Process method for preparing calcium phytate and calcium lactate by using corn soaking water

A technology of corn soaking water and process methods, applied in the preparation method of peptides, chemical instruments and methods, and carboxylate preparation, etc., can solve the problems of waste water and other problems, achieve the effect of zero discharge of waste water and avoid the generation of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

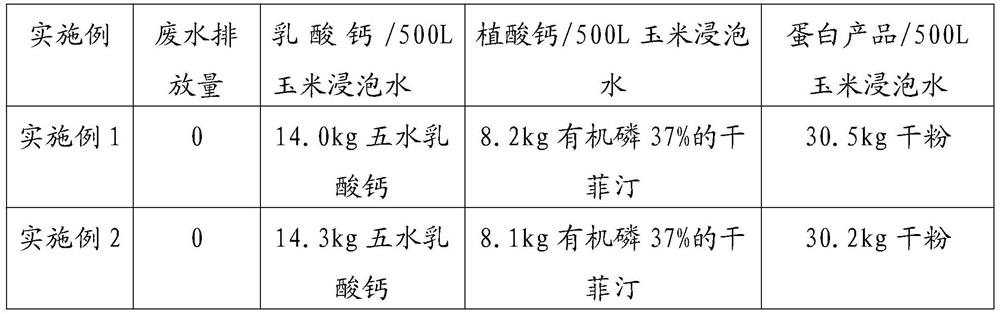

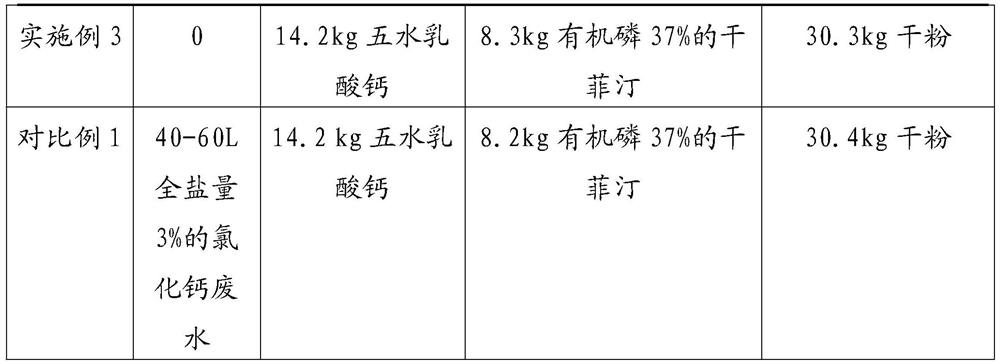

Examples

Embodiment 1

[0022] A process for preparing calcium phytate and calcium lactate by utilizing corn soaking water, comprising the following steps:

[0023] (1) 200L of corn soaking water enters the anion resin column (resin model is LX-67, and the volume of the resin in the anion resin column is 15L) with 1.5BV / h after the supernatant after 4h sedimentation of corn soaking water, collects the first effluent for subsequent use, Adopting resin volume 1.5BV, concentration is that 5% w / v hydrochloric acid enters in the anion resin column according to the flow velocity of 0.5BV / h as desorbing agent, adds lime milk in the desorbing liquid that collects and is neutralized to the pH value of desorbing liquid is 6, adopts Plate and frame filter press, adding hydrochloric acid in the collected liquid phase (the main component is calcium chloride) is used as the desorbent of the next batch of anion resin columns (the content control of chloride ions in the desorbent prepared together by the collected li...

Embodiment 2

[0028] A process for preparing calcium phytate and calcium lactate by utilizing corn soaking water, comprising the following steps:

[0029] (1) 200L of corn soaking water enters the anion resin column (resin model is LX-67, and the volume of the resin in the anion resin column is 15L) with 1.5BV / h after the supernatant after 4h sedimentation of corn soaking water, collects the first effluent for subsequent use, Use hydrochloric acid with a resin volume of 1.5BV and a concentration of 5.5% w / v as a desorbent to enter the anion resin column at a flow rate of 0.5BV / h, add lime milk to the collected desorption solution and adjust the pH to 6.3, and use plate and frame filter press , add hydrochloric acid in the collected liquid phase (main component is calcium chloride) after adding hydrochloric acid as the desorbent of the next batch of anion resin column (the content of chloride ion in the desorbent prepared together in the collected liquid phase and hydrochloric acid is control...

Embodiment 3

[0034] A process for preparing calcium phytate and calcium lactate by utilizing corn soaking water, comprising the following steps:

[0035] (1) 200L of corn soaking water enters the anion resin column (resin model is LX-67, and the volume of the resin in the anion resin column is 15L) with 1.5BV / h after the supernatant after 4h sedimentation of corn soaking water, collects the first effluent for subsequent use, Using a resin volume of 1.5BV and a concentration of 6% w / v hydrochloric acid as a desorbent enters the anion resin column at a rate of 0.5BV / h, adds milk of lime to the collected desorption solution to neutralize the pH of the desorption solution to 6.5, and press-filters. After adding hydrochloric acid in the collected liquid phase (the main component is calcium chloride), it is used as the desorbent of the next batch of anion resin columns (the content of chloride ions in the desorbent prepared together from the collected liquid phase and hydrochloric acid is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com