Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Increase the degree of aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

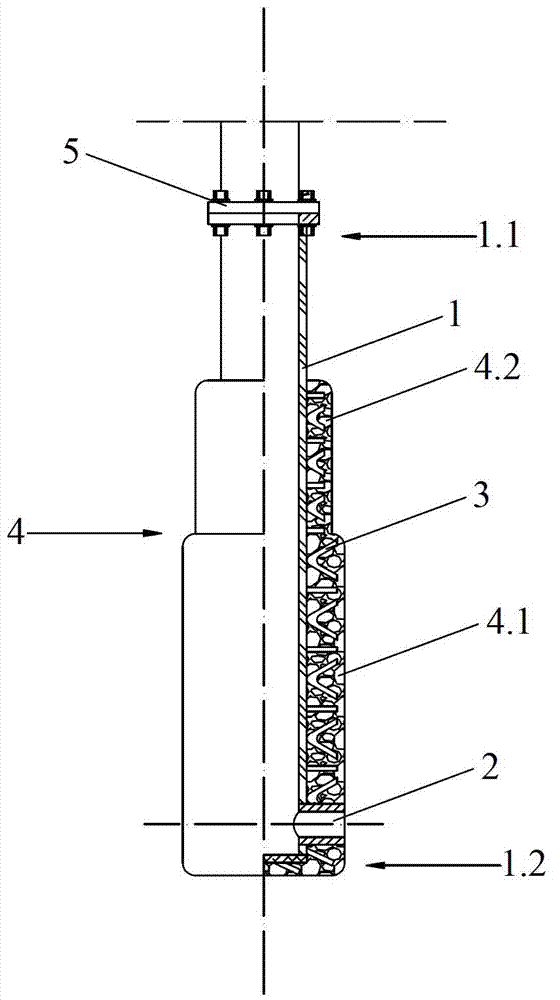

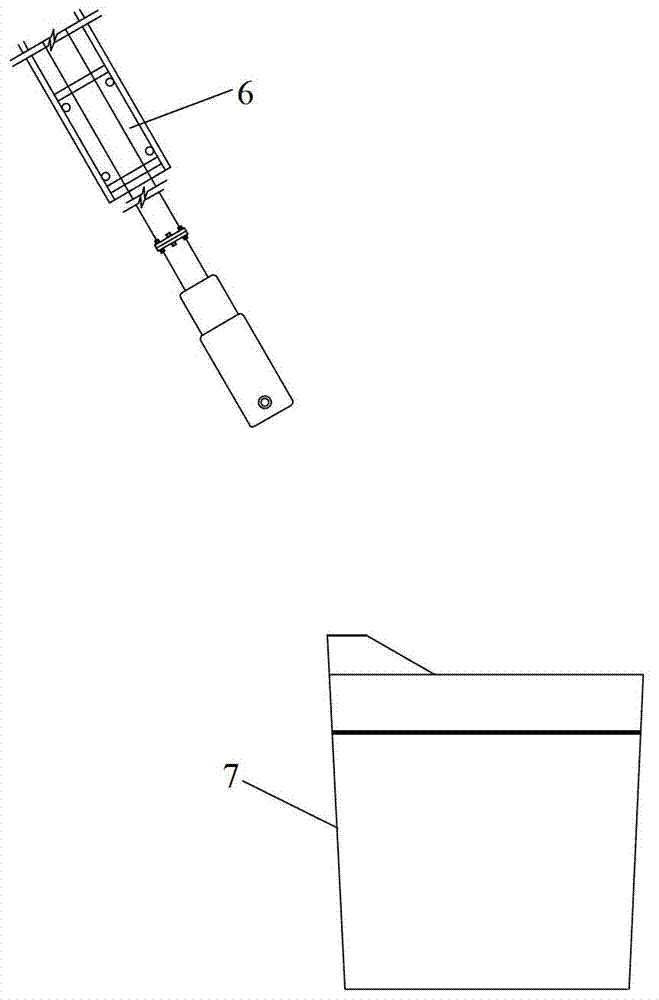

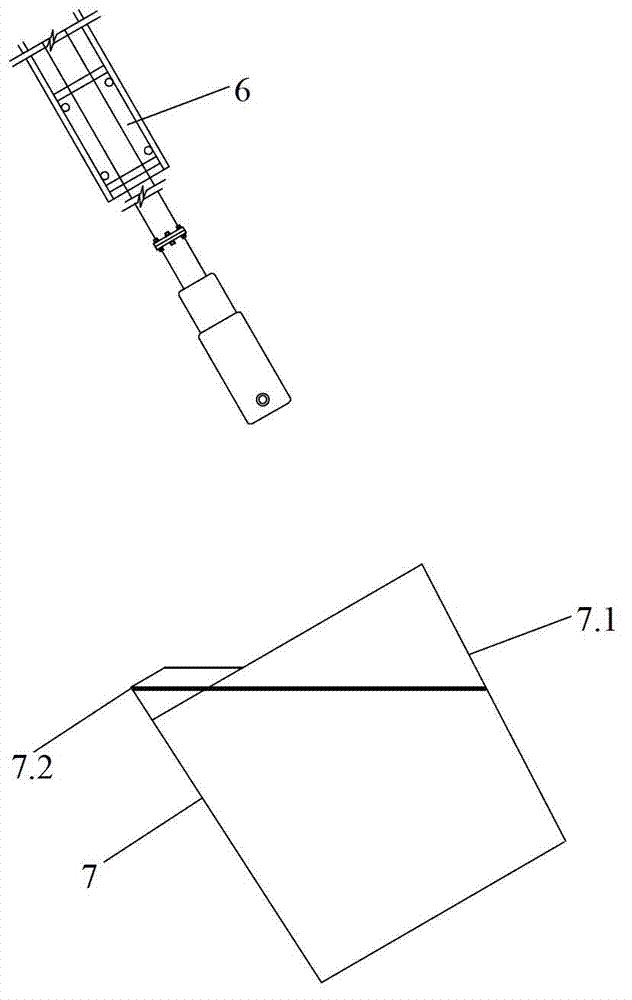

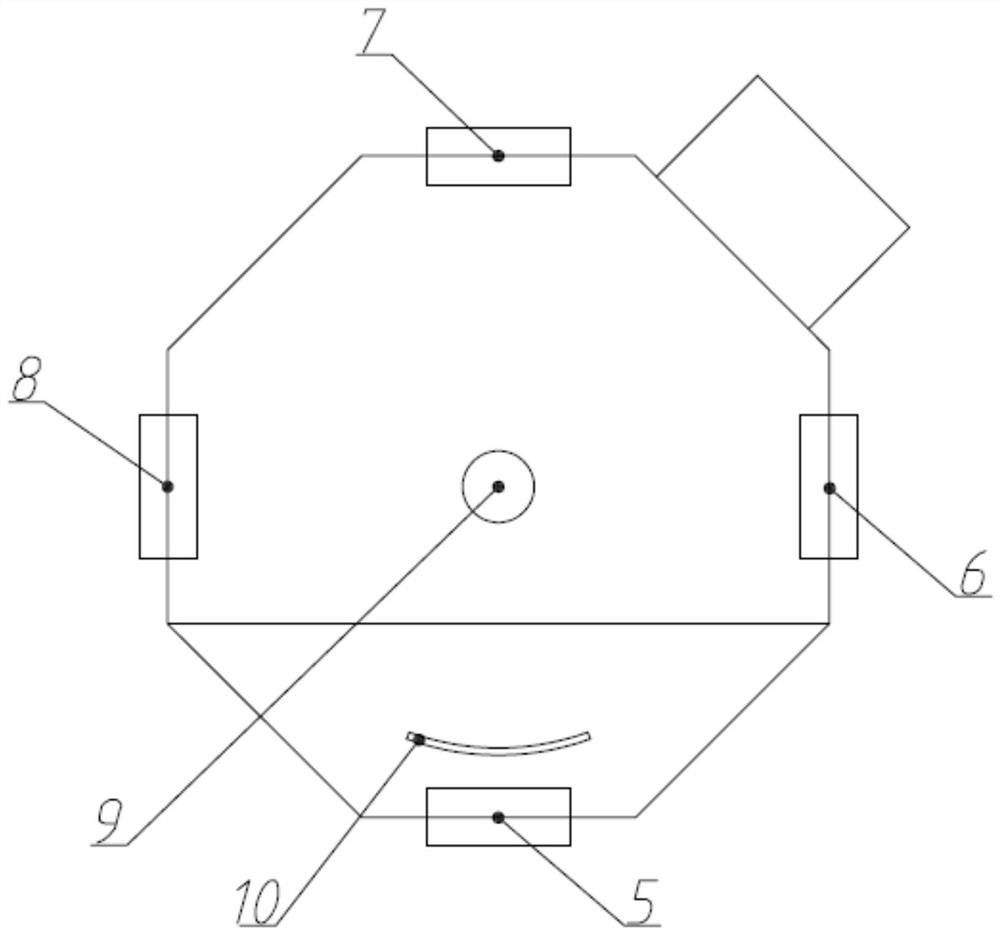

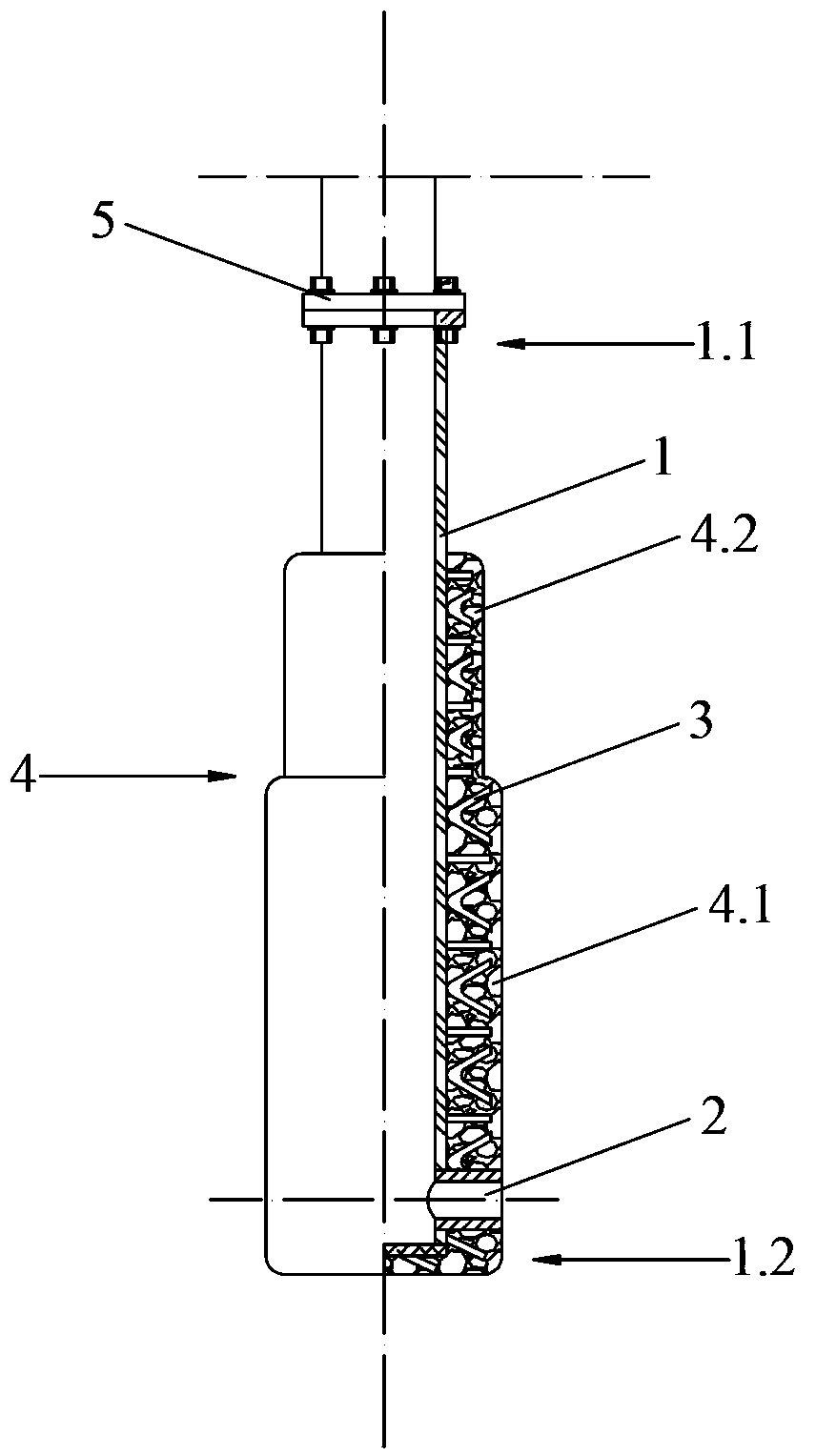

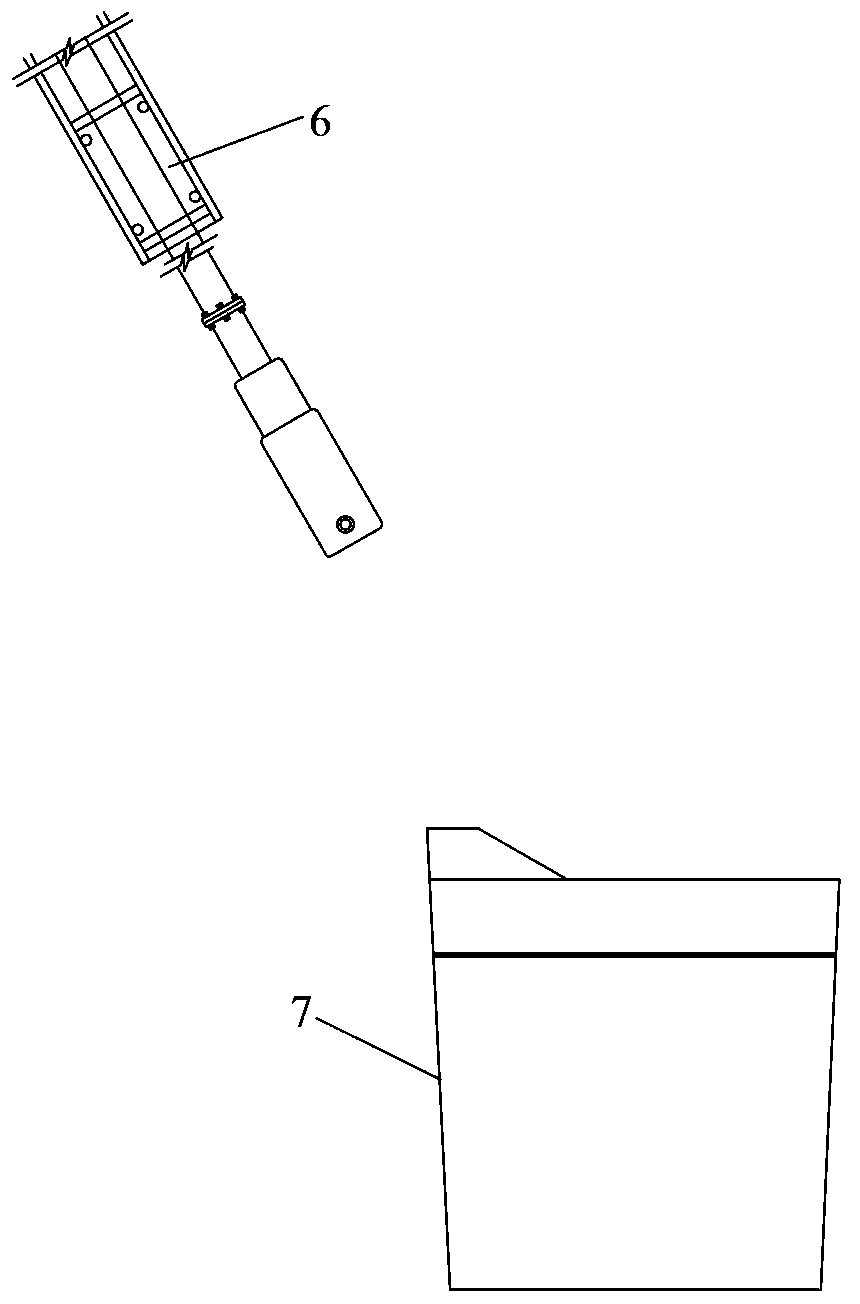

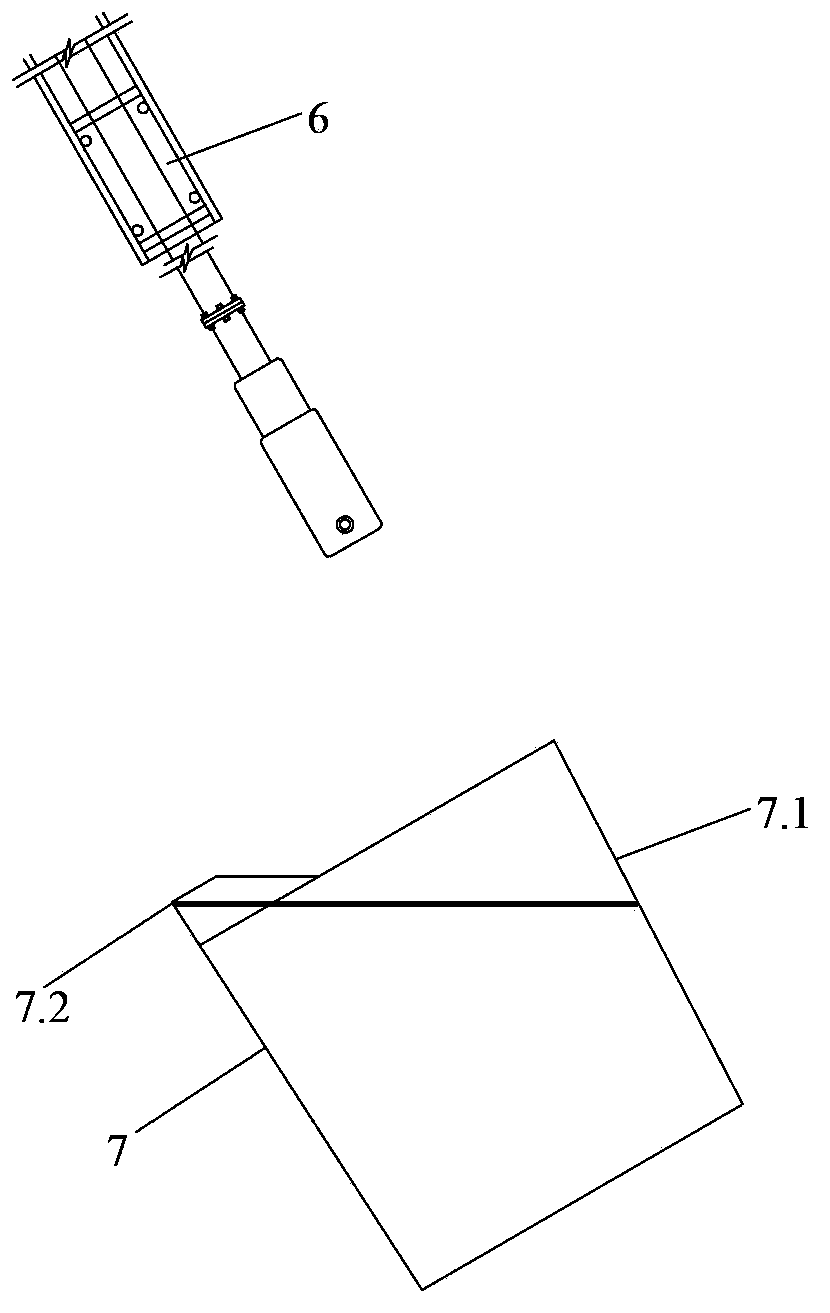

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

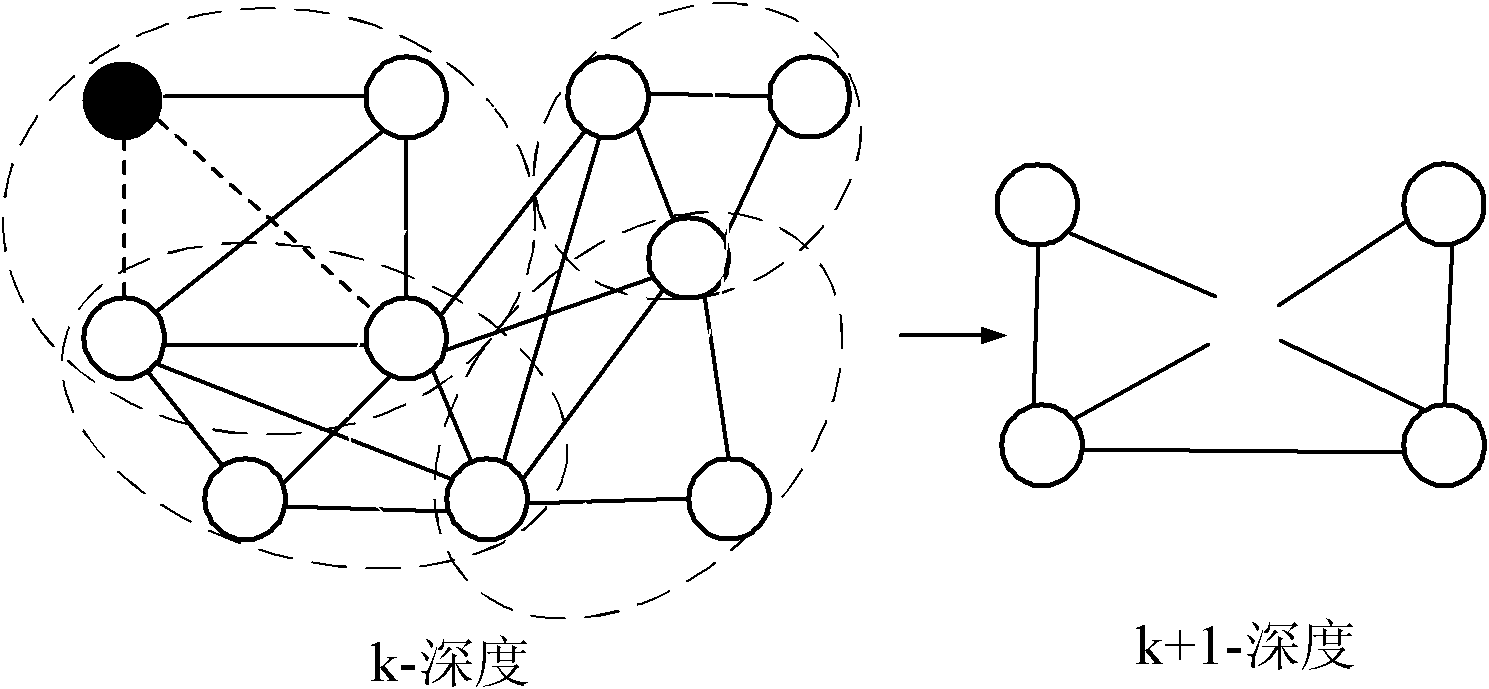

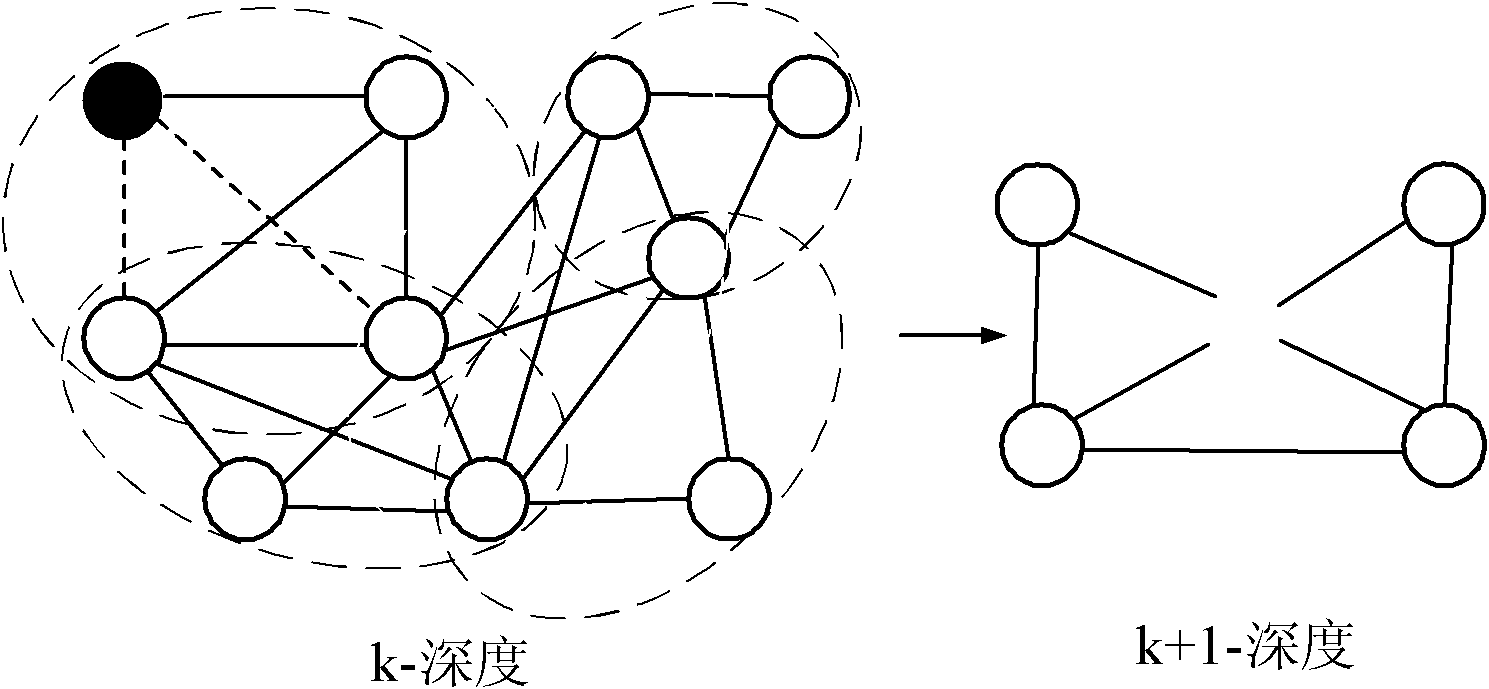

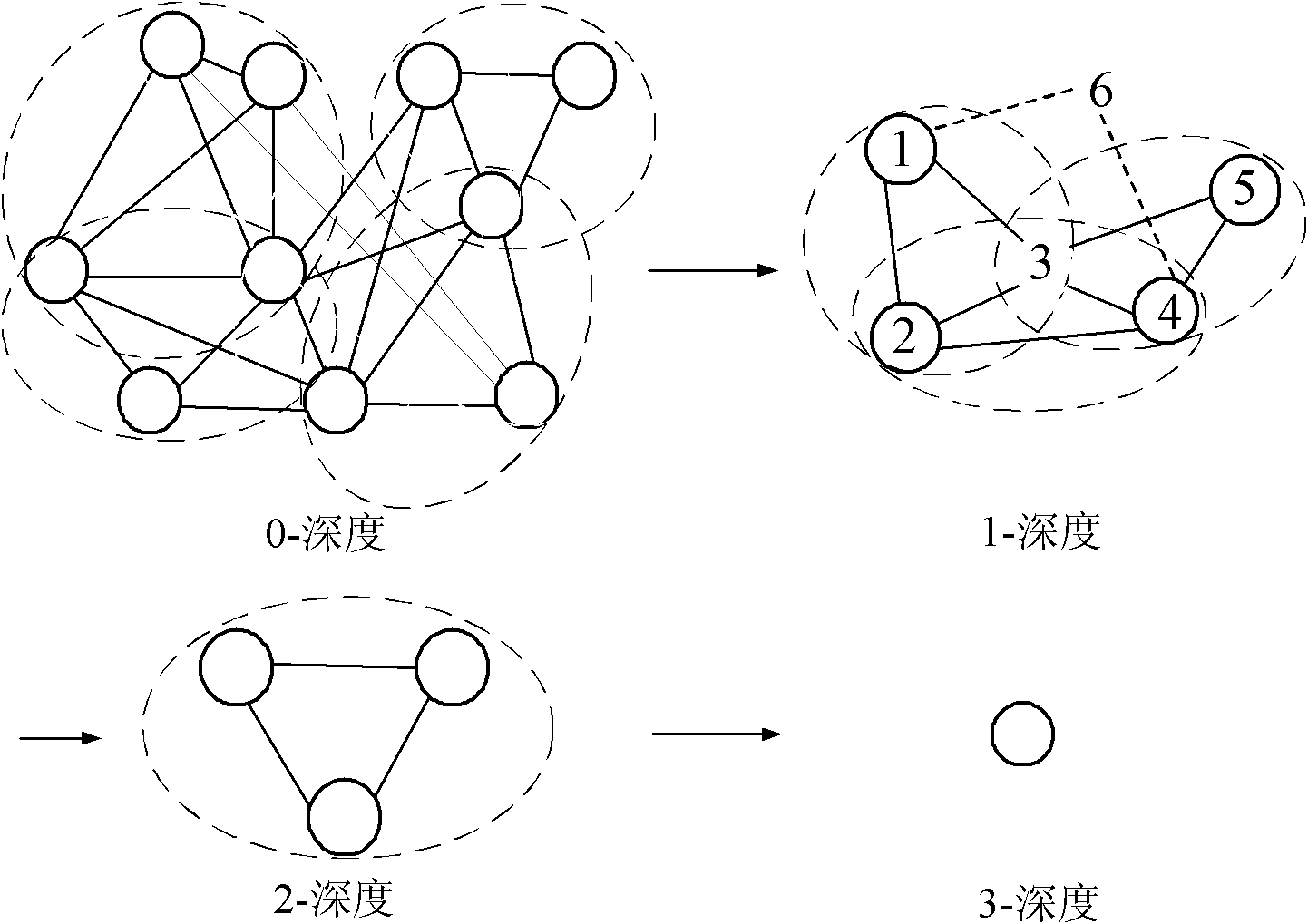

Urban public transport network optimization method capable of improving overall transfer performance

ActiveCN102122434AImprove performanceIncrease the degree of aggregationRoad vehicles traffic controlStructure of Management InformationTransport network

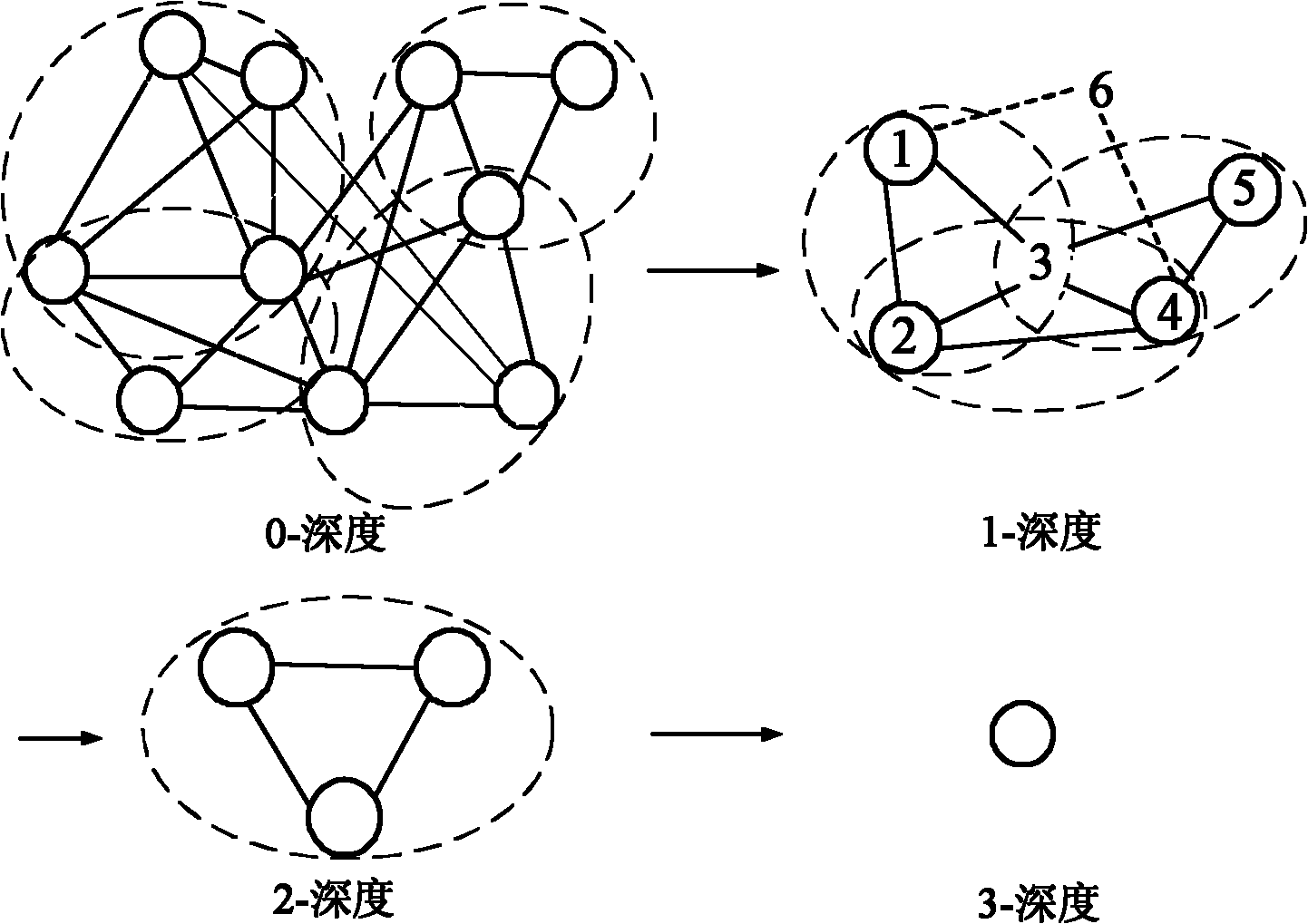

The invention provides an urban public transport network optimization method capable of improving overall transfer performance. In the method, a public transport network is expressed as relation between stations and lines (cliques, the largest complete subgraph in the network). The method comprises the following steps: setting network diameter to be N; simulating the growth process of the actual public transport network to be optimized; starting from an original network with only one clique, adding one clique to the original network at each time step, and forming the network which is composedof overlapped cliques and is logically shown as a structure with (N+1) layers, wherein, the clique at a (m-1) layer is mapped into a point at a m layer, and m is not less than 1 and not more than N+1; and regulating the network after one clique is added at each time step so as to ensure that the network at each layer is composed of the cliques so that the optimized public transport network becomes an ideal clique network with the depth N. By utilizing the method, average transfer time and average shortest path time coefficient of the public transport network can be effectively reduced, and concentration degree of the bus lines is improved, thus realizing higher transfer efficiency of a public transport system.

Owner:ZHEJIANG UNIV OF TECH

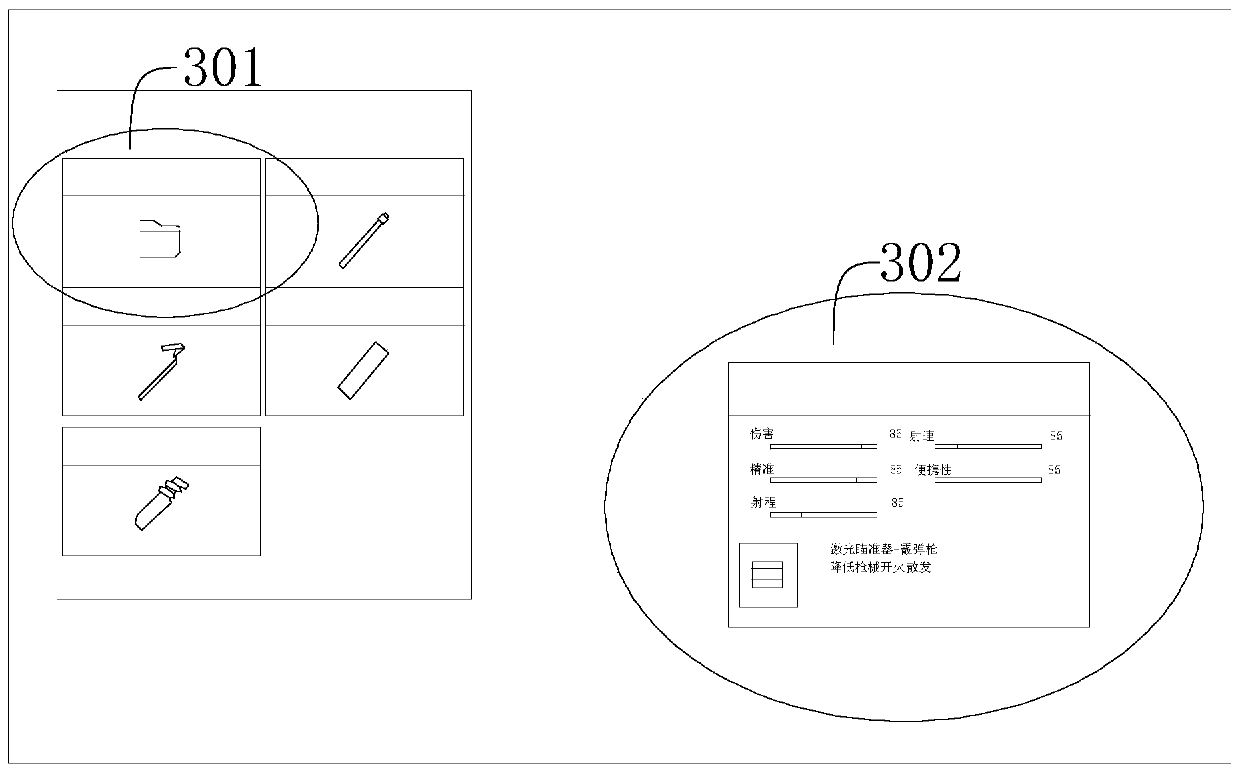

Operation control method and device, storage medium and electronic device

Owner:TENCENT TECH (SHENZHEN) CO LTD

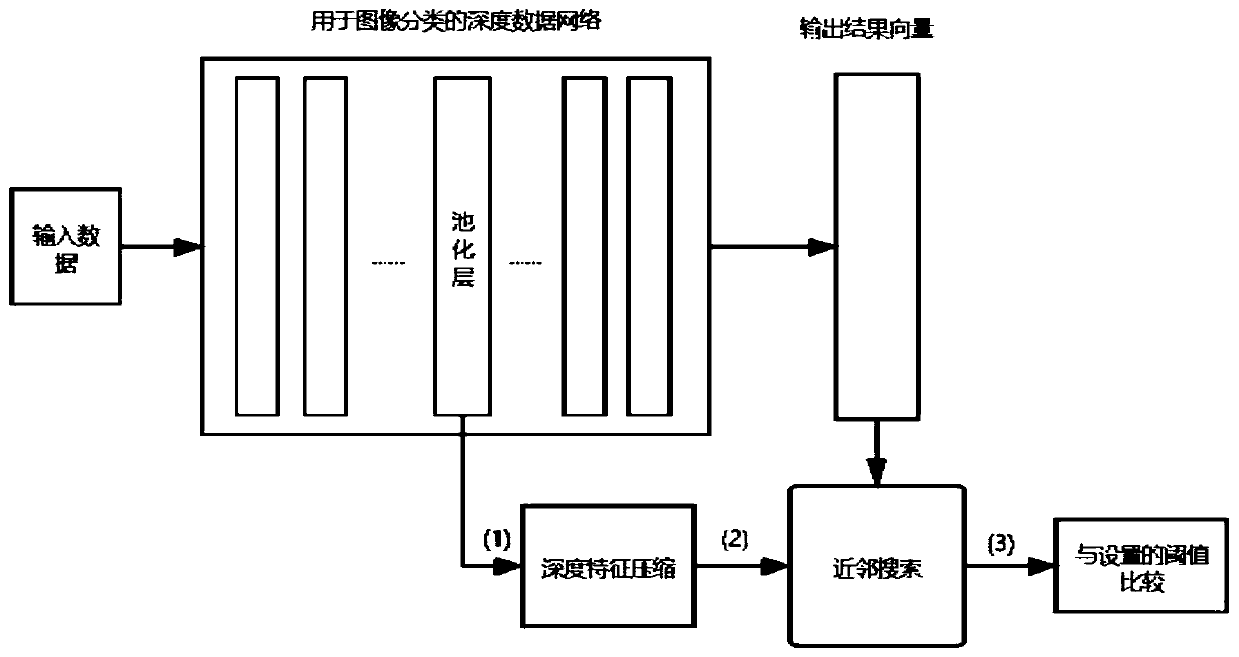

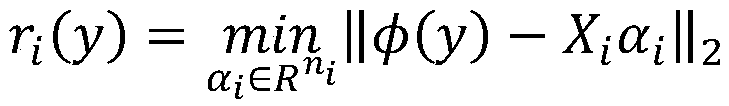

Traffic sign adversarial sample detection method based on neighbor discrimination and classification device

InactiveCN111460881AIncreased generation difficultyImprove computing efficiencyCharacter and pattern recognitionNeural learning methodsData setOriginal data

The invention discloses a traffic sign adversarial sample detection method based on neighbor discrimination and a classification device, and belongs to the field of machine learning. The method comprises: inputting a to-be-detected sample into a trained traffic sign classification network to obtain a first classification result and an intermediate feature map; inputting the intermediate feature map of the to-be-detected sample into a neighbor discrimination model, and taking a data set of the neighbor discrimination model as an intermediate feature map set of the training sample to obtain theprobability that the to-be-detected sample belongs to each traffic sign category; and judging whether the probability that the to-be-detected sample belongs to the first classification result is greater than or equal to a set threshold, if so, determining that the sample is a normal sample, otherwise, determining that the sample is an adversarial sample. AThe idea of calculating the similarity between the samples of the neighbor discriminant classification model and the simplicity and high efficiency of the method are utilized, on the premise of not influencing the classification performance of the deep neural network, the representation of an original data sample is changed, and the generation difficulty and attack difficulty of an adversarial sample are increased, so that the active defense capability of the system is improved, and the complexity of the model is not increased.

Owner:HUAZHONG UNIV OF SCI & TECH

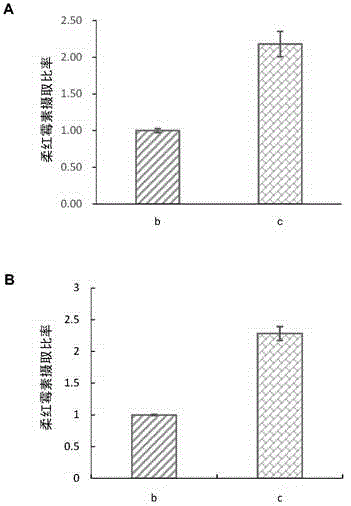

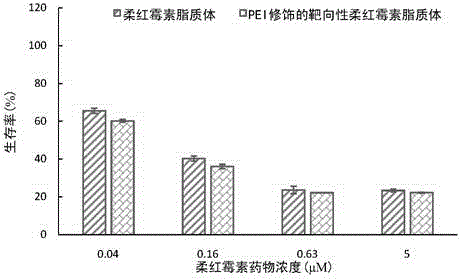

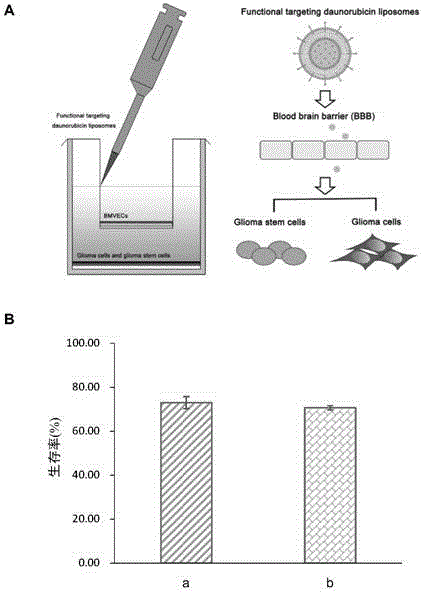

Functional targeting vector material distearoyl phosphatidylethanolamine-polyethylene glycol-polyethylenimine compound and modified liposome thereof

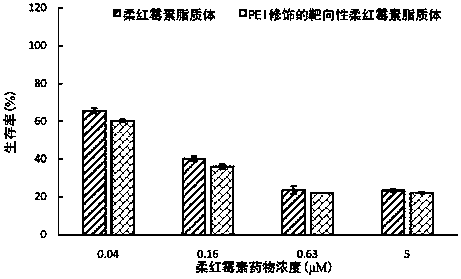

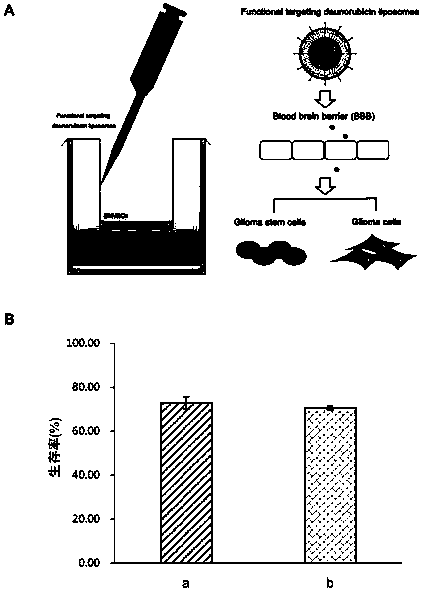

ActiveCN106798923ARatio of uptake increasedStrongly selective centralized distributionPharmaceutical non-active ingredientsAntineoplastic agentsGrowth inhibitoryLiposome

The invention discloses a functional targeting vector material distearoyl phosphatidylethanolamine-polyethylene glycol-polyethylenimine compound and a modified liposome thereof. According to the invention, a DSPE-PEG2000-PEI600 compound is taken as a targeting molecule to modify a drug-carrying liposome surface, so that the drug can selectively gather in tumor cells through a blood brain barrier effectively so as to generate a targeting effect. For instance, the drug uptake rate of C6 glioma cells and glioma stem cells is increased significantly, so that the drug can have strongest selective concentrated distribution on mitochondria of C6 glioma cells and glioma stem cells, shows stronger growth inhibitory effect on glioma cells, and shows stronger effects of crossing the blood brain barrier and killing glioma stem cells, i.e. dual targeting effect, and the cycle time of the drug in ICR mice and the gathering degree in tumor tissues can be prolonged, thus prolonging the life time of organisms.

Owner:PEKING UNIV

Composite filter-pressing centrifugal dehydrant

InactiveCN103058491AIncrease in sizeEasy dischargeSludge treatment by de-watering/drying/thickeningFoaming agentComposite filter

The invention discloses a composite filter-pressing centrifugal dehydrant, which comprises lime, PAM and a foaming agent, wherein the mass ratio of the lime, the PAM and the foaming agent is (1.0-1.4):(1-0.3):( 0.05-0.1). The composite filter-pressing centrifugal dehydrant disclosed by the invention is high in dehydrating efficiency.

Owner:WENZHOU UNIVERSITY

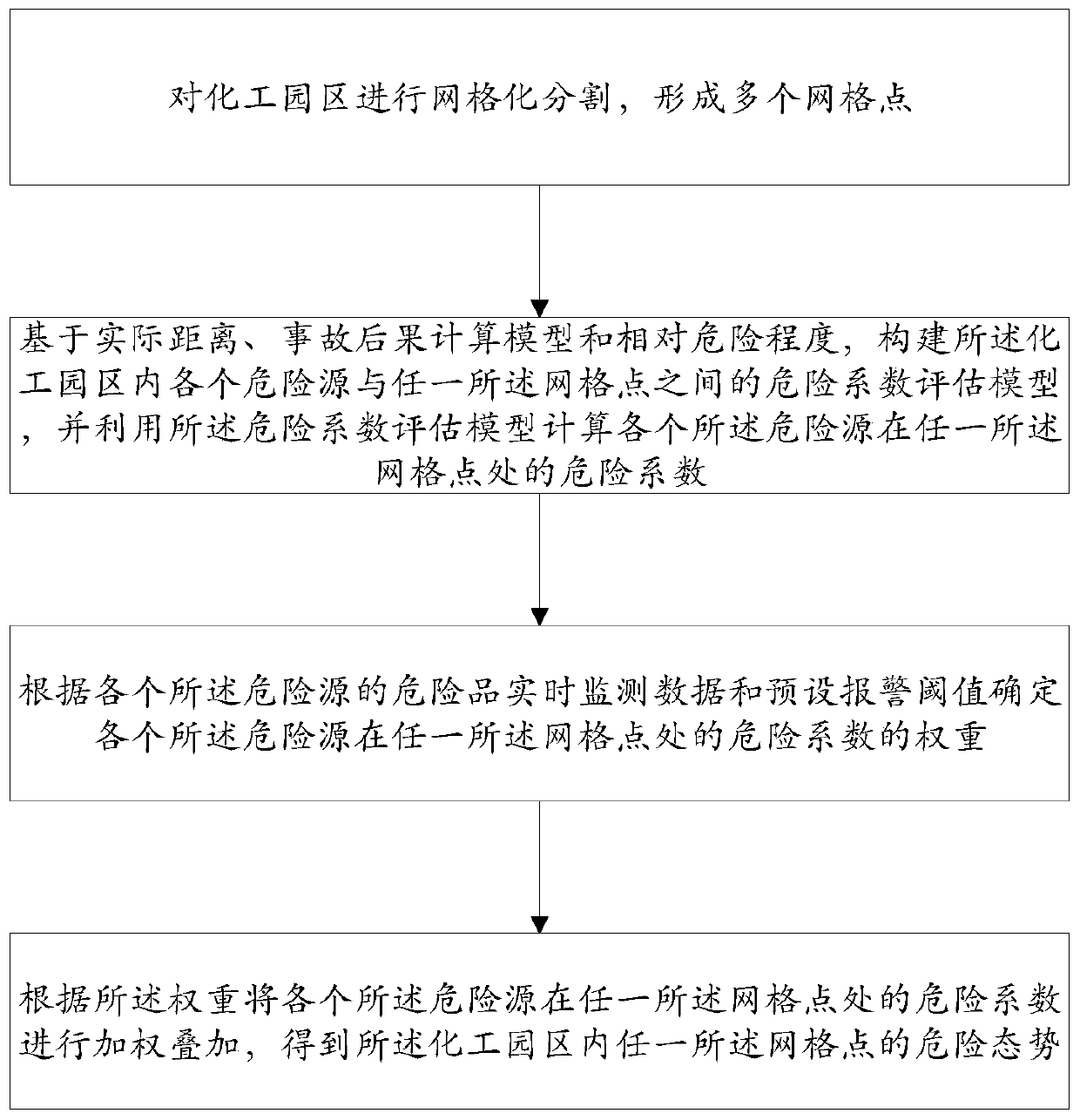

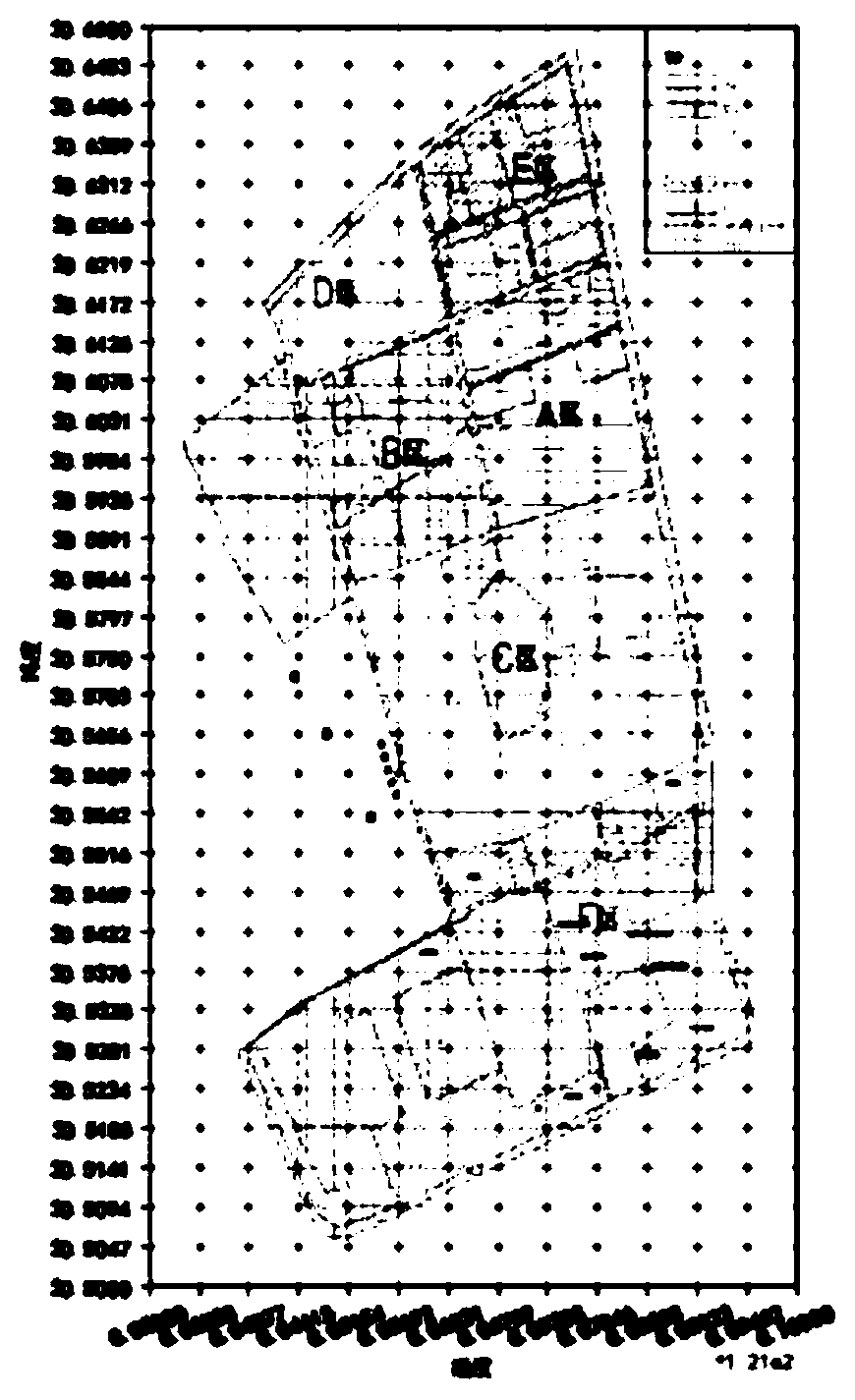

Chemical industry park hazard situation awareness method and system based on multi-source data fusion

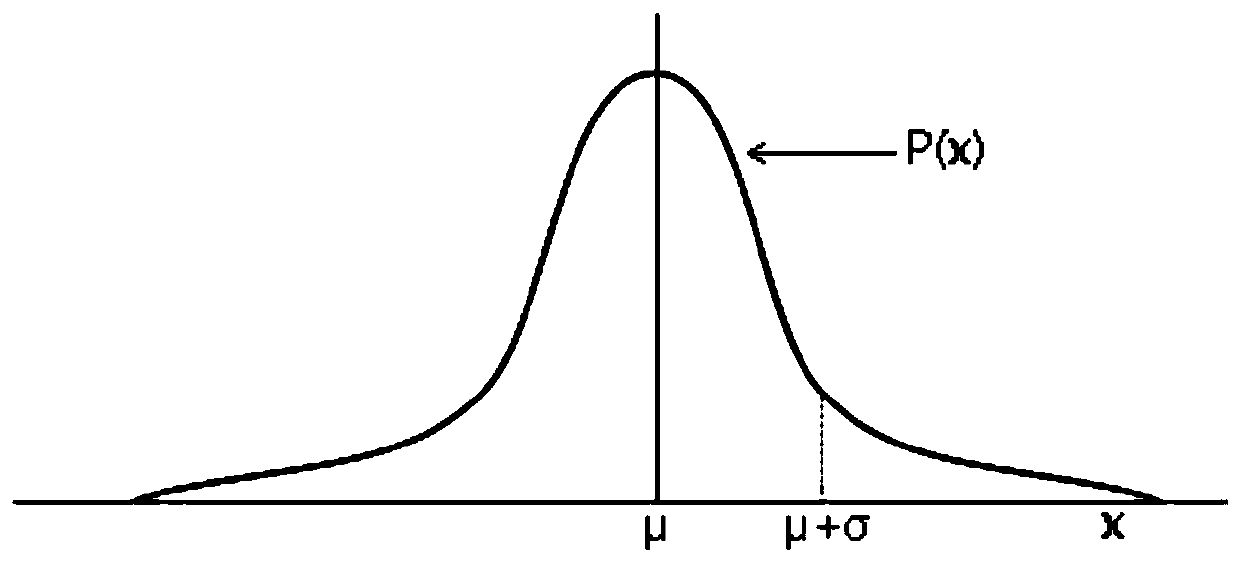

The invention relates to a chemical industrial park hazard situation awareness method and system based on multi-source data fusion. The chemical industrial park hazard situation awareness method comprises the steps: carrying out the grid segmentation of a chemical industrial park, and forming a plurality of grid points; based on the actual distance, the accident consequence calculation model and the relative danger degree, constructing a danger coefficient evaluation model between each danger source and any grid point in the chemical industry park; determining the weight of the danger coefficient of each danger source at any grid point according to the dangerous goods real-time monitoring data of each danger source and a preset alarm threshold; and according to the weight, carrying out weighted superposition on the danger coefficient of each danger source at any grid point to obtain the danger situation of any grid point in the chemical industry park. According to the chemical industrial park hazard situation awareness method, whether danger occurs can be sensed, and the distribution of the danger degree of the chemical industrial park can be sensed when danger occurs, and the sensing capability of the chemical industrial park in the aspects of danger situation and dangerous area distribution can be improved, and the danger is prevented.

Owner:嘉兴恒云数据科技有限公司

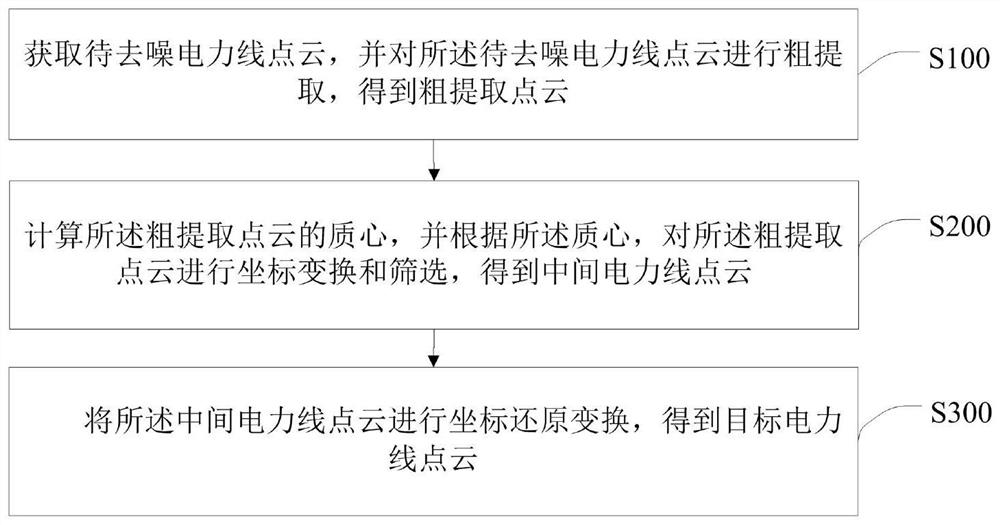

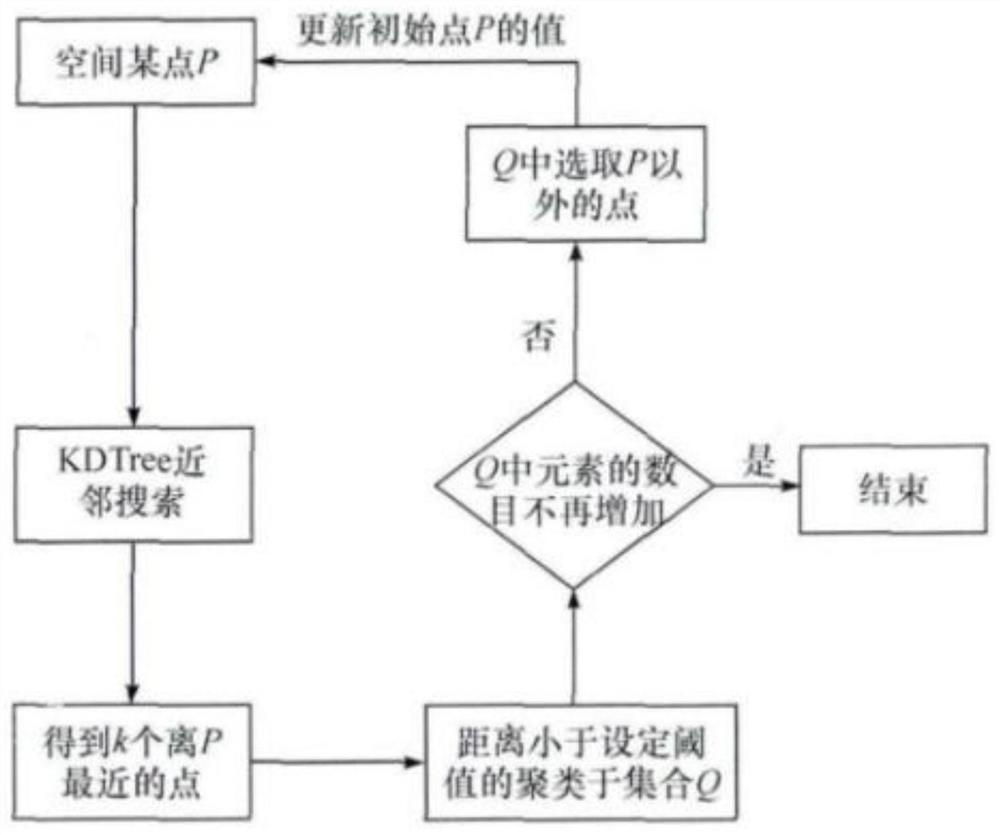

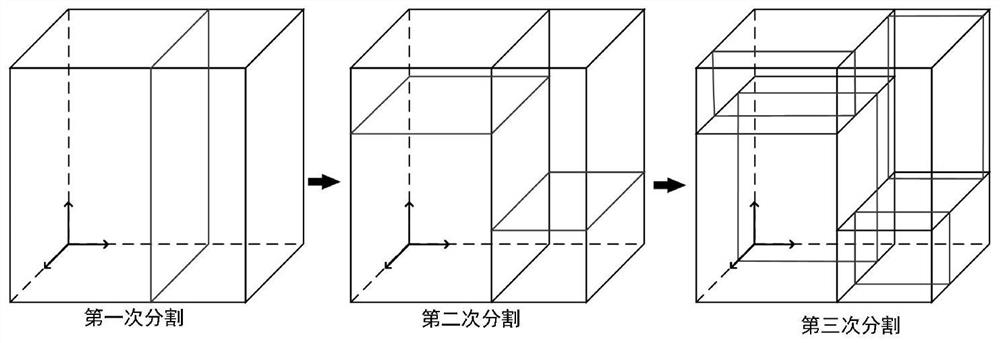

Denoising method and device for point cloud data and storage medium

ActiveCN113538264AIncrease the degree of aggregationPreserve integrityImage enhancementImage analysisData integrityAlgorithm

The invention discloses a denoising method and a device for point cloud data and a storage medium. The method comprises the following steps: obtaining a to-be-denoised power line point cloud, and carrying out the coarse extraction of the to-be-denoised power line point cloud, and obtaining a coarse extraction point cloud; calculating the center of mass of the coarsely extracted point cloud, and performing coordinate transformation and screening on the coarsely extracted point cloud according to the center of mass to obtain an intermediate power line point cloud; and performing coordinate reduction transformation on the intermediate power line point cloud to obtain a target power line point cloud. According to the method provided by the embodiment of the invention, the point cloud data is compressed along the power line direction in a coordinate transformation manner, so that the aggregation degree of the power line point cloud is improved, noise points influencing subsequent operation are removed as many as possible on the premise of keeping the integrity of the power line data, and the denoising accuracy and effect are improved; the processed point cloud data has higher robustness, better data is provided for subsequent point cloud processing work, and the convenience is brought to users.

Owner:SHENZHEN UNIV

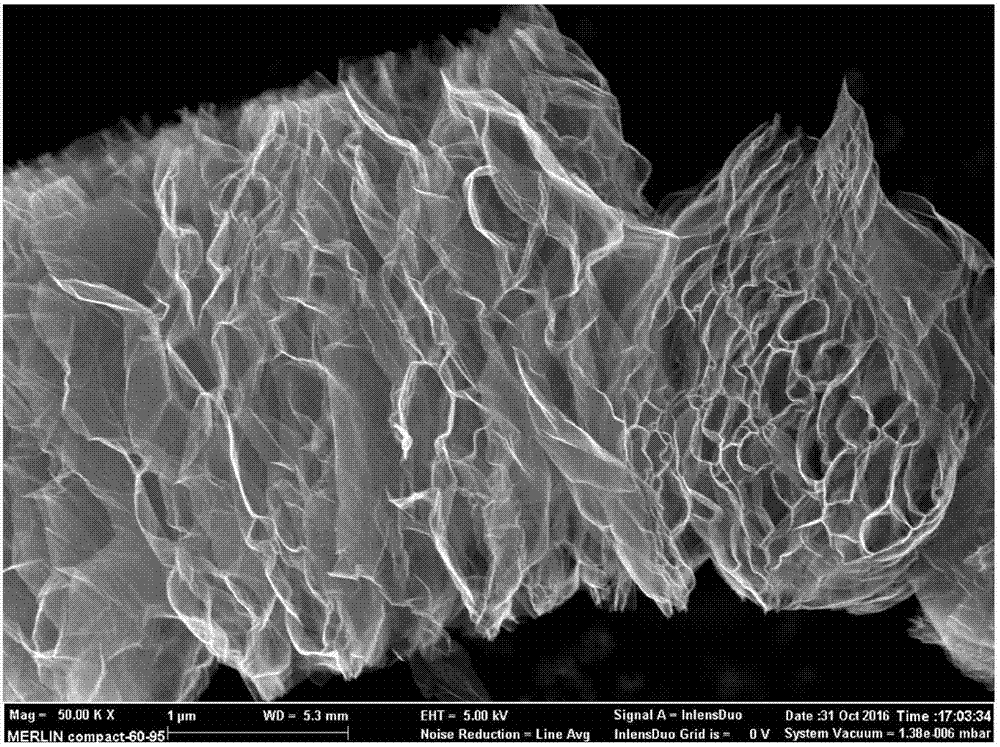

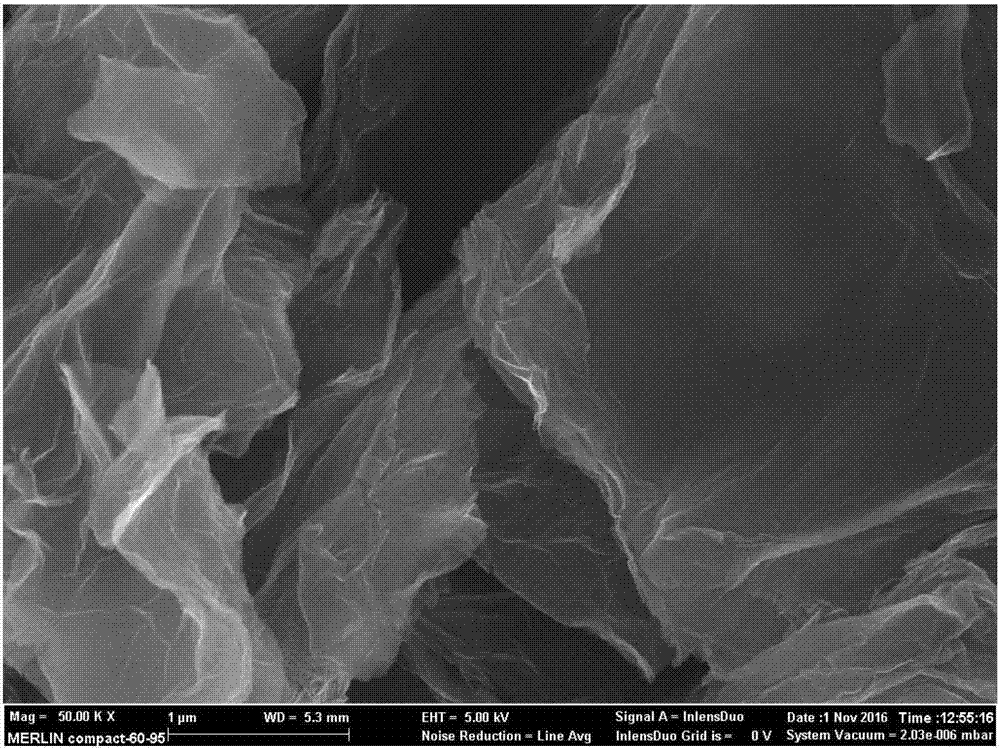

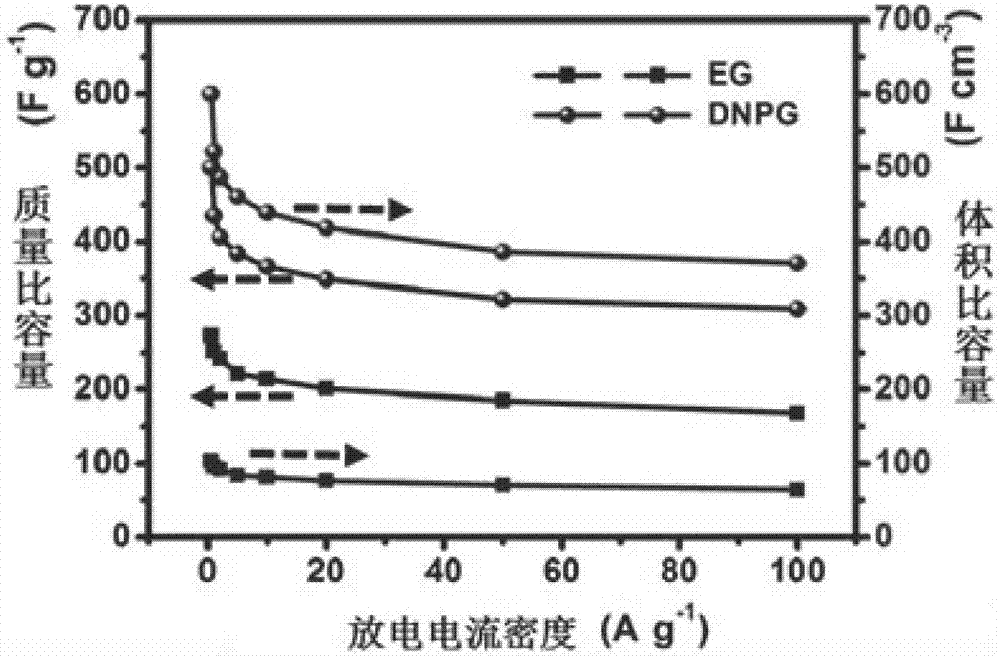

Graphene with high density and high electrochemical specific capacity, as well as preparation method and application thereof

ActiveCN107244668AIncrease the degree of aggregationHigh reactivityCarbon compoundsHybrid capacitor electrodesIonCvd graphene

The invention discloses graphene with high density and high electrochemical specific capacity, as well as a preparation method and application thereof. The preparation method comprises the following steps: putting low-density graphene into ionic liquid, performing heat treatment at 100 to 450 DEG C for more than 1 hour, then performing solid liquid separation, cooling, washing the product with deionized water until the pH value is 7, and finally putting into a blast drying box and drying to obtain the graphene with high density and high electrochemical specific capacity, wherein the ionic liquid is liquid of one or more of inorganic acid, inorganic alkali, inorganic salt and organic salt. In the compacting process of the graphene, the graphene is doped with heterotopic atoms, the plane of the graphene is subjected to pore formation, the density of the prepared graphene can reach above 1 g / cm<3>, the specific surface area can reach above 300 m<2> / g, and high-quality specific capacity and high-volume capacity can be shown simultaneously when being applied in the field of electrochemical energy storage.

Owner:WUHAN UNIV

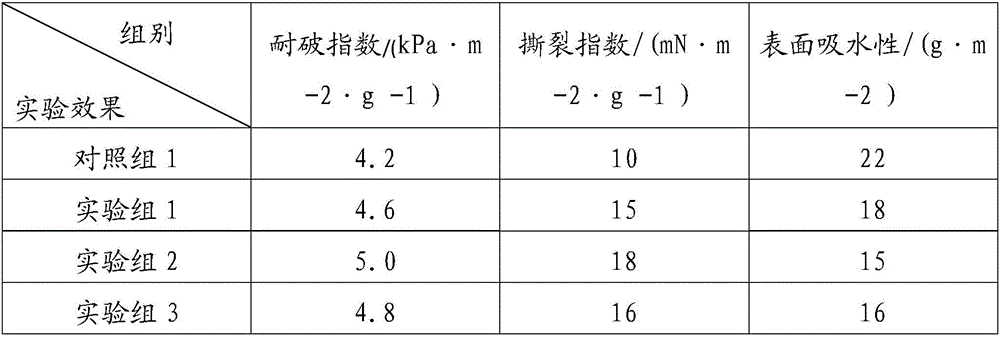

Burst-resistant brown paper and making method thereof

InactiveCN106522016AHigh strengthImprove uniformityPulp bleachingInorganic compound additionFiberZinc borate

The invention discloses a burst-resistant brown paper and a making method thereof. The burst-resistant brown paper is produced from, by weight, 50-70 parts of coniferous bark, 40-60 parts of broadleaf tree bark, 30-50 parts of waste paper, 10-20 parts of cotton fibers, 15-30 parts of wingceltis bark, 10-15 parts of bamboo, 18-26 parts of bagasse, 8-15 parts of wool, 20-30 parts of grass, 5-10 parts of talcum powder, 8-15 parts of calcium carbonate, 3-5 parts of titanium dioxide, 4-10 parts of diatomite, 5-8 parts of clay, 1-5 parts of zinc borate and 5-10 parts of aluminum sulfate. The t brown paper produced in the invention has good burst resistance.

Owner:广州市极合技术咨询有限公司

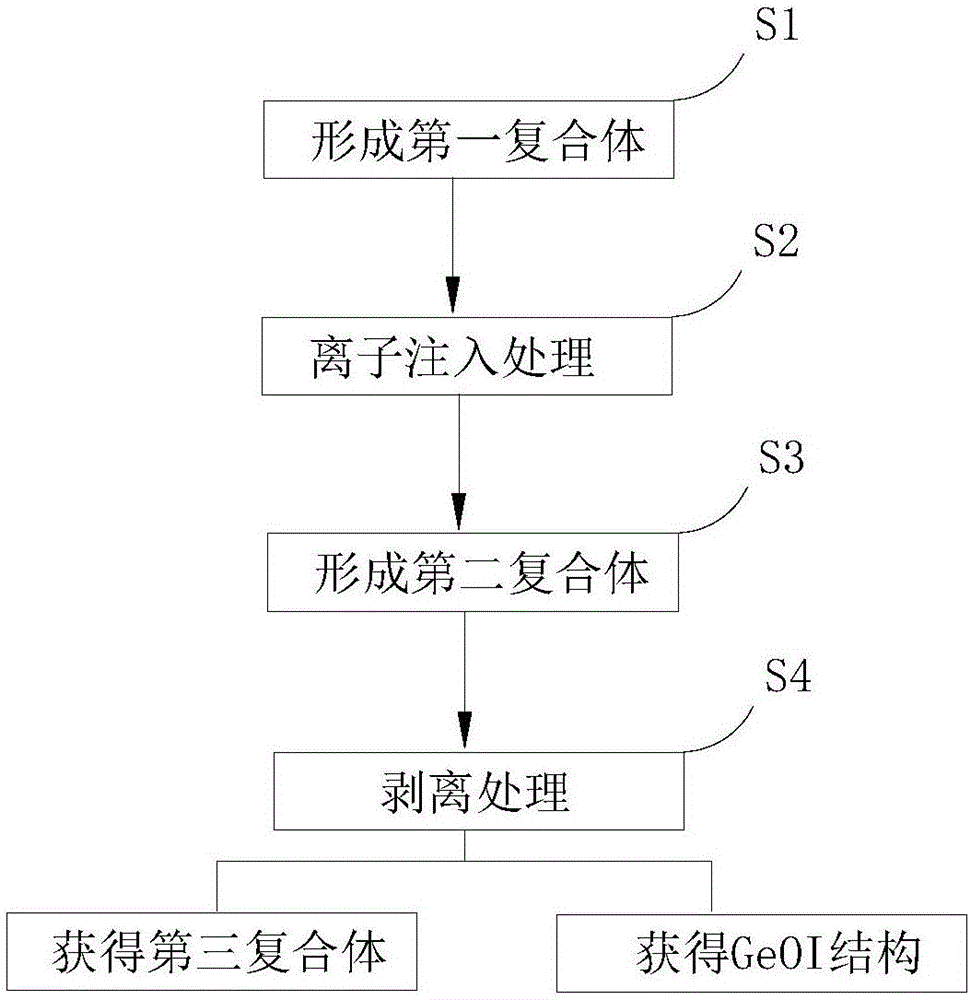

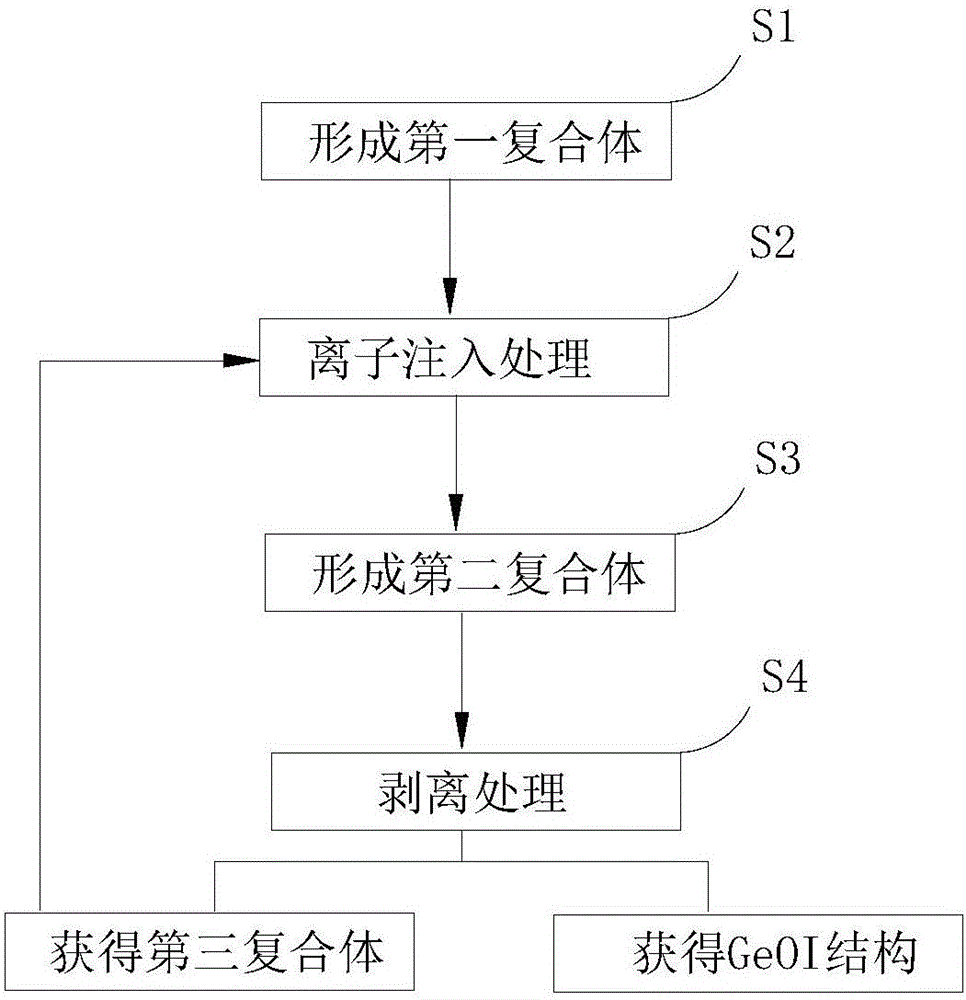

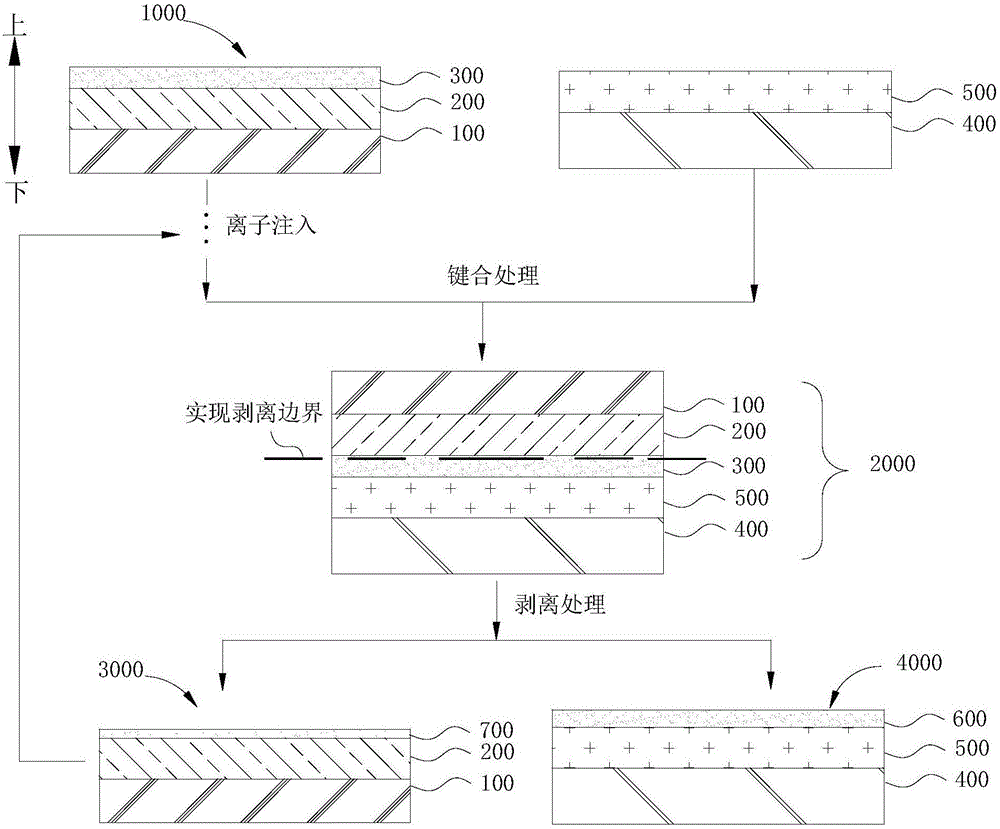

GeOI (Ge-on-insulator) structure and preparation method

InactiveCN106531682AReduce manufacturing costSmall doseSemiconductor/solid-state device manufacturingHydrogenBonding process

The invention discloses a GeOI (Ge-on-insulator) structure and a preparation method. The method comprises the steps of: (1) forming a germanium transition layer and a germanium layer on the upper surface of a substrate in sequence to obtain a first complex; (2) injecting ions containing hydrogen ions to the first complex; (3) bonding the first complex with the substrate to obtain a second complex, wherein an insulating layer is formed on the upper surface of the substrate, and the insulating layer contacts the germanium layer in the bonding process; and (4) peeling the second complex to obtain a third complex and the GeOI structure respectively. The method is simple in operation and low in requirement for equipment, and can avoid size limit to the GeOI structure due to too small size of a Ge wafer for preparing the GeOI structure.

Owner:TSINGHUA UNIV

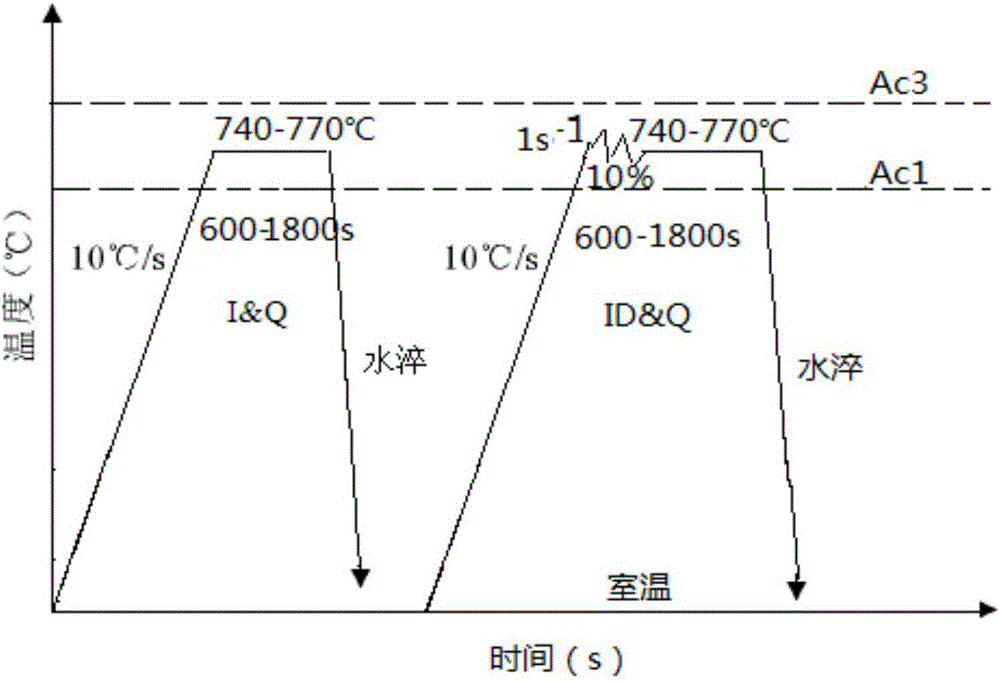

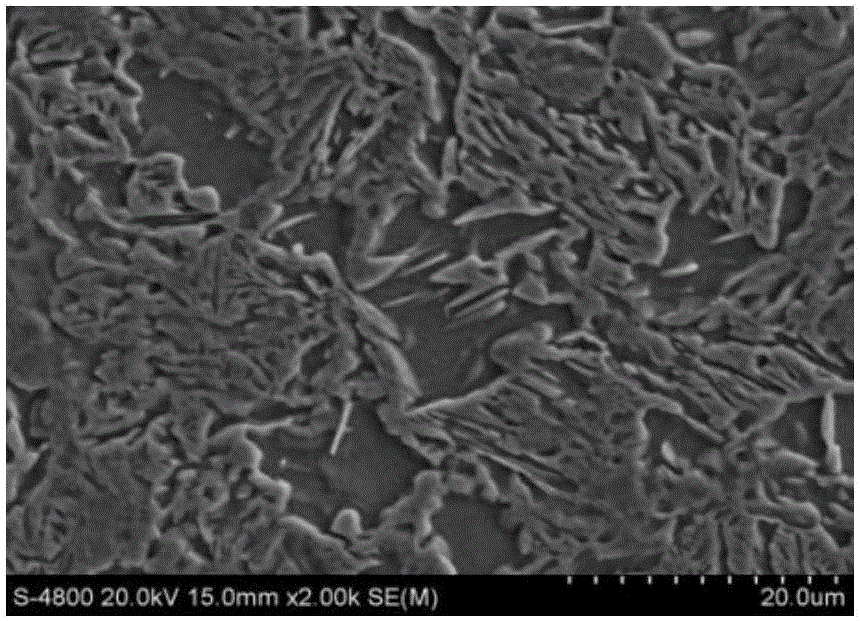

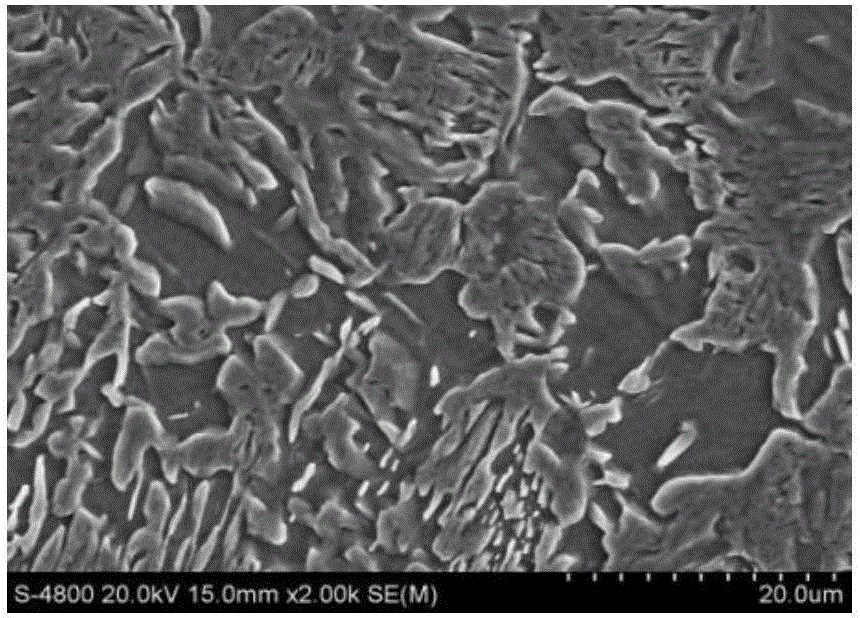

Low carbon alloy steel treatment method

The invention provides a low carbon alloy steel treatment method. The low carbon alloy steel treatment method comprises the following steps that (a) a low carbon alloy steel blank is cast and forged into a plate blank; (b) the plate blank is subjected hot rolling to obtain an finish-rolled plate; and (c) the end-rolled plate is deformed immediately after being heated to the two-phase region temperature and subjected to water quenching to the room temperature after heat preservation. According to the low carbon alloy steel treatment method, two-phase region heat preservation alloy element partition behaviors, vacancy generation of two-phase region heat deformation and interstitial atoms of low carbon alloy steel are combined to achieve the effect of improving alloy element partition, the effect of inherent alloy elements in steel is achieved, the concentration degree, in austenite (room temperature martensite), of the alloy elements is improved on the basis that original C partition is fully achieved, and favorable support is provided for stabilizing more residual austenite and making up strength and ductility product reduction in the subsequent Q and P treatment technology; and experimental results show that the concentration degree of the alloy elements can be increased by 2%-5% through the low carbon alloy steel treatment method.

Owner:秦皇岛宏兴钢铁有限公司

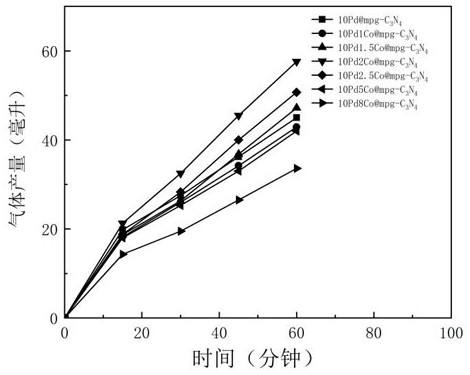

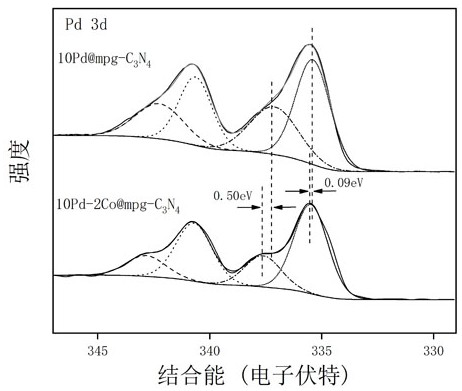

Preparation method of palladium-cobalt/carbon nitride composite material and product and application thereof

PendingCN112121836AIncrease electron densityIncrease the degree of aggregationHydrogenCatalyst activation/preparationCarbon compositesHeterojunction

The invention discloses a preparation method of a palladium-cobalt / carbon nitride composite material and a product and an application thereof. The preparation of the palladium-cobalt / carbon nitride composite material with a heterojunction structure is achieved by utilizing a hard template method and a step-by-step impregnation reduction method, and by virtue of rich pore structure formation of mesoporous graphite-phase carbon nitride, the obtained palladium-cobalt nanoparticles are ultrafine nanoparticles and are attached to pore channels and the surface of the carbon nitride material. The product obtained by the method is the palladium-cobalt / carbon nitride composite material, due to the existence of a heterojunction structure between the palladium-cobalt nanoparticles and the carbon nitride, the surfaces of the palladium particles have high electron density, photoelectrons generated by the carbon nitride under illumination can be captured, therefore, the prepared composite material shows excellent photocatalytic hydrogen production performance and has great application potential in the field of hydrogen production from formic acid and other raw materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

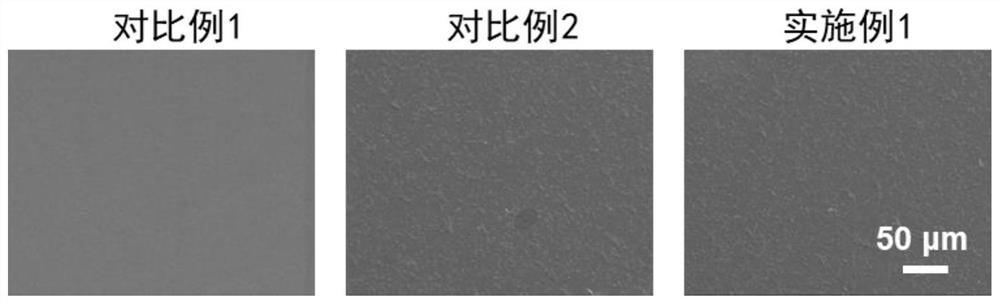

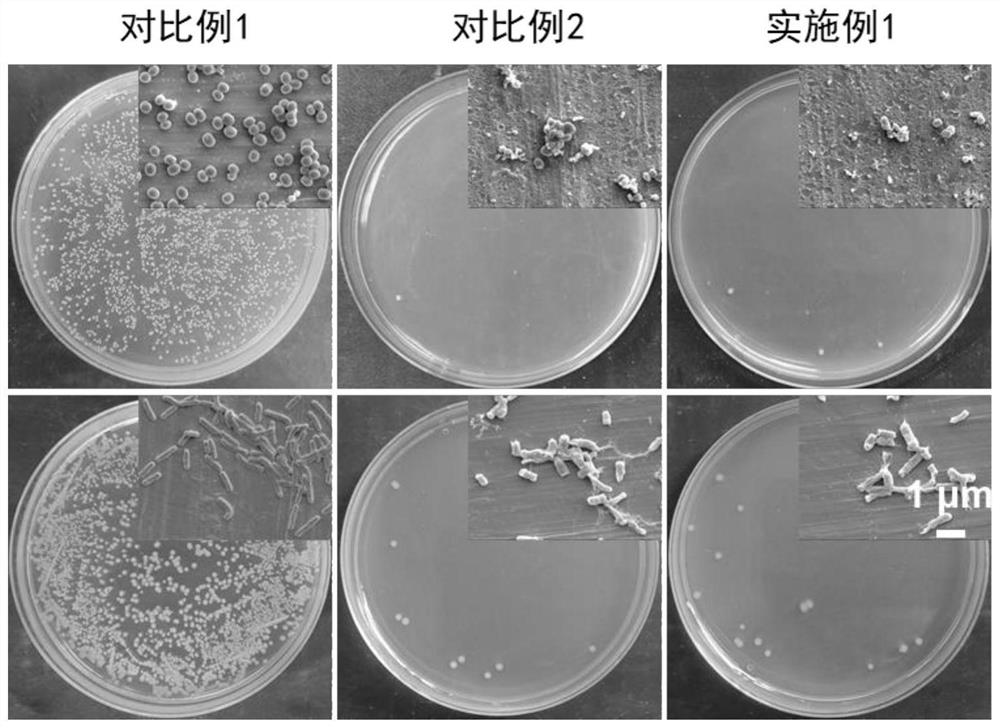

Coating material with modified protein as well as preparation method and application of coating material

PendingCN114601970AImprove thermal stabilityGood stabilitySurgeryPharmaceutical delivery mechanismProtein proteinSide chain

Owner:DONGGUAN PEOPLES HOSPITAL

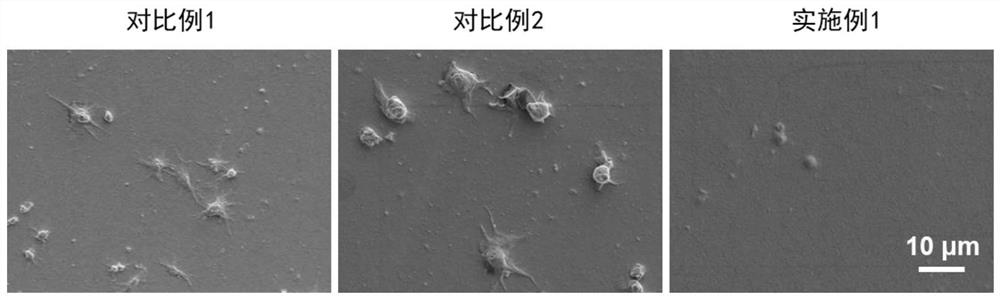

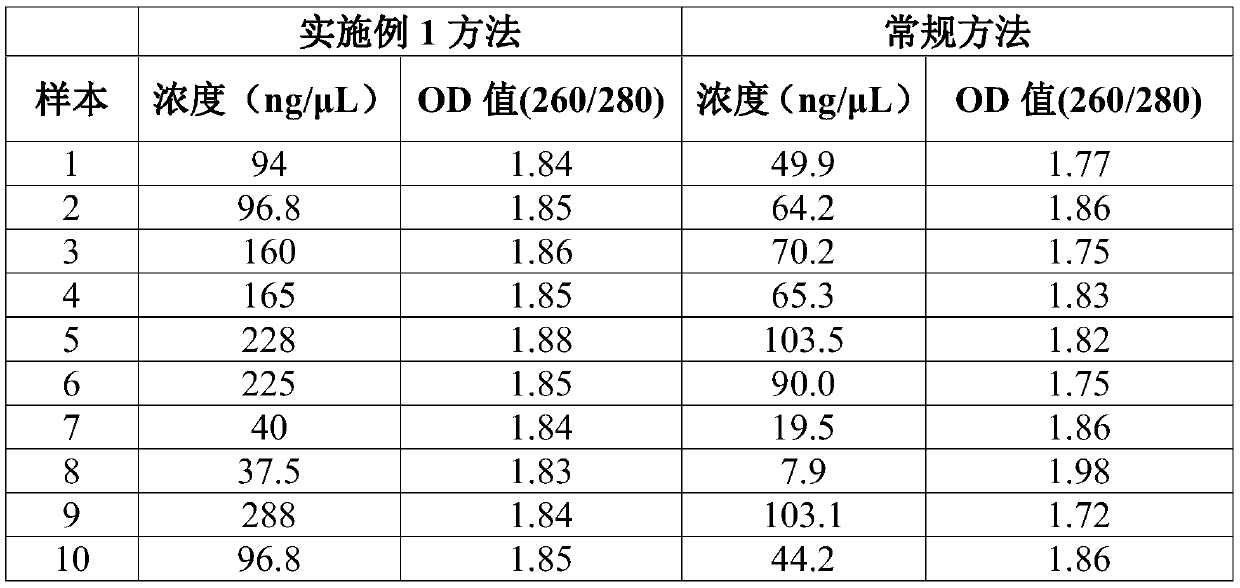

Extraction method of mycobacterium tuberculosis DNA

ActiveCN110172497AImprove extraction efficiencyIncrease concentrationMicrobiological testing/measurementMicroorganism based processesIsoamyl alcoholMicrobiology

The invention belongs to the technical field of biology, and particularly relates to an extraction method of mycobacterium tuberculosis DNA, comprising the following steps: obtaining mycobacterium tuberculosis, and inactivating the mycobacterium tuberculosis to obtain the inactivated mycobacterium tuberculosis; firstly performing vortex oscillation dispersion treatment on the sterilized mycobacterium tuberculosis is subjected to, and then ultrasonically dispersing to obtain mycobacterium tuberculosis dispersion liquid; performing wall breaking treatment on the mycobacterium tuberculosis dispersion liquid to obtain a wall breaking product; performing first extraction on the wall breaking product by a CTAB / NaCl solution, and then performing second extraction by using a mixed liquor of phenol, chloroform and isoamyl alcohol to obtain an extracted product; precipitating the extracted product by isopropanol and glycogen to obtain mycobacterium tuberculosis DNA. The extraction method disclosed by the invention has the advantages of high extraction quality and easiness in operation, and is suitable for being carried out in an ordinary biological laboratory.

Owner:SHENZHEN UNI MEDICA TECH

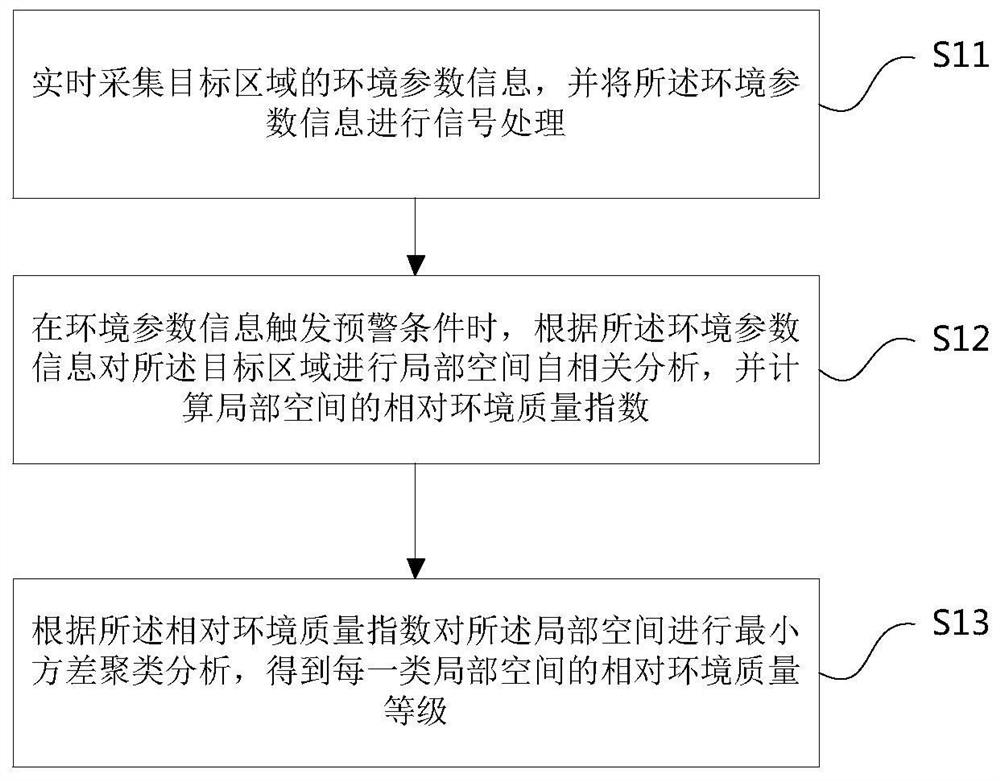

Environment monitoring method and system based on Internet, storage medium and equipment

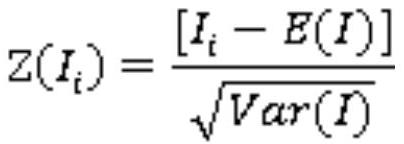

InactiveCN112232251AImprove monitoring accuracyAccurately reflect the environmental qualityCharacter and pattern recognitionMaterial analysisEnvironmental resource managementThe Internet

The invention relates to an environment monitoring method and system based on the Internet, a storage medium and equipment. The method comprises the steps of collecting environment parameter information of a target area in real time; making local space autocorrelation analysis on the target area when the environmental parameter information after signal processing triggers an early warning condition, and calculating a relative environmental quality index of a local space; and making minimum variance clustering analysis on the local spaces to obtain a relative environment quality grade of each type of local space. By preliminarily judging whether the early warning condition is triggered or not, the overall environment quality of the target area can be preliminarily evaluated, then local space autocorrelation analysis is conducted on the target area to conduct targeted analysis on the local space, clustering analysis is conducted in combination with the relative environment quality indexof the local space. The environmental quality grade of the local space of each category is determined, so that the environmental quality monitoring precision is greatly improved, the environmental quality condition of the target area can be reflected more accurately, and guidance is provided for scientific environmental governance.

Owner:兰州旭阳祥辉科技有限公司

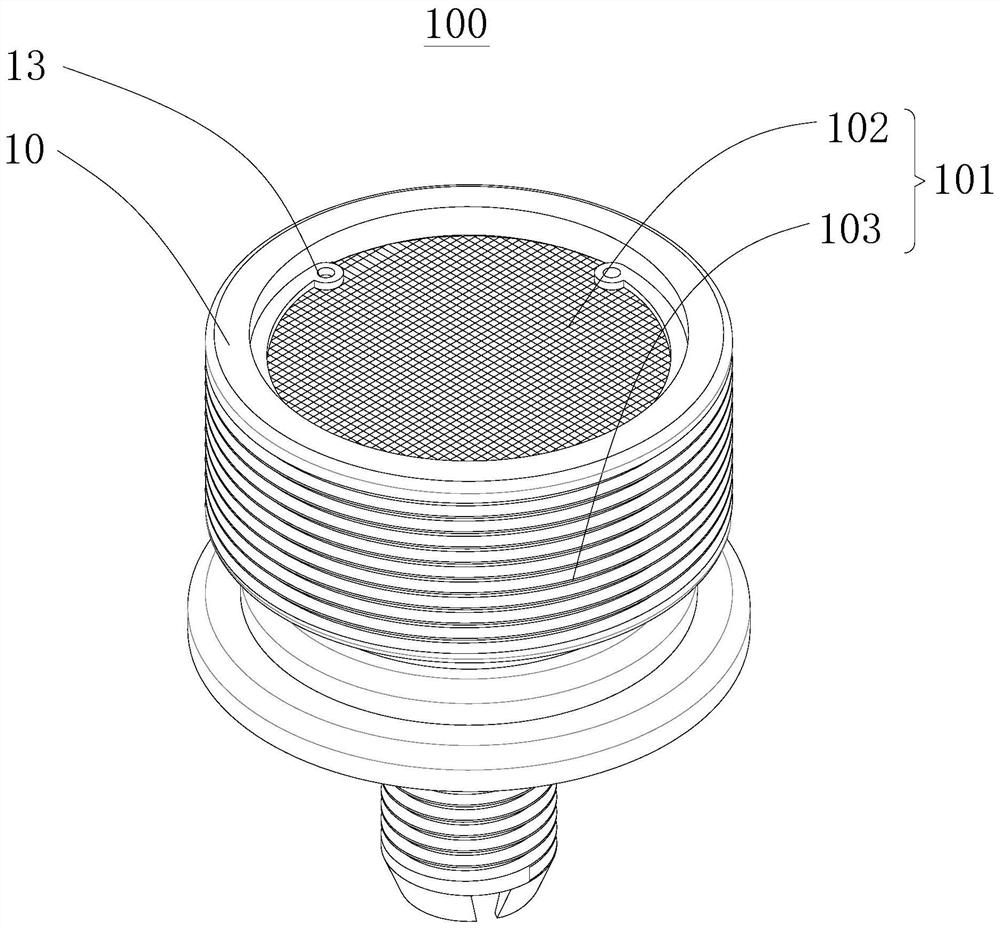

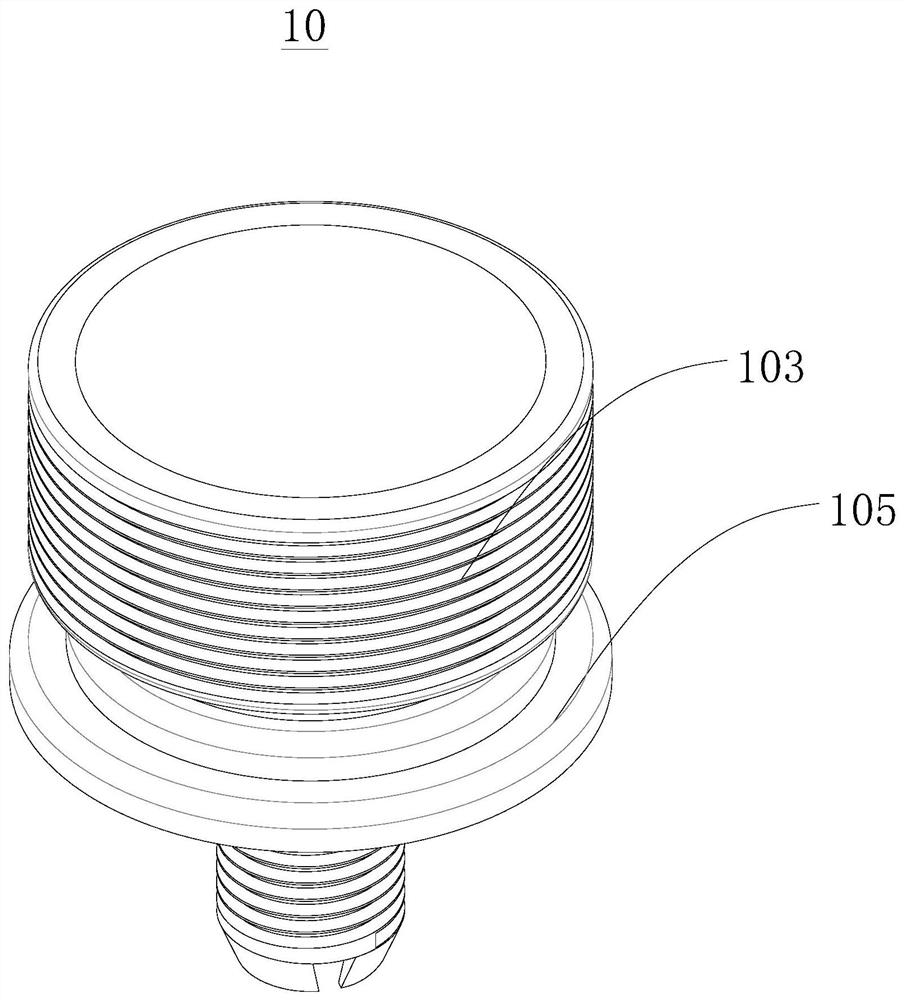

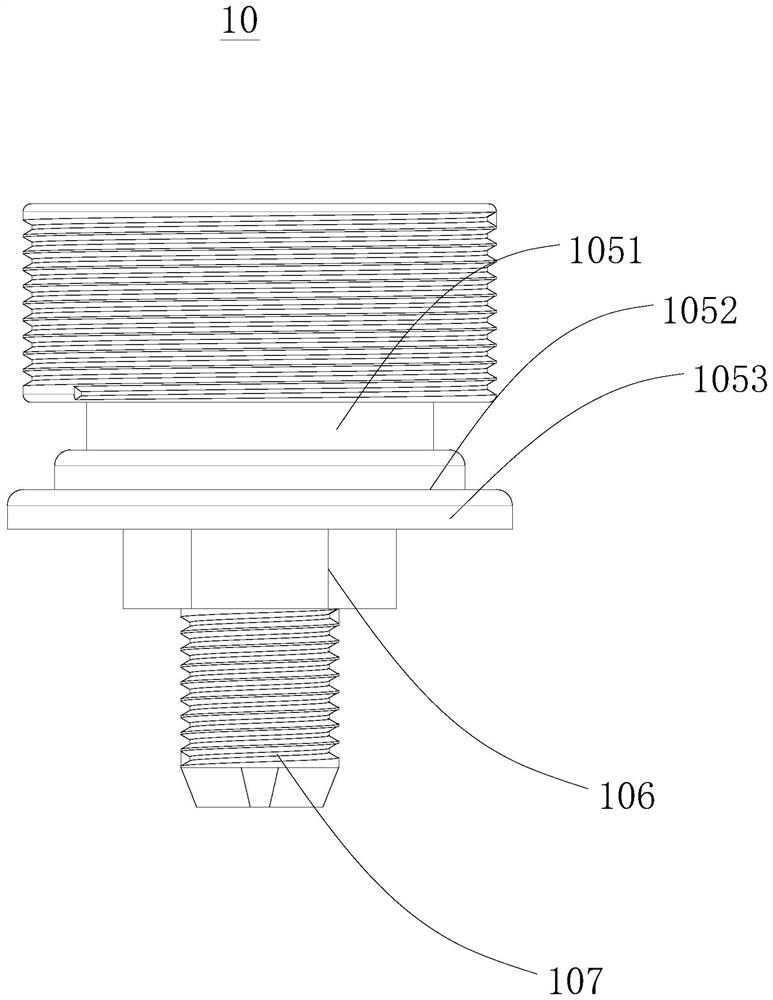

Fuel saving joint and fuel economizer

PendingCN113153586ASmall diameterImprove fuel efficiencyInternal combustion piston enginesCombustion-air/fuel-air treatmentFlue gasFuel efficiency

The invention provides a fuel saving joint and a fuel economizer, and relates to the technical field of automobile fuel saving. The oil saving joint comprises a joint body, a magnetic sheet assembly, and a filter screen assembly. The joint body is provided with a containing cavity; and the filter screen assembly is embedded in the containing cavity and divides the containing cavity into a first containing cavity and a second containing cavity. The magnetic sheet assembly comprises a magnetic sheet body and a clamping body layer; the clamping body layer is arranged in the second containing cavity and matched with the second containing cavity to form a magnetic sheet containing cavity for containing the magnetic sheet body; and the magnetic sheet body is embedded in the magnetic sheet containing cavity. The magnetic sheet body and the clamping body layer are both provided with notches, and the notches correspond to each other and are matched with each other. According to the oil saving joint, the magnetic sheet assembly and a filtering assembly are arranged in the containing cavity, and fuel is filtered and magnetized, so that the diameter of fuel drops is reduced, the fuel efficiency is improved, flue gas emission is reduced, and the effects of energy conservation and emission reduction are achieved. The fuel economizer comprises the fuel saving joint, and has all the beneficial effects of the fuel saving joint.

Owner:朱小琴

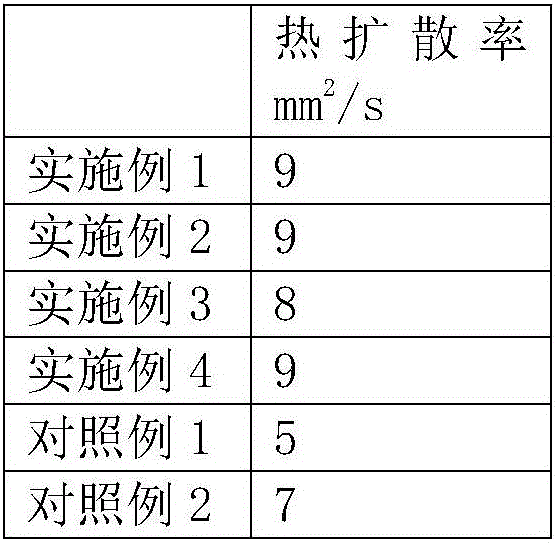

Preparation method of cryptocrystalline graphite/polyvinyl alcohol heat-conducting composite material

InactiveCN106751267AThermally conductiveIncrease the degree of aggregationChemical industryHeat-exchange elementsSodium bicarbonateHeat conducting

The invention discloses a preparation method of a cryptocrystalline graphite / polyvinyl alcohol heat-conducting composite material, and belongs to the field of composite materials. The method comprises the following steps: 1, mixing cryptocrystalline graphite, ammonium fluoride and a hydrochloric acid solution, heating, washing with deionized water until the pH value is 7, and drying; 2, mixing weighed sodium bicarbonate, corn starch and cryptocrystalline graphite, performing wet ball milling and drying; 3, dissolving polyvinyl alcohol into water, adding the treated cryptocrystalline graphite mixture, mixing uniformly and drying in a drying oven; 4, pulverizing and performing hot-press molding. The thermal diffusion rate is 8 to 9 mm<2> / s, because in the cryptocrystalline graphite granules subjected to purifying treatment, the aggregation degree is high, the density is increased, the heat-conducting effect is denser, and the heat transfer efficiency is improved.

Owner:NANJING JOOZ INFORMATION SCI & TECH

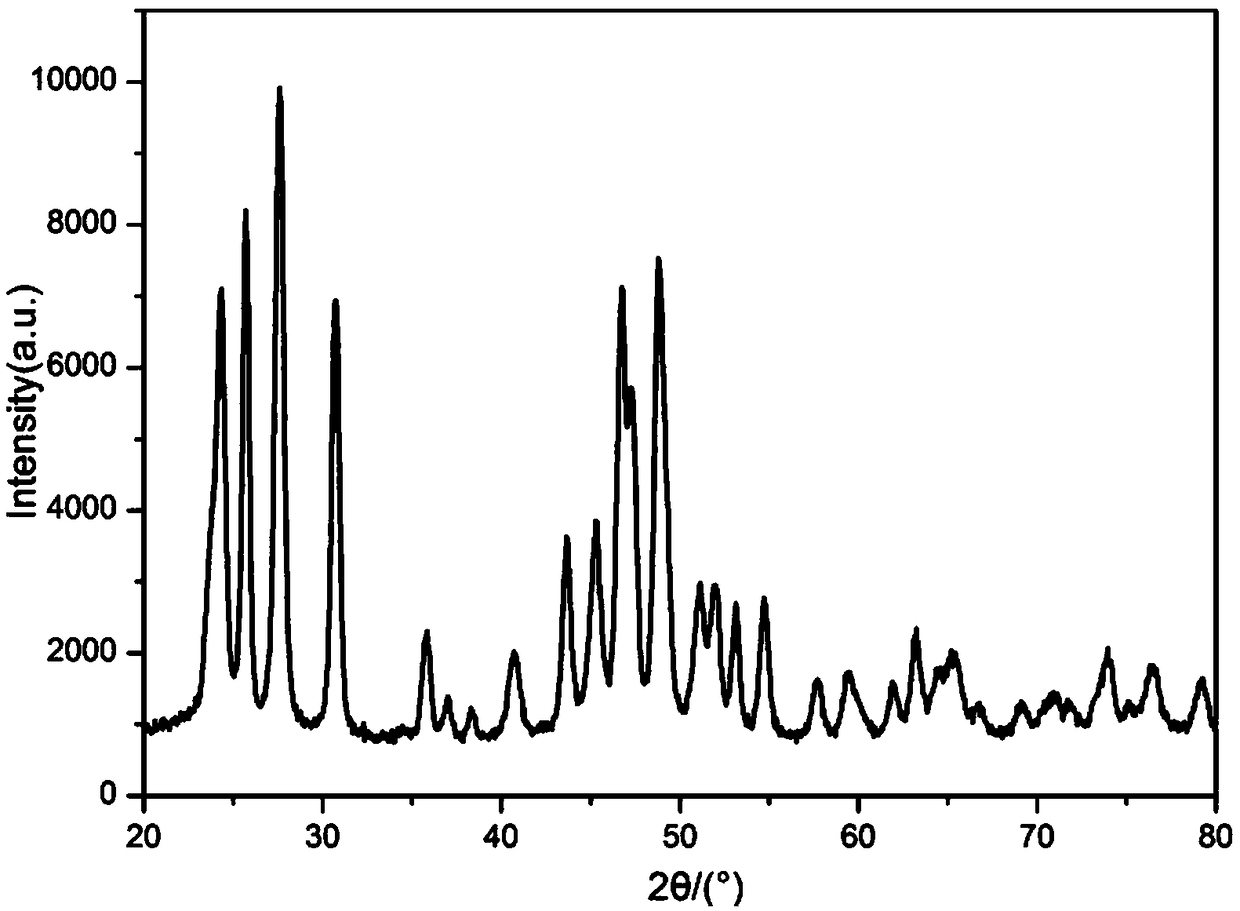

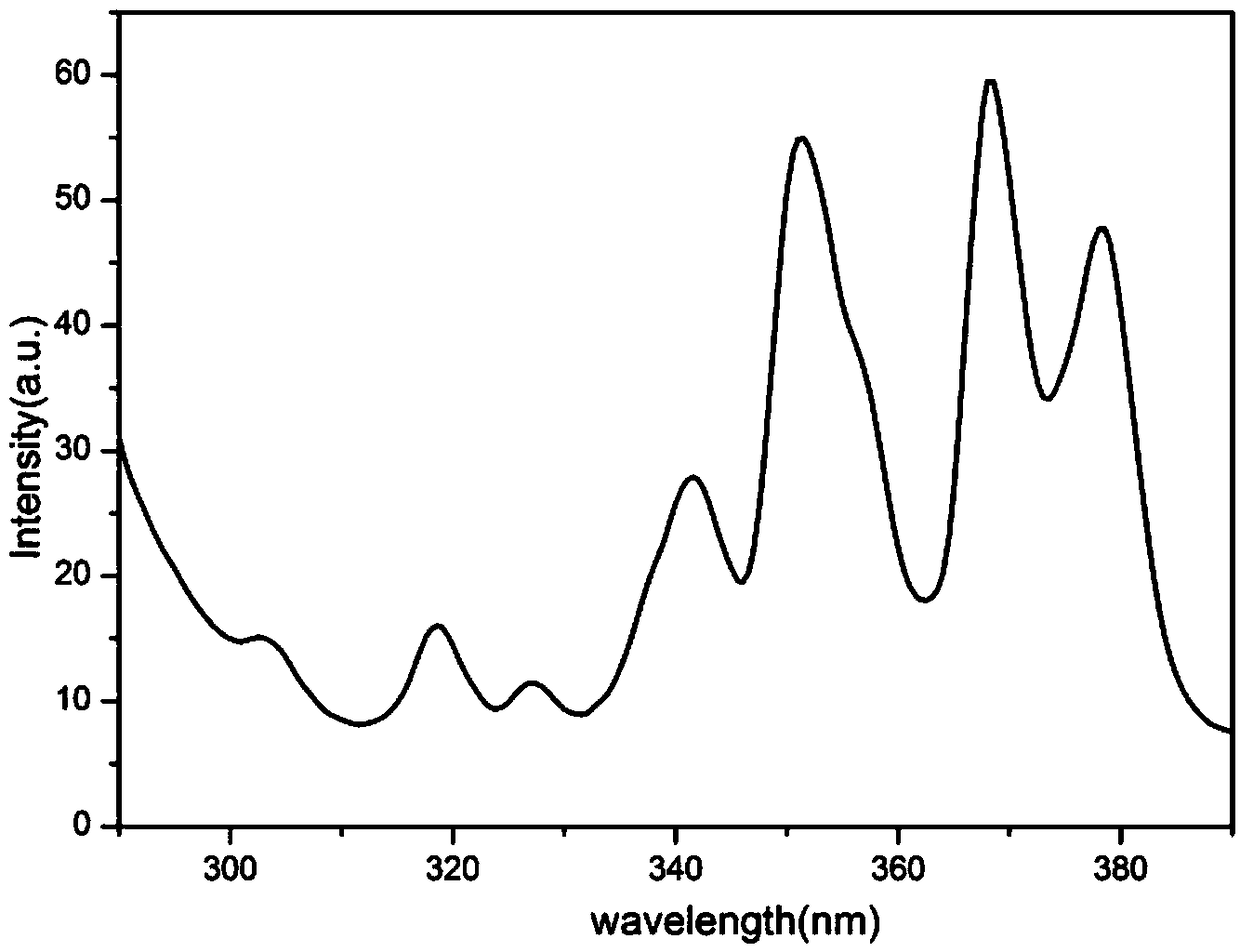

Preparation method of Y0.95F3:0.05Tb<3+> nano particle fluorophor

InactiveCN108753300AWill not polluteHigh purityLuminescent compositionsTetrafluoroborateLuminous intensity

The invention relates to a preparation method of a Y0.95F3:0.05Tb<3+> nano particle fluorophor. The method comprises the steps of taking Y(NO3)3.6H2O, Tb4O7, 1-butyl-3-methylimidazole tetrafluoroborate, a surfactant and 2.5mol / L diluted nitric acid as raw materials, and performing solution preparation, prepared solution stirring, hydrothermal reaction, centrifugal washing, drying and the like. Thepreparation method of the Y0.95F3:0.05Tb<3+> nano particle fluorophor successfully achieves Tb doping; no toxic and harmful substances such as HF are generated in a preparation process; the method isenvironmentally friendly, and does not pollute an environment; a prepared product is high in luminous intensity and stable in luminescence; a finished product is in a short rod form, and is high in aggregation degree and uniform in dispersion; a luminous refracting surface is smooth; a luminous effect is good; the finished product is high in purity and yield; the yield is as high as 97.8%; the luminous stability is good; the luminous intensity after placement for 3 months almost has no change as compared with that on day 0; the preparation raw materials are simple, easy to obtain and low in price; and the method is worthy of market popularization and application.

Owner:CHONGQING UNIV OF ARTS & SCI

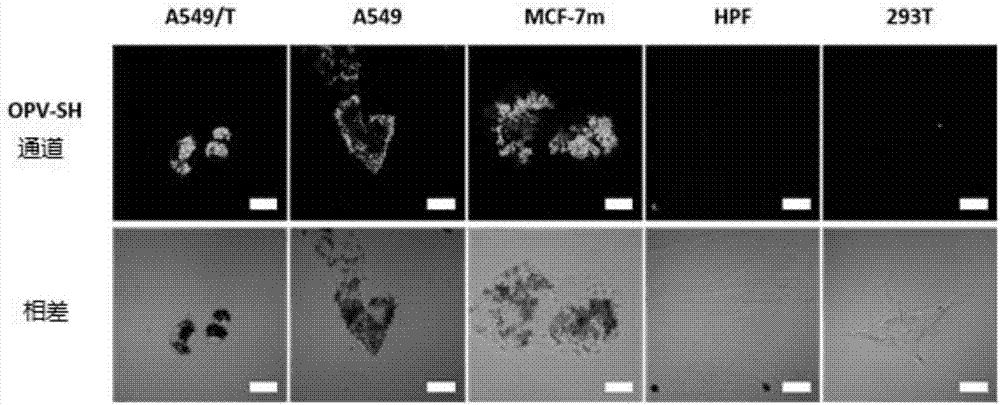

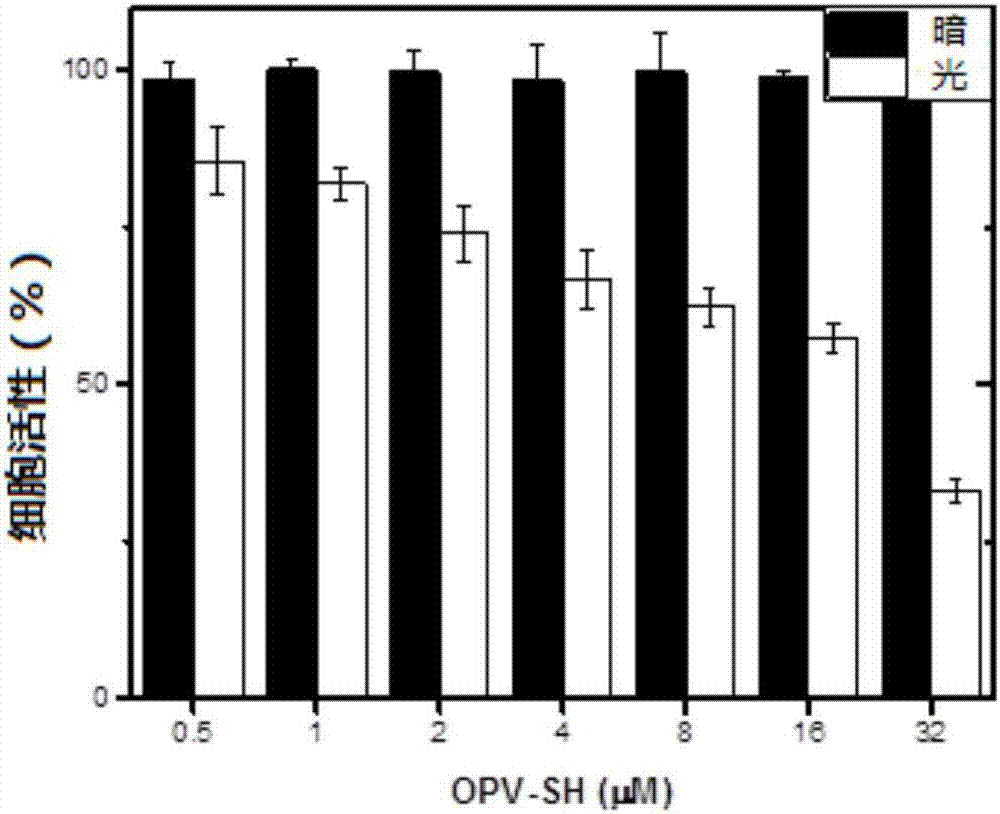

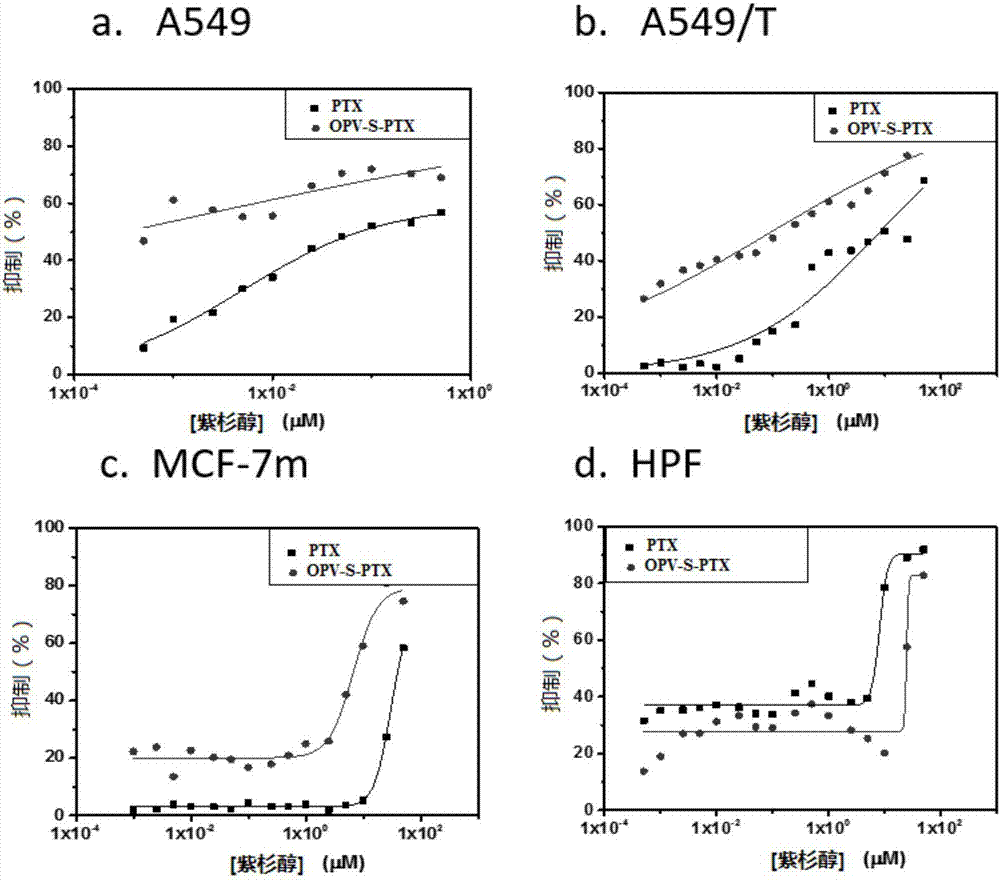

Oligopolyphenylene vinyl compound as well as preparation method and application thereof

ActiveCN107382786AImprove photoelectric performanceAvoid drug resistanceOrganic active ingredientsOrganic chemistrySide effectNormal cell

The invention relates to the field of antitumor drugs and discloses an oligopolyphenylene vinyl compound as well as a preparation method and application thereof. The oligopolyphenylene vinyl compound provided by the invention is of a structure shown in a formula (3), wherein n is an integer of 2-10. The provided compound of the structure shown in the formula (3) has good tumor cell proliferation inhibiting effect, especially has good inhibitory effect on proliferation of drug-resistant tumor cells, but has smaller toxic and side effects on normal cells. (The formula (3) is described in the specification.).

Owner:INST OF CHEM CHINESE ACAD OF SCI

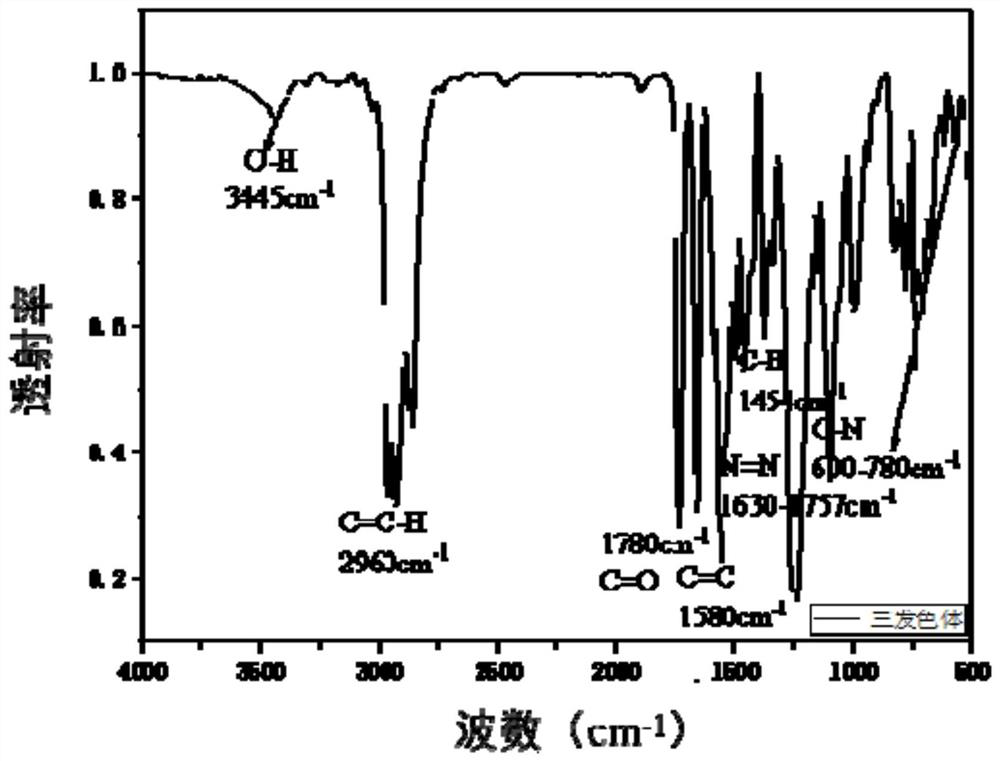

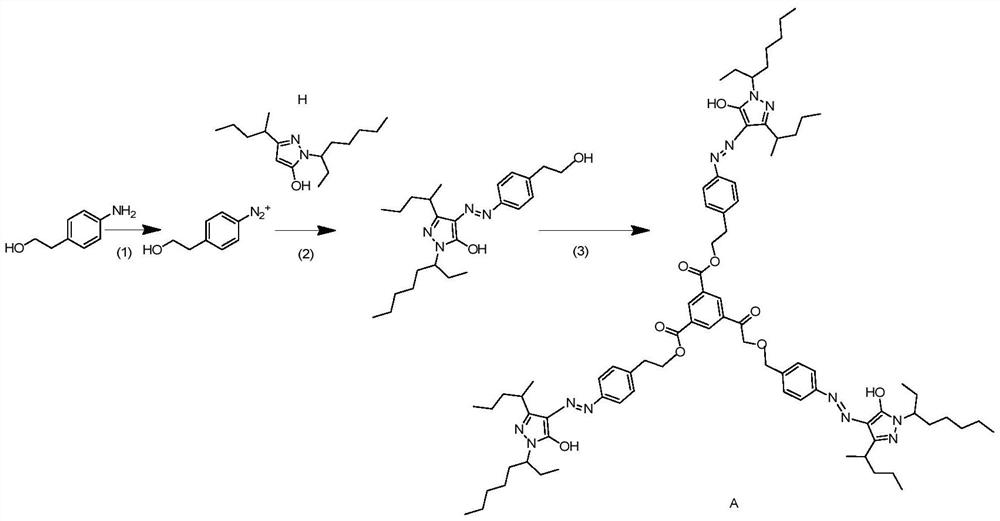

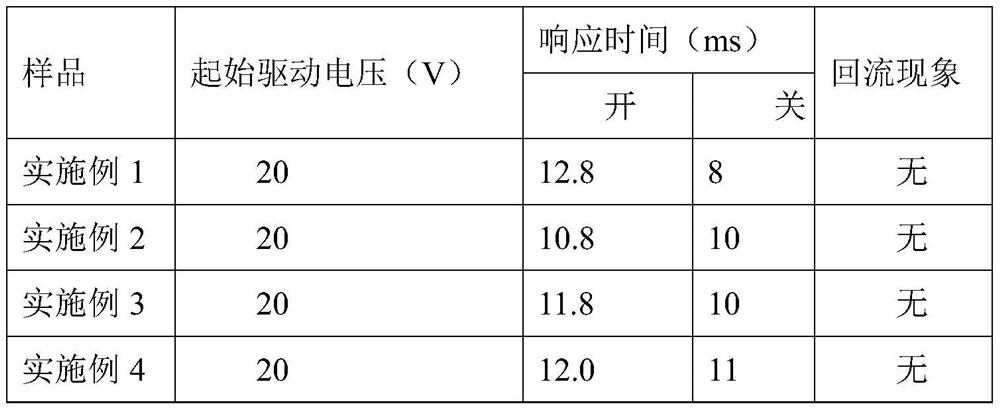

Multichromophoric pyrazolone azo-based dyes, inks and electrowetting displays

ActiveCN111534126BAchieve symmetryReduce apparent molecular polarityInksPreparation by acylationPhoto stabilityDisplay device

Owner:SHENZHEN GUOHUA OPTOELECTRONICS +1

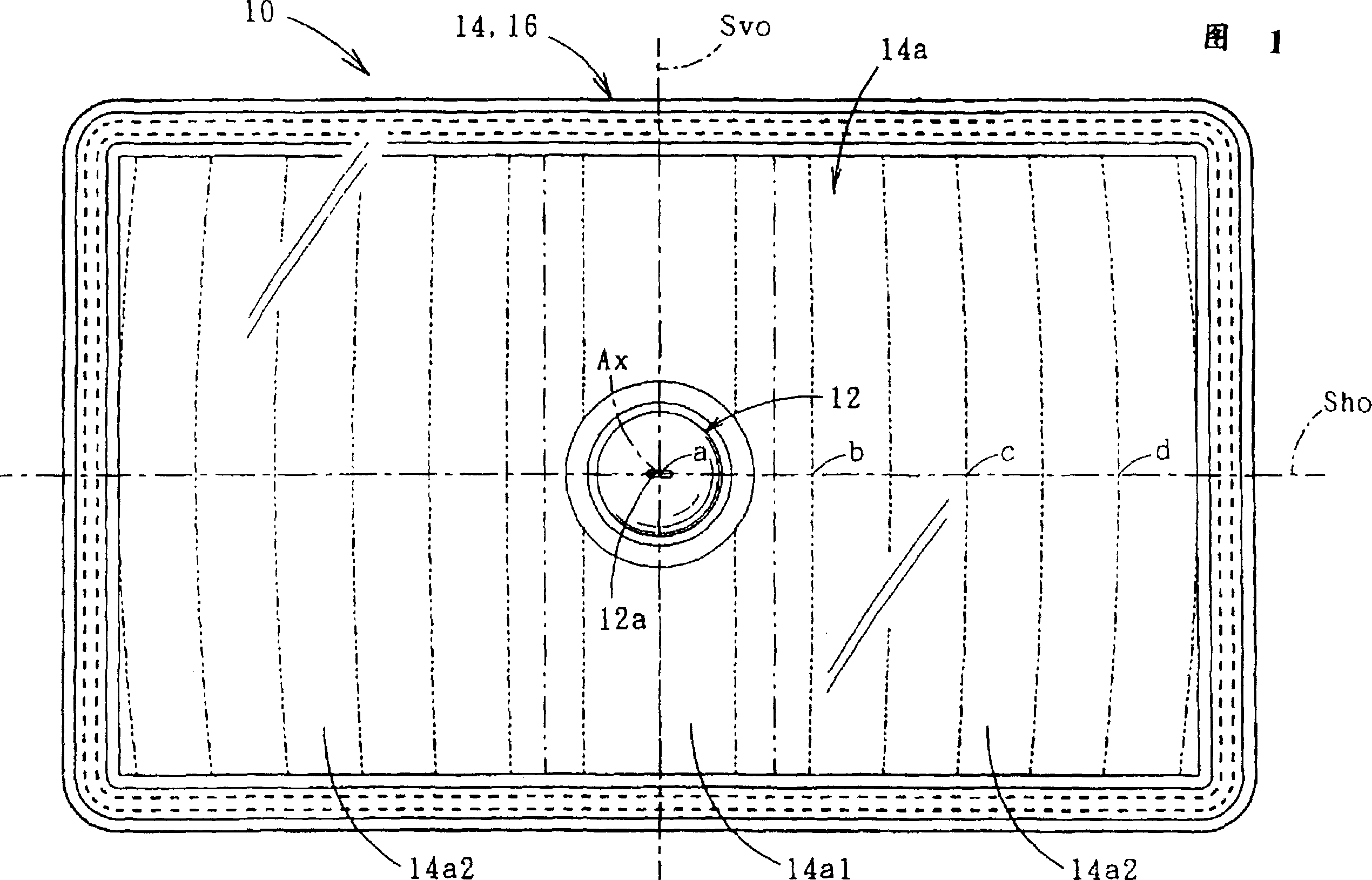

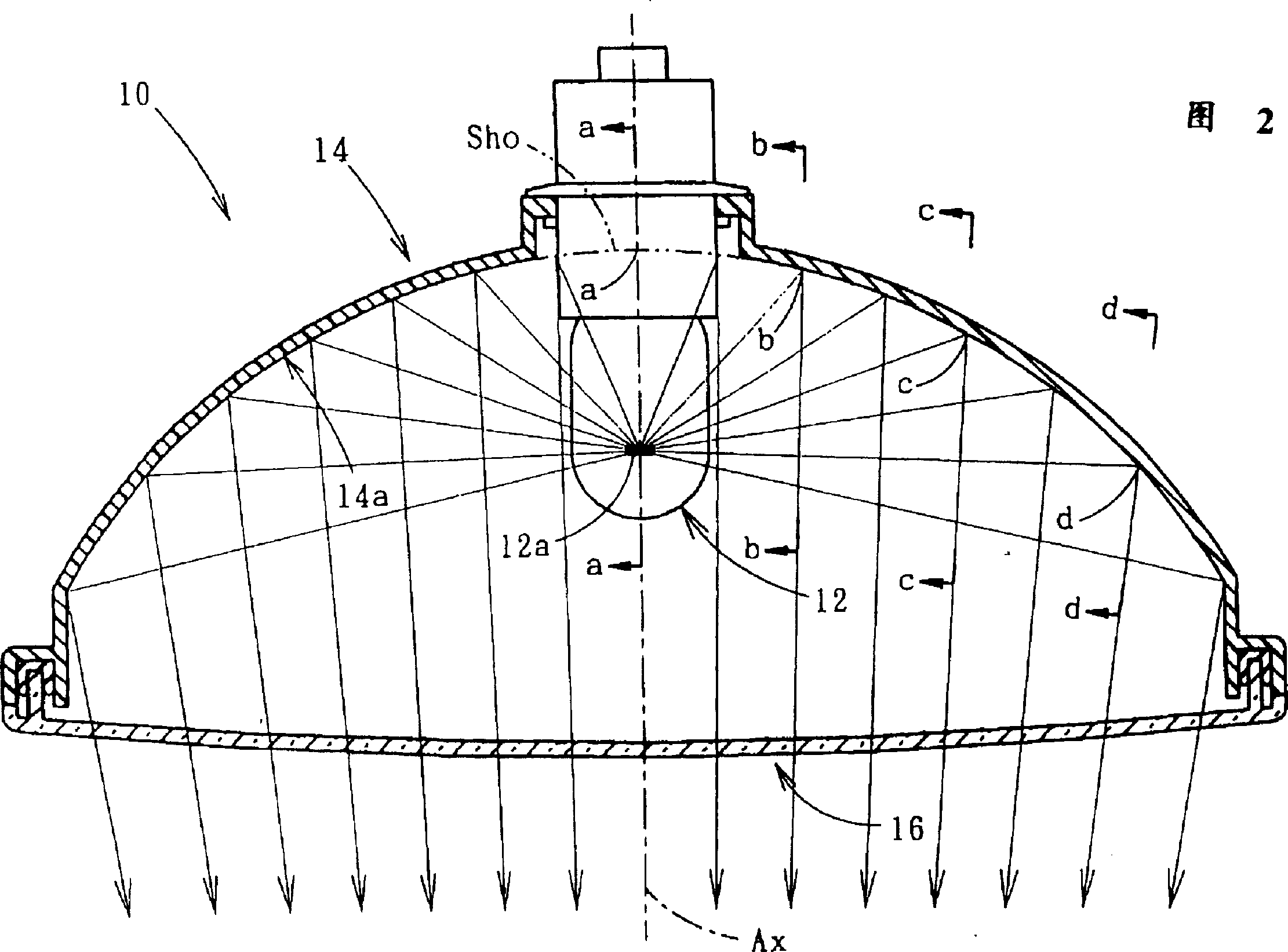

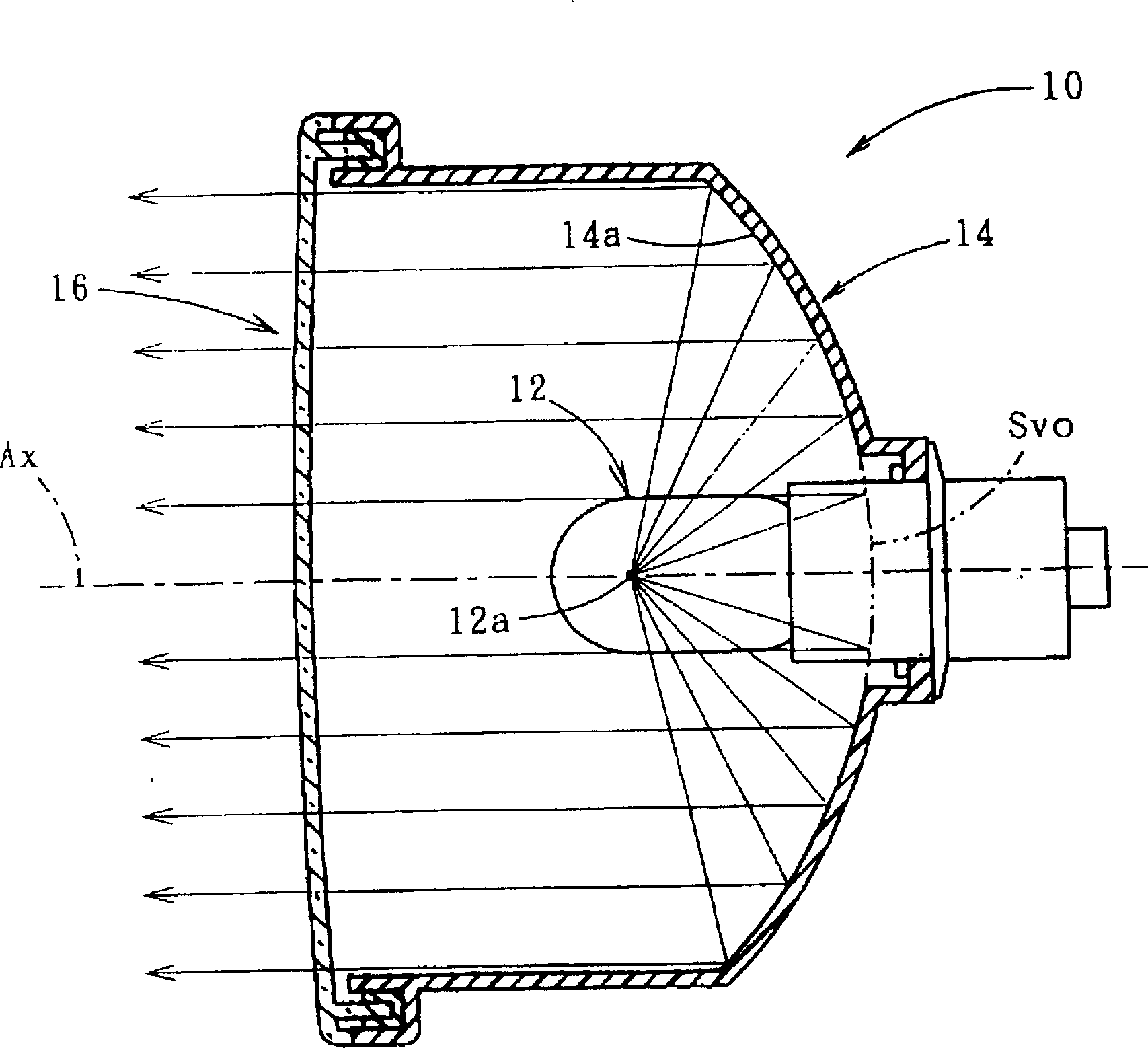

Lamp for vehicles

InactiveCN1109838CImprove light uniformityHigh transparencyVehicle headlampsVehicle lighting systemsDistribution patternOptoelectronics

The invention provides a lamp for vehicle, capable of easily providing a light distribution pattern with reduced light unevenness, superior in appearance and feeling of transparency. The shape of a horizontal section Sho, including a base axis Ax on a reflective surface, is set to a curved shape for convergingly reflecting the light from a light source 12a toward the base axis Ax on the horizontal section Sho. The shape of a vertical section which includes an axis line for reflected light emitting direction at each point on the horizontal section Sho, including the base axis Ax on the reflective surface 14a, is set to a curved shape to reflect the light from the light source 12a approximately parallel to the axis line for reflected light-emitting direction in a center reflective area 14a1 in the left and right neighborhood of the base axis Ax. The shape is set to a curved shape to convergingly reflect the light from the light source 12a towards the axis line for reflected light-emitting direction in a peripheral reflective area 14a2 on both left and right sides of the center reflective area 14a1. This constitution easily provides a light distribution pattern, having an approximately oblong rectangular spread with reduced light unevenness.

Owner:KOITO MFG CO LTD

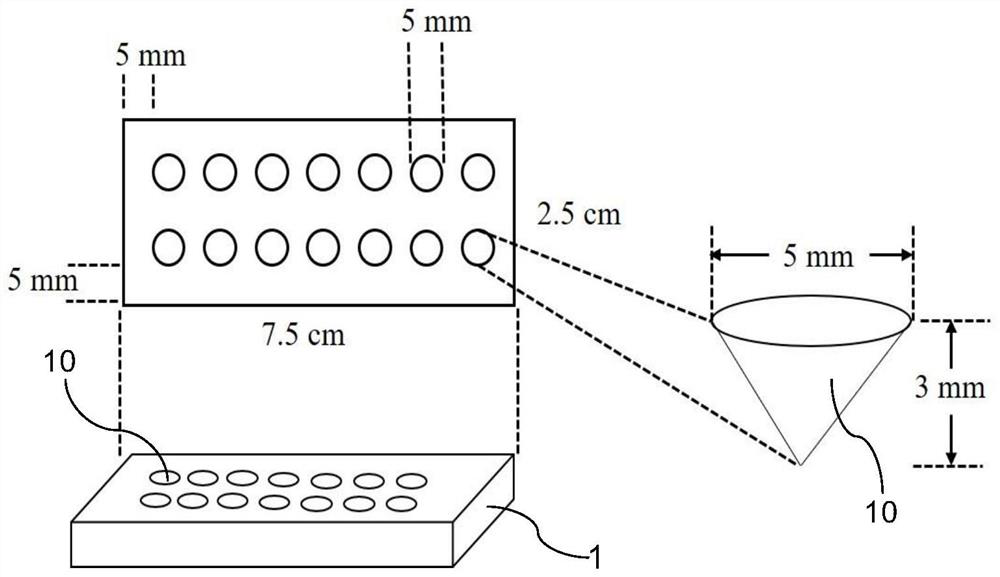

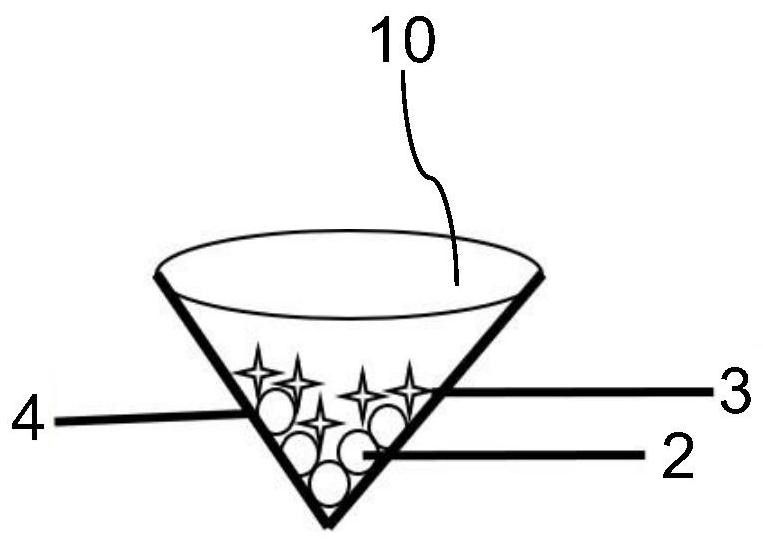

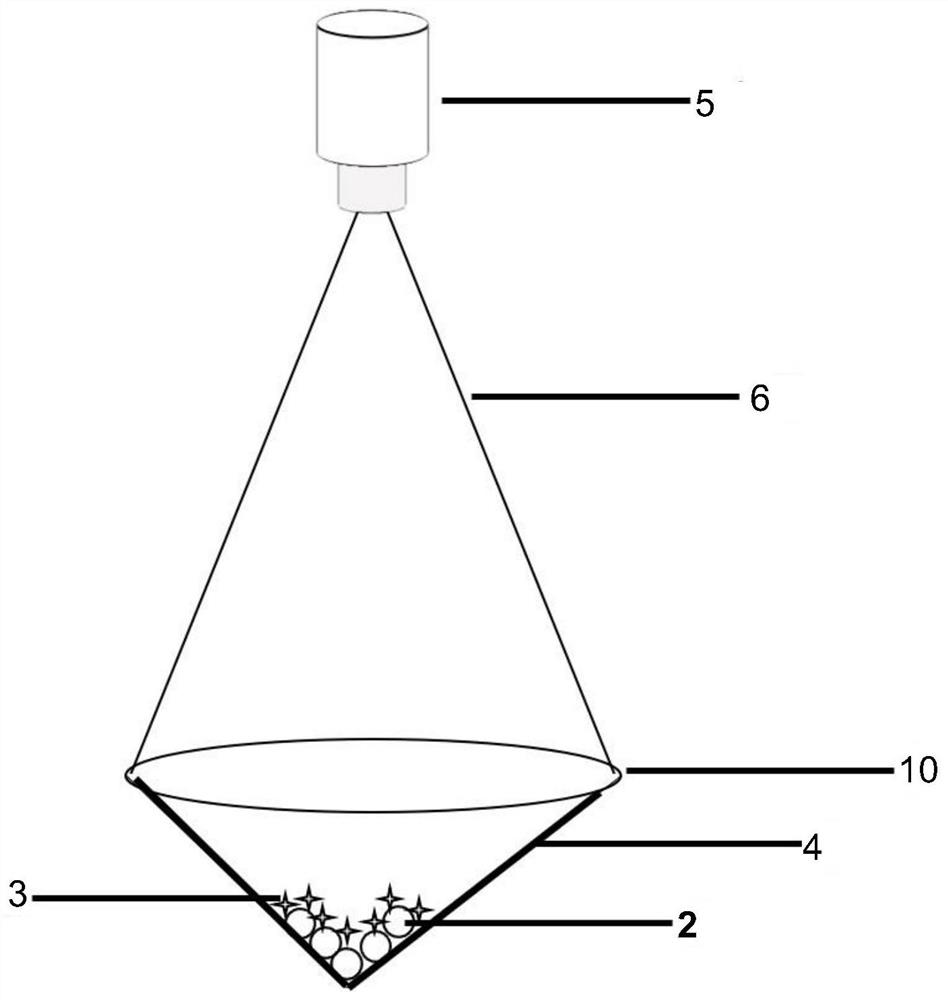

Module for Raman detection and preparation method thereof

InactiveCN111678907AIncrease the degree of aggregationAvoid distractionRaman scatteringNanoparticlePhysical chemistry

The invention provides a module for Raman detection and a preparation method thereof. The module includes a substrate, the plurality of conical grooves formed in the substrate in a manner that the conical tips face downwards, nanoparticles aggregated in the vicinity of the conical tips of the plurality of conical grooves, and to-be-detected molecules arranged in the plurality of conical grooves and covering the nano particles. According to the method, effective aggregation of the nanoparticles can be promoted, the usage amount of the nanoparticles can be effectively reduced, the raw material cost can be saved, and the sensitivity and repeatability of Raman detection can be effectively improved.

Owner:HUAZHONG AGRI UNIV +1

Method for preparing aluminum oxide coating by modulating high-current pulsed arc

ActiveCN112030117AImprove ionization rateIncrease the degree of aggregationVacuum evaporation coatingSputtering coatingAluminum coatingElectric arc

The invention belongs to the technical field of surface coating preparation, and particularly relates to a method for preparing an aluminum oxide coating by modulating a high-current pulsed arc. The method comprises the following steps that a functional layer is formed, wherein the functional layer is a single layer formed by depositing aluminum oxide or a single layer formed by depositing aluminum oxynitride or a multi-layer composite coating formed by alternately depositing nitride and aluminum oxide; the aluminum oxide or aluminum oxynitride is formed by modulating high-current pulse arc discharge deposition; and the modulated high-current pulse arc adopts direct-current base current and low-frequency large-beam pulse current as a discharge power supply to perform arc discharge. Stablearc discharge is achieved through low-base-value current in a pulse arc discharge technology, accumulation poisoning of an oxide layer in the target surface discharge process is avoided through instantaneous maximum peak current, the ionization rate of oxygen is increased, an oxide coating is fully formed, arc spots are made to cover the whole target surface, generation of large particles in the arc discharge process is reduced, the ionization rate of particles is improved, and the high-quality and high-performance aluminum oxide coating is obtained.

Owner:WENZHOU POLYTECHNIC

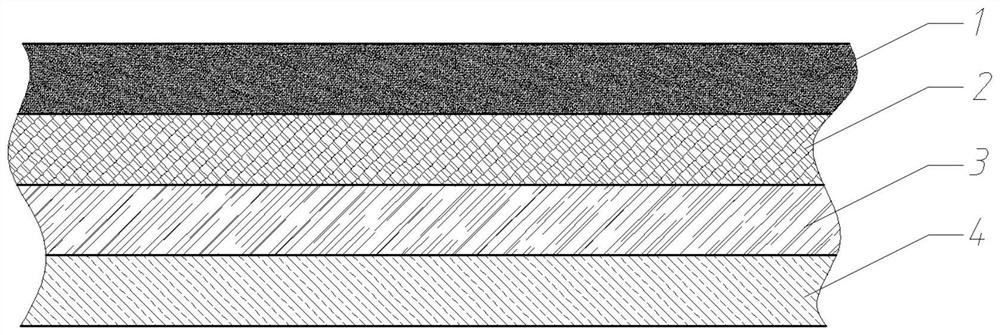

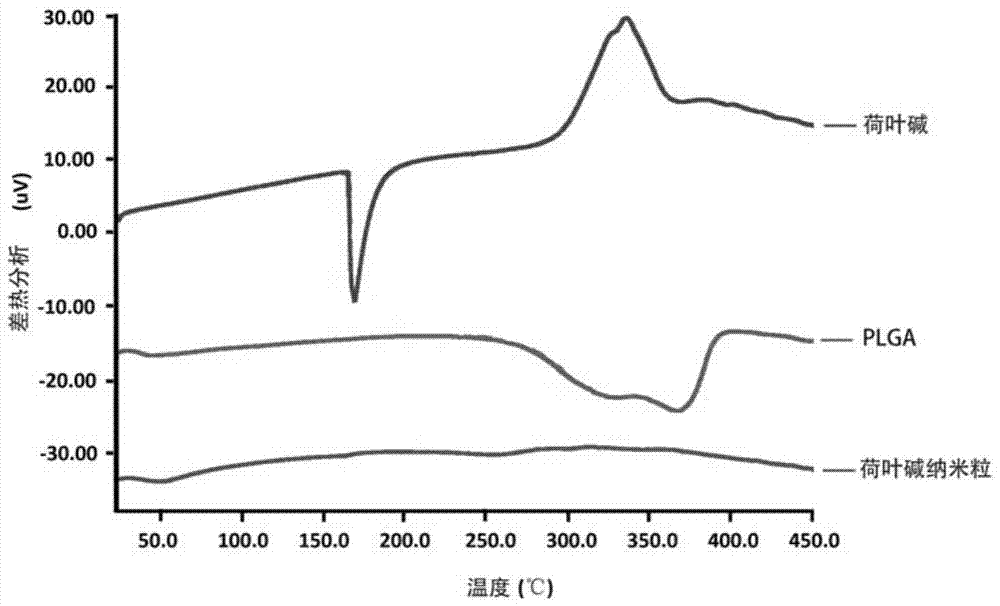

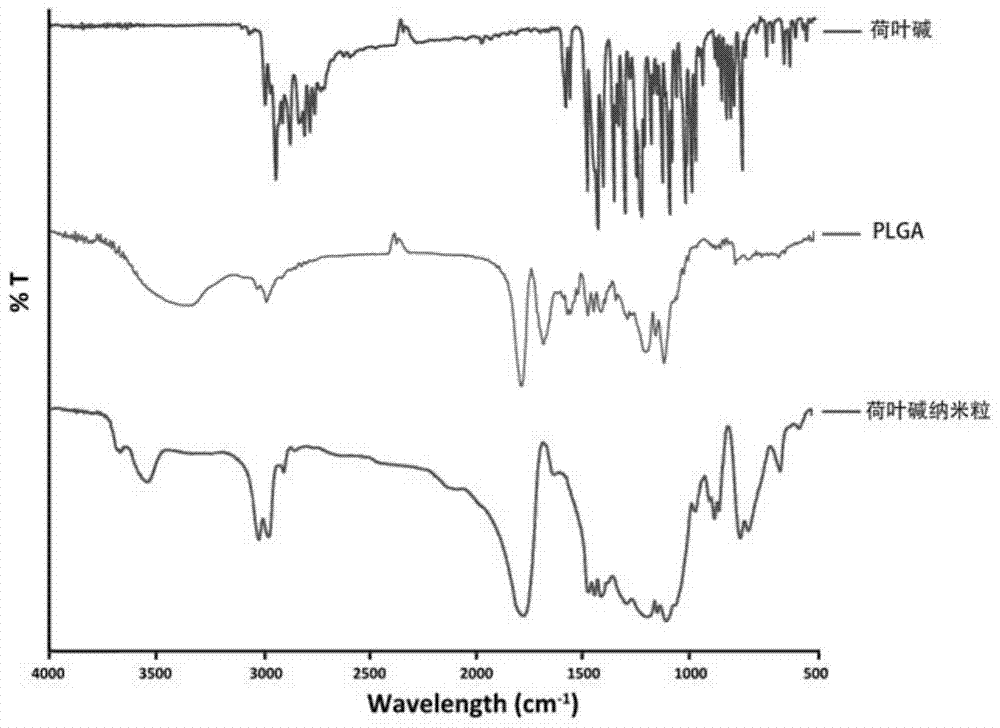

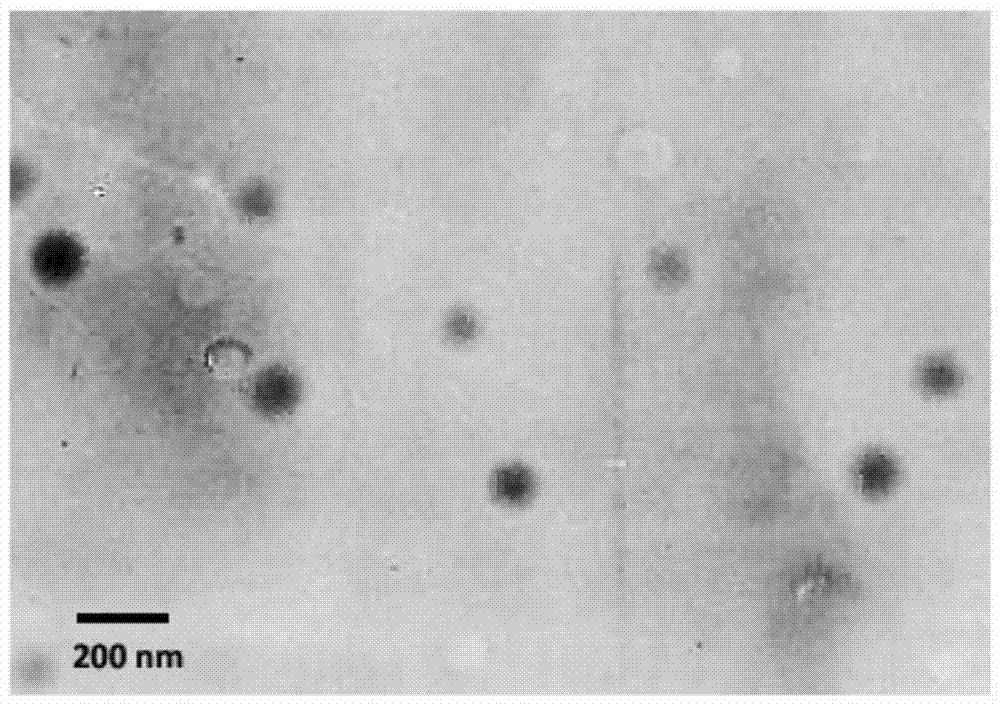

A kind of oral nano drug delivery system of nuciferine and its preparation method

InactiveCN104473903BReduce contentReduce food intakeOrganic active ingredientsMetabolism disorderHydrolysisPharmaceutical formulation

The invention belongs to the technical field of medicinal preparations, and particularly relates to a nuciferine oral nano-administration system and a preparation method thereof. The system uses nuciferine as a medicinal material and PLGA as a carrier material, has the advantages of low toxicity, sensitive medicine hydrolysis prevention, drug release control, high bioavailability and the like. The preparation method of nuciferine nano-particles adopts an emulsion-solvent evaporation method, so that the stability of nuciferine can be improved, and the bioavailability of the nuciferine can be improved. Compared with lipidosome, the preparation prepared by the invention has the advantages of good stability, and a more effective and more convenient administration method is provided to application of nuciferine in blood fat reduction.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

Urban public transport network optimization method capable of improving overall transfer performance

ActiveCN102122434BImprove performanceIncrease the degree of aggregationRoad vehicles traffic controlStructure of Management InformationTransport network

The invention provides an urban public transport network optimization method capable of improving overall transfer performance. In the method, a public transport network is expressed as relation between stations and lines (cliques, the largest complete subgraph in the network). The method comprises the following steps: setting network diameter to be N; simulating the growth process of the actual public transport network to be optimized; starting from an original network with only one clique, adding one clique to the original network at each time step, and forming the network which is composedof overlapped cliques and is logically shown as a structure with (N+1) layers, wherein, the clique at a (m-1) layer is mapped into a point at a m layer, and m is not less than 1 and not more than N+1; and regulating the network after one clique is added at each time step so as to ensure that the network at each layer is composed of the cliques so that the optimized public transport network becomes an ideal clique network with the depth N. By utilizing the method, average transfer time and average shortest path time coefficient of the public transport network can be effectively reduced, and concentration degree of the bus lines is improved, thus realizing higher transfer efficiency of a public transport system.

Owner:ZHEJIANG UNIV OF TECH

Functional targeting carrier material distearoylphosphatidylethanolamine-polyethylene glycol-polyethyleneimine compound and its modified liposome

ActiveCN106798923BRatio of uptake increasedStrongly selective centralized distributionPharmaceutical non-active ingredientsAntineoplastic agentsPolyethylene glycolPhospholipid

Owner:PEKING UNIV

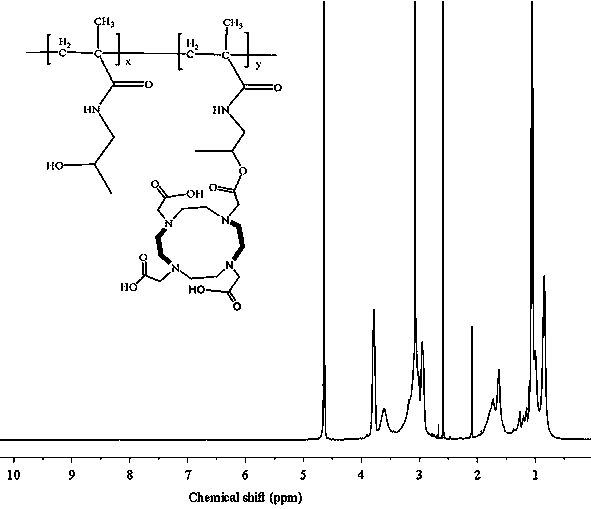

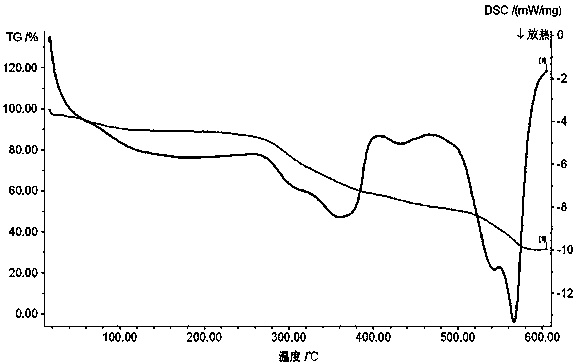

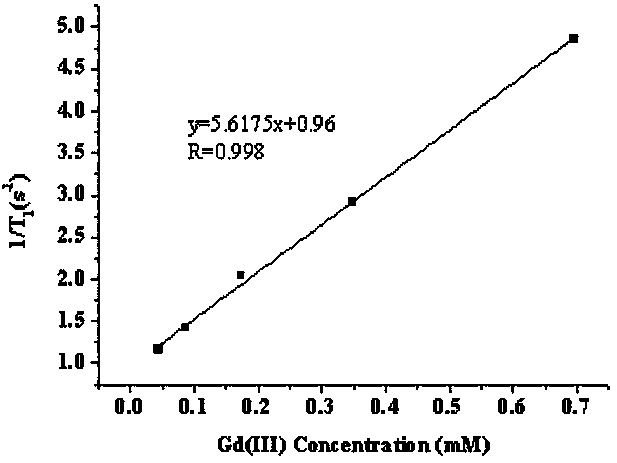

Poly (HPMA)-DOTA-Gd nuclear magnetic resonance contrast agent and preparation method thereof

InactiveCN108478814AExtend cycle timeIncrease the degree of aggregationNMR/MRI constrast preparationsPharmaceutical non-active ingredientsNMR - Nuclear magnetic resonanceWeight distribution

The invention relates to a Poly (HPMA)-DOTA-Gd nuclear magnetic resonance contrast agent. The formula of the contrast agent is as follows (please see the specification for the formula). In the formula, x equals to 10-90 mol%, and y equals to 10-90 mol%. At the same time, the invention further discloses a preparation method of the contrast agent. The molecular weight of the contrast agent is less than a renal threshold, the molecular weight distribution is narrow, and the contrast agent can be eliminated through metabolism.

Owner:GANSU AGRI UNIV

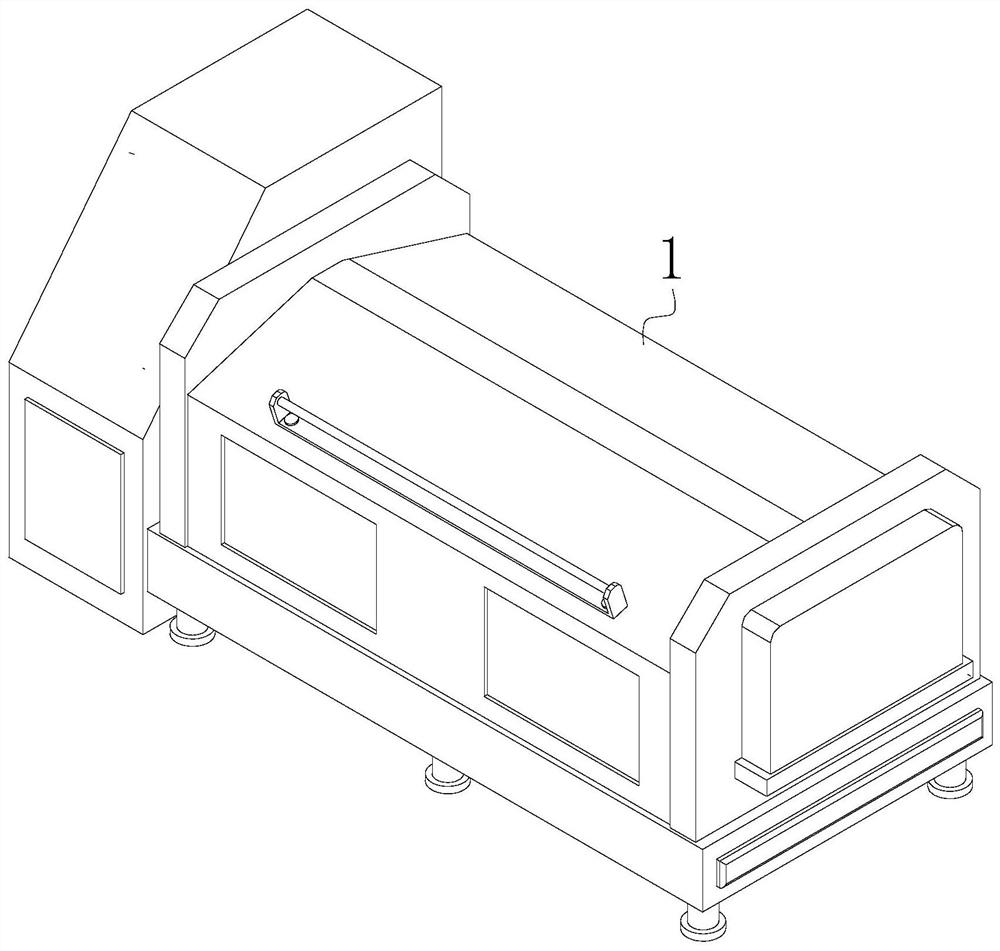

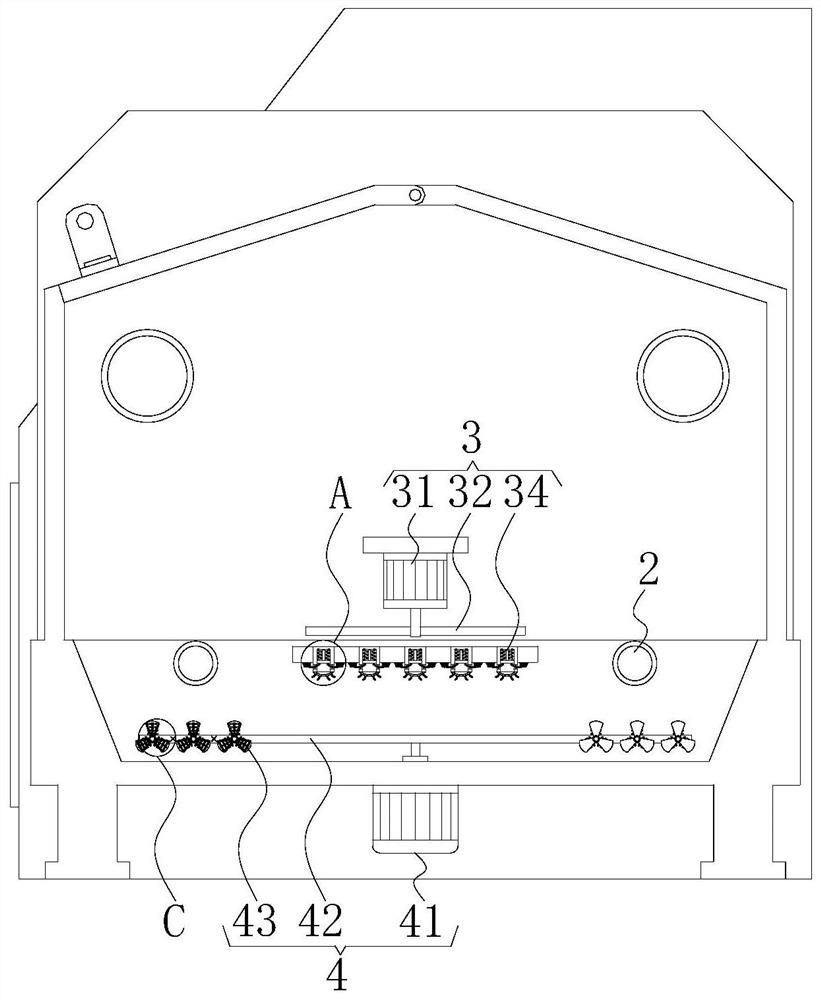

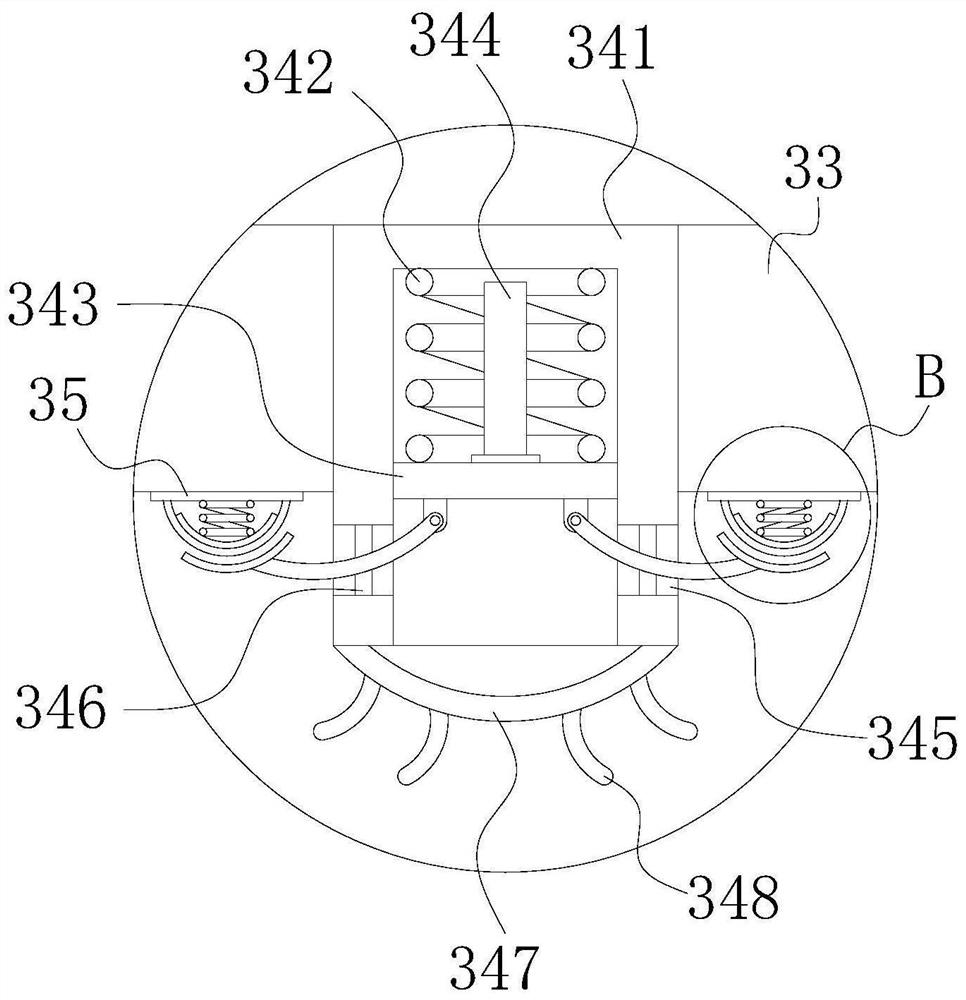

Cotton cloth dip dyeing equipment

InactiveCN114657728AImprove dyeing efficiencyIncrease swingTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentFiberTextile printer

The invention discloses cotton cloth dip dyeing equipment, and relates to the technical field of textile printing and dyeing. The cotton cloth dip dyeing equipment comprises a machine body, four rollers are arranged in the machine body, a dyeing pool is formed in the inner bottom of the machine body, every two of the four rollers form a group and are located in the upper half portion of an inner cavity of the machine body and the dyeing pool respectively, a turbulent expansion mechanism is arranged on the lower half portion of the inner cavity of the machine body, and a fiber collecting mechanism is arranged in the dyeing pool. And the turbulence expansion mechanism comprises a first motor, four magnetic plates, a fixing plate, a contact mechanism and a vibration mechanism, the first motor is fixedly installed in the middle of an inner cavity of the machine body, an output shaft of the first motor faces downwards, and the number of the magnetic plates is four. According to the cotton cloth dip-dyeing equipment, full turbulence can be generated in the dye liquor based on cooperation of the turbulence expansion mechanism and the fiber collecting mechanism, and compared with a traditional dip-dyeing mode, flowing of the dye liquor on the surface of unit fiber can be accelerated in the process that the fabric is soaked in the dye liquor and absorbs the dye liquor through the fiber.

Owner:宁波诚可威新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com