System and method for flue gas desulfurization

A desulfurization system and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., to achieve the effect of low price, wide range of sources, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

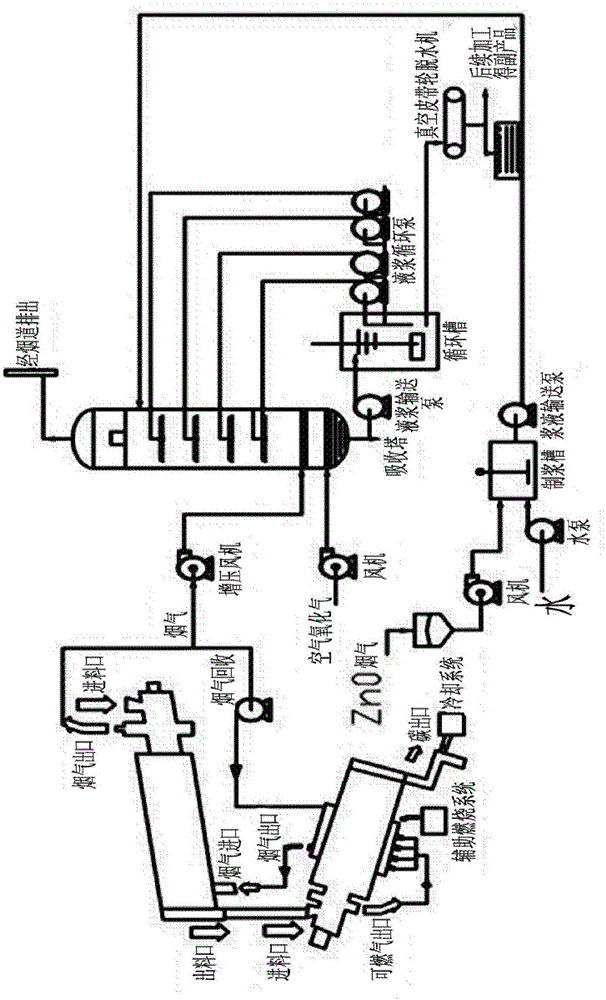

[0044] see figure 1 , implement a kind of rotary kiln type treatment of village and town domestic garbage and its flue gas purification process proposed by the present invention, mainly including drying furnace, dry distillation carbonization furnace, pulping tank, circulation tank, absorption tower, demister, oxidation tank, oxidation fan , filter, purifier, flue gas booster fan, aeration pipe, circulation pump, slurry pump, zinc oxide silo, etc. The rotary kiln system first screens and crushes the garbage in the early stage, and then the garbage is heat-treated in the drying furnace and carbonization furnace. After heat treatment, the flue gas is sent to the desulfurization system. The first step in the desulfurization system is the production of zinc oxide slurry. The zinc oxide powder and process water are prepared in a stirring tank according to a certain ratio to form a slurry. The technical requirement is that the solid phase weight concentration of the zinc oxide slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com