Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "The realization of the production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

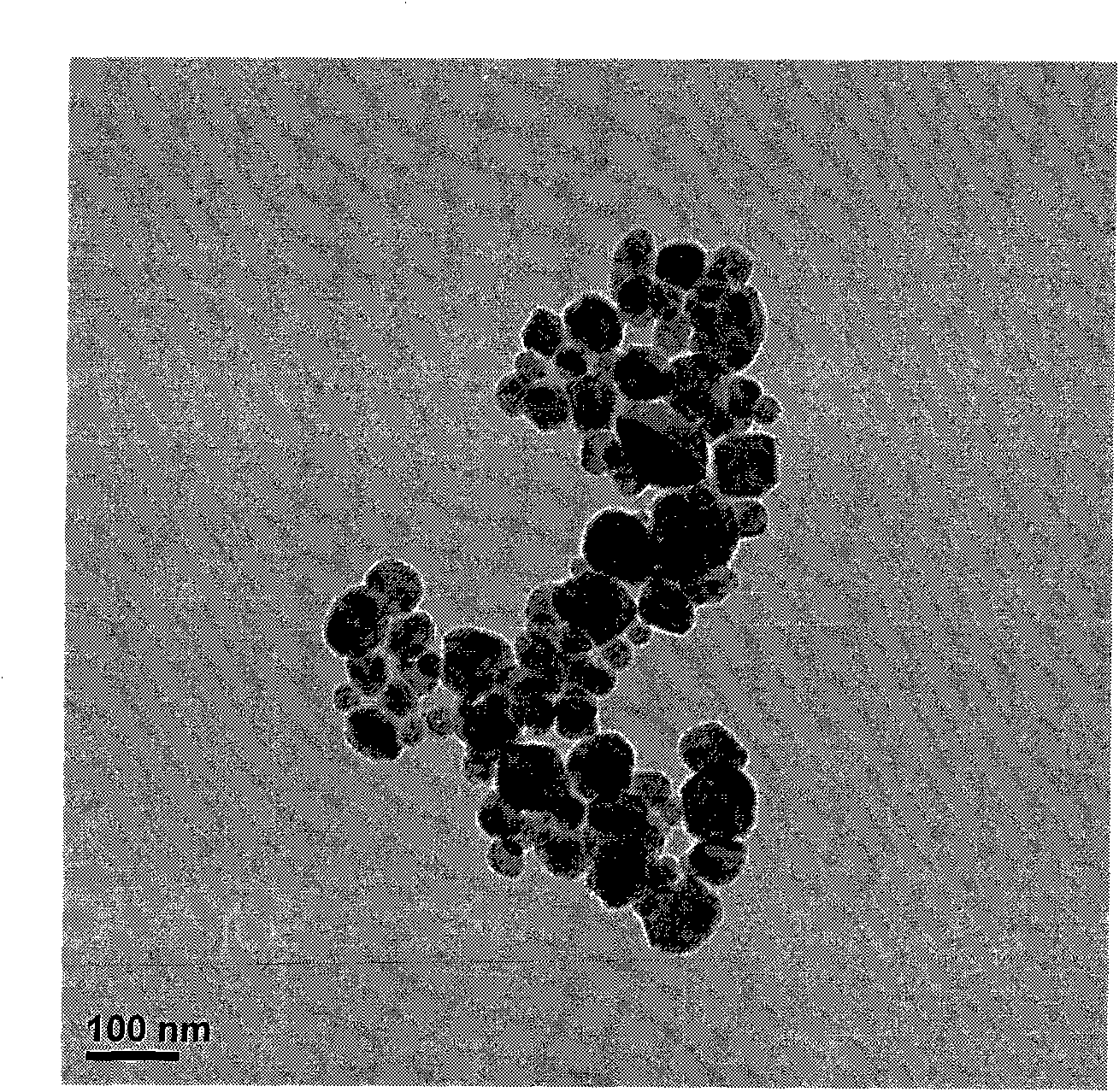

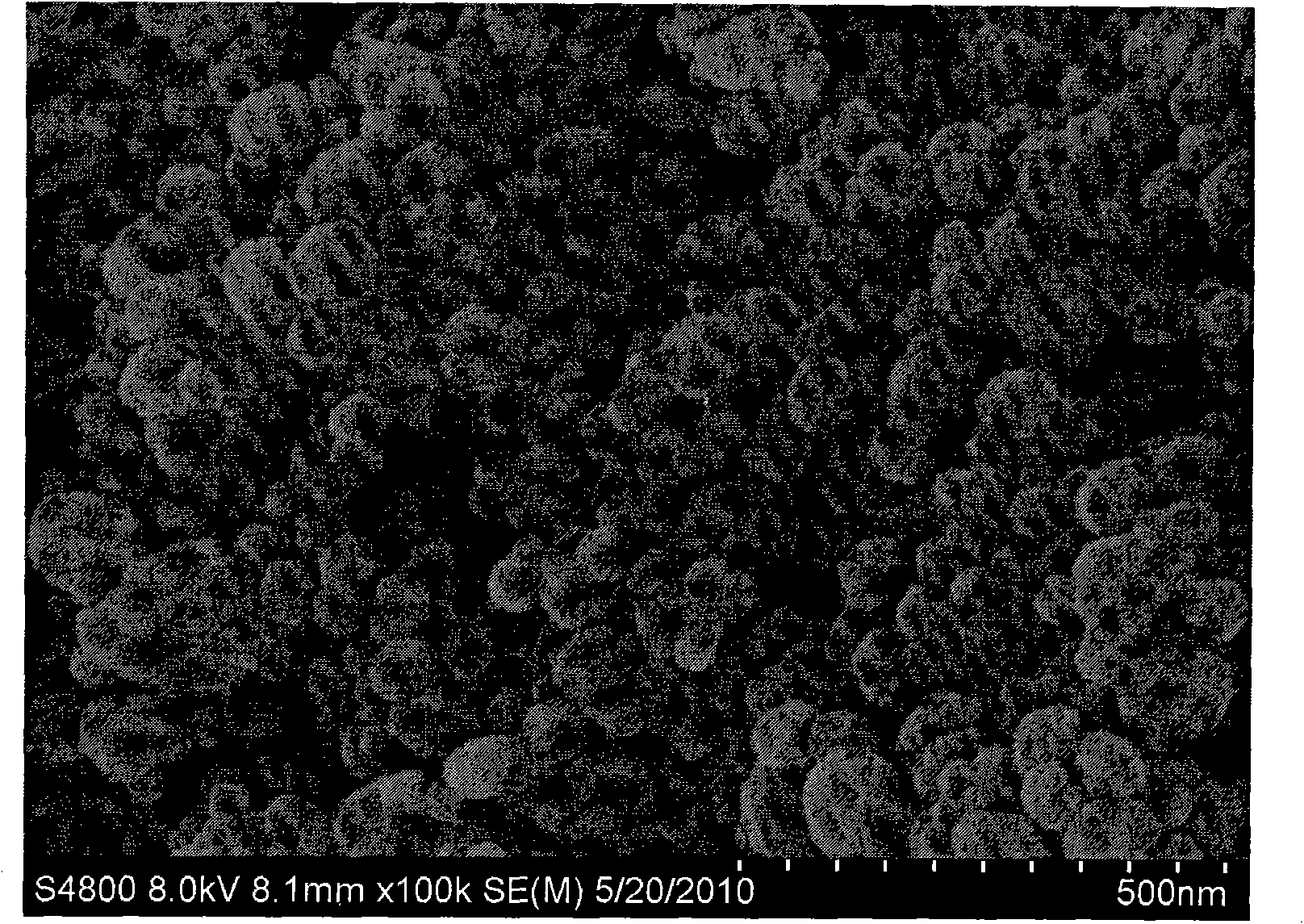

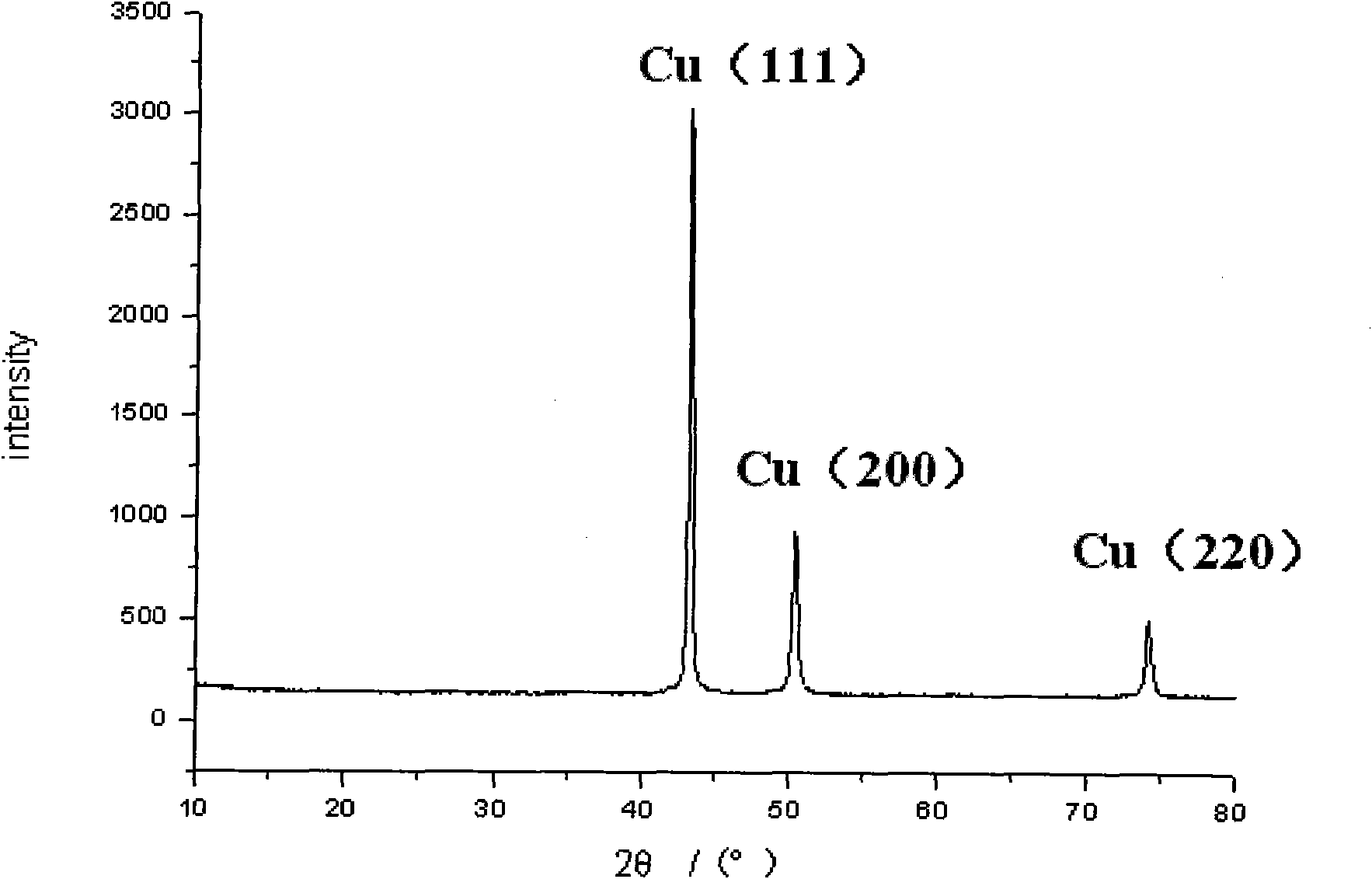

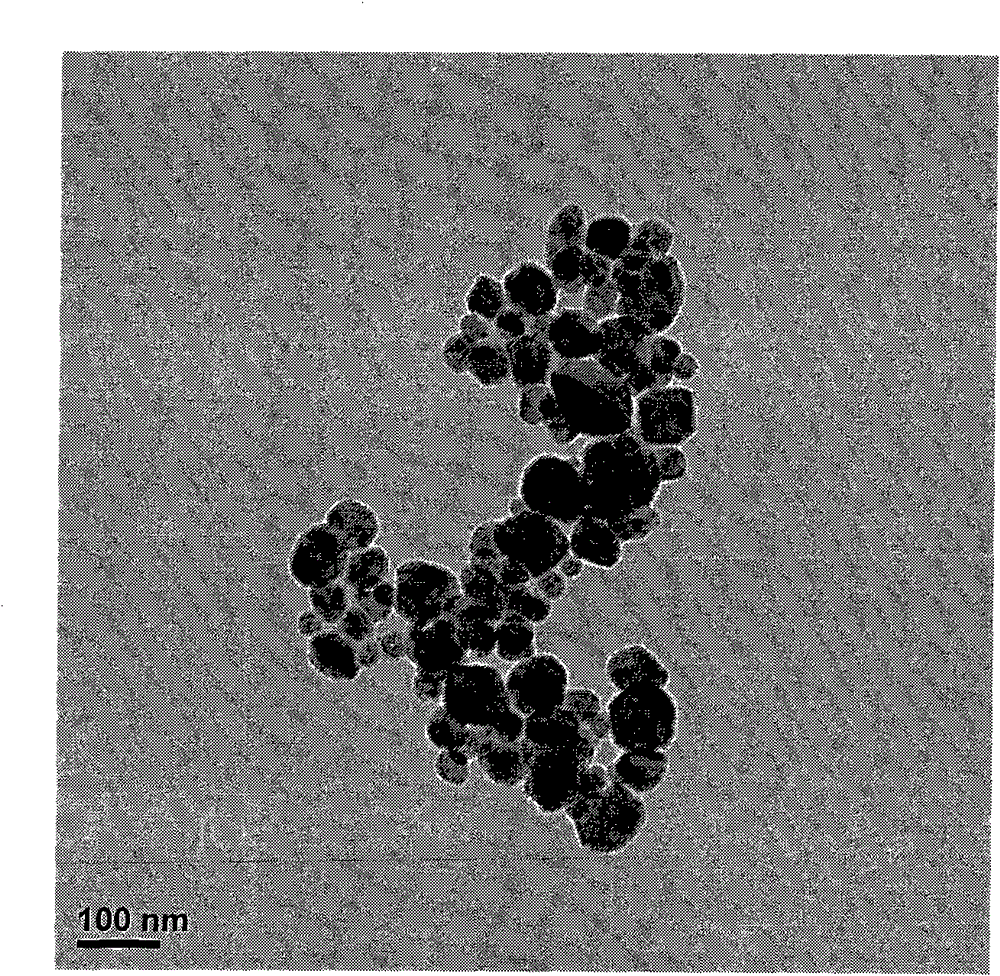

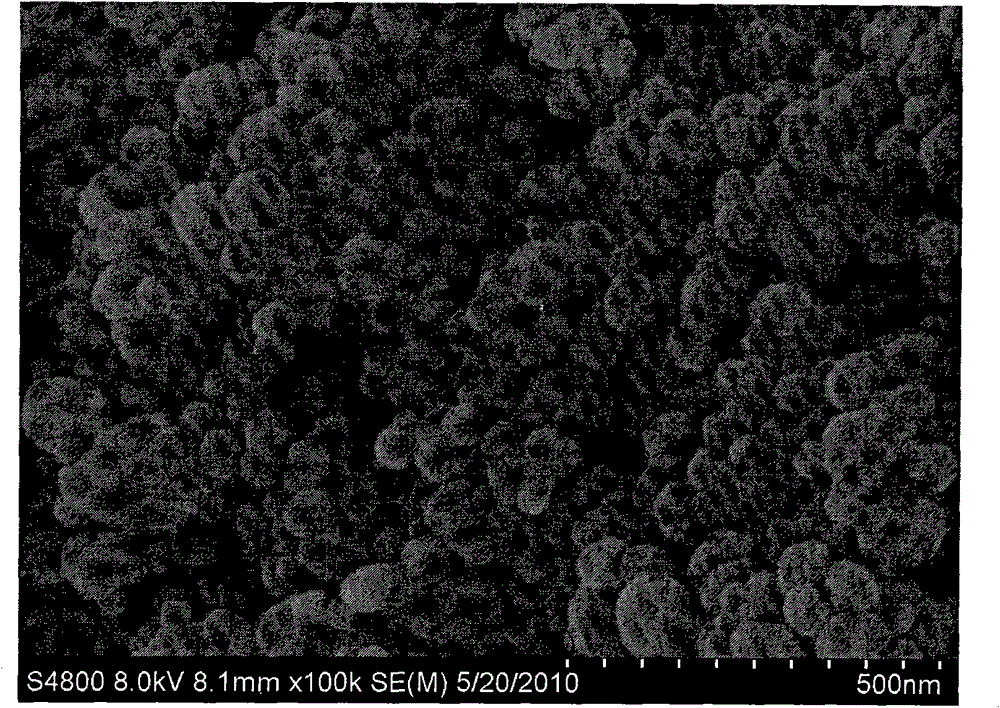

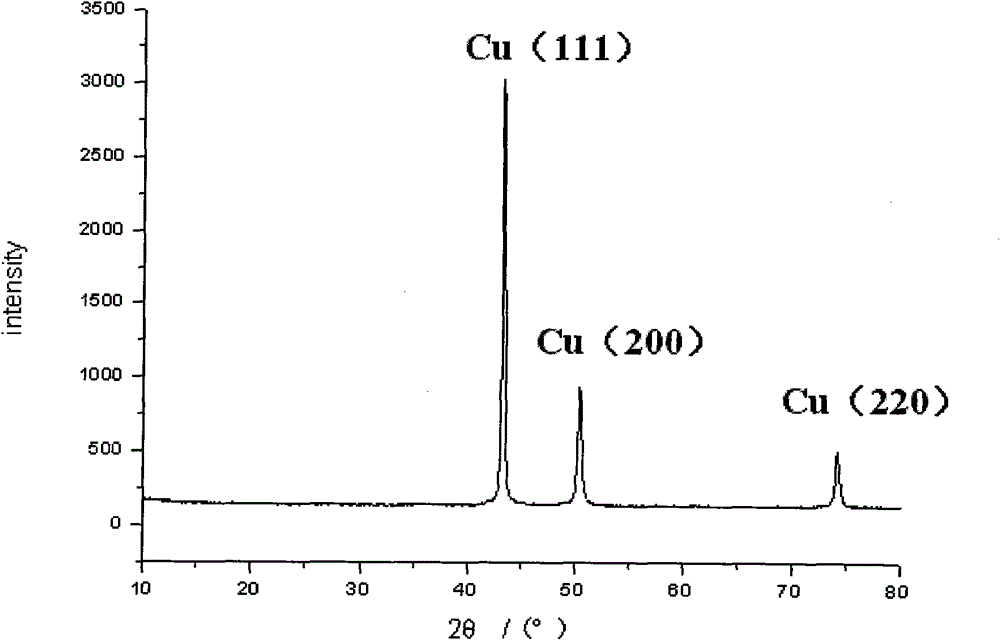

Method for preparing nano copper conductive ink

ActiveCN101880493AGood dispersionCharacteristic peaks are obviousInksNon-conductive material with dispersed conductive materialOrganic solventRoom temperature

The invention discloses a method for preparing nano copper conductive ink, which can be applied in the field of printing electronic technology, in particular ink jet printing technology. The preparation method comprises the following steps of: dissolving copper salt and protective agent into a solvent, heating and stirring the solution, adding a small amount of alkali solution to adjust the pH ofthe solution to between 7 and 10, dripping a reducing agent into the solution, continuously stirring the solution to react for 30 to 60 minutes, and then cooling the reaction solution to room temperature to obtain nano copper dispersion; performing centrifuging, washing and vacuum drying at room temperature on the nano copper dispersion to obtain nano copper granules; and dispersing the nano copper granules into an organic solvent, and ultrasonically treating the solution to obtain the nano copper conductive ink. The method solves the problems of complex preparation process and long preparation period in the prior art, has the advantages of simple and convenient operation, low production cost, short flow and no harmful waste generation, and realizes the goals of environmental protection and economy; and the prepared nano copper conductive ink has good dispersion property and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Photovoltaic module recycling method and system

ActiveCN110571306AWon't happenThe realization of the productionWaste processingFinal product manufactureElectrical batteryResource recovery

The invention discloses a photovoltaic module recycling method and system. The method comprises the following steps: removing a frame, a junction box and a glass panel on a photovoltaic module to obtain primarily-separated materials; shearing the primarily-separated materials to obtain primarily-separated material fragments; placing the primarily-separated material fragments in a stripping deviceprovided with a rotary striking mechanism and performing stripping to obtain a mixture of EVA film fragments, backplane fragments, bus-bar fragments, solder strip fragments and silicon powder; and sorting out silicon powder, EVA film fragments, backplane fragments, bus-bar fragments and solder strip fragments through a sorting device. The method for disassembling and recycling the backplane, EVA,battery cells and complete glass has the advantages of high disassembling and recycling efficiency, low energy consumption, no environmental pollution and the like. Resource waste and waste dischargeare greatly reduced, and the recycling cost is reduced. The method is an environment-friendly resource recycling method.

Owner:YINGLI ENERGY CHINA +1

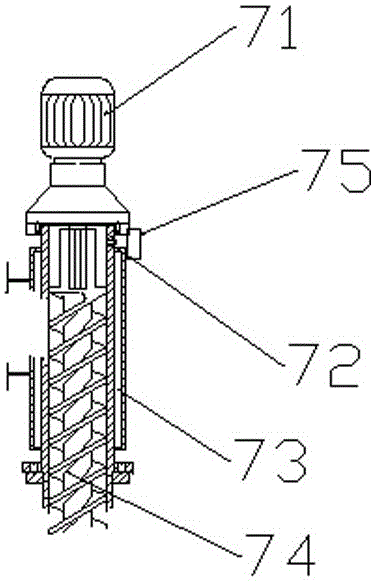

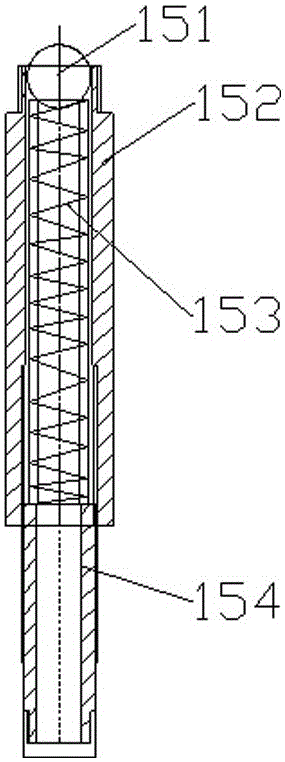

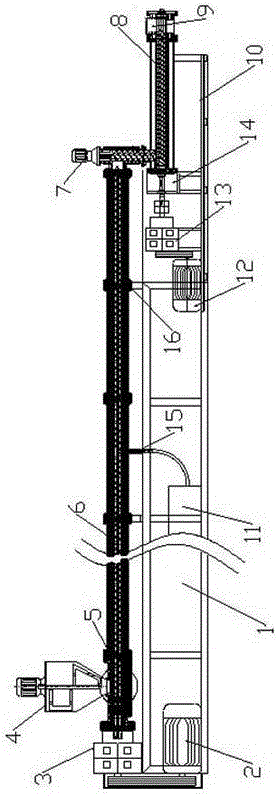

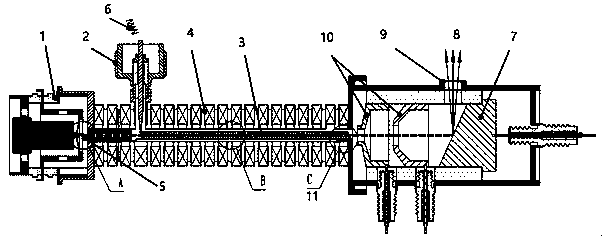

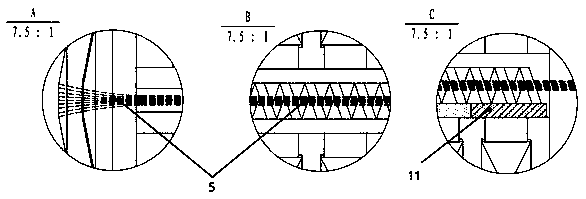

Environment-friendly desulfurization extruder of regenerated rubber

The invention discloses an environment-friendly desulfurization extruder of regenerated rubber. The environment-friendly desulfurization extruder comprises a base, an upper motor, an upper gearbox, a charging device, a double-screw feeding device, cylinder screws, a transitional conveying device, a double-screw cooling extruding device and a waste recovery device, wherein the upper motor and the upper gearbox are installed on the left side of the base, the double-screw feeding device is installed at the right end of the upper gearbox, the charging device is installed at the upper part of the double-screw feeding device, the multiple cylinder screws are installed on the right side of the double-screw feeding device, the transitional conveying device is installed at the right ends of the cylinder screws, the double-screw cooling extruding device is installed at the lower part of the transitional conveying device, and the waste recovery device is installed in the middle of the base and communicates with the interiors of the cylinder screws through pipelines. A distribution box, a lower gearbox and a lower motor are sequentially installed on the left side of the double-screw cooling extruding device, the distribution box, the lower gearbox, the lower motor and the double-screw cooling extruding device are installed on a sliding rail through supports, and the sliding rail is located on the base. According to the environment-friendly desulfurization extruder, dynamic installation is realized.

Owner:舟山富德斯机械有限公司

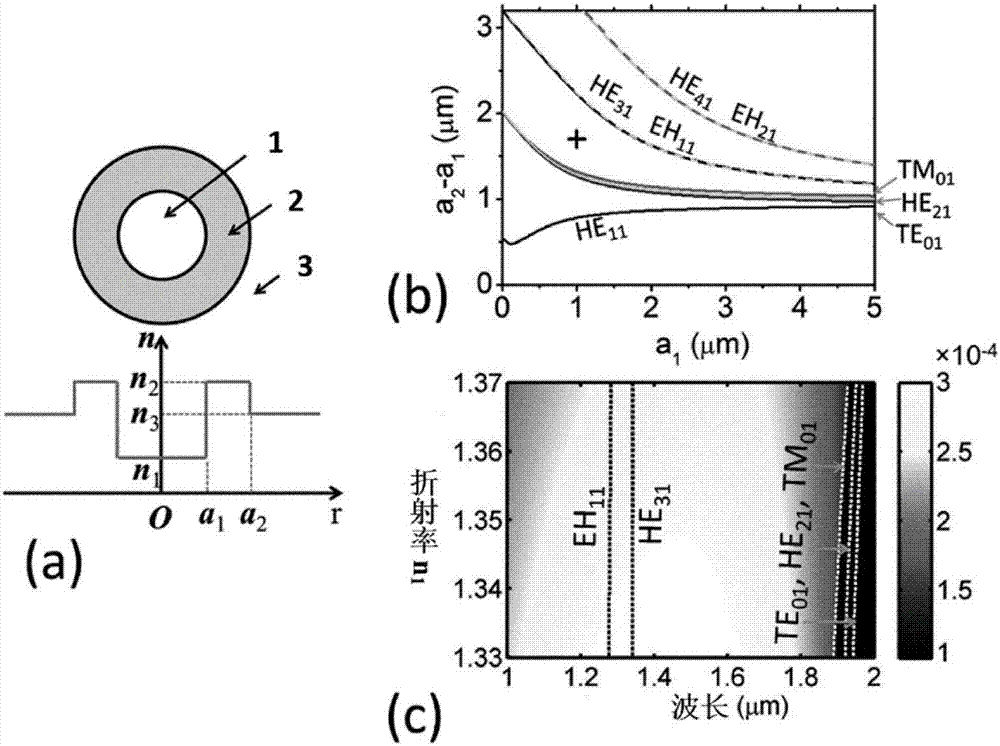

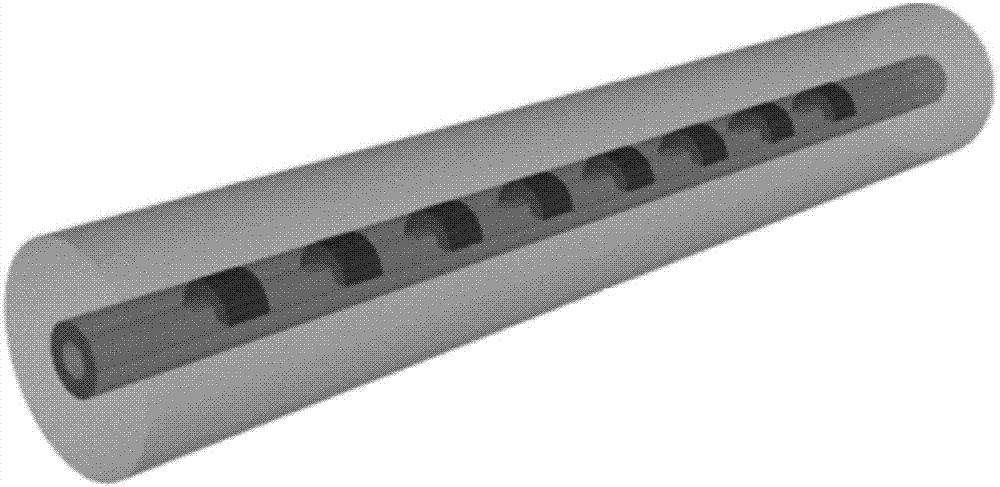

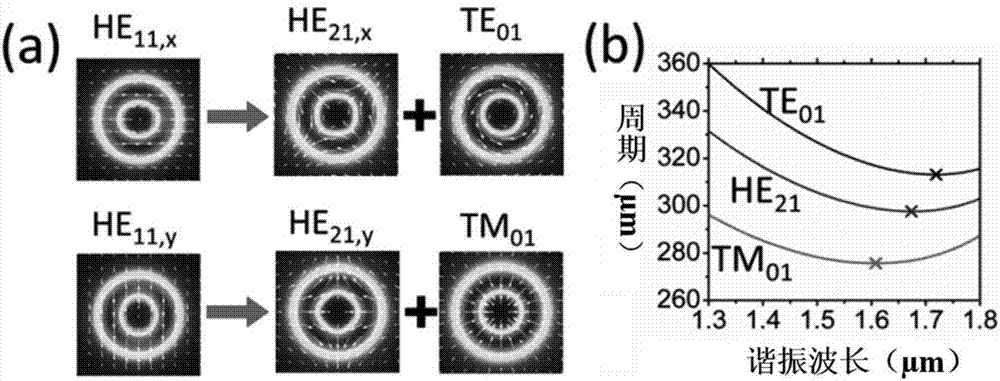

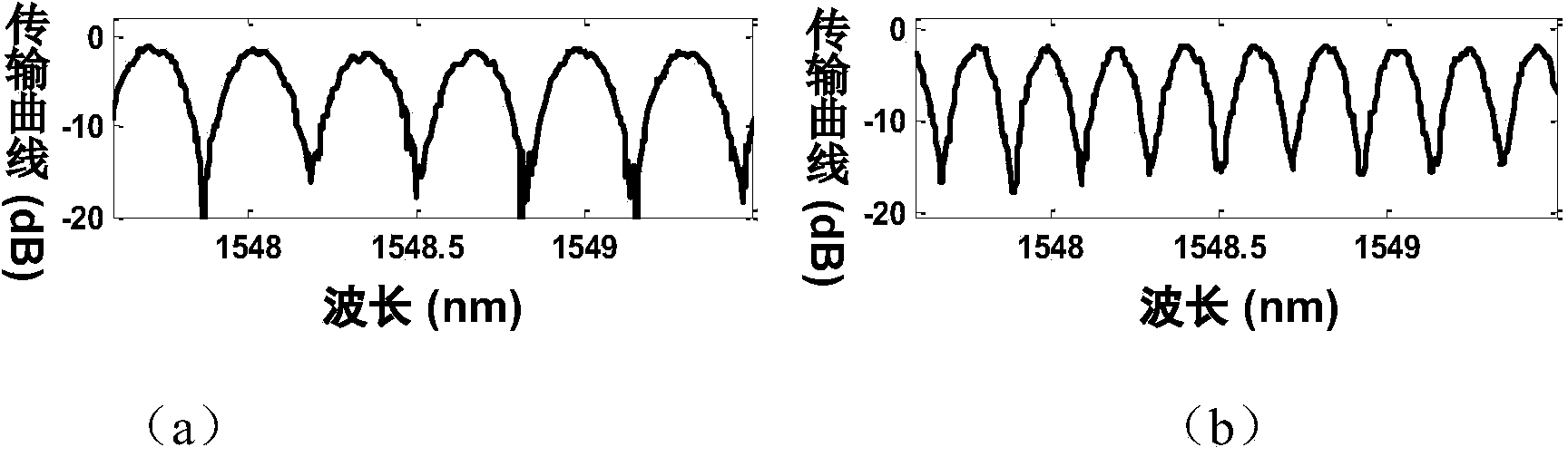

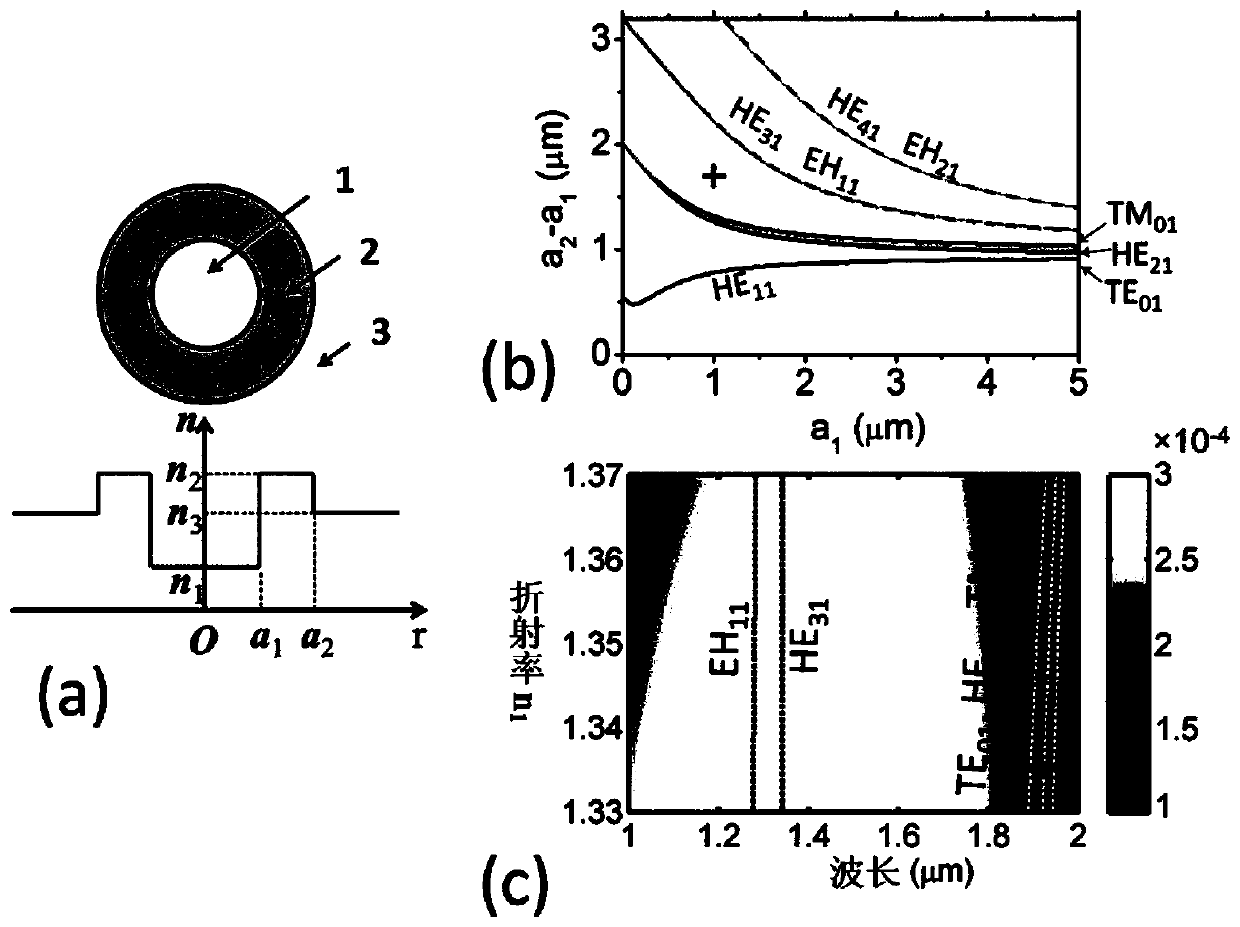

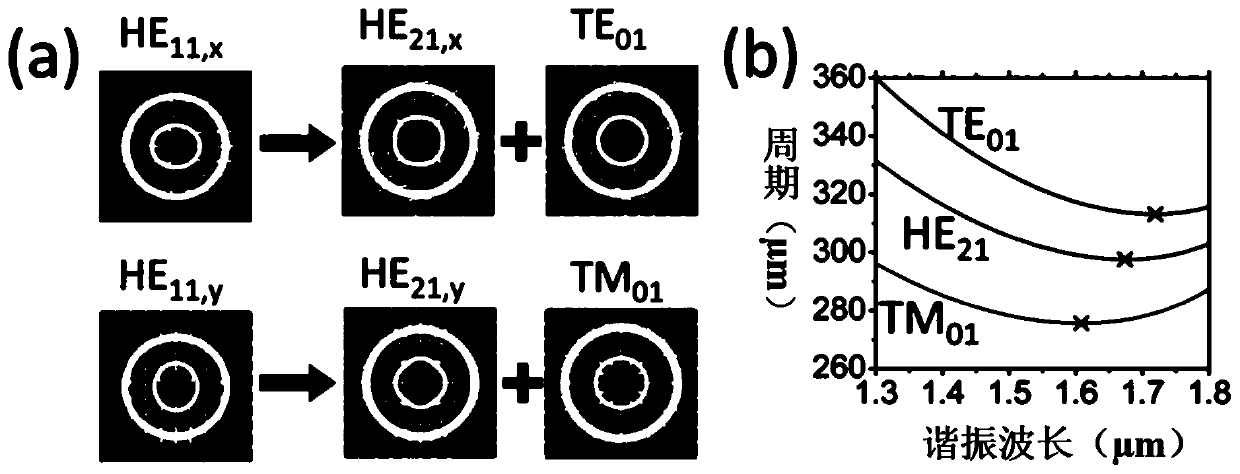

An annular optical fiber with an asymmetrical optical grating and application in orbital angular momentum generation thereof

ActiveCN107462948AEfficient separationCrosstalk ignoreCladded optical fibreOptical waveguide light guideGratingNon symmetric

The invention provides an annular optical fiber with an asymmetrical optical grating and application in orbital angular momentum generation thereof. A hollow core annular optical fiber can increase the effective refractive index between degeneracy-similar modes, thereby preventing crosstalk between the modes. A long period optical grating inscribed on the upper half ring of the hollow core annular optical fiber breaks a circular symmetry structure of the optical fiber and achieves conversion between angular non-same order modes. When input light is of a circular polarization fundamental mode, a first-order orbital angular momentum mode can be generated. The hollow core of the hollow core annular optical fiber is filled with an optical functional material with the refractive index adjustable and the wave length for generating the orbital angular momentum mode can be tuned by the refractive index of the liquid, so that the structure can generate the orbital angular momentum mode in an adjustable cross band wave length range. Simulation shows that when the optical grating period is 292 [mu]m and the optical grating length is 1.460cm, the range of broad band wave lengths with the angular momentum mode conversion rate higher than 90% can reach 237nm, the greatest conversion rate is 98.91%, and the modulation rate of the refractive index of the filling liquid for the wave lengths for orbital angular momentum mode generation is 400nm / RIU.

Owner:NORTHEASTERN UNIV

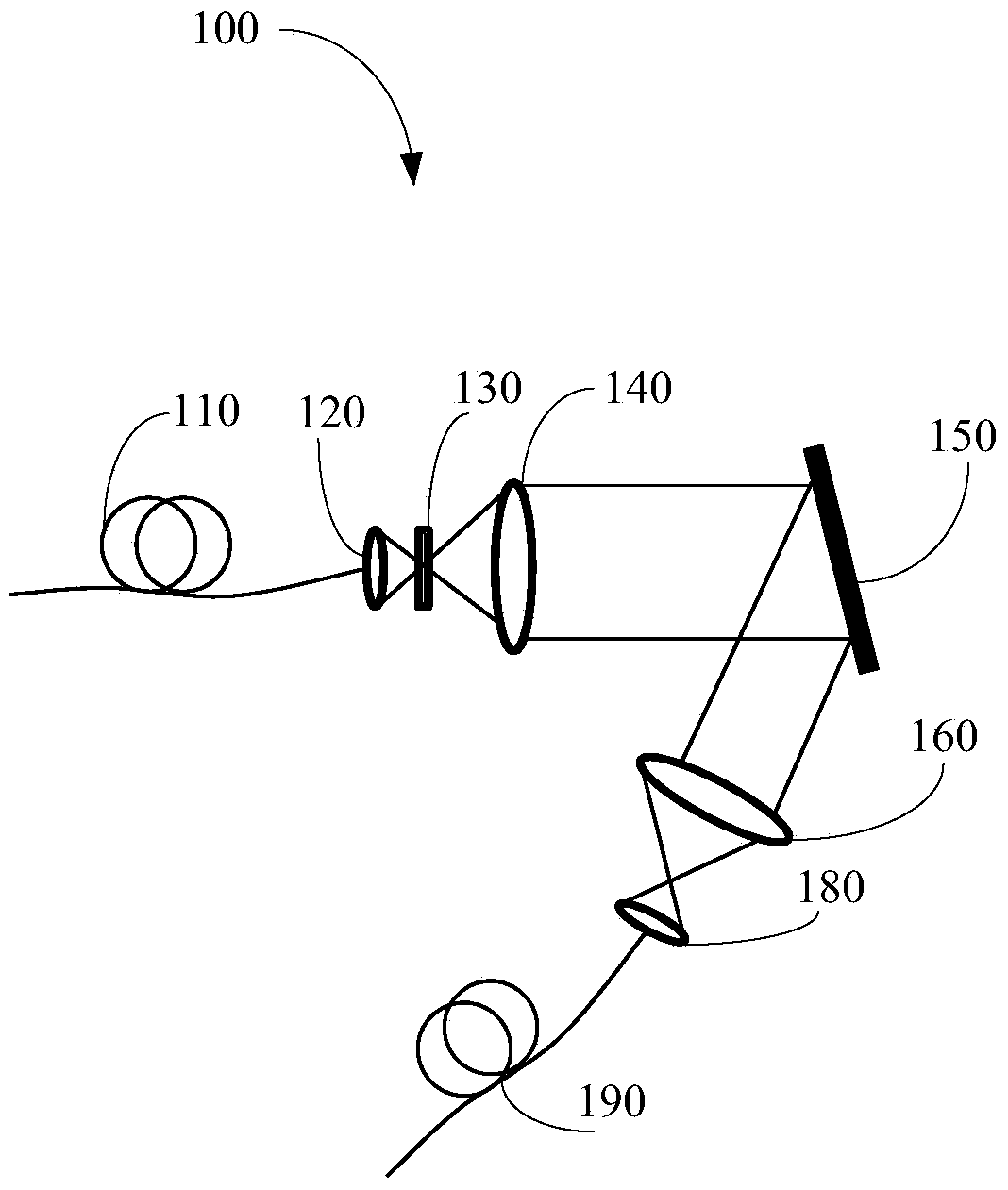

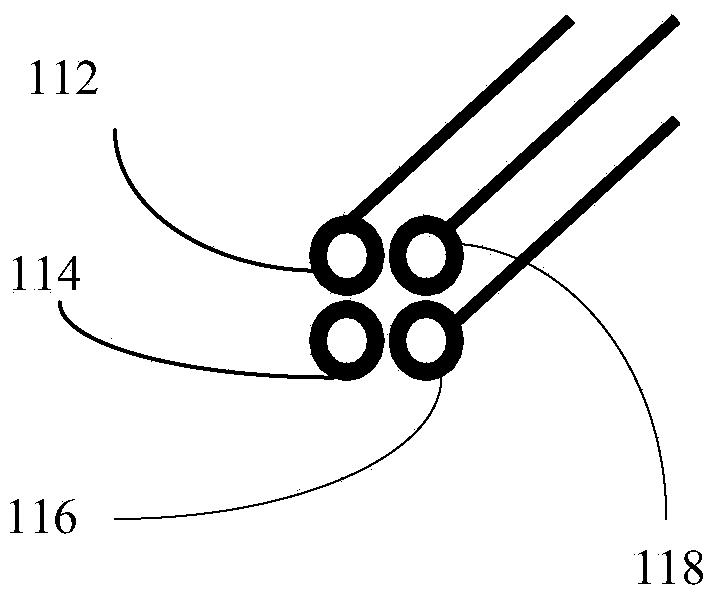

Light beam orbital angular momentum generating device

The invention provides a light beam orbital angular momentum generating device which is used for generating corresponding angular momentum to at least one light beam. The light beam orbital angular momentum generating device comprises a first lens, a second lens, silicon-based liquid crystal, a third lens and a fourth lens. A telescope system combined by the first lens and the second lens amplifies at least one light beam. The silicon-based liquid crystal is divided into multiple partitions, and the number of the partitions correspond to that of the light beams. The silicon-based liquid crystal allows the amplified light beams to generate orbital angular momentum corresponding to partition number. A telescope system combined by the third lens and the fourth lens sends out the light beams generating orbital angular momentum. The light beam orbital angular momentum generating device has the advantages that the silicon-based liquid crystal is divided into multiple partitions, the light beams respectively enter the partitions, the number of the partitions equals to that of the light beams, the phase of each partition is the spiral phase different in level, multiple light beams and multi-level spiral phases can be generated, and number of the silicon-based liquid crystal can be reduced effectively.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

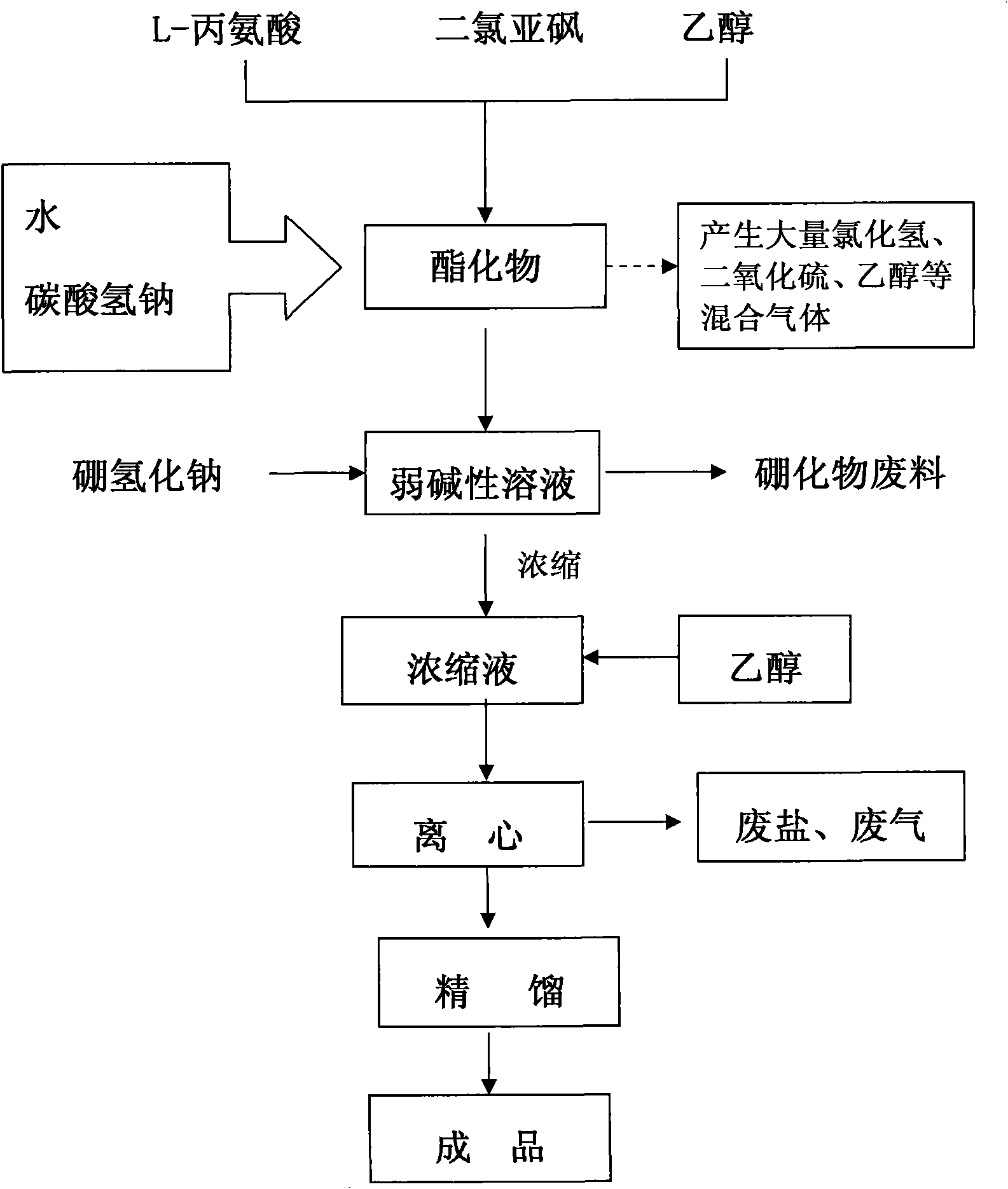

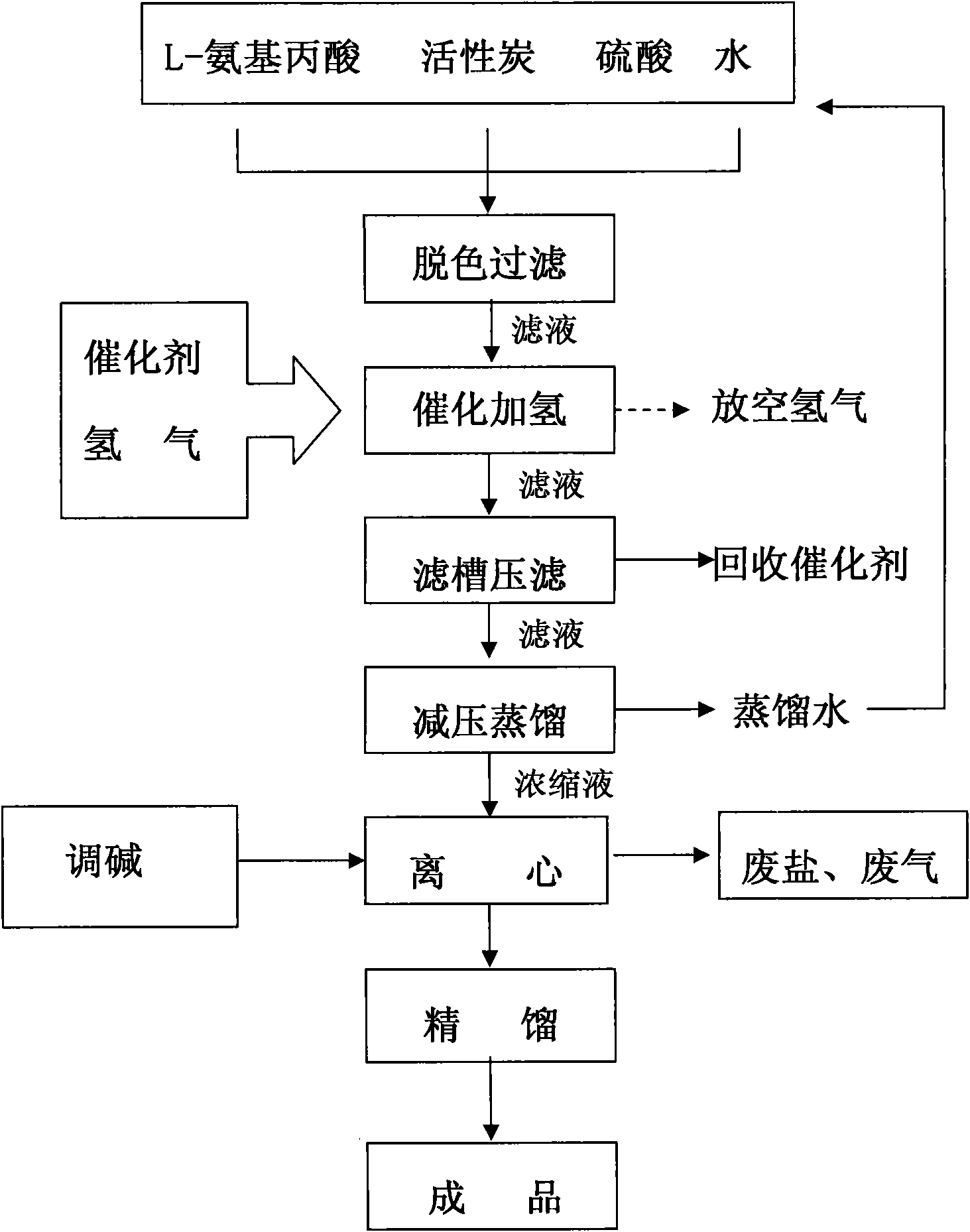

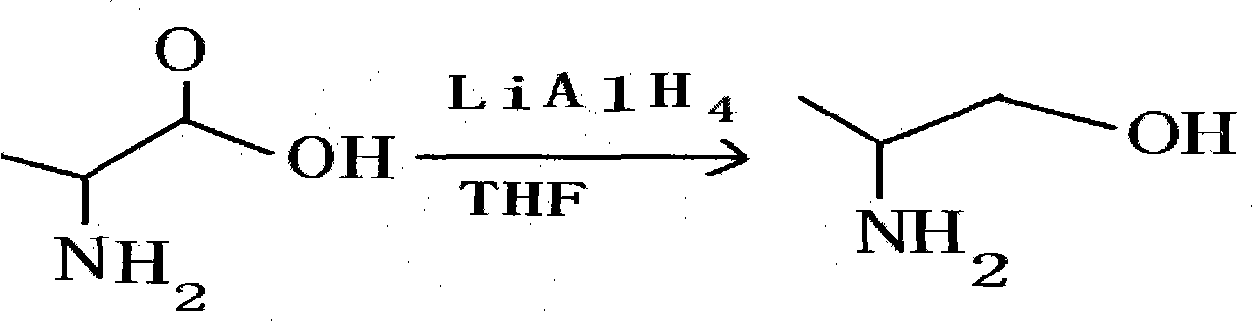

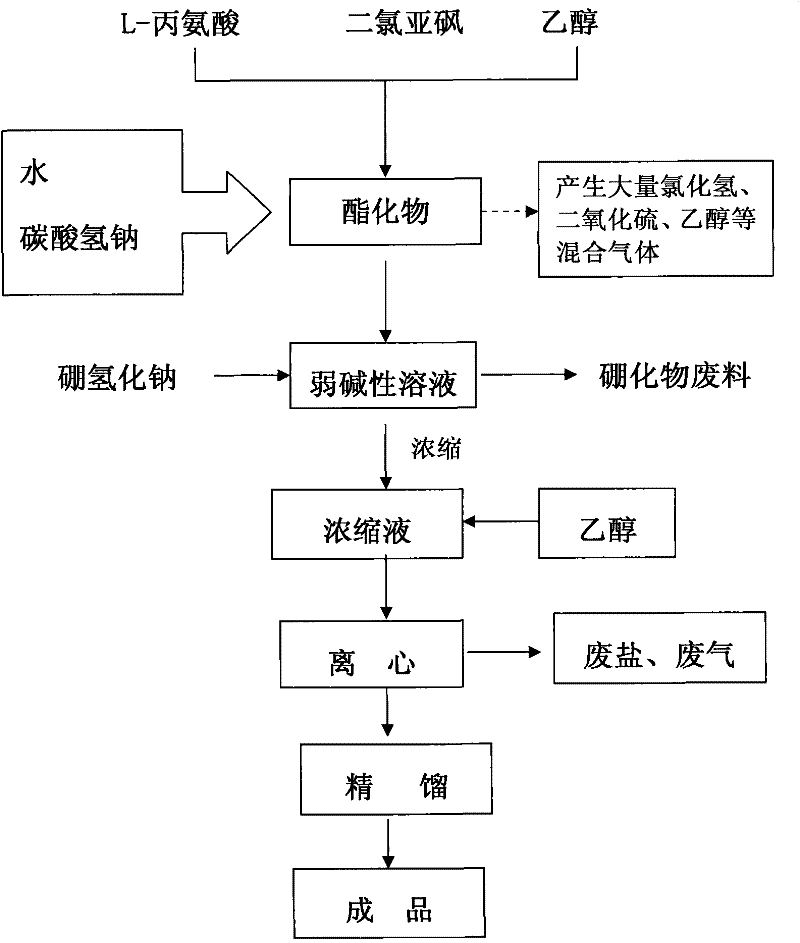

Synthetic method of L-aminopropanol

InactiveCN101648879AHigh selectivityFast responseOrganic compound preparationAmino-hyroxy compound preparationPollutantAlanine

The invention provides a preparation method of L-aminopropanol, using L-alanine and H2 as main raw materials and carbon ruthenium as a catalyst to carry out direct catalytic hydrogenation to synthesize the L-aminopropanol. The method increases the selectivity of process reaction, accelerates reaction speed and shortens reaction step, thereby greatly reducing the production cost, increasing the L-aminopropanol yield, reducing the production of harmful wastes and realizing the greenization of the reaction process; and the aspects of energy saving and emission reduction of SOD and SO2 are obviously improved in order to realize less environment pollution. Any organic solvent is not added to the whole reaction process, thereby reducing the emission of pollutants, and protecting environment.

Owner:浙江凯迪药业有限公司

Air purification system used in public area

InactiveCN104888568AIncrease flow rateIncrease air volumeCombination devicesBatteries circuit arrangementsElectricityPower station

The invention relates to an air purification system used in a public area. The air purification system comprises a connector, wherein an air guiding and purifying barrel is rotationally connected with the connector; an air inlet and an air outlet are formed in two ends of the air guiding and purifying barrel respectively; a horn-shaped guiding and purifying cavity is formed in the air guiding and purifying barrel and between the air inlet and the air outlet; the cross-sectional area of the guiding and purifying cavity is reduced gradually in the direction from the air inlet to the air outlet; a purifying and filtering component is mounted in the guiding and purifying cavity and is close to the air outlet; a fan blade is mounted in the guiding and purifying cavity and located between the purifying and filtering component and the air outlet; an air guiding tail wing extends out of the outer wall of the air guiding and purifying barrel and is close to the air outlet. The air purification system is simple and reasonable in structure, can achieve the purpose of purifying air, can take outdoor wind energy and solar energy as a power supply system, and can even store extra electrical energy as a power station to supply electricity to the surrounding area where electricity is needed, thereby realizing organic combination of air purification and clean energy generation.

Owner:仇登伟 +1

Ultrahigh-temperature composting method for treating vegetable waste

InactiveCN107382395AImproved soilReduce incidenceMagnesium fertilisersAlkali orthophosphate fertiliserNutrientDecomposition

The invention discloses an ultrahigh-temperature composting method for treating vegetable waste. The method comprises the steps of mixing well vegetable waste and agricultural waste, and subjecting the mixture to high-temperature aerobic composting treatment with forced ventilation so that the vegetable waste is harmlessly treated. The invention is intended to solve the problems that a vegetable planting zone produces a large amount of waste that may carry various pathogens, the vegetable waste containing pathogens is difficult to recycle, and safety risk easily occurs in the subsequent utilization of the vegetable waste. By regulating initial materials and increasing highest composting temperature to higher than 70 DEG C without affecting thorough decomposition of compost, the vegetable waste can be converted into compost products safely. By using the compost products of the vegetable waste, soil can be improved, nutrients can be provided, and occurrence of plant disease and pest damage can be partly decreased; therefore, the input of pesticides and other agricultural chemicals is reduced, waste resources are recycled, and clean production of vegetable fields is achieved. The method of the invention is significant both economically and environmentally.

Owner:CHINA AGRI UNIV

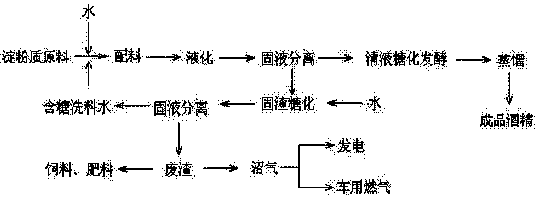

Method for producing alcohol through liquor fermentation

InactiveCN103382489AReduce production of fermentation by-productsIncrease profitBiofuelsFermentationFertilizerBiogas

The invention discloses a method for producing alcohol through liquor fermentation. The method comprises the steps of performing solid-liquid separation on liquefied starchy raw materials to obtain liquor and solid residues, and adding glucoamylase and yeast to the liquor for alcohol fermentation; adding water to the solid residues for saccharification processing, performing solid-liquid separation again to obtain sugary washing water and waste residues, wherein the sugary washing water can be used for preparation or cultivation and fermentation of the yeast, and the waste residues can be produced into fertilizers and feeds or used for biogas fermentation. According to the method, the alcohol content of prepared fermented mature mash exceeds 15.2% (v / v), the residual total sugar can be lower than 1.03%, the content of residues and starch is lower than 2.91%, and the utilization rate of starch can reach above 96.5%; the liquor obtained through mash liquidation is not easy to contaminate and does not produce high glucose suppression in a fermentation process, fermentation by-products are reduced, equipment wear can be reduced obviously, and the utilization rate and the distillation efficiency of fermentation equipment can be improved.

Owner:HENAN TIANGUAN GRP

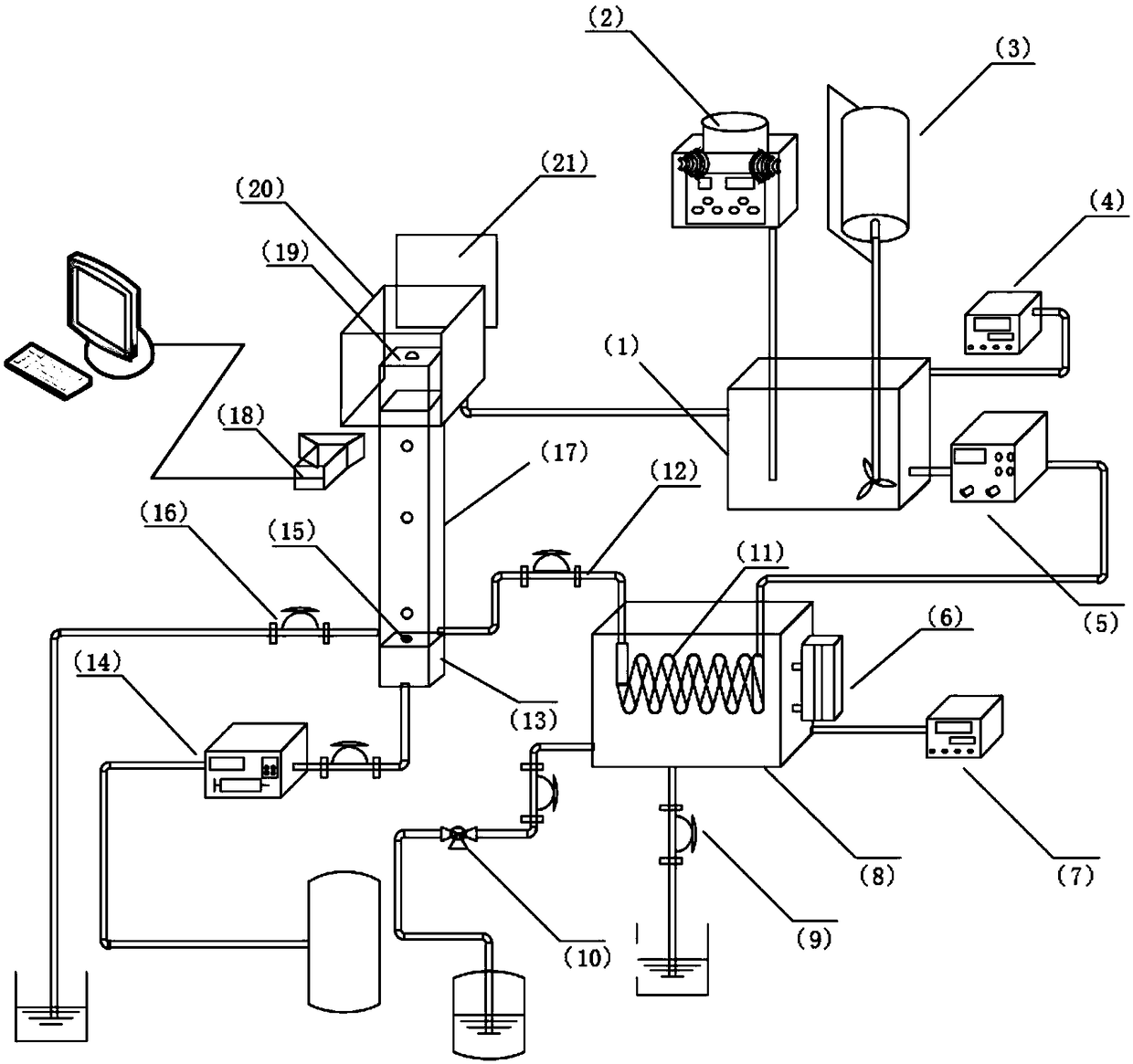

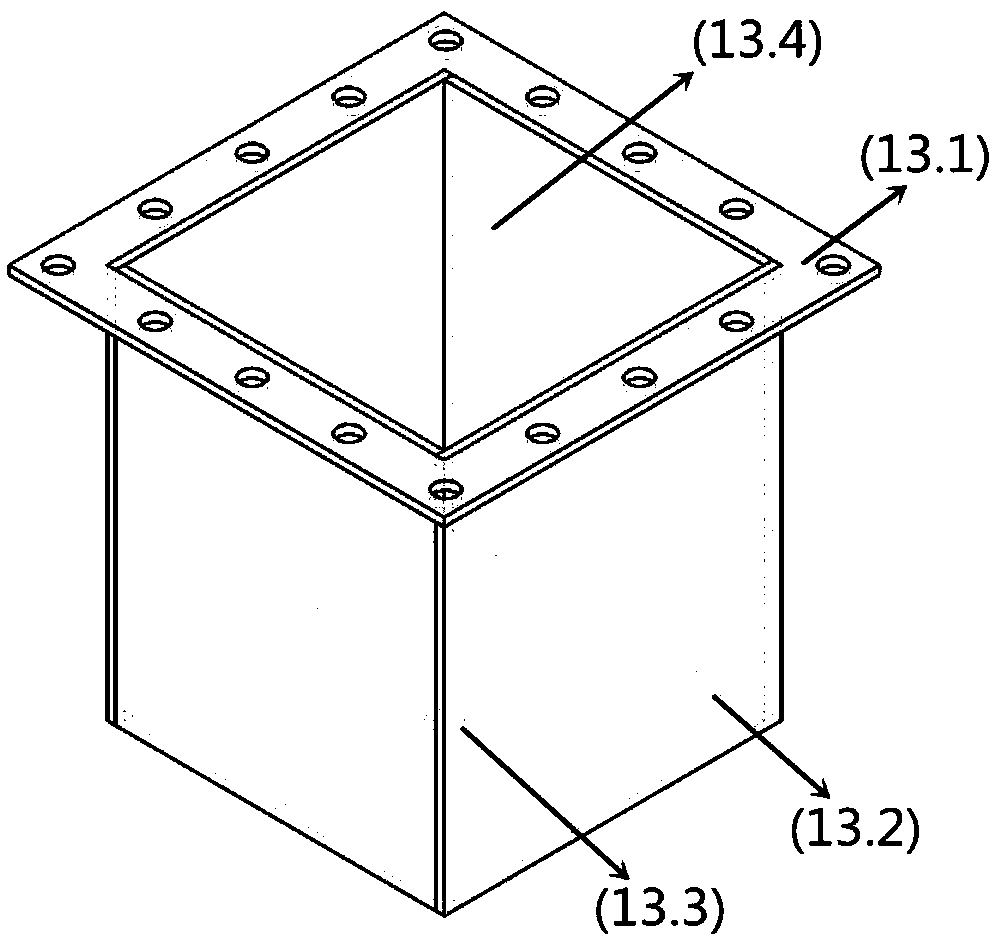

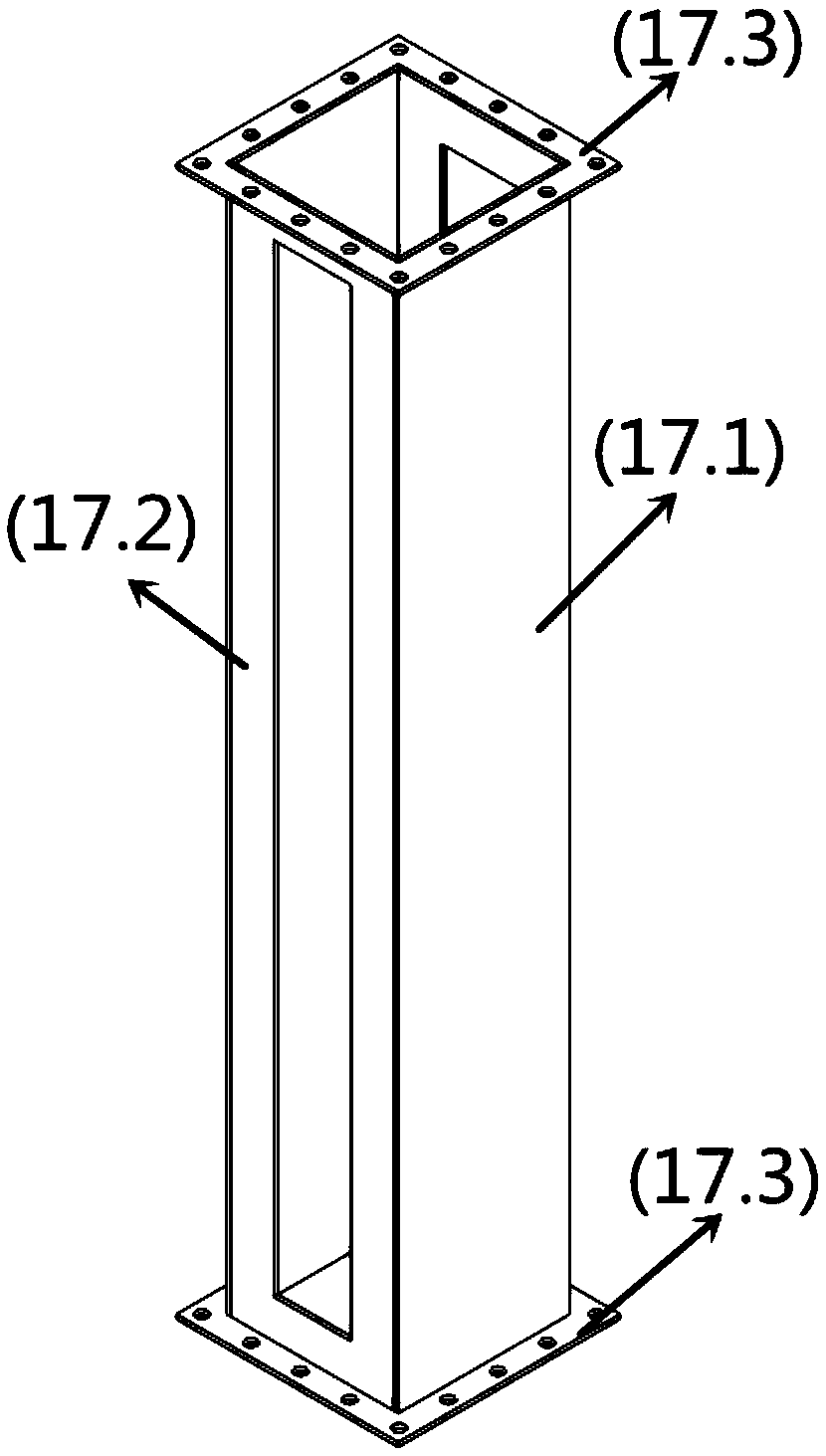

Experiment device for study characteristic of breakage behavior of aerosol-containing liquid bath surface bubble and experiment method of experiment device

ActiveCN109342492ASolve the difficulty of distinguishingSolve problems such as liquid level fluctuationsInvestigating phase/state changePeristaltic pumpNuclear power

The invention aims to provide an experiment device for study characteristics of breakage behaviors of aerosol-containing liquid bath surface bubbles and an experiment method of the experiment device.The experiment device comprises a preheating water tank, a heating water tank, an air cavity, a flash rising section, an overflowing water tank, a backflow water tank and an ultrasonic generator, wherein the lower part of the ultrasonic generator is connected with a descending tube; the descending tube extends into the preheating water tank; the bottom of the preheating water tank is communicatedwith a peristaltic pump; the peristaltic pump is communicated with a coiled tube through a hose; the coiled tube is arranged inside the heating water tank; the heating water tank is communicated witha water storage container through a water injection pipeline and a valve; the outlet of the coiled tube is communicated with the inlet of a flash section; the overflowing water tank, the flash risingsection and the air cavity are sequentially connected from top to bottom; the overflowing water tank is fixed inside the backflow water tank; the flash rising section is fixed below the backflow watertank. By adopting the experiment device, behaviors that bubbles are broken to generate liquid droplets in different liquid-phase environments at different temperatures can be measured, and entrainment behaviors of aerosol under accident working conditions of nuclear power plants can be well reappeared.

Owner:HARBIN ENG UNIV

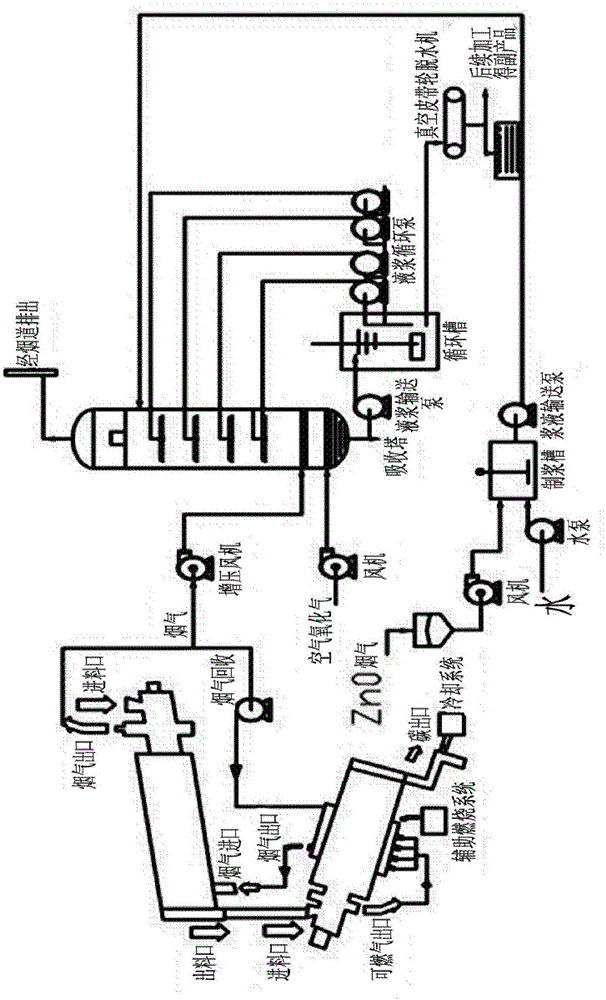

System and method for flue gas desulfurization

InactiveCN106345263AHigh-efficiency desulfurization system processIncrease oxidation rateGas treatmentDispersed particle separationSulfateFlue gas

The invention discloses a system and method for flue gas desulfurization. The method comprises the following steps: inputting flue gas to be treated to the bottom of a desulfurizing tower, inputting zinc oxide slurry from an upper section of the desulfurizing tower, and enabling the flue gas to be treated and the zinc oxide slurry to contact with each other and flow in opposite directions in the desulfurizing tower; introducing an oxidizing gas from the bottom of the desulfurizing tower to oxidize zinc sulfite, which is generated by the contact of the flue gas and the zinc oxide slurry, into zinc sulfate; and delivering the slurry after absorption of SO2 in the desulfurizing tower to the top of the desulfurizing tower for cyclic utilization. The principle is that SO2 in the flue gas reacts with zinc oxide to generate zinc sulfite, and then the zinc sulfite is oxidized into zinc sulfate by using air, thereby achieving the aim of desulfurization. The desulfurization efficiency of the system and method disclosed by the invention reaches 96% or above, no waste liquid is discharged, and the raw materials are low in price and can be used repeatedly, so that the system and the method meet requirements for clean production.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

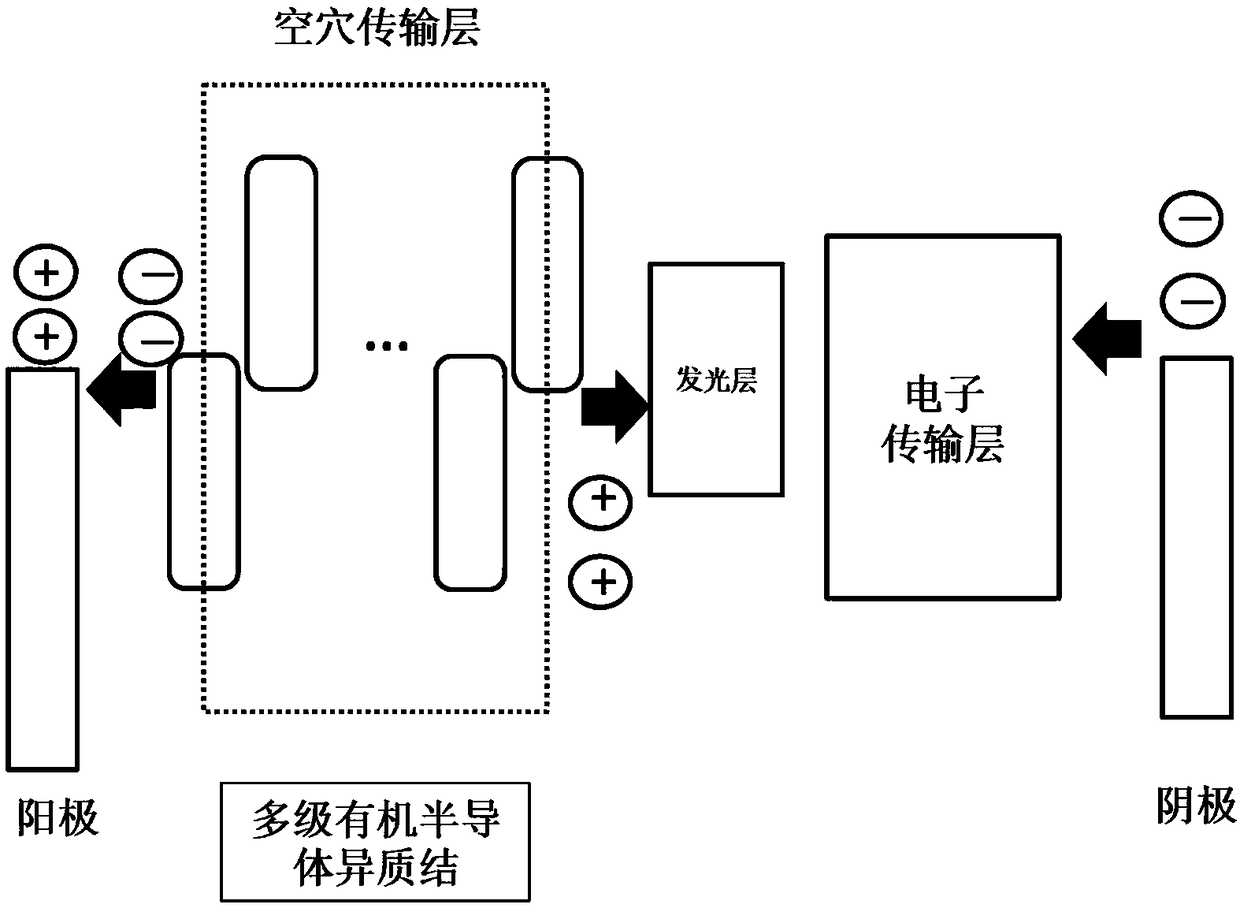

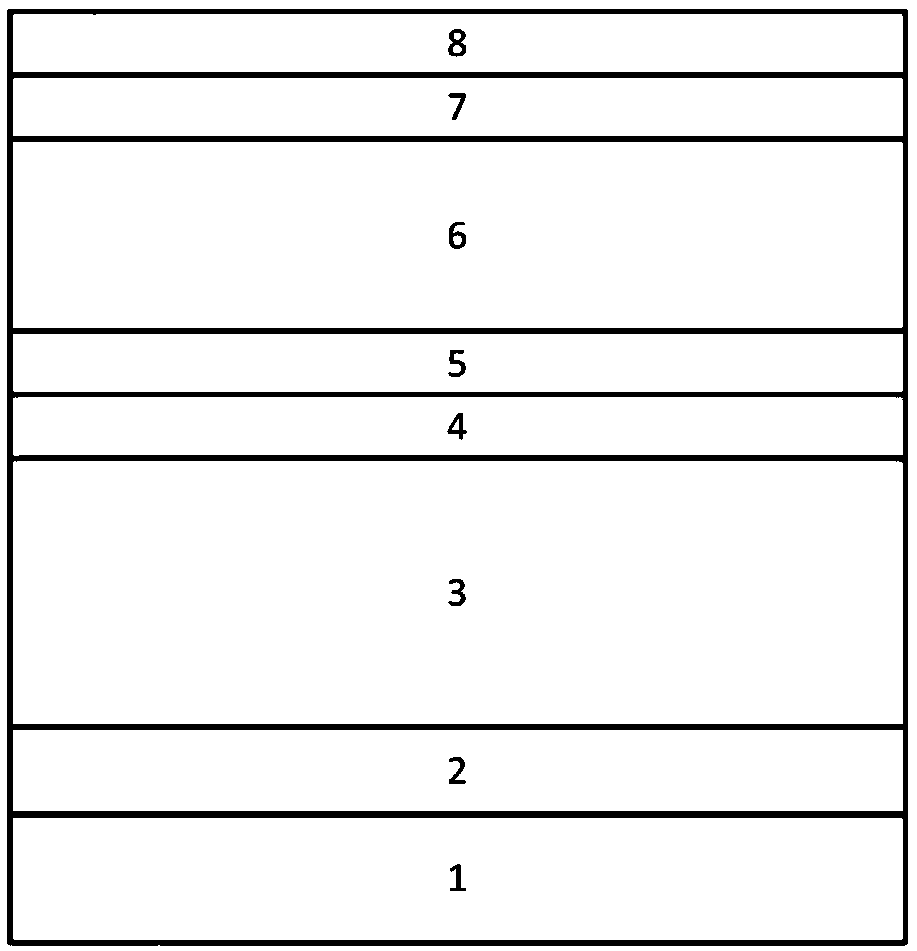

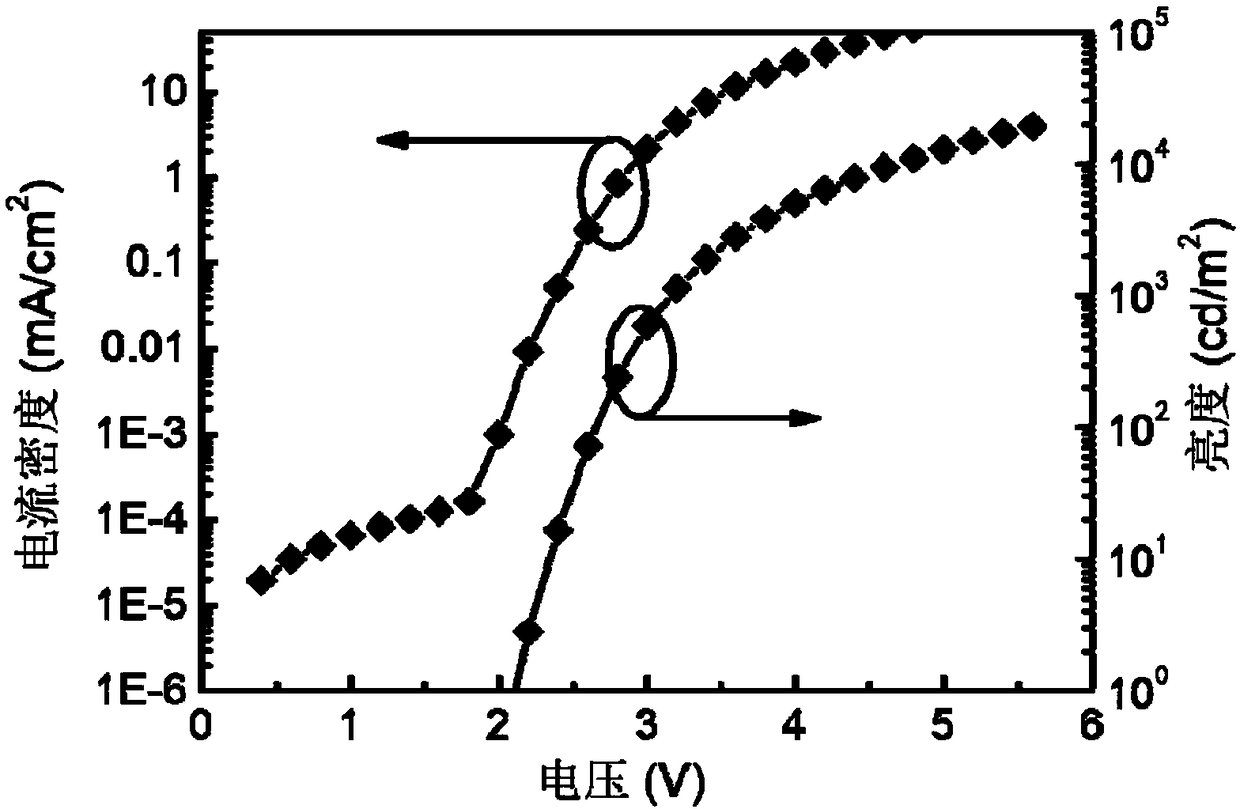

Organic light emitting diode containing multi-level organic semiconductor heterojunction

ActiveCN108666432AEfficient hole transportEfficient holeSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionSemiconductor materials

The invention belongs to the field of organic light emitting diodes, and discloses an organic light emitting diode containing a multi-level organic semiconductor heterojunction. At least one of a holetransport layer, an electron transport layer, and a charge generation layer in the organic light emitting diode containing the multi-level organic semiconductor heterojunction is formed by a multi-level organic semiconductor heterostructure, wherein the multi-level organic semiconductor heterojunction is formed by a p-type semiconductor material layer and an n-type semiconductor material layer inan alternate manner, wherein the number of layers of the p-type semiconductor material layer and the number of layers of the n-type semiconductor material layer are equal to 2 or greater. The organiclight emitting diode containing the multi-level organic semiconductor heterojunction of the invention employs the multi-stage organic semiconductor heterojunction structure, and has properties of efficient hole transport, electron transport and charge generation. The properties of efficient hole and electron transport allow it to completely replace conventional p-doped hole transport and n-dopedelectron transport.

Owner:SOUTH CHINA UNIV OF TECH

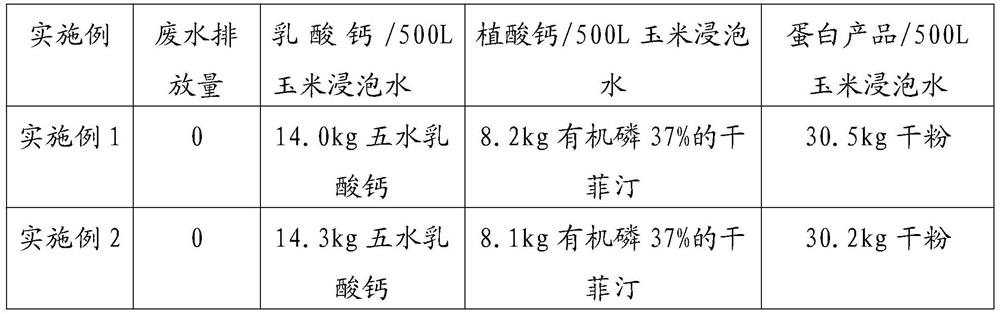

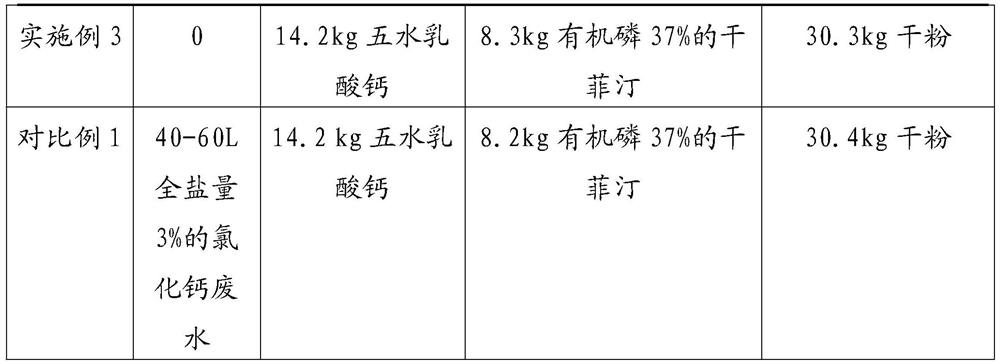

Process method for preparing calcium phytate and calcium lactate by using corn soaking water

ActiveCN113135954AThe realization of the productionTo avoidOrganic compound preparationGroup 5/15 element organic compoundsCALCIUM LACTOBIONATEEnvironmental engineering

The invention relates to the technical field of corn soaking water treatment, in particular to a process method for preparing calcium phytate and calcium lactate by using corn soaking water, which comprises the following steps: (1) settling the corn soaking water to obtain supernate, enabling the supernate to enter an anion resin column, collecting first effluent, enabling the first effluent to enter the anion resin column by using hydrochloric acid as a desorption agent, and collecting a desorption solution; (2) after the first effluent in the step (1) is filtered by a nanofiltration membrane, respectively collecting trapped fluid and permeate; (3) enabling the permeate collected in the step (2) to enter a weakly alkaline anion resin column, collecting a second effluent, enabling a calcium chloride solution as a desorption agent to enter the weakly alkaline anion resin column, and collecting a desorption solution; and (4) drying the trapped fluid in the step (2), and concentrating the second effluent collected in the step (3). According to the process method, the corn soaking water is effectively treated, the calcium phytate and the calcium lactate are obtained, and the discharge of wastewater is greatly reduced.

Owner:ZHUCHENG HAOTIAN PHARMA

Synthetic method of L-aminopropanol

InactiveCN101648879BHigh yieldReduce generationOrganic compound preparationAmino-hyroxy compound preparationOrganic solventRuthenium

The invention provides a preparation method of L-aminopropanol, using L-alanine and H2 as main raw materials and carbon ruthenium as a catalyst to carry out direct catalytic hydrogenation to synthesize the L-aminopropanol. The method increases the selectivity of process reaction, accelerates reaction speed and shortens reaction step, thereby greatly reducing the production cost, increasing the L-aminopropanol yield, reducing the production of harmful wastes and realizing the greenization of the reaction process; and the aspects of energy saving and emission reduction of SOD and SO2 are obviously improved in order to realize less environment pollution. Any organic solvent is not added to the whole reaction process, thereby reducing the emission of pollutants, and protecting environment.

Owner:浙江凯迪药业有限公司

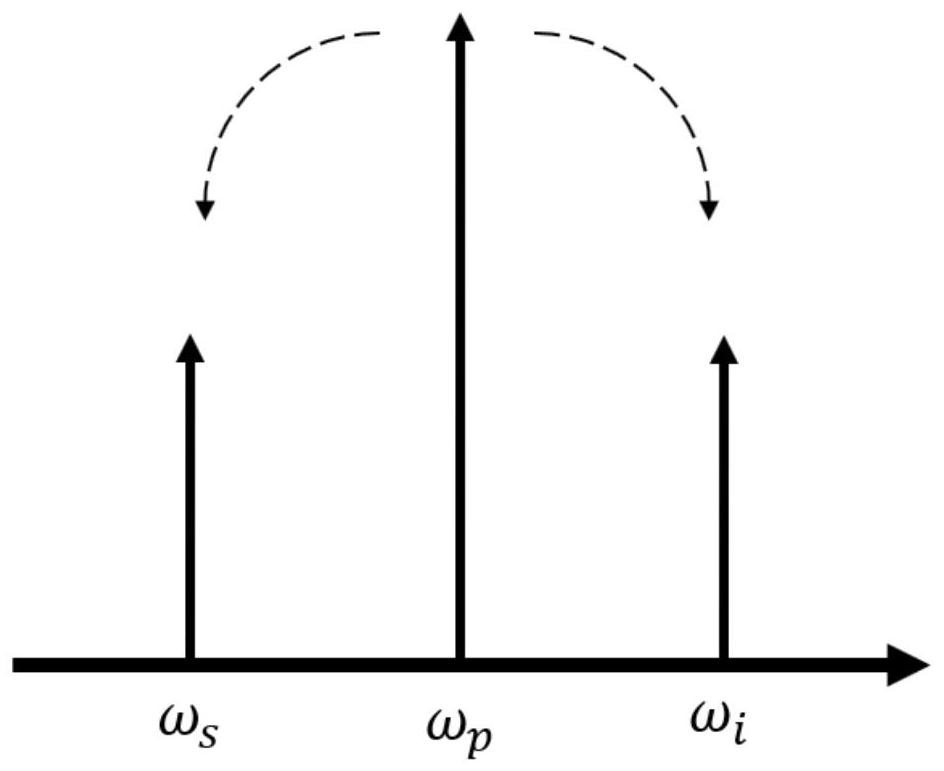

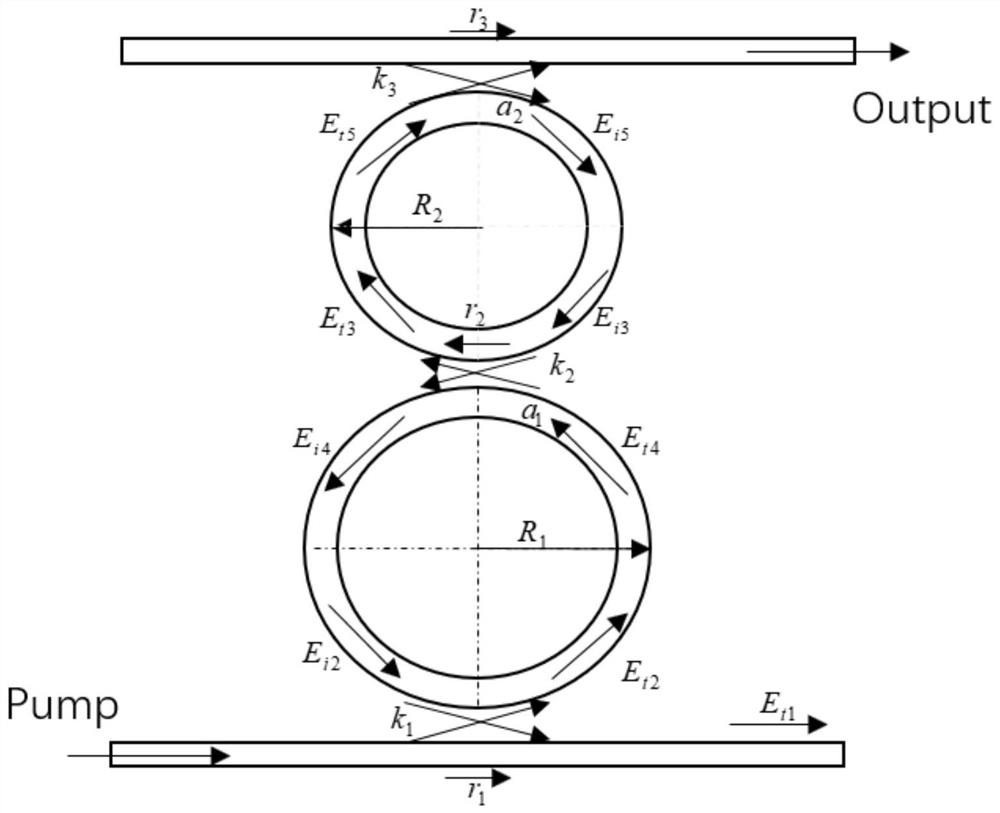

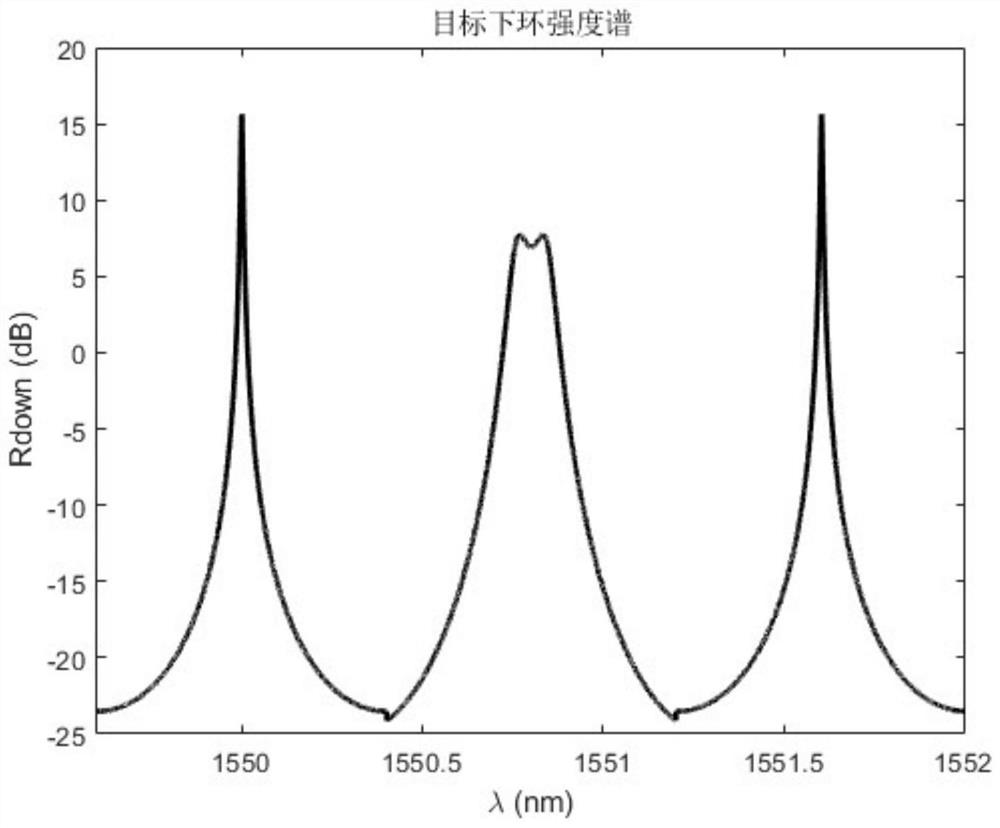

System and method for generating spectral de-entanglement photon pairs

PendingCN114675465AAchieve disentanglementSmall structureNon-linear opticsLight sourceResonant cavity

The invention provides a system and a method for generating spectral de-entanglement photon pairs. The first micro-ring resonant cavity and the first waveguide are in a critical coupling state; the radius of the first micro-ring resonant cavity is an integral multiple of the radius of the second micro-ring resonant cavity; the first micro-ring resonant cavity is used for resonance of pump light, and the resonance of the pump light automatically generates photon pairs at the wavelengths of signal light and idler frequency light under the effect of spontaneous four-wave mixing; the generated signal photons and idler frequency photons are generated at the wavelength corresponding to the resonance peak of the first micro-ring resonant cavity; the wavelength of the pump light is the wavelength corresponding to the resonance peak of coupling of the first micro-ring resonant cavity and the second micro-ring resonant cavity. When pulse pumping is used, when the width of a resonance peak of pumping light is larger than that of resonance peaks of signal light and idler frequency light, entanglement correlation of generated photon pairs can be removed in frequency, and pure-state single photons are generated. According to the quantum light source, the resonance peak of the quantum light source based on the micro-ring resonant cavity is regulated and controlled, so that the effect of generating spectrum de-entanglement photon pair emission is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

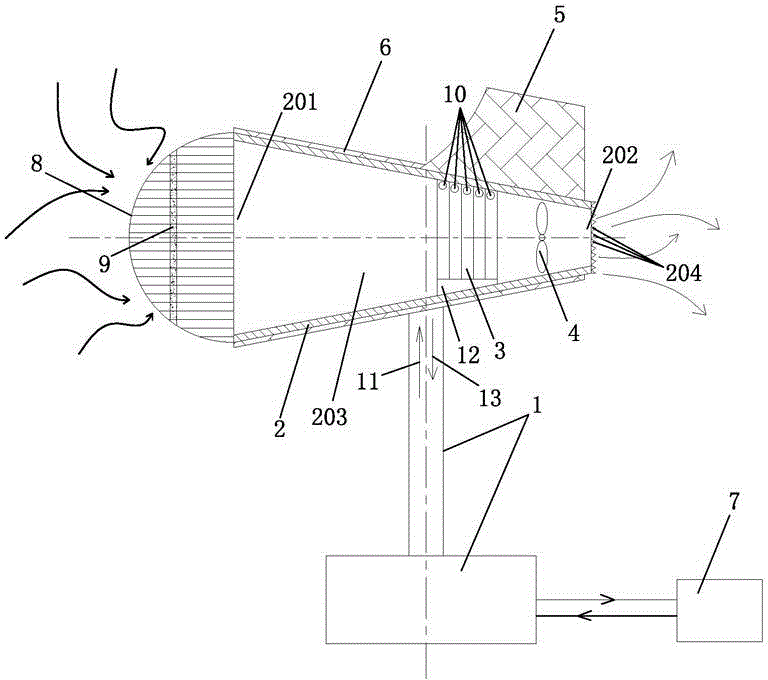

Travelling wave tube based X-ray communication device

ActiveCN110085497AThe realization of the productionSolve communication problemsTravelling-wave tubesX-ray tube electrodesElectricityX-ray

The invention relates to a travelling wave tube based X-ray communication device, and belongs to the fields of electric vacuum devices and communication. In the process that an aerospace vehicle crosses a blackout zone of the aerosphere, the device modulates electron flow of a bombardment X-ray target in a travelling wave tube signal modulation manner, X ray signals are modulated and used for X ray communication, the problem that the blackout zone shields microwave signals is overcome, effective technical means is provided for communication in the blackout zone, and the device has significancein reducing the volume, weight and power consumption of the load.

Owner:SOUTHEAST UNIV

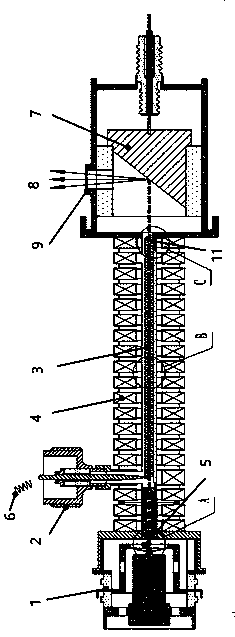

Method for simultaneously and comprehensively recycling zinc ash and high-arsenic zinc oxide in iron and steel plant

The invention provides a method for simultaneously and comprehensively recycling zinc ash and high-arsenic zinc oxide in an iron and steel plant. A great deal of iron in the zinc ash is recycled by using unsaturated fatty acid (saponified) and tea saponin intermixture in tea-oil dregs in a flotation manner; the zinc ash (subjected to flotation) and the high-arsenic zinc oxide in the iron and steel plant are respectively leached by using sulfuric acid; As<3+> in the high-arsenic zinc oxide is rapidly oxidized by using peroxy-sodium carbonate; corresponding indissolvable arsenate is generated after As<3+> is oxidized into As<5+> in the presence of Fe<3+> and Fe<2+>, and arsenic in the solution is eliminated by virtue of a secondary arsenic elimination method; zinc powder is purified to generate zinc sulfate, and the purpose that two varieties of waste slags are simultaneously and comprehensively recycled is achieved.

Owner:HENGYANG NORMAL UNIV

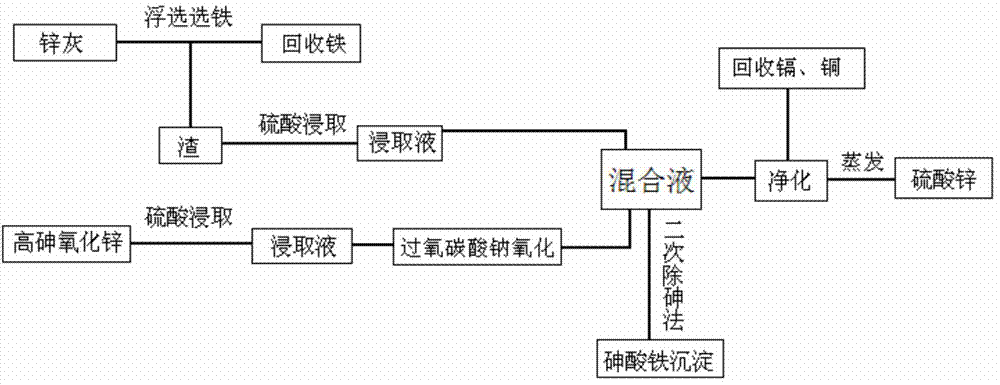

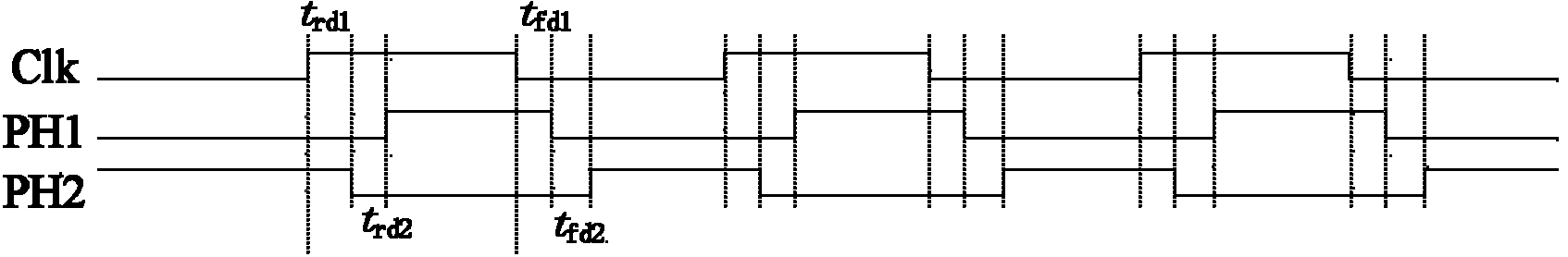

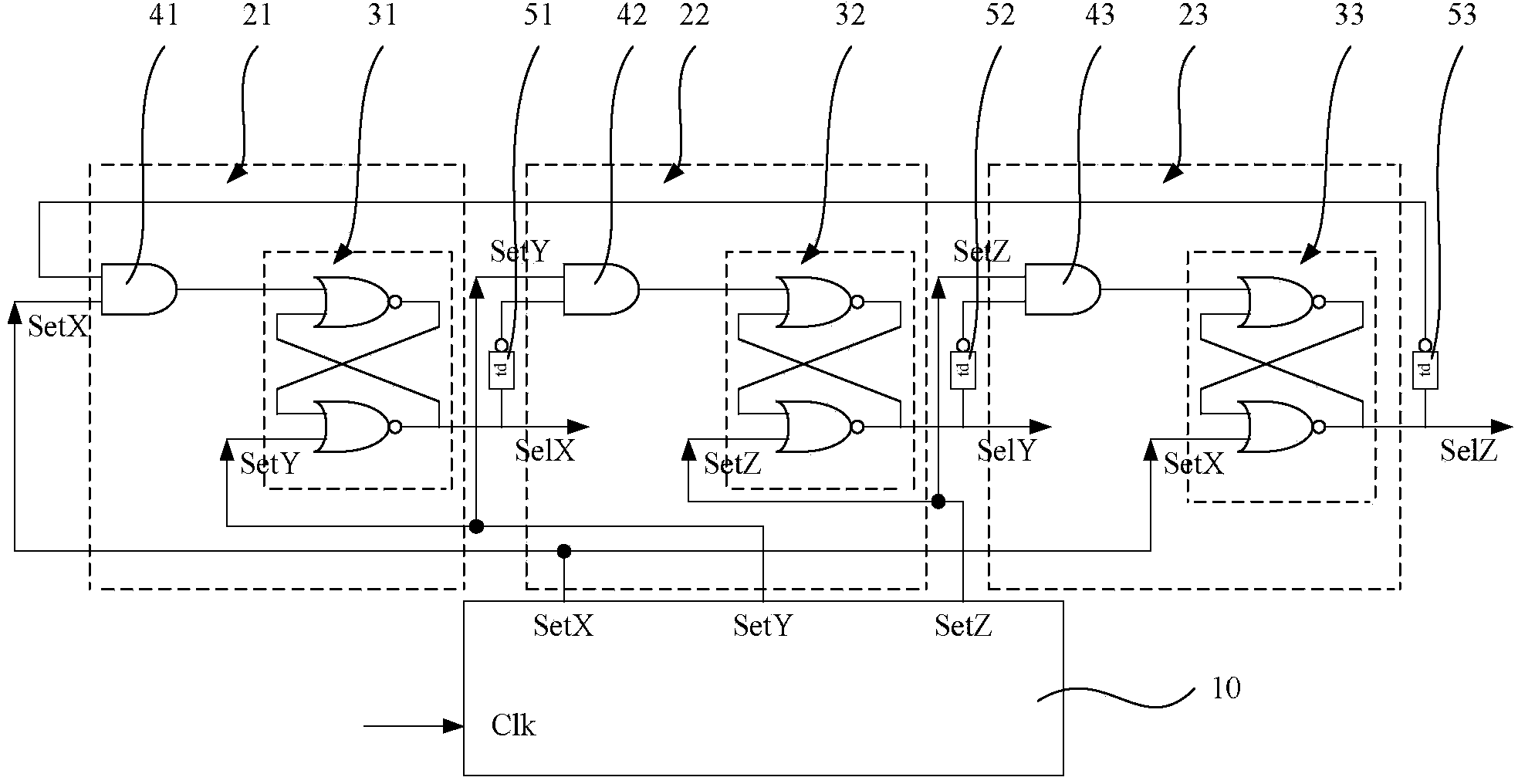

Non-overlapping clock generation circuit

ActiveCN103647528AThe realization of the productionElectric pulse generator circuitsFinite-state machineThree-phase

The invention provides a non-overlapping clock generation circuit. The circuit comprises a finite-state machine and n trigger circuits which are connected with the finite-state machine. The finite-state machine can successively generate n driving clocks according to a basic clock, wherein the n driving clocks are a first driving clock, a second driving clock,..., and a nth driving clock. The n trigger circuits are a first trigger circuit, a second trigger circuit,..., and a nth trigger circuit. Each trigger circuit comprises an AND gate and a trigger. An output terminal of the AND gate is connected with a setting terminal of the trigger. Through the finite-state machine, according to the basic clock, the n driving clocks are generated. Each trigger circuit generates a non-overlapping clock through accessing the driving clocks and an inversion signal of an output signal of the previous trigger circuit. Therefore, generation of the more than three-phase non-overlapping clock is realized.

Owner:HANGZHOU SILAN MICROELECTRONICS

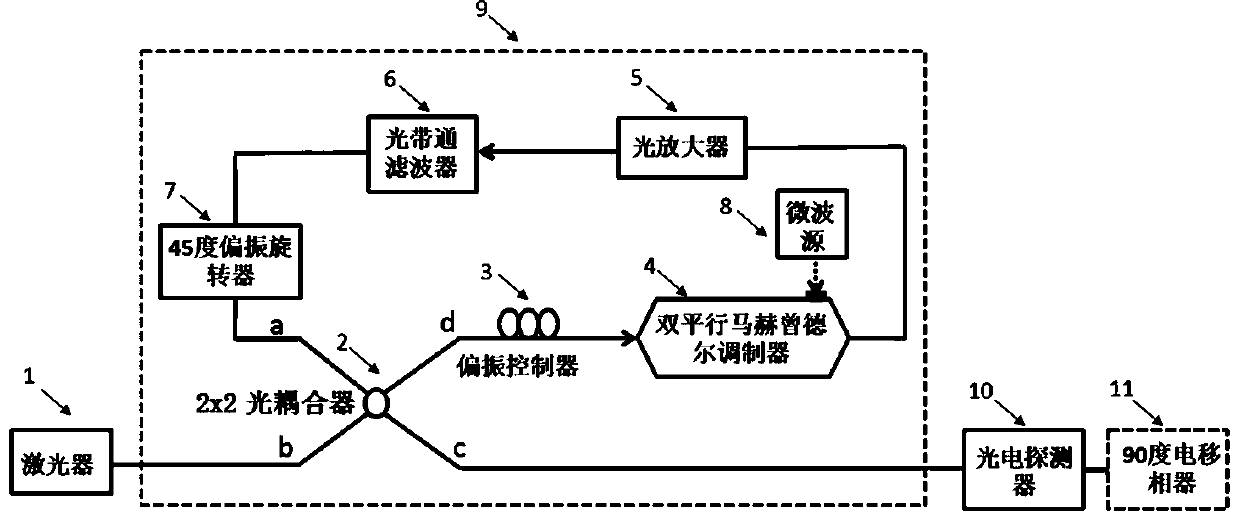

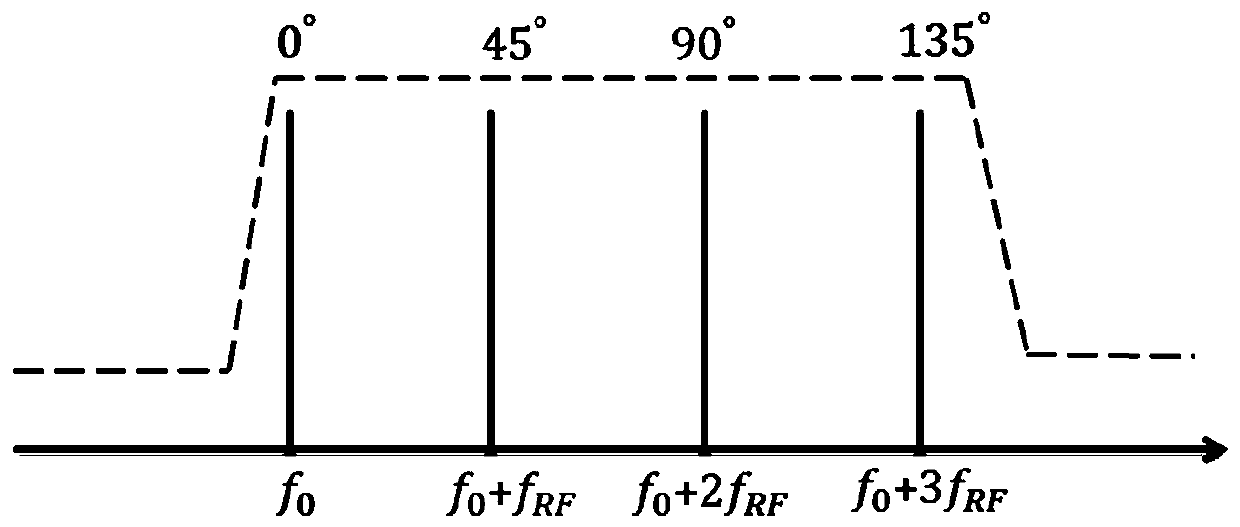

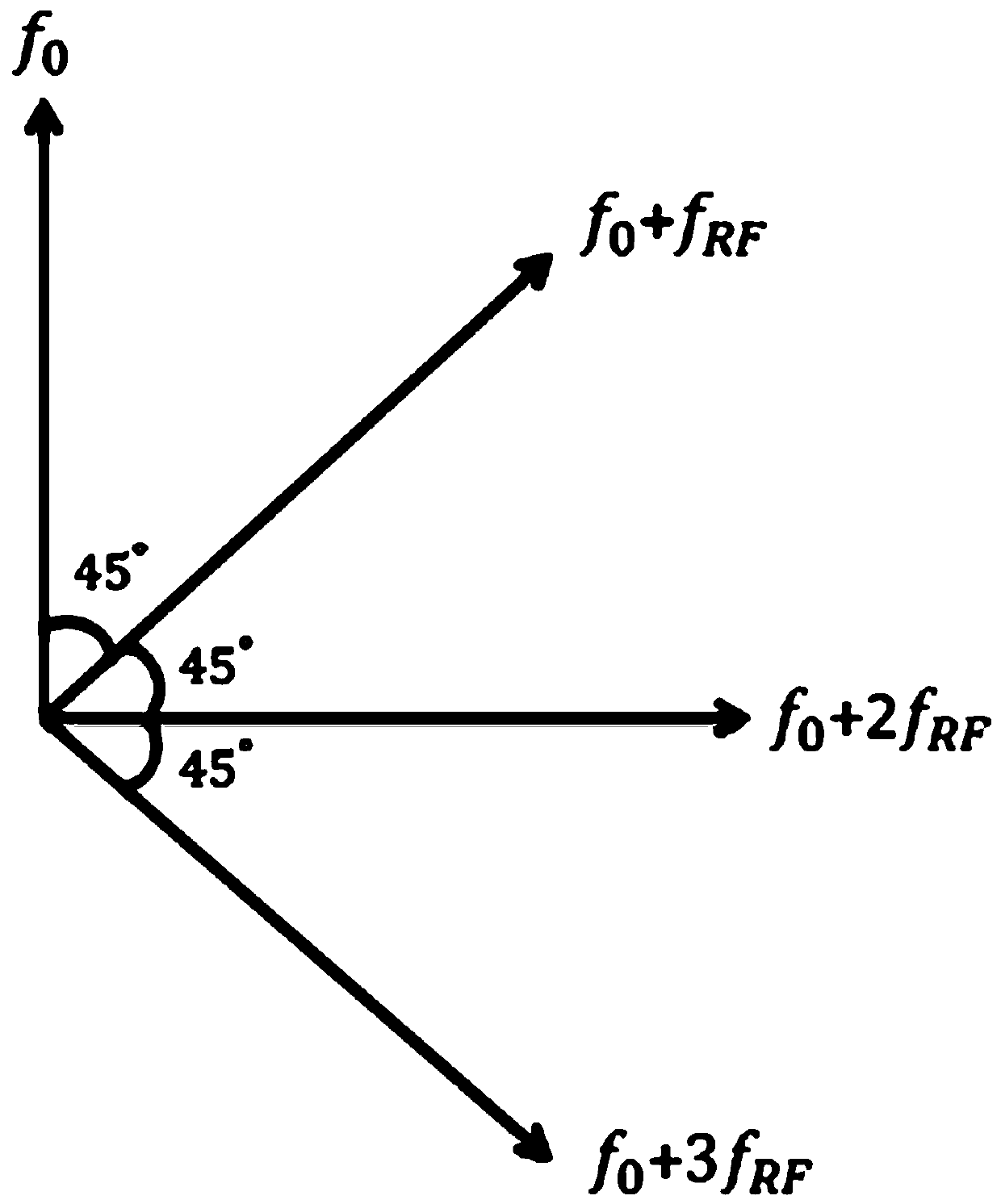

Microwave photon waveform generation device and method based on cyclic frequency shift

ActiveCN111193548APure productionThe generation of tunableElectromagnetic transmittersPhotovoltaic detectorsEngineering

The invention relates to a microwave photon waveform generation device based on cyclic frequency shift. The device comprises a laser, a cyclic frequency shift module, a photoelectric detector and a 90-degree electric phase shifter; the laser is optically connected with a light input port b of the cyclic frequency shift module, a light input port of the photoelectric detector is optically connectedwith a light output port c of the cyclic frequency shift module, and the 90-degree electric phase shifter is electrically connected with an output port of the photoelectric detector. The invention provides a microwave photon waveform generation device and a microwave photon waveform generation method based on cyclic frequency shift, which can realize waveform generation of a broadband tunable microwave signal of which a second-order harmonic component is completely suppressed.

Owner:苏州枫桥光电科技有限公司

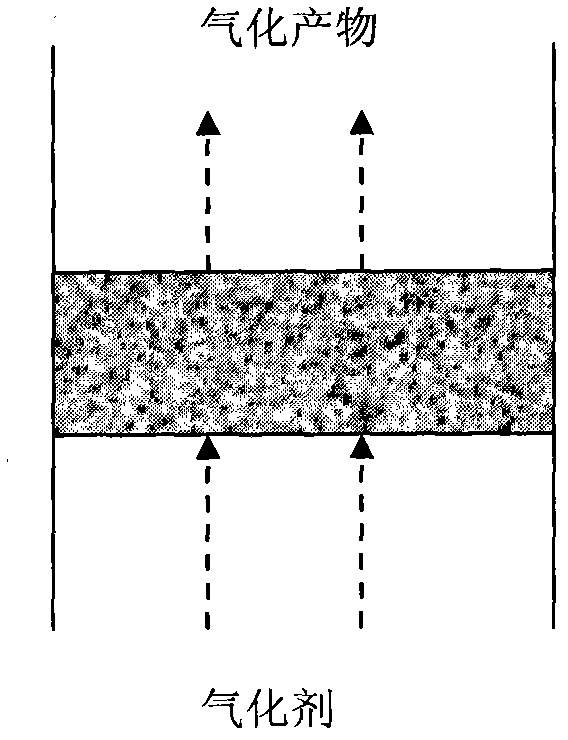

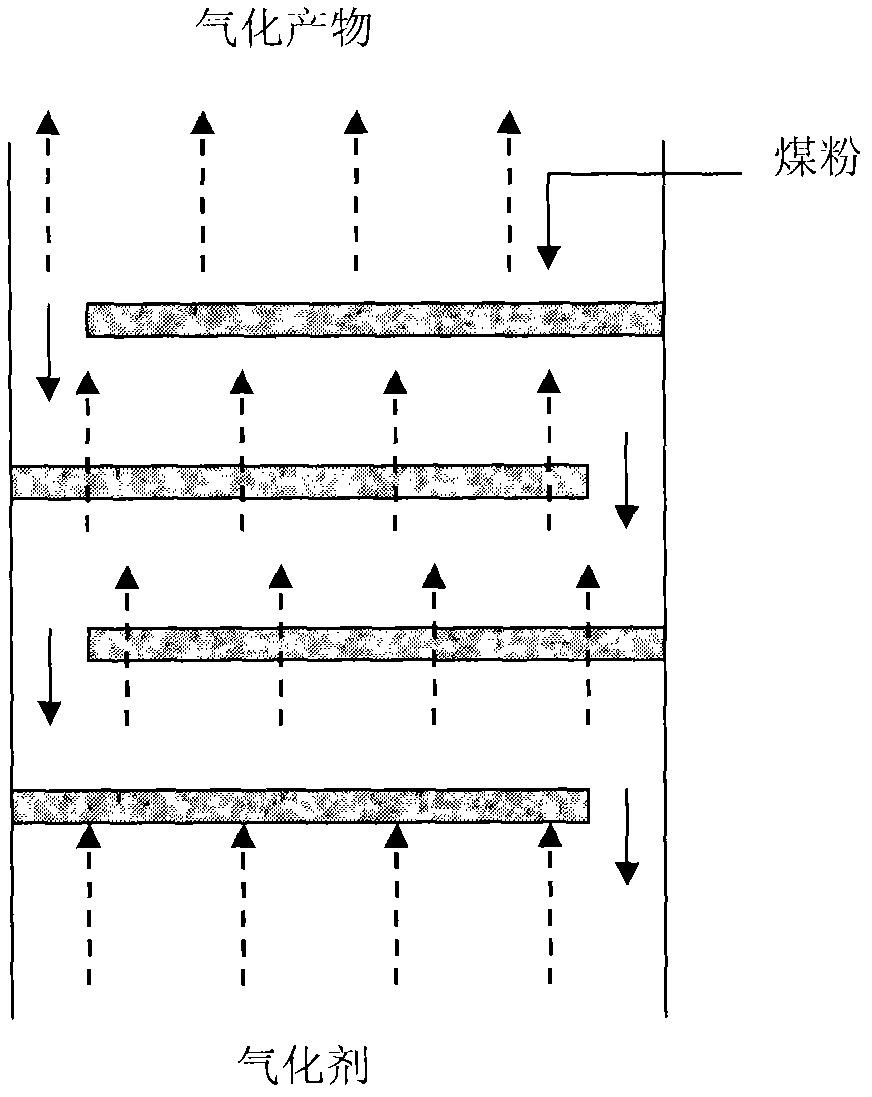

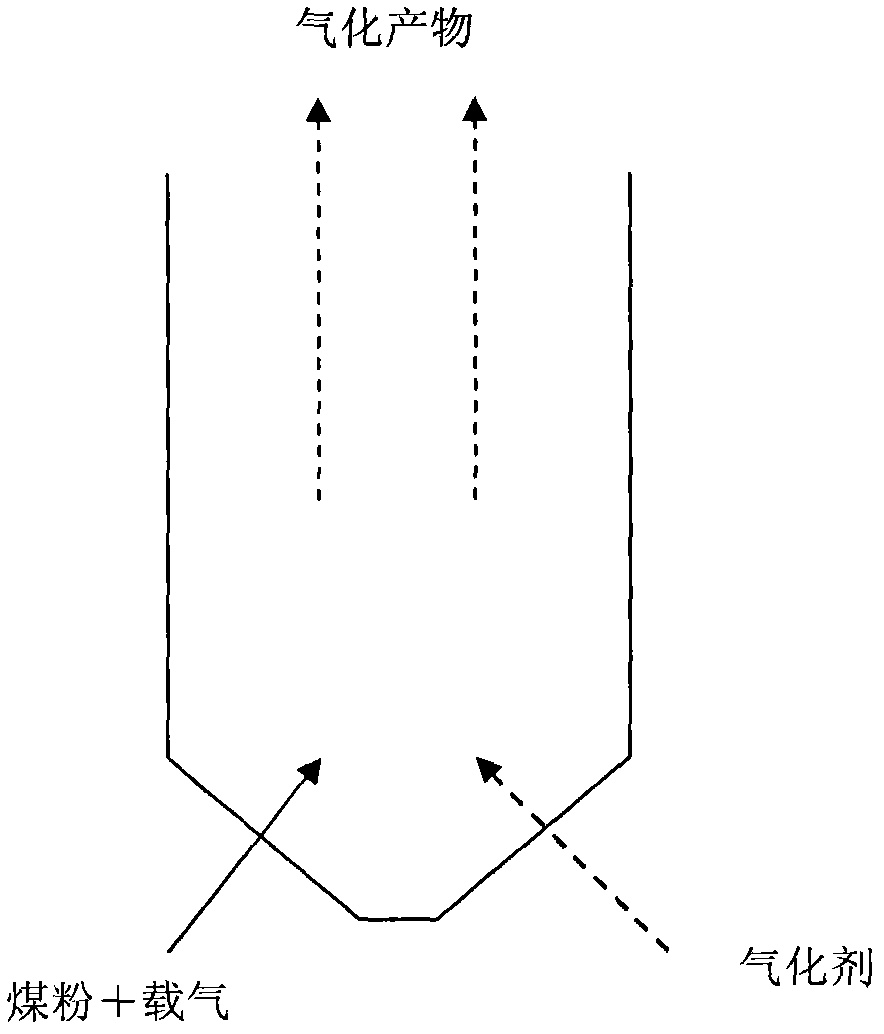

Coal gasification method

The invention discloses a coal gasification method which comprises the step of enabling coal powder to contact a first gas flow flowing in a first runner to obtain a first product flow containing a first gas product and semi-coke, wherein the temperature of the first gas flow is T1 which is at least 900 DEG C, when the contact occurs, the difference of superficial velocities of the first gas flow and the coal powder on the macro flowing direction of the first gas flow is more than 10m / s, the first gas flow can be flame, combusting smoke, water vapor, air, oxygen, plasma, inert gas or a mixture of flame, combusting smoke, water vapor, air, oxygen, plasma and inert gas, and the first gas product comprises synthesis gas and / or acetylene and / or methane.

Owner:赵庆晨

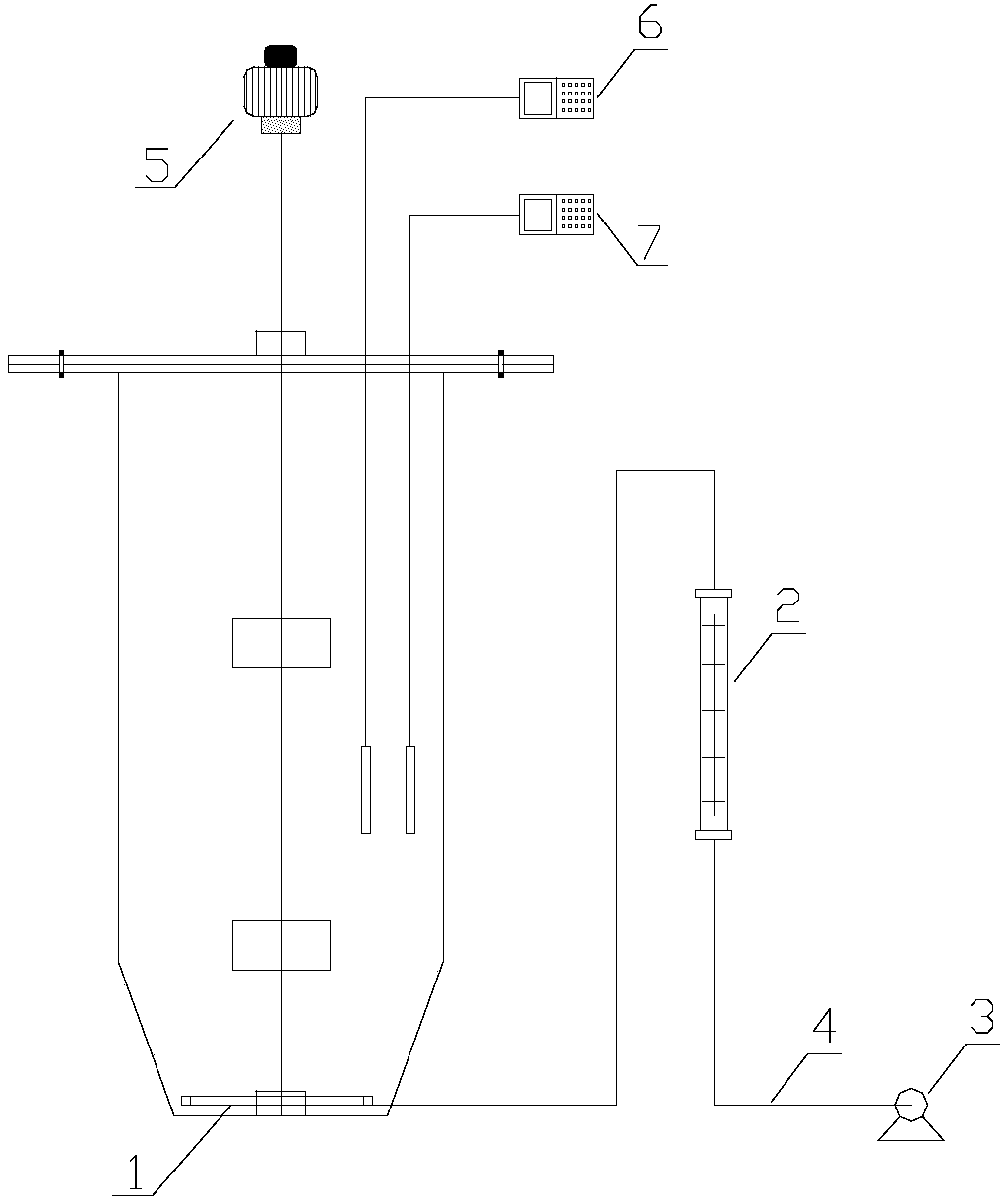

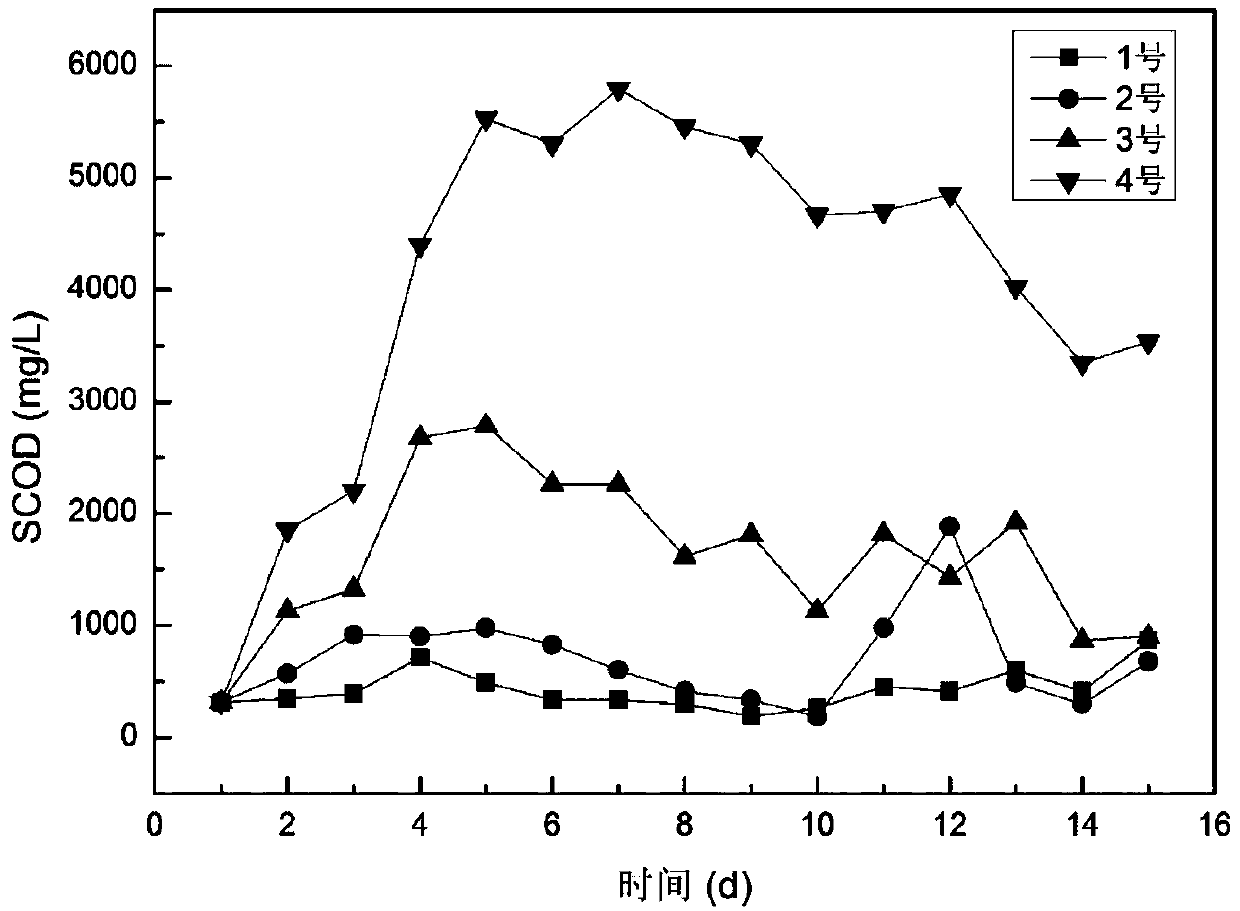

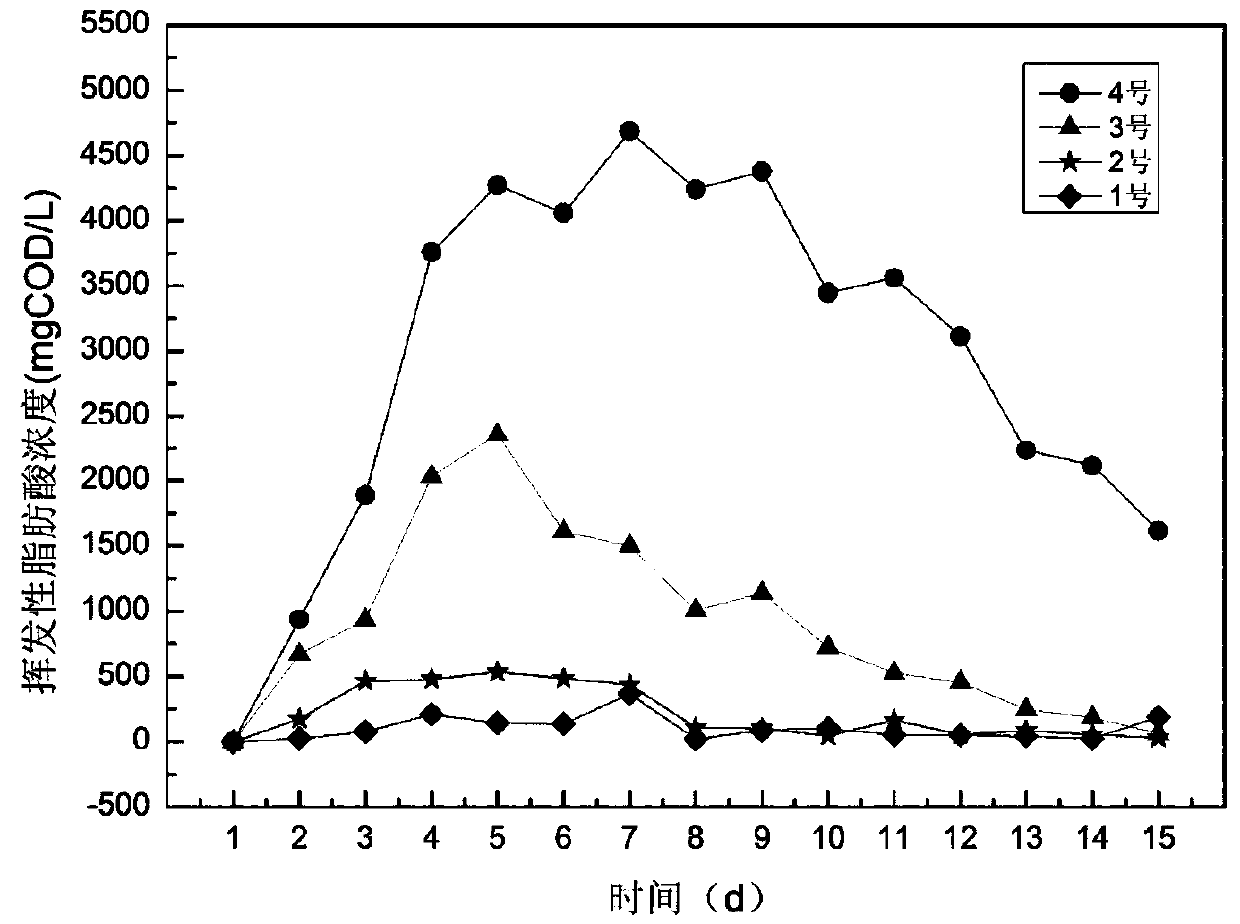

Method for producing volatile fatty acid by normal-temperature low-oxygen digestion of yeast reinforced excess activated sludge

InactiveCN108046554APromote degradationImprove biodegradability and digestion rateBiological sludge treatmentBiological water/sewage treatmentMunicipal sewageCarbon source

The invention provides a method for producing volatile fatty acid by normal-temperature low-oxygen digestion of yeast reinforced excess activated sludge and belongs to the technical field of treatmentof municipal sewage and sludge. Aiming at the problem of insufficient accumulation of volatile fatty acids in an excess sludge digestion process, a yeast inoculation method is adopted during initialsludge digestion, macromolecular organic substances in sludge are degraded by rich enzyme systems of the yeast, and production of volatile fatty acids is promoted. Cheap and easily available yeast isadopted in the method, the yield of volatile fatty acids is increased substantially, and when the concentration of the yeast is 10 g / L, the highest concentration of volatile fatty acids is 10-12 timesthe concentration of volatile fatty acids without the yeast. A digestion product rich in volatile fatty acids is used as an organic carbon source of function microbes for removing nitrogen and phosphorus from the sewage, sludge reduction and recycling are realized, the problem of insufficient carbon source of a municipal sewage treatment plant in a biological nitrogen and phosphorus removal process is solved, cost for feeding an external carbon source is saved, and the nitrogen and phosphorus removal effect of the sewage treatment plant is improved.

Owner:BEIJING UNIV OF TECH

Digital modulation signal source based on microwave photon technology

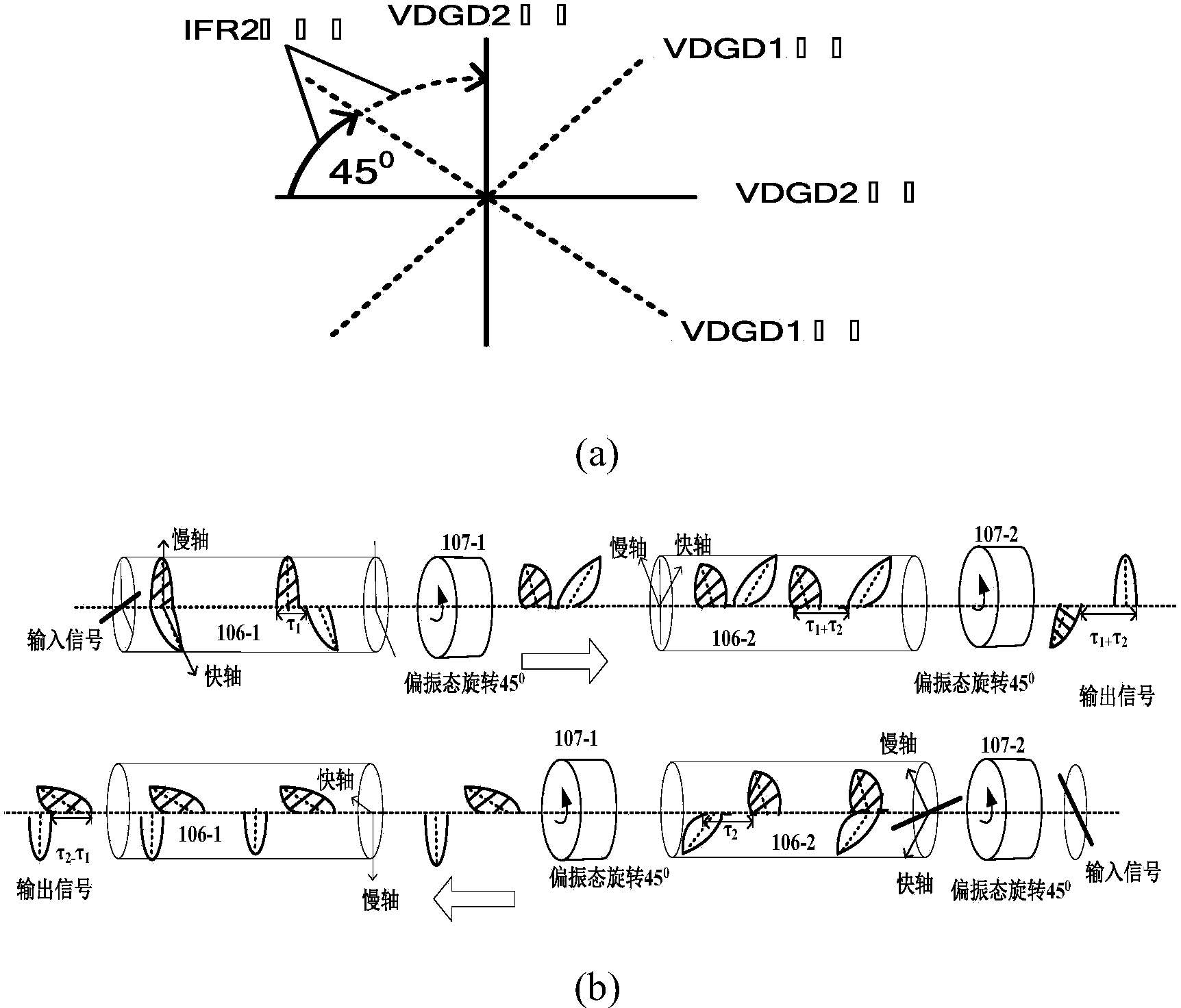

InactiveCN103986526ALarge tunable rangeIncrease flexibilityElectromagnetic transmissionPhysicsLinear polarization

The invention discloses a digital modulation signal source based on a microwave photon technology. In a digital modulation signal source composed of a mode locked laser 101, a luminous intensity modulator 102, a light polarization modulator 103, a tunable polarization correlation light comb filter 111, a tunable light band pass filter 108, a linearity dispersion medium 109 and a photoelectric detection unit 110, the tunable polarization correlation light comb filter 111 is formed by connecting a light circulator 104, a polarization beam splitter 105, programmable polarization mold dispersion units 106-1 and 106-2, and 45-degree Faraday rotators 107-1 and 107-2 in a specific mode, such that independent tunable comb filtering can be performed on mutually vertical linear polarization states, digital modulation signals with different modulation rates, different carrier wave frequencies, different modulation modes and different duty ratios are generated, and the digital modulation signal source can be applied to multiple important fields such as the transmitting end of a super-speed network, a radio-on-fiber system, a military radar and the like.

Owner:闫连山 +1

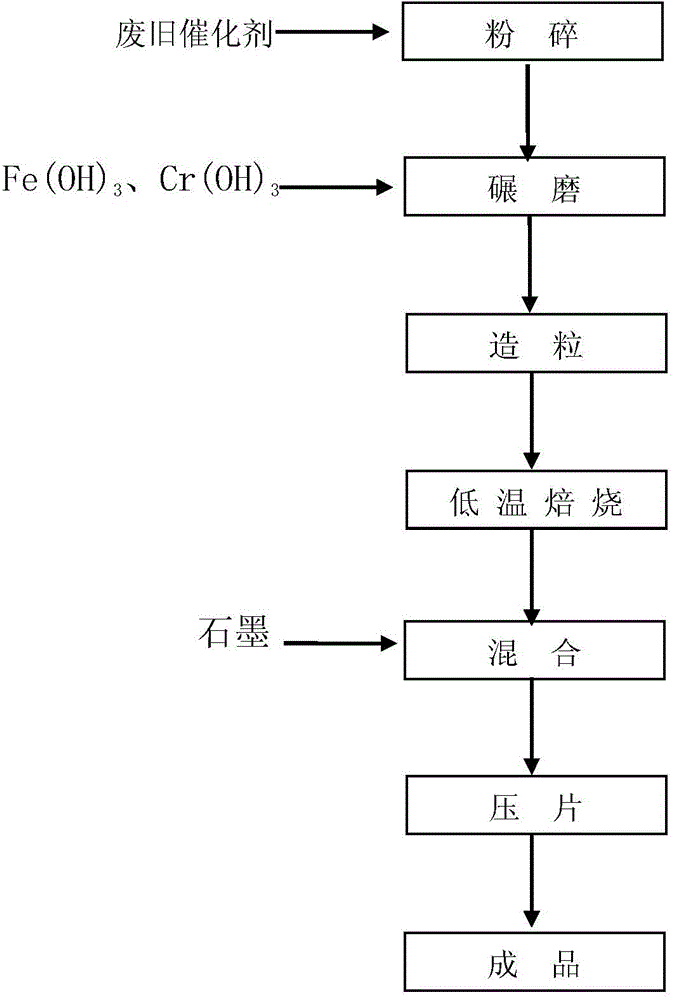

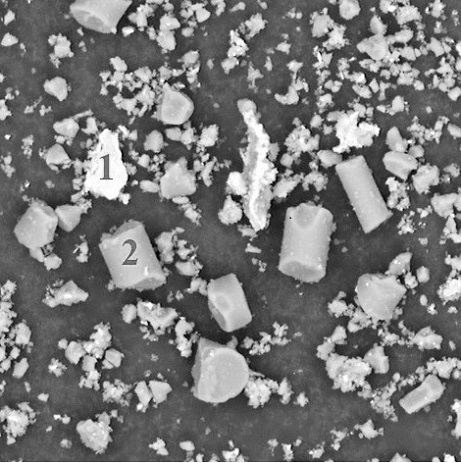

Recycling method for waste CO sulfur-tolerant shift catalysts

ActiveCN104353471AImprove sulfur resistanceNo secondary pollutionHydrogenPhysical/chemical process catalystsChemical industryResource utilization

The invention relates to a recycling method for waste CO sulfur-tolerant shift catalysts. The recycling method comprises the following steps: crushing the waste CO sulfur-tolerant shift catalysts, milling the crushed waste CO sulfur-tolerant shift catalysts, Fe(OH)3 and Cr(OH)3 together for 1-2 hours to be made into particles through a 8-mesh screen cloth, roasting the particles for 6-8 hours at the low temperature of 250-300 DEG C, cooling the roasted particles, and then tabletting and shaping the cooled particles to obtain CO high-temperature shift catalysts. Through detection according to the national chemical industry standard HG / T 3546-2011, all the performance indexes are much higher than quality technology requirements of B116 type CO high-temperature shift catalysts which are sold in the market. Through the adoption of the recycling method, the resource utilization rate of the waste CO sulfur-tolerant shift catalysts reaches 100%, sulfur in waste catalysts does not need to be removed, SO2 waste gas, NO waste gas and NO2 waste gas are not generated in the whole recovery process, and waste liquid and waste residues are not generated, so that the purposes of zero secondary pollution and zero new 'three wastes' are really realized, and not only are molybdenum sources saved, but also the recycling method is environmental-friendly.

Owner:湖北双雄催化剂有限公司

Method and system for recycling photovoltaic modules

ActiveCN110571306BWon't happenThe realization of the productionWaste processingSolid waste disposalResource recoveryBusbar

The invention discloses a method and system for recycling photovoltaic components. The method includes the following steps: removing the frame, the junction box and the glass panel on the photovoltaic module to obtain the preliminary material; cutting the preliminary material to obtain the preliminary material fragment; placing the preliminary material fragment in the Stripping is carried out in a peeling device equipped with a rotary hitting mechanism to obtain a mixture of EVA film fragments, backplane fragments, bus bar fragments, welding ribbon fragments and silicon powder; Board fragments, busbar fragments, and ribbon fragments. The method for dismantling and recycling backplanes, EVA, battery sheets and complete glass of the present invention has the advantages of high dismantling and recycling efficiency, low energy consumption, no environmental pollution, etc., greatly reduces resource waste and waste discharge, and reduces recycling cost, is an environmentally friendly resource recovery method.

Owner:YINGLI ENERGY CHINA +1

Ring Fiber with Asymmetric Grating and Its Application in Orbital Angular Momentum Generation

ActiveCN107462948BEfficient separationCrosstalk ignoreCladded optical fibreOptical waveguide light guideGratingWavelength

The present invention proposes a ring-shaped optical fiber with an asymmetric grating and its application in orbital angular momentum generation. Hollow-core ring fiber can increase the effective refractive index difference between quasi-degenerate modes, thereby avoiding crosstalk between modes. The long-period grating inscribed on the half-ring of the hollow-core ring fiber breaks the circular symmetry structure of the fiber and realizes conversion between angular modes of non-same order. When the input light is a circularly polarized fundamental mode, a first-order orbital angular momentum mode can be generated. The hollow core of the hollow-core ring fiber is filled with optical functional materials with adjustable refractive index. The wavelength that generates the orbital angular momentum mode can be tuned by the refractive index of the liquid. Therefore, this structure can generate the orbital angular momentum mode within an adjustable broadband wavelength range. The simulation shows that when the grating period is 292μm and the grating length is 1.460cm, the angular momentum mode conversion rate is higher than 90% in the broadband wavelength range up to 237nm, and the maximum conversion rate is 98.91%. The refractive index of the filled liquid has an impact on the orbital angular momentum mode. The wavelength modulation rate is 7400nm / RIU.

Owner:NORTHEASTERN UNIV LIAONING

Method for preparing nano copper conductive ink

ActiveCN101880493BGood dispersionCharacteristic peaks are obviousInksNon-conductive material with dispersed conductive materialOrganic solventRoom temperature

The invention discloses a method for preparing nano copper conductive ink, which can be applied in the field of printing electronic technology, in particular ink jet printing technology. The preparation method comprises the following steps of: dissolving copper salt and protective agent into a solvent, heating and stirring the solution, adding a small amount of alkali solution to adjust the pH of the solution to between 7 and 10, dripping a reducing agent into the solution, continuously stirring the solution to react for 30 to 60 minutes, and then cooling the reaction solution to room temperature to obtain nano copper dispersion; performing centrifuging, washing and vacuum drying at room temperature on the nano copper dispersion to obtain nano copper granules; and dispersing the nano copper granules into an organic solvent, and ultrasonically treating the solution to obtain the nano copper conductive ink. The method solves the problems of complex preparation process and long preparation period in the prior art, has the advantages of simple and convenient operation, low production cost, short flow and no harmful waste generation, and realizes the goals of environmental protection and economy; and the prepared nano copper conductive ink has good dispersion property and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

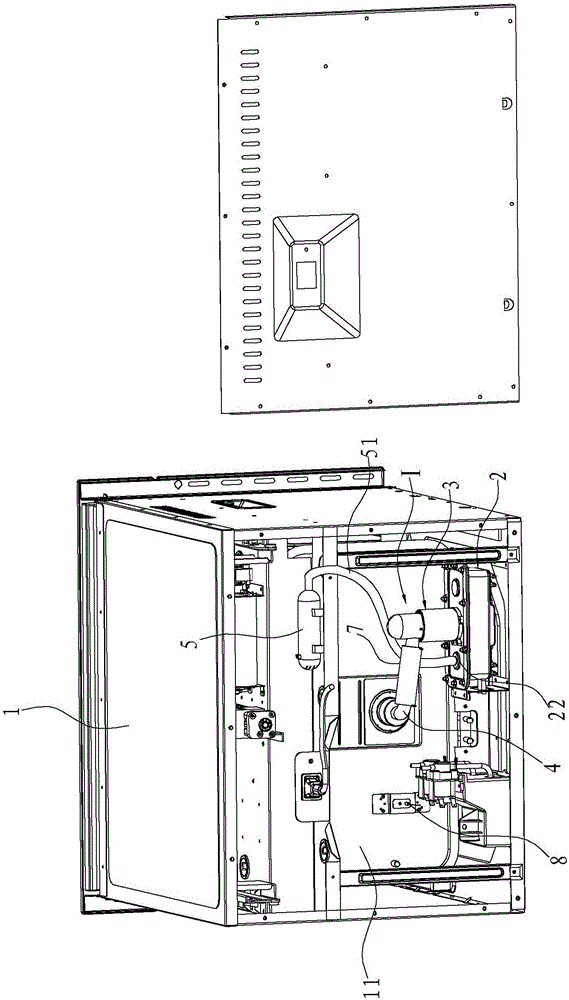

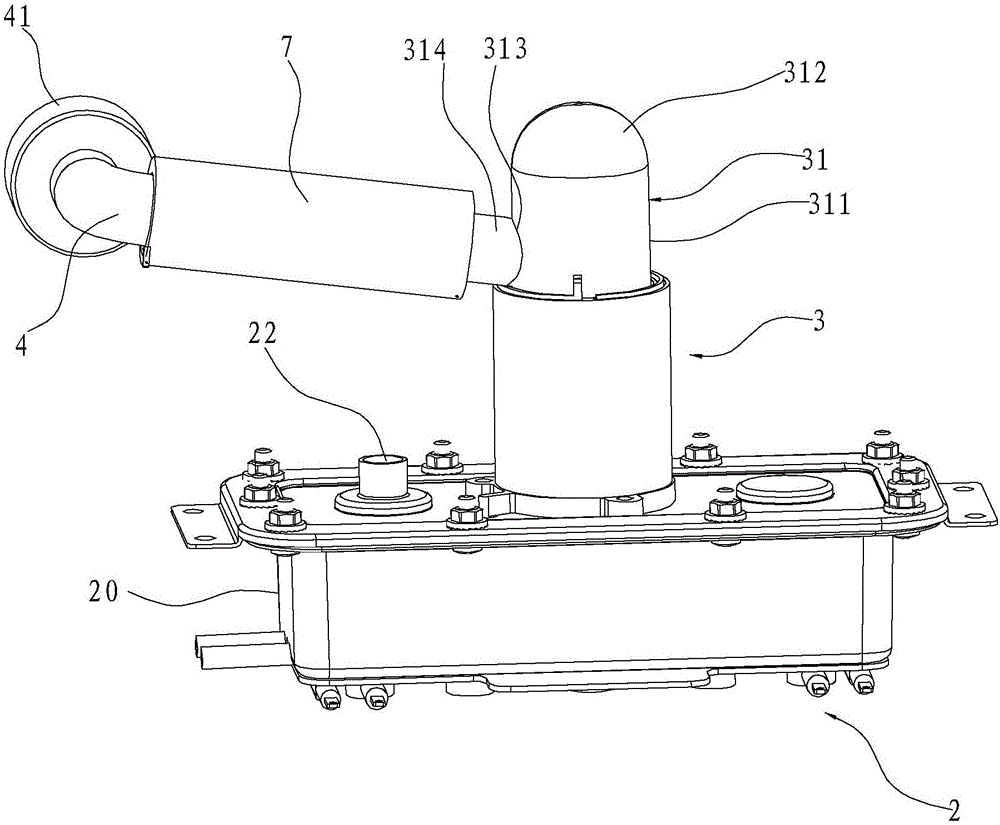

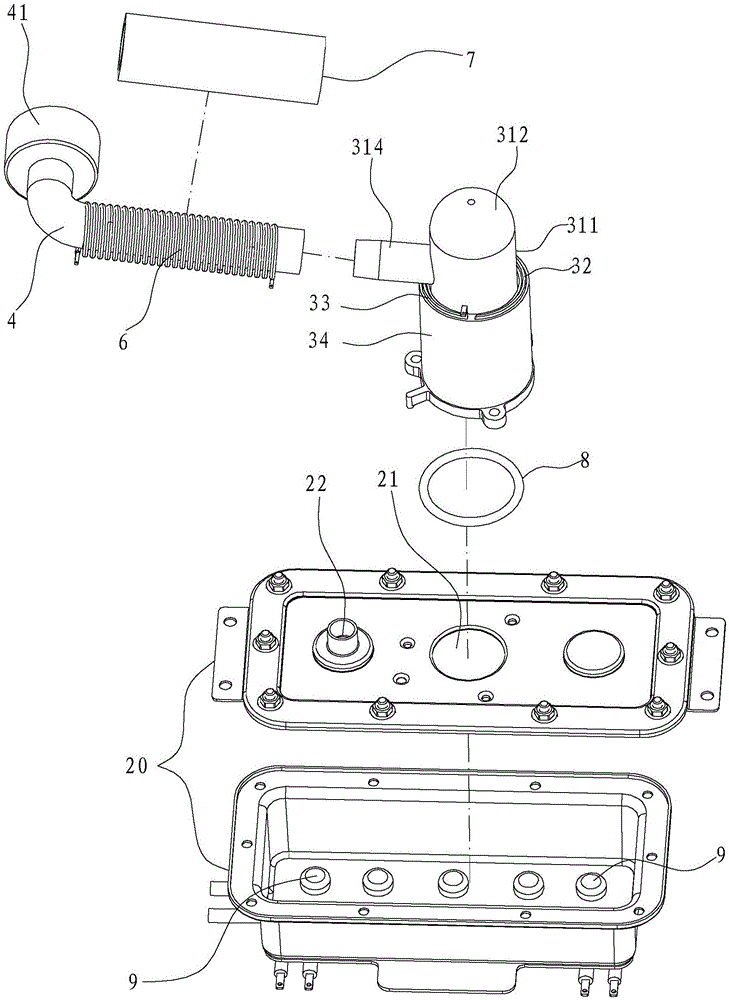

Novel steam box

ActiveCN106510447AReduce volumeRapid coolingSteam cooking vesselsVessels with intergral heatingEngineeringSteam generation

The invention relates to a novel steam box. The steam box comprises an atomization device, a conveying pipe and a water mist processing device; the atomization device comprises a box body and at least one ultrasonic generator arranged in the box body, and the box body is provided with a mist outlet; the a water mist processing device comprises a shell body provided with a mist inlet and a mist conveying port, the mist inlet communicates with the mist outlet of the atomization device, and the mist conveying port communicates with a port in one side of the conveying pipe; and a port in the other side of the conveying pipe communicates with an inner container, and the conveying pipe is provided with a controllable heating device. According to the novel steam box, the producing time of steam in the steam box is obviously shortened, and the producing efficiency of the steam is significantly improved; in addition, after the steam box completes work, water mist at the normal temperature is directly conveyed to the inner container by stopping the heating device, and accordingly, the inner container can be quickly cooled in the environment filled with the steam; and compared with an air cooling mode, the taste of food can be ensured in the cooling process.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

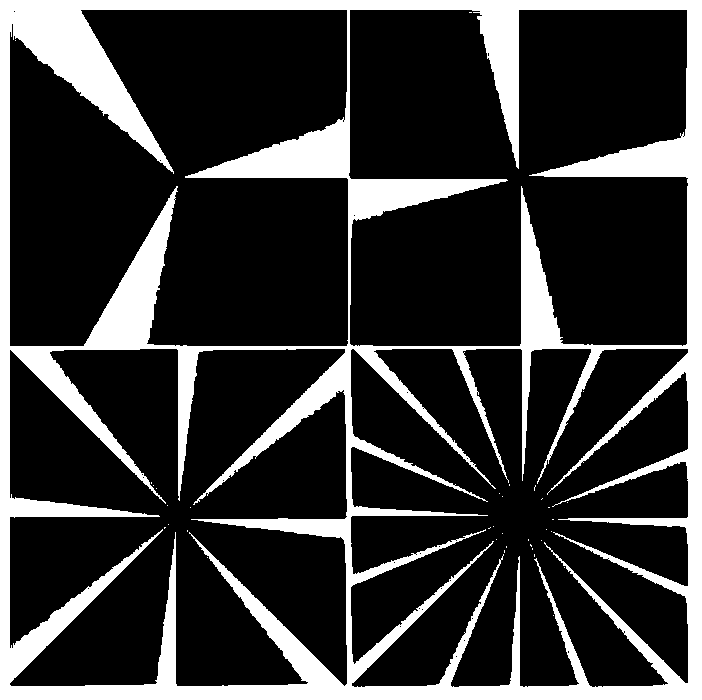

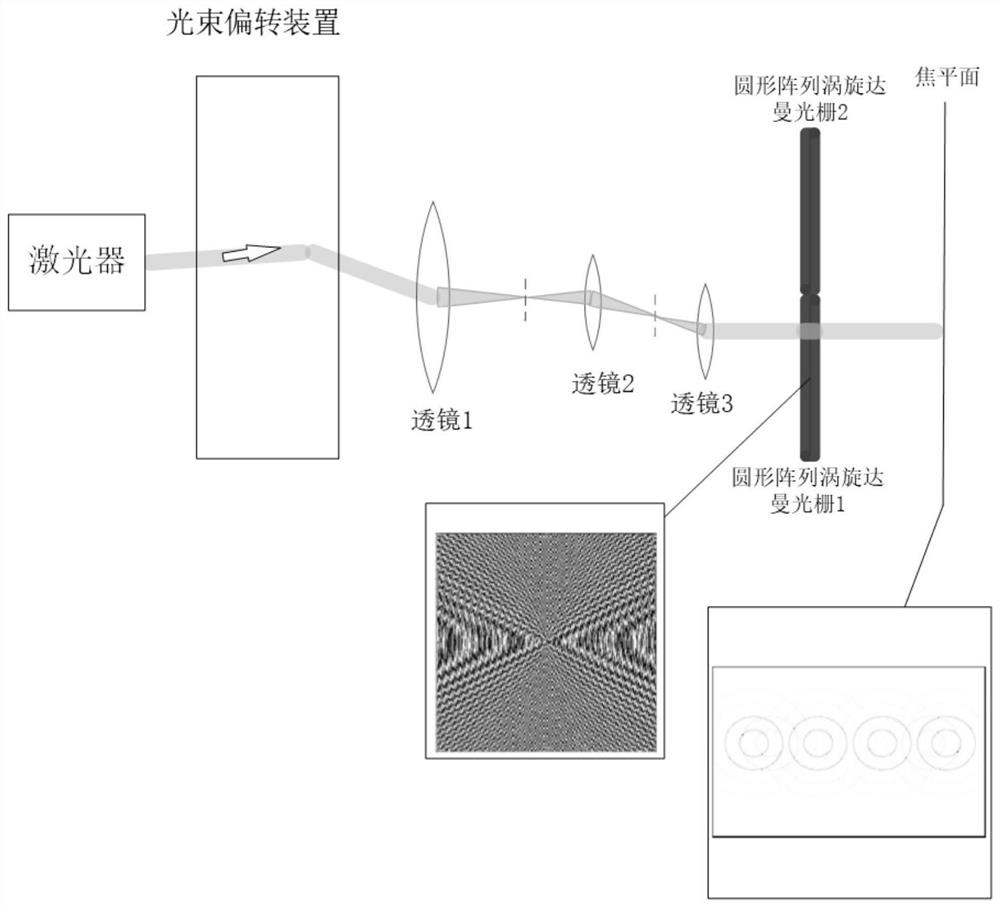

Method for generating orbital angular momentum states of multiple coaxial orbits at one time

ActiveCN113267899AWith equal intensityThe realization of the productionDiffraction gratingsErbium lasersCollimator

The invention discloses a method for generating angular momentum states of multiple coaxial orbits at one time, which comprises the following steps that 1, after being collimated by a collimator, Gaussian light is fed from a laser into a light beam deflection device; 2, the Gaussian beam deflects at different angles under the control of a controller of the light beam deflection device, and the emitted Gaussian beam irradiates different positions of the circular array vortex Dammann grating after passing through a collimation system composed of a plurality of lenses, so as to form a circular array vortex Dammann grating; the light beam transmitted by the circular array vortex Dammann grating is converted into a plurality of coaxial orbital angular momentum light beams with different topological charge values, and a plurality of concentric circle patterns are displayed on a focal plane. According to the invention, the light beam deflection device and the improved circular array vortex Dammann grating are applied to the field of generation of orbital angular momentum light beams, and a novel rapid generation method for a plurality of coaxial orbital angular momentum states is realized.

Owner:NANJING UNIV OF POSTS & TELECOMM

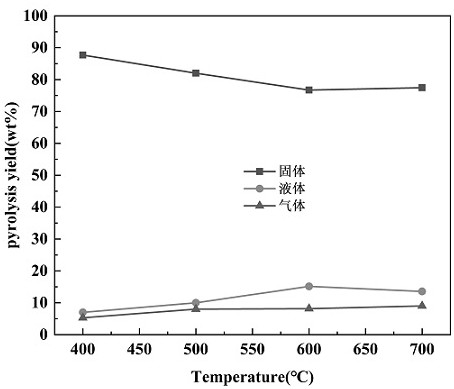

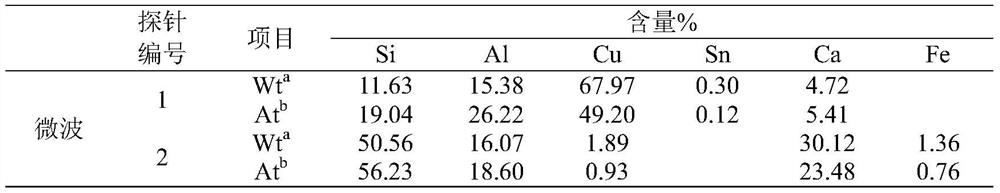

Microwave pyrolysis comprehensive utilization method for waste computer circuit boards

PendingCN112760109AReduce secondary decompositionReduce generationSpecial form destructive distillationEnergy based chemical/physical/physico-chemical processesProcess engineeringEnvironmental engineering

The invention relates to a microwave pyrolysis comprehensive utilization method for waste computer circuit boards, and belongs to the technical field of waste electronic product recycling. The method comprises the steps: preheating the circuit boards to remove soldering tin, cutting the circuit boards into small blocks, adding carbon powder for microwave pyrolysis, and controlling microwave pyrolysis conditions to achieve comprehensive utilization of the waste computer circuit boards. According to the method, bromine in the circuit boards can be effectively removed, meanwhile, generation of toxic gas such as dioxin is avoided, pyrolysis oil and pyrolysis gas with high calorific value are generated, and full, high-calorific-value and comprehensive utilization of all components of the circuit boards is achieved.

Owner:楚雄滇中有色金属有限责任公司 +1

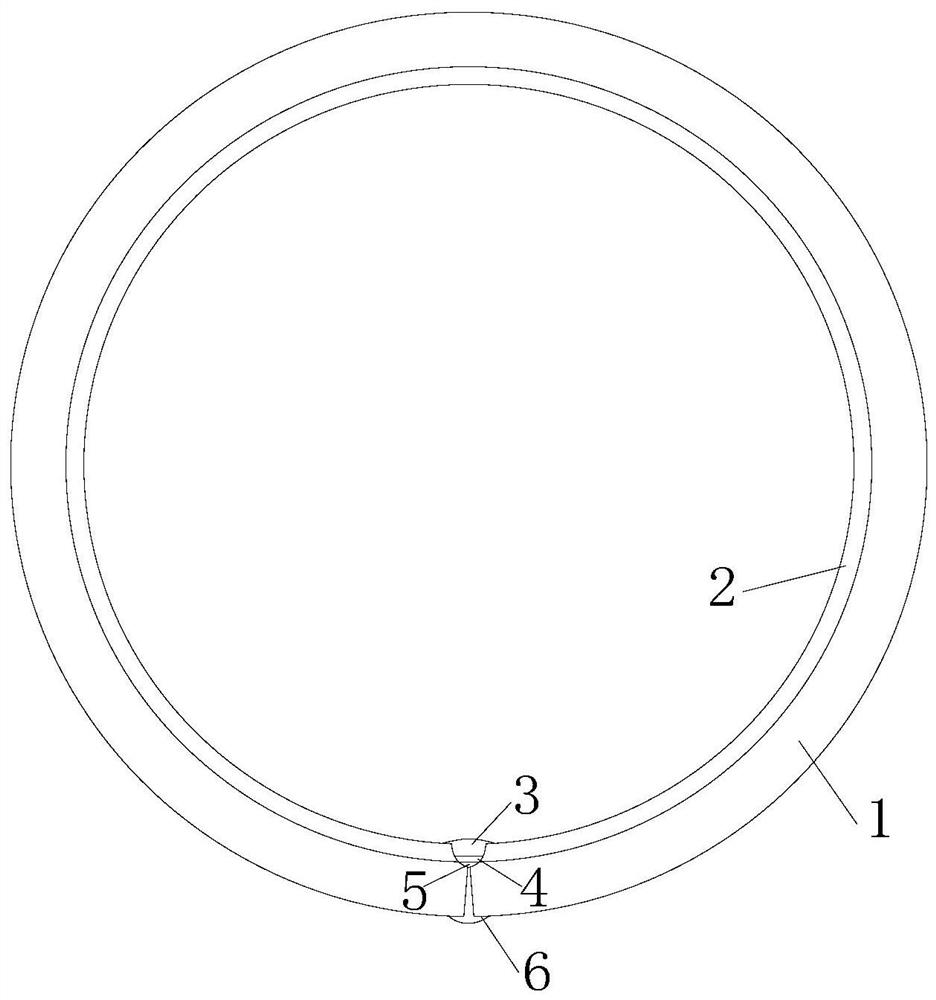

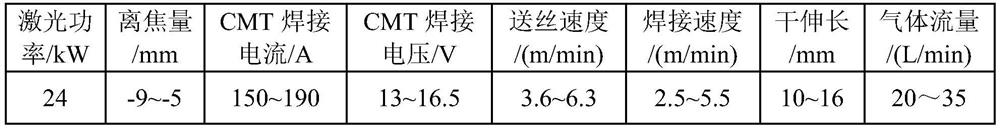

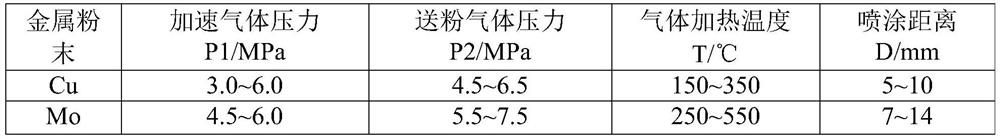

Compound pipe production method based on spraying technology

ActiveCN113458549AGood weld mechanical propertiesSimple designArc welding apparatusLaser beam welding apparatusHard metalTitanium

The invention discloses a compound pipe production method based on a spraying technology. The compound pipe production method based on the spraying technology comprises the following steps: firstly, producing a pure titanium or titanium alloy material and a carbon steel material into a bimetal layered structure compound plate with a required specification in a mode of assembling, explosive welding and continuous controlled rolling and controlled cooling; then designing and processing special grooves; and finally, conducting welding production of a bimetal compound pipe by adopting a laser and cold metal transition compound welding technology, the spraying technology and a pulse TIG welding method. According to the compound pipe production method based on the spraying technology, welding heat input is small, a transition layer can well prevent mutual dissolution of Ti and Fe and mutual dissolution of Ti and C, and generation of brittle hard intermetallic compounds is effectively avoided, so that the comprehensive mechanical performance of a pipe welding seam is guaranteed.

Owner:SHAANXI RAILWAY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com