Treatment method of benzene-containing wastewater

A treatment method and wastewater technology, applied in water/sewage treatment, biological water/sewage treatment, light water/sewage treatment, etc. The treatment of benzene wastewater has little significance and stays at the stage of academic discussion, and achieves the effects of no secondary pollution in the reaction time, improved oxidation efficiency, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

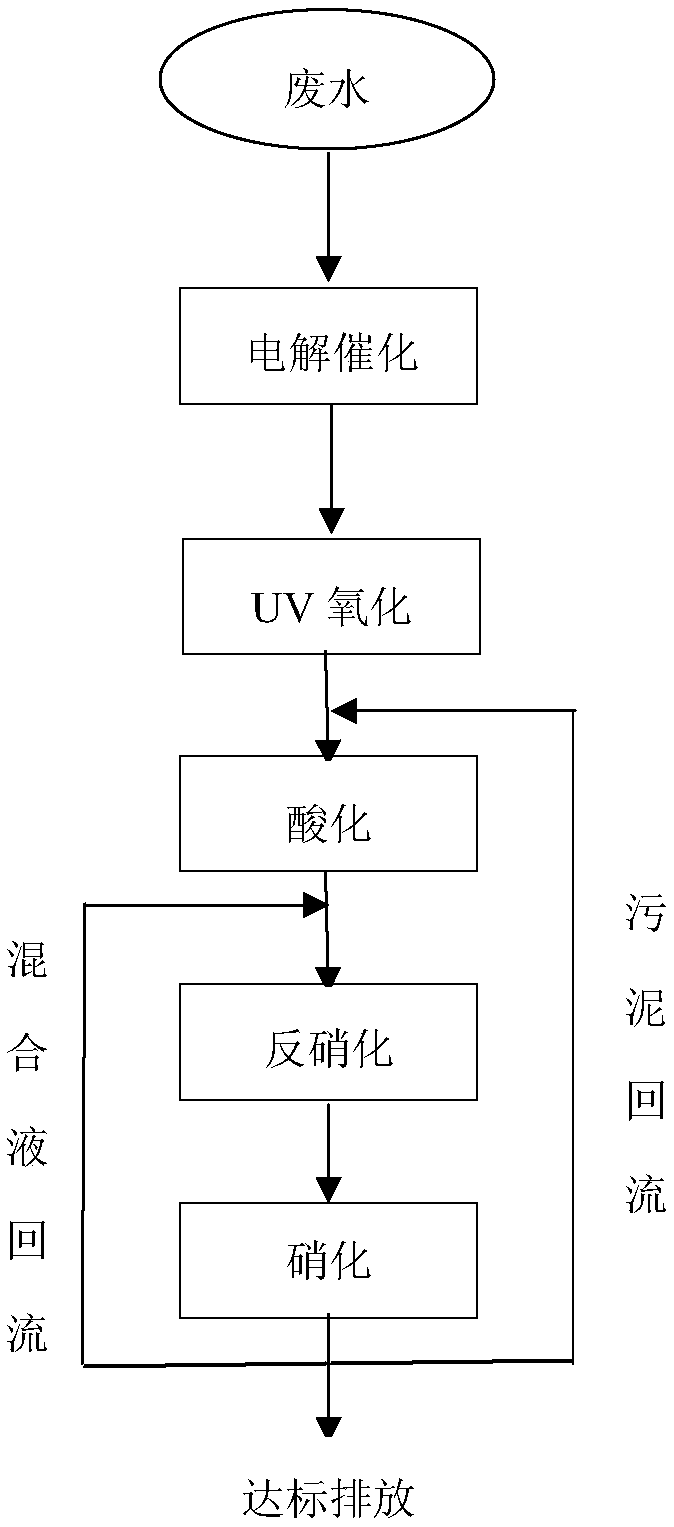

Method used

Image

Examples

Embodiment 1

[0047] The water quality characteristics of nitrochlorobenzene wastewater are: pH=8.0, COD=3820mg / L, nitrobenzene=450mg / L, aniline=20mg / L, ammonia nitrogen=30mg / L, BOD5 / COD=0.05.

[0048] (1) The nitrochlorobenzene wastewater to be treated is pumped to the ultrafiltration system, filtered through an ultrafiltration membrane with a pore size of 0.05 μm, and then promoted to the electrolytic cell, and the H concentration of 35% is added. 2 o 2 , H 2 o 2 The dosage is 0.5‰ of the quality of the treatment solution I, the control working voltage is 120V, and the electrolytic catalytic time is 30min to obtain the treatment solution I.

[0049] It was determined that BOD5 / COD=0.28 in the treatment solution I.

[0050] (2) The treatment liquid I is promoted to the UV reaction tower, and a low-pressure mercury lamp is arranged in the UV reaction tower, and it is 35% H that the mass concentration is 35% when the UV wavelength is 220nm. 2 o 2 , H 2 o 2 The dosage is 0.2‰ of the qu...

Embodiment 2

[0059] The water quality characteristics of nitroaniline wastewater are: pH=7.5, COD=2780mg / L, nitrobenzene=182mg / L, aniline=156mg / L, ammonia nitrogen=58mg / L, BOD5 / COD=0.08.

[0060] (1) The nitroaniline wastewater to be treated is pumped to the ultrafiltration system, filtered through an ultrafiltration membrane with a pore size of 0.06 μm, and then promoted to the electrolytic cell, and H2O with a mass concentration of 27.5% is added. 2 o 2 , H 2 o 2 The dosage is 0.4‰ of the quality of the treatment solution I, the control working voltage is 220V, and the electrolytic catalysis time is 25min to obtain the treatment solution I.

[0061] It was determined that BOD5 / COD=0.29 in the treatment liquid I.

[0062] (2) The treatment liquid I is promoted to the UV reaction tower, and a low-pressure mercury lamp is arranged in the UV reaction tower, and the mass concentration of 27.5% H is passed into under the condition that the UV wavelength is 260nm 2 o 2 , H 2 o 2 The dosa...

Embodiment 3

[0071] The water quality characteristics of chlorinated benzene wastewater are: pH=8.5, COD=1680mg / L, nitrobenzene=52mg / L, aniline=18mg / L, ammonia nitrogen=18mg / L, BOD5 / COD=0.06.

[0072] (1) Pump the chlorinated benzene waste water to be treated to the ultrafiltration system, filter it through an ultrafiltration membrane with a pore size of 0.05 μm, and then lift it to the electrolytic cell, and add H with a mass concentration of 27.5% to 35%. 2 o 2 , H 2 o 2 The dosage is 0.3‰ of the quality of the treatment solution I, the control working voltage is 40V, and the electrolytic catalytic time is 20min to obtain the treatment solution I.

[0073] It was determined that BOD5 / COD=0.32 in the treatment solution I.

[0074] (2) The treatment liquid I is promoted to the UV reaction tower, and a low-pressure mercury lamp is arranged in the UV reaction tower, and the mass concentration of 30% H is passed into the UV reaction tower under the condition of 250 nm 2 o 2 , H 2 o 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com