Nitric acid gas absorber

A technology of absorber and gunpowder smoke, which is applied in the field of gunpowder smoke absorber, can solve the problems of increasing the total cost of the device, huge equipment, consumption of lye, etc., and achieve good absorption effect, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

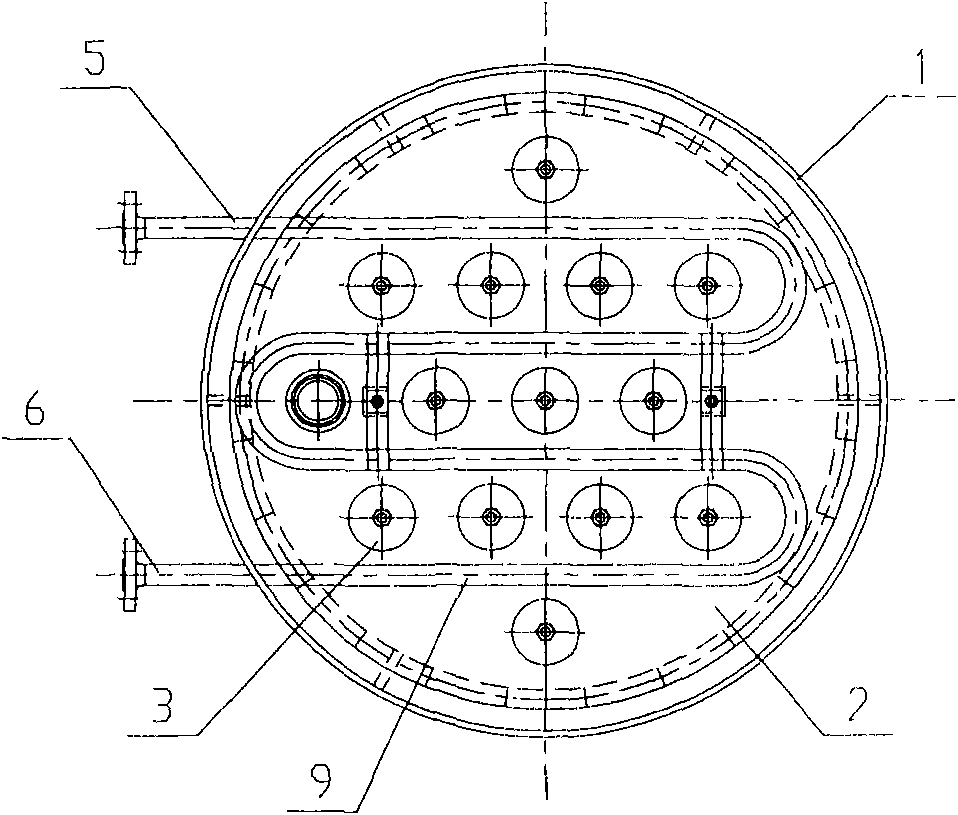

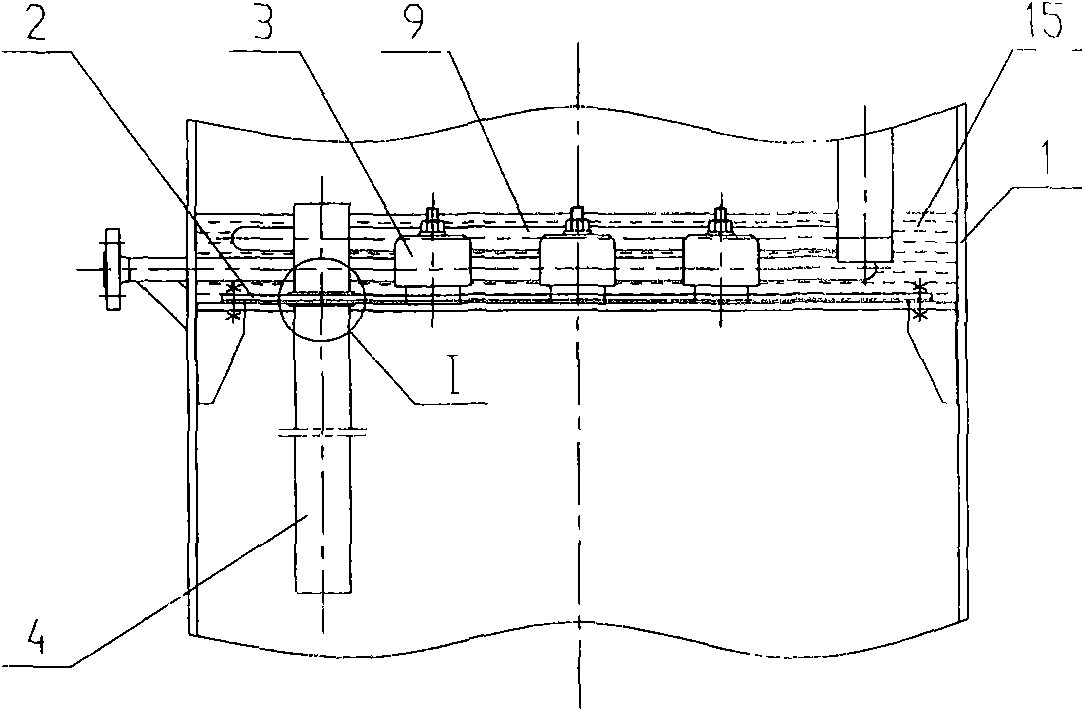

[0025] There is a gas outlet 8 on the top of the shell 1, a water inlet 7 on the upper part of the shell 1, a cooling coil 9, a tray 2, a bubble cap 3 and a downcomer 4 in the middle of the shell 1, and the bubble cap 3 and the cooling coil 9 are fixed On the tray 2, the downcomer 4 is fixed on the tray 2, and the downcomer 4 between the two layers is staggered and fixed on the two ends of the tray 2, and the flow passages of the two trays 2 are connected. The distance from the outlet of the downcomer 4 of a tray 2 to the next tray 2 should be less than the protruding height of the downcomer 4 of the next tray 2, and the protruding height of the downcomer 4 on the tray 2 should be higher than that of the next tray 2. At the height of the bubble cap 3 and the cooling coil 9 above the tray 2, the outlet of the downcomer 4 at the bottom of the housing 1 communicates with the nitric acid chamber 12 at the bottom of the housing 1, and the lower part of the housing 1 is a smoke chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com