Coal gasification method

A gas and pulverized coal technology, applied in the field of coal gasification, can solve the problems of slow heat transfer rate and long duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

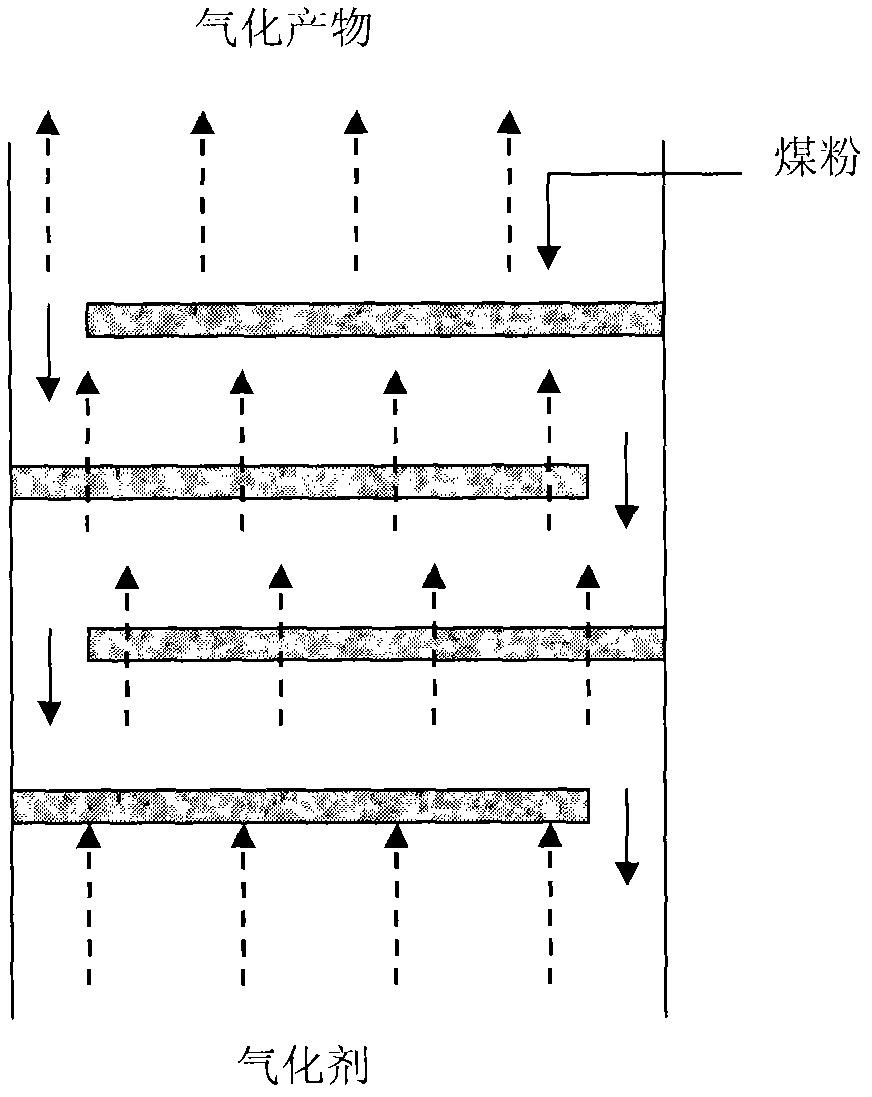

[0041] use figure 2 In the manner described in , the lignite pulverized coal produced in Inner Mongolia that is dried and ground to a particle size of about 1mm is loaded into the pulverized coal silo, and the pulverized coal is directly discharged perpendicular to the first flow channel through the star discharge valve. was added to the combustion flue gas from an oil burner flowing at the temperatures and superficial velocities described in the table below, without using any carrier gas to transport the pulverized coal. The first flow channel is a section of horizontal pipeline, made of 310S steel, lined with mullite refractory layer, the length of the first flow channel is 6 meters, and a high-temperature cyclone separator is installed at the end of the pipeline to separate the semi-coke and the first gas product Separate and immediately analyze the volatile content in the semi-coke. The analysis method is according to GB / T212-2008, and the results are also listed in Table...

Embodiment 6-8

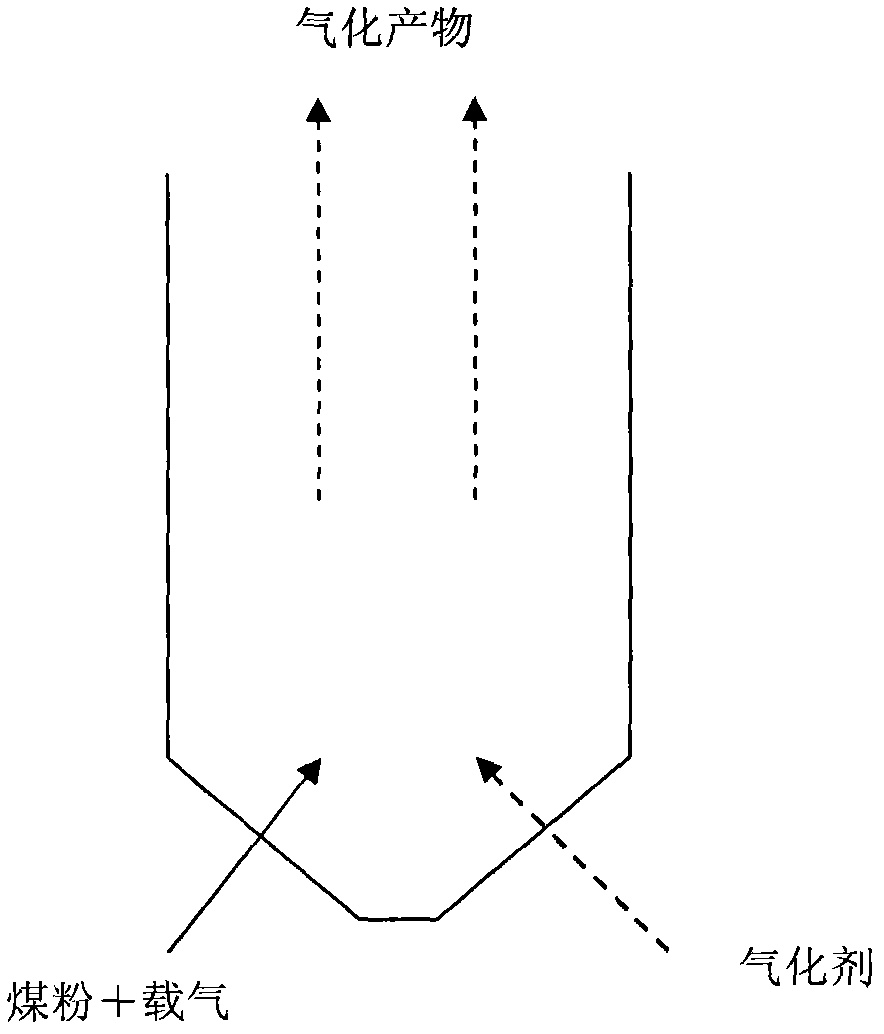

[0054] use Figure 4 The gasification device shown in series with the first flow channel and the second flow channel is used for gasification experiments, and the high-temperature cyclone separator is placed at the end of the second flow channel, wherein the cross-sectional area of the second flow channel is the first flow channel The cross-sectional area is 25 times, and the experimental parameters are shown in Table 4. Wherein the second gas stream is oxygen, and its temperature after mixing with the first product stream is controlled at 800°C. A high temperature cyclone separates the ash from the second gaseous product. The residual carbon content in the ash was measured and found to be substantially less than 4%, indicating that the total carbon conversion rate can reach more than 96%. Of course, if the length of the second flow channel is further extended or the feed amount of O2 is increased, the total carbon conversion rate will be further improved, even close to 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com