Single body pressure testing tool, single body pressure testing tool combination and pressure testing method for blast furnace cooling equipment

A technology for cooling equipment and monomers, which is applied in the direction of measuring the acceleration and deceleration rate of fluids and using liquid/vacuum for liquid tightness measurement. Fast interface and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

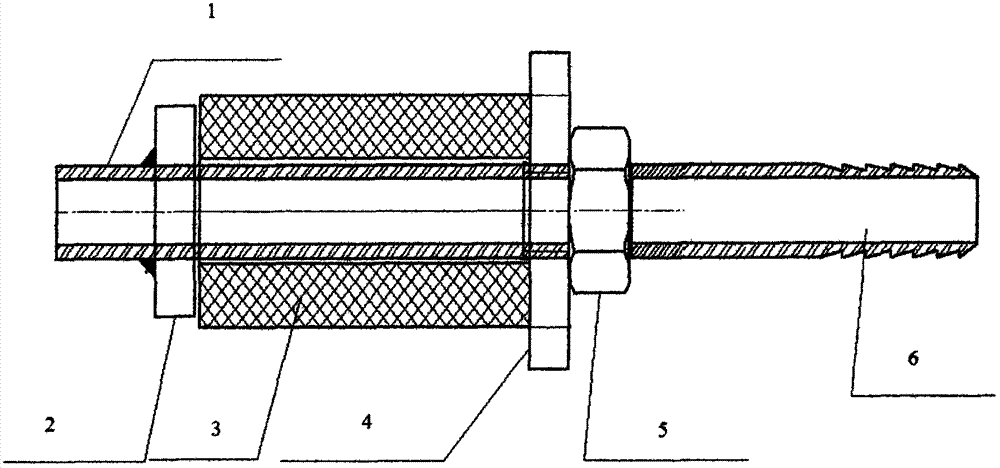

[0023] The single pressure test tooling of the blast furnace cooling equipment adopts the following technical scheme: it includes a screw rod and a rubber hose 3 sleeved on its outside. The rubber hose 3 has a nut 5 at one end. on the screw of hose 3.

[0024] A further technical solution of the present invention is: the two ends of the rubber hose 3 are provided with a washer 1 2 and a washer 2 4 respectively, and the rubber hose 3 is connected to the nut 5 through the washer 2 4 .

[0025] A further technical solution of the present invention is that: the screw is a hollow screw.

[0026] A further technical solution of the present invention is that: the end of the monomer with the nut 5 has a joint 6 .

[0027] Set up the wall unit pressure test working platform, generally set up 150-300m according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com