Method for producing alcohol through liquor fermentation

A clear liquid and alcohol technology, applied in fermentation, biofuel and other directions, can solve the problems of increased content of fermentation by-products, contamination of bacteria, and reduced starch utilization rate, and achieves the goal of reducing the production of fermentation by-products, exuberant metabolism, and reducing losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

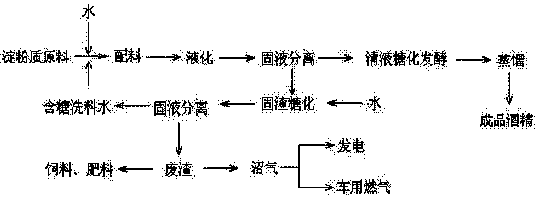

Image

Examples

Embodiment 1

[0017] This embodiment is the experimental data of a small test, adopts cassava, sorghum, wheat mixed raw material, carries out batching with tap water, and its process step comprises:

[0018] a. Take 50g of cassava flour, 50g of sorghum flour, 50g of wheat flour, crushed to 50 mesh, put them into a 1000ml Erlenmeyer flask, add 225mL of tap water, stir evenly with a glass rod, adjust the pH value of the slurry to 5.5 with NaOH, and add 11u of amylase / g dry material, stir evenly, put it into a constant temperature water bath, heat it, and keep it at 86°C for 3 hours to liquefy. Repeat for three parallel samples;

[0019] b. Filter with a 90-mesh filter cloth and press manually, cool the clear liquid to 28°C, add 120 u / g dry material of glucoamylase, inoculate 0.2g of dry yeast, and culture and ferment at a constant temperature of 28°C for 50 hours to complete the fermentation, and the mature mash after fermentation Carry out distillation to produce alcohol, and test fermenta...

Embodiment 2

[0023] This embodiment is the experimental data of a small test, adopts cassava, corn, wheat mixed raw material, carries out batching with tap water, and its process step comprises:

[0024] a. Take 50g of cassava flour, 50g of corn flour, 50g of wheat flour, crushed to a size of 50 mesh, put them into a 1000ml Erlenmeyer flask, add 380mL of tap water, stir well with a glass rod, adjust the pH of the slurry to 6.0 with NaOH, and add 13u of amylase / g dry material, stir evenly, put it into a constant temperature water bath, heat it, and keep it at 93°C for 2.6h to liquefy. Repeat for three parallel samples;

[0025] b. Filter with a 90-mesh filter cloth and press manually, cool the clear liquid to 33°C, add glucoamylase 190 u / g dry material, inoculate 0.3g of dry yeast, culture and ferment at a constant temperature of 33°C for 40 hours, and the fermentation is completed. The mature mash after fermentation Carry out distillation to produce alcohol, and test fermentation indicat...

Embodiment 3

[0029] This embodiment is the experimental data of a small test, adopts potato, sorghum mixed raw material, carries out batching with tap water, and its process step comprises:

[0030] a. Take 75g of potato flour and 75g of sorghum flour, crushed to a particle size of 50 mesh, put them into a 1000ml conical flask, add 525mL of tap water, stir evenly with a glass rod, adjust the pH value of the slurry to 6.5 with NaOH, add 17u / g of amylase to dry Stir the material evenly, put it into a constant temperature water bath, heat it, and heat it at 100°C for 2 hours to liquefy. Repeat for three parallel samples;

[0031] b. Filter with a 90-mesh filter cloth and press manually, cool the clear liquid to 36°C, add 250u / g dry material of glucoamylase, inoculate 0.5g of dry yeast, culture and ferment at a constant temperature of 36°C for 30 hours, and ferment the mature mash after fermentation. Alcohol is produced by distillation, and fermentation indicators such as alcohol content and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com