Method for preparing nano copper conductive ink

A technology of conductive ink and nano-copper, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, inks, household appliances, etc., can solve the problems of high heating temperature, long preparation cycle, complicated preparation process, etc., and achieve particle dispersion Good, low cost, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 10 mmol CuCl 2 .2H 2 O and 2.6 grams of polyvinylpyrrolidone (PVP) were dissolved in 50 milliliters of deionized water respectively, mixed and stirred, and the temperature was raised to 80° C., and an amount of ammonia was added to adjust its pH value to 10; 5 milliliters of 50% hydrazine hydrate solution was slowly added dropwise, and Stir for 60 minutes and cool to room temperature to obtain a nano-copper dispersion; centrifuge the obtained copper dispersion at a speed of 8000 rpm for 15 minutes, wash twice with deionized water and absolute ethanol, and then vacuum at room temperature Dry for 2 hours to obtain nano-copper particles; weigh 0.4 g of nano-copper particles, dissolve in 0.6 g of diethylene glycol monobutyl ether, and obtain nano-copper conductive ink with a solid content of 40% after ultrasonication for 15 minutes.

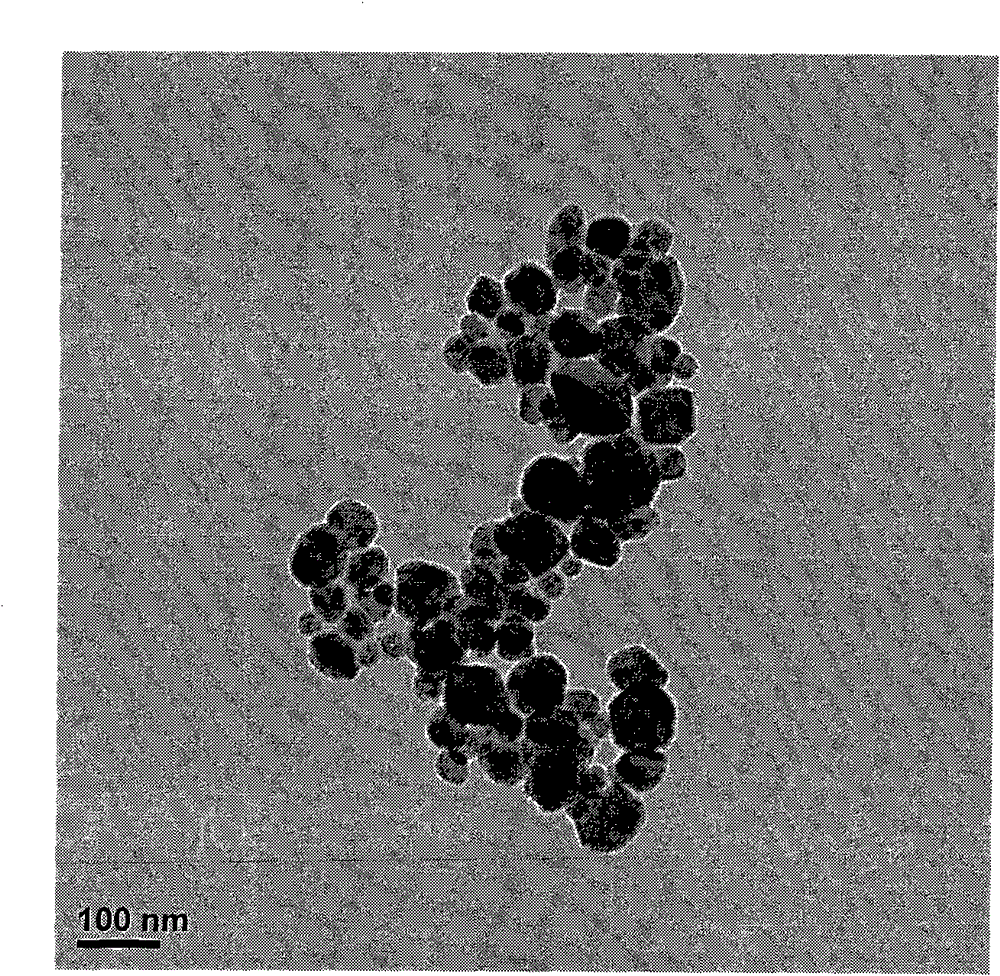

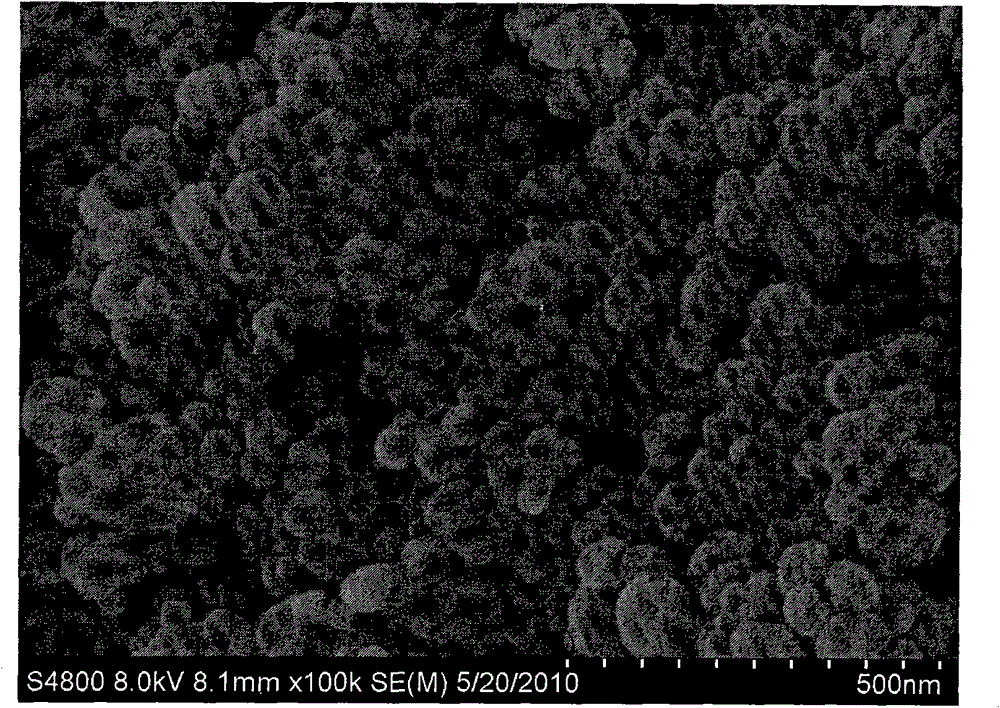

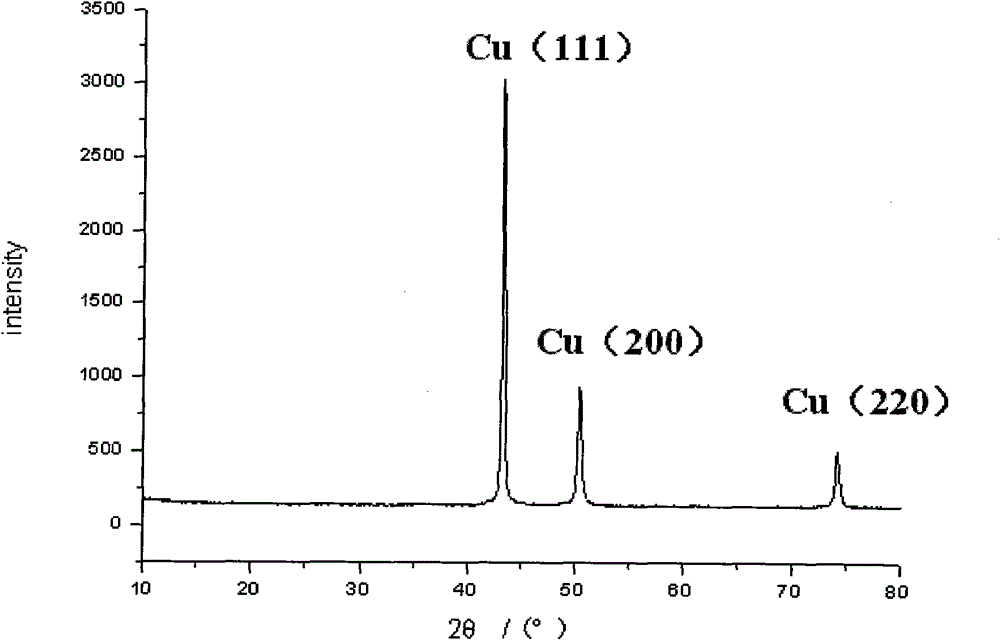

[0029] The nano-copper conductive ink obtained above is sampled, and the copper particles in the nano-copper conductive ink are observed usi...

Embodiment 2

[0031] 10 mmol CuSO 4 5H 2O and 1.62 grams of polyacrylamide were respectively dissolved in 50 milliliters of ethylene glycol and 50 milliliters of deionized water, mixed and stirred, heated to 80 ° C, and an appropriate amount of ammonia water was added to adjust its pH value to 9; 5 milliliters of 50% hydrazine hydrate solution was slowly added dropwise , continuously stirred for 30 minutes, cooled to room temperature to obtain a nano-copper dispersion; the obtained copper dispersion was centrifuged at a speed of 8000 rpm for 15 minutes, washed twice with deionized water and absolute ethanol, and then heated at room temperature Dry under vacuum for 2 hours to obtain nano-copper particles; weigh 0.2 g of nano-copper particles, dissolve in 0.8 g of ethylene glycol butyl ether, and obtain nano-copper conductive ink with a solid content of 20% after ultrasonication for 15 minutes.

[0032] The TEM figure, SEM figure and XRD figure of this nano copper conductive ink are similar ...

Embodiment 3

[0034] 10 mmol CuCl 2 .2H 2 O and 2.6 grams of polyvinylpyrrolidone (PVP) were respectively dissolved in 50 milliliters of diethylene glycol, mixed and stirred, heated to 30 ° C, and an appropriate amount of ammonia was added to adjust its pH to 7; slowly dropwise added 5 milliliters of 50% hydrated Hydrazine solution, continuously stirred for 60 minutes, cooled to room temperature to obtain a nano-copper dispersion; the obtained copper dispersion was centrifuged at a speed of 8000 rpm for 20 minutes, washed twice with deionized water and absolute ethanol, and then Vacuum-dry at room temperature for 3 hours to obtain nano-copper particles; weigh 0.3 g of nano-copper particles and dissolve in 0.7 g of diethylene glycol monobutyl ether, and obtain nano-copper conductive ink with a solid content of 30% after ultrasonication for 15 minutes.

[0035] The TEM figure, SEM figure and XRD figure of this nano copper conductive ink are similar to those in Example 1 figure 1 , figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com