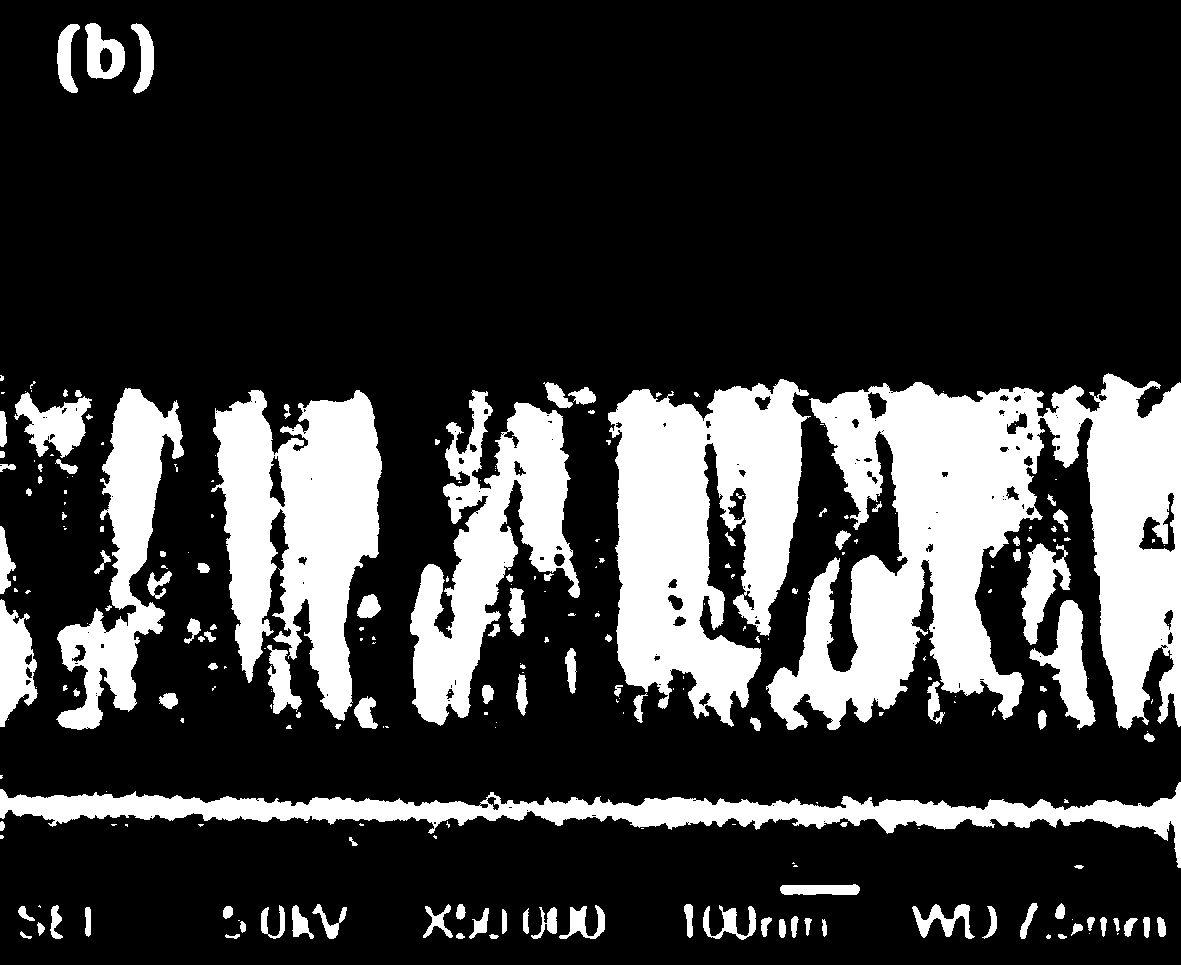

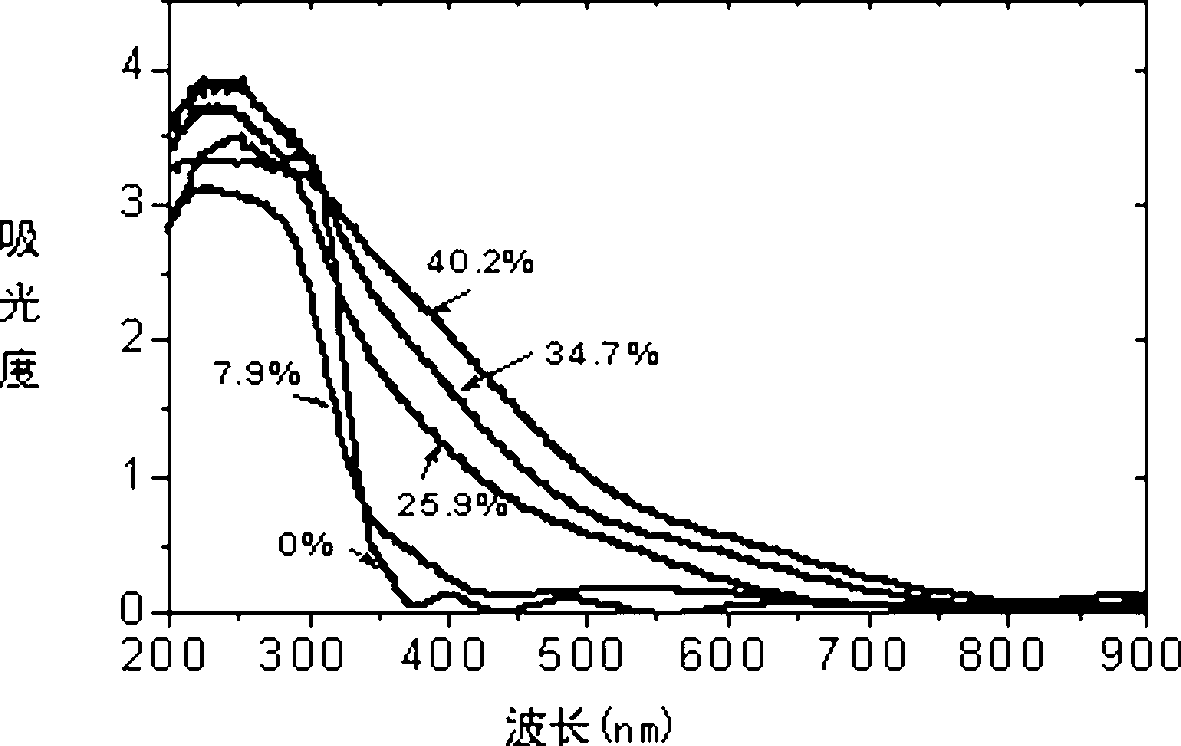

Embodiment example 1

[0025] Put the substrate into acetone, alcohol, and deionized water for 15 minutes, and then dry it for later use. Fix the Ti target with a purity of 99.999% at the DC position of the cathode of the magnetron sputtering system, fix the Mn metal target at the radio frequency position of the cathode of the reactive magnetron sputtering system, and fix the cleaned substrate in the vacuum chamber of the magnetron sputtering system On the base of the chamber, adjust the distance between the target and the substrate to be 65mm. Before preparation, the substrate was splash cleaned for 15 minutes, the vacuum chamber was baked, and the background vacuum was evacuated to 1×10 -5 After Pa, the substrate was heated to 250° C., 20 sccm and 15 sccm of argon gas and oxygen gas were fed respectively, and the pressure of the chamber was adjusted to 5 mtorr. Adjust the power of the DC Ti target to 315W, and the power of the RF Mn target to 0W, and take out the sample from the vacuum chamber af...

Embodiment example 2

[0028] Put the substrate into acetone, alcohol, and deionized water for 15 minutes, and then dry it for later use. Fix the Ti target with a purity of 99.999% at the DC position of the cathode of the magnetron sputtering system, fix the Mn metal target at the radio frequency position of the cathode of the reactive magnetron sputtering system, and fix the cleaned substrate in the vacuum chamber of the magnetron sputtering system On the pedestal, adjust the distance between the target and the substrate to be 65mm. Before preparation, the substrate was splash cleaned for 15 minutes, the vacuum chamber was baked, and the background vacuum was evacuated to 1×10 -5 After Pa, the substrate was heated to 250° C., 20 sccm and 15 sccm of argon gas and oxygen gas were fed respectively, and the pressure of the chamber was adjusted to 5 mtorr. Adjust the power of the DC Ti target to 315W, and the power of the RF Mn target to 60W, and take out the sample from the vacuum chamber after contin...

Embodiment example 3

[0031] Put the substrate into acetone, alcohol, and deionized water for 15 minutes, and then dry it for later use. Fix the Ti target with a purity of 99.999% at the DC position of the cathode of the magnetron sputtering system, fix the Mn metal target at the radio frequency position of the cathode of the reactive magnetron sputtering system, and fix the cleaned substrate in the vacuum chamber of the magnetron sputtering system On the pedestal, adjust the distance between the target and the substrate to be 65mm. Before preparation, the substrate was splash cleaned for 15 minutes, the vacuum chamber was baked, and the background vacuum was evacuated to 1×10 -5 After Pa, the substrate was heated to 550° C., 20 sccm and 15 sccm of argon gas and oxygen gas were fed respectively, and the pressure of the chamber was adjusted to 5 mtorr. Adjust the power of the DC Ti target to 378W, and the power of the RF Mn target to 75W, and take out the sample from the vacuum chamber after contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com