Method for producing volatile fatty acid by normal-temperature low-oxygen digestion of yeast reinforced excess activated sludge

A volatile fatty acid, residual activity technology, applied in chemical instruments and methods, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of slow hydrolysis process, anoxic state, long residence time, etc. , to achieve low operating costs, promote degradation, and improve the effect of nitrogen and phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

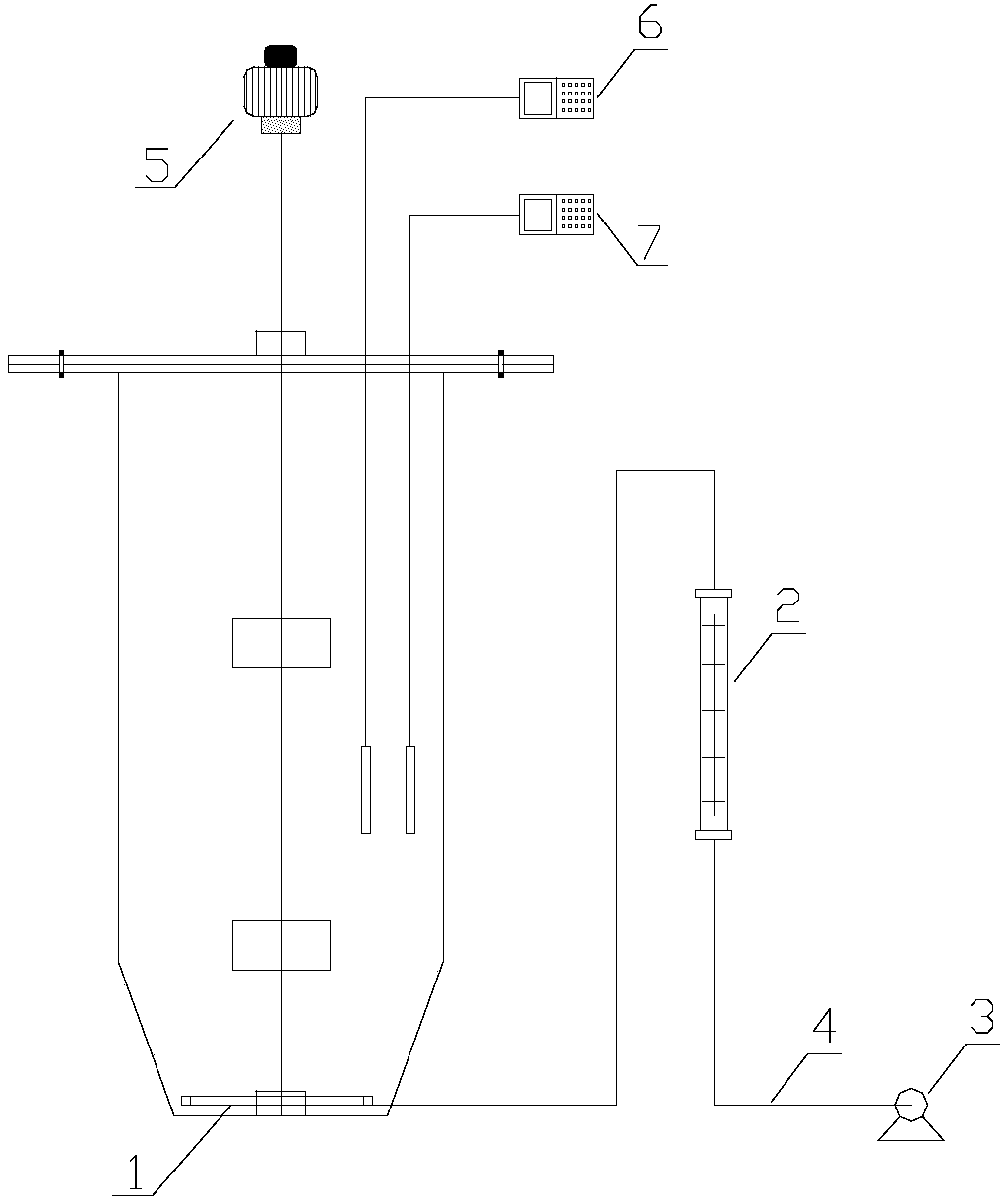

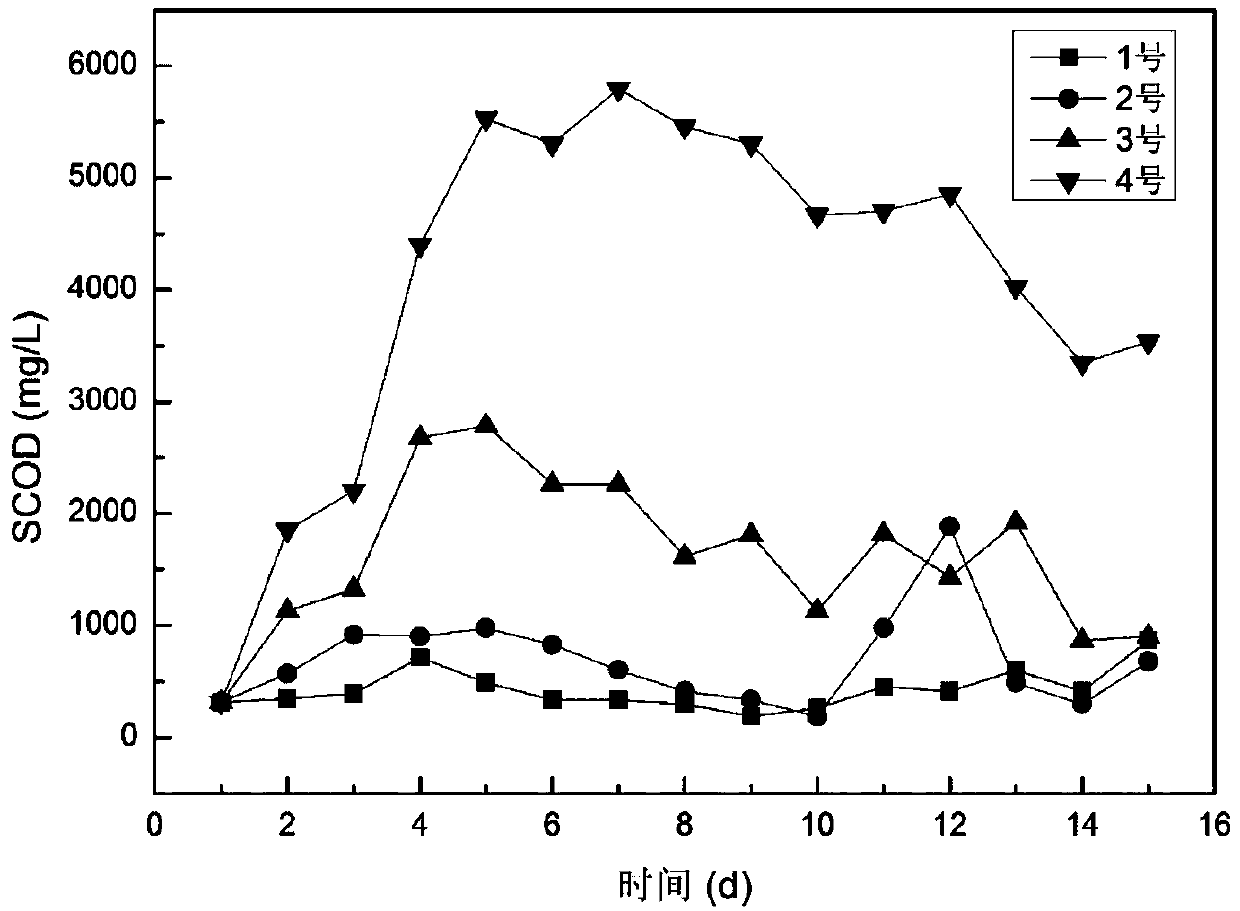

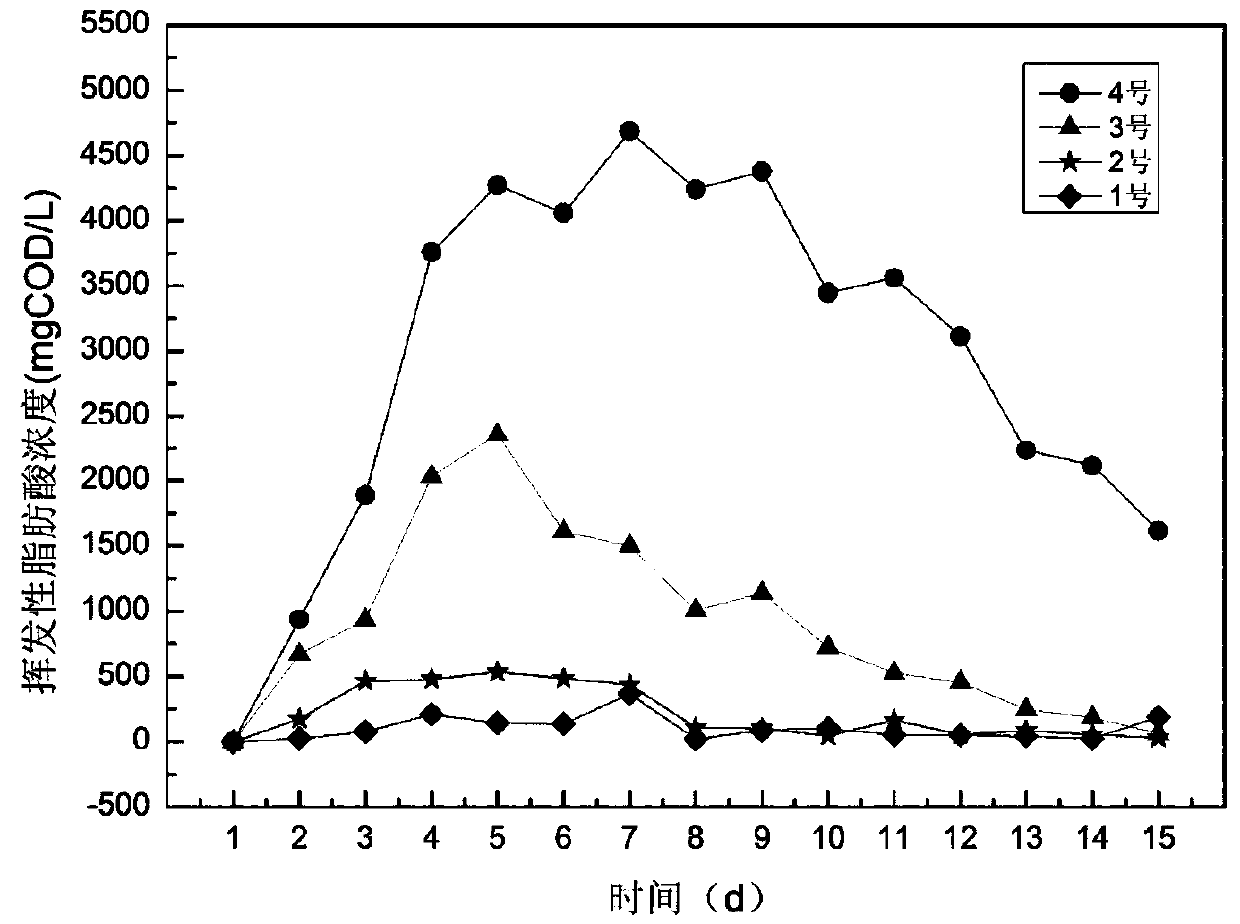

[0022] Digestion reactor in the present invention such as figure 1 shown. Take the return sludge from the secondary settling tank of the sewage treatment plant and settle it at 4°C for 24 hours, remove the supernatant, and measure the suspended solid concentration SS of the concentrated residual sludge to be 24067mg / L, the volatile suspended solid concentration VSS to be 14500mg / L, and the pH is 6.8. Take the concentrated sludge and put it into the microaerobic digestion reactor, set up 4 reactors, and inoculate different quality yeasts respectively. The yeast inoculated in the experiment is Angel high active dry yeast sold in the market. The concentration of yeast in each reactor after inoculation is 0g / L, 1g / L, 5g / L, 10g / L. Adjust the stirring speed of the agitator 5 to fully mix the sludge. Turn on the air pump 3, and the gas enters the reactor through the air pipe 4, the gas flow meter 2 and the air diffuser 1. Adjust the gas flow meter 2 so that the measured value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com