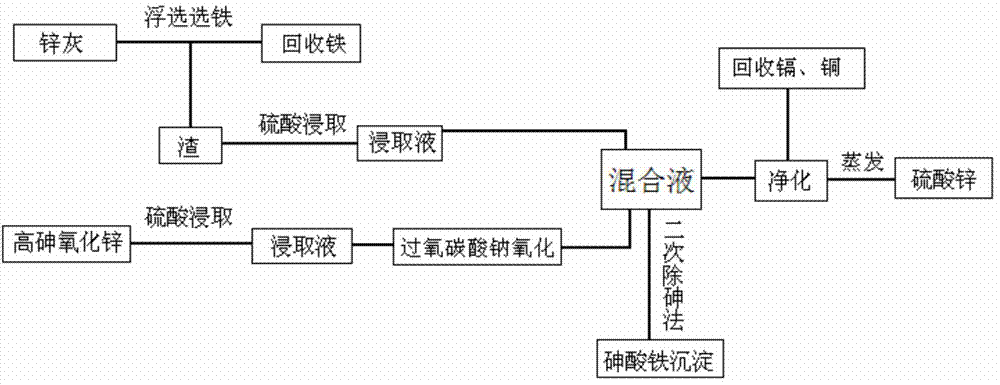

Method for simultaneously and comprehensively recycling zinc ash and high-arsenic zinc oxide in iron and steel plant

A high-arsenic zinc oxide, iron and steel plant technology, applied in zinc sulfate, solid separation, flotation and other directions, can solve the problem of complex operation of hydrogen peroxide, achieve obvious economic and social benefits, achieve clean production, avoid secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for simultaneously comprehensively recycling iron and steel plant zinc ash and high-arsenic zinc oxide, firstly using camellia oleifera meal extract as a flotation agent to recover iron in the zinc ash by flotation. The preparation method of the camellia oleifera meal extract is as follows: dissolving the camellia oleifera meal in water (the liquid-to-solid weight ratio is 2:1 when dissolving), and saponifying with 2% NaOH for 2 hours at 70°C. After filtration, the filtrate was concentrated to half of the original volume and washed with an appropriate amount of 20% H 2 SO 4 Adjust the pH to 5.8. The amount of unsaturated fatty acid (saponification) in the flotation agent is 6%; the amount of tea saponin is 8%. Relative to 100 parts by weight of iron and steel factory zinc dust, the amount of flotation agent is 0.5 parts by weight. The pH value of the flotation is 5.8, the temperature of the flotation is 35° C., and the flotation time is 2 hours. The final f...

Embodiment 2

[0058] A method for simultaneously comprehensively recycling iron and steel plant zinc ash and high-arsenic zinc oxide, firstly using camellia oleifera meal extract as a flotation agent to recover iron in the zinc ash by flotation. The preparation method of the camellia oleifera meal extract is as follows: dissolving the camellia oleifera meal in water (the liquid-to-solid weight ratio is 2:1 when dissolving), and performing saponification with 1% NaOH at 80°C for 2 hours. After filtration, the filtrate was concentrated to half of the original volume and washed with an appropriate amount of 20% H 2 SO 4 Adjust the pH to 5.5. The amount of unsaturated fatty acid (saponification) in the flotation agent is 7%; the amount of tea saponin is 9%. Relative to 100 parts by weight of iron and steel factory zinc dust, the amount of flotation agent is 0.5 parts by weight. The pH range of flotation is 5.5; the temperature of flotation is 37°C, and the flotation time is 3 hours. The soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com