Fuel saving joint and fuel economizer

A technology of body and magnetic sheet, applied in machine/engine, internal combustion piston engine, engine components, etc., can solve the problems of inability to intercept large particles of impurities, inconspicuous magnetic force line aggregation, low fuel efficiency improvement, etc., to reduce the diameter of oil droplets, The effect of improving the degree of aggregation and improving the magnetization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

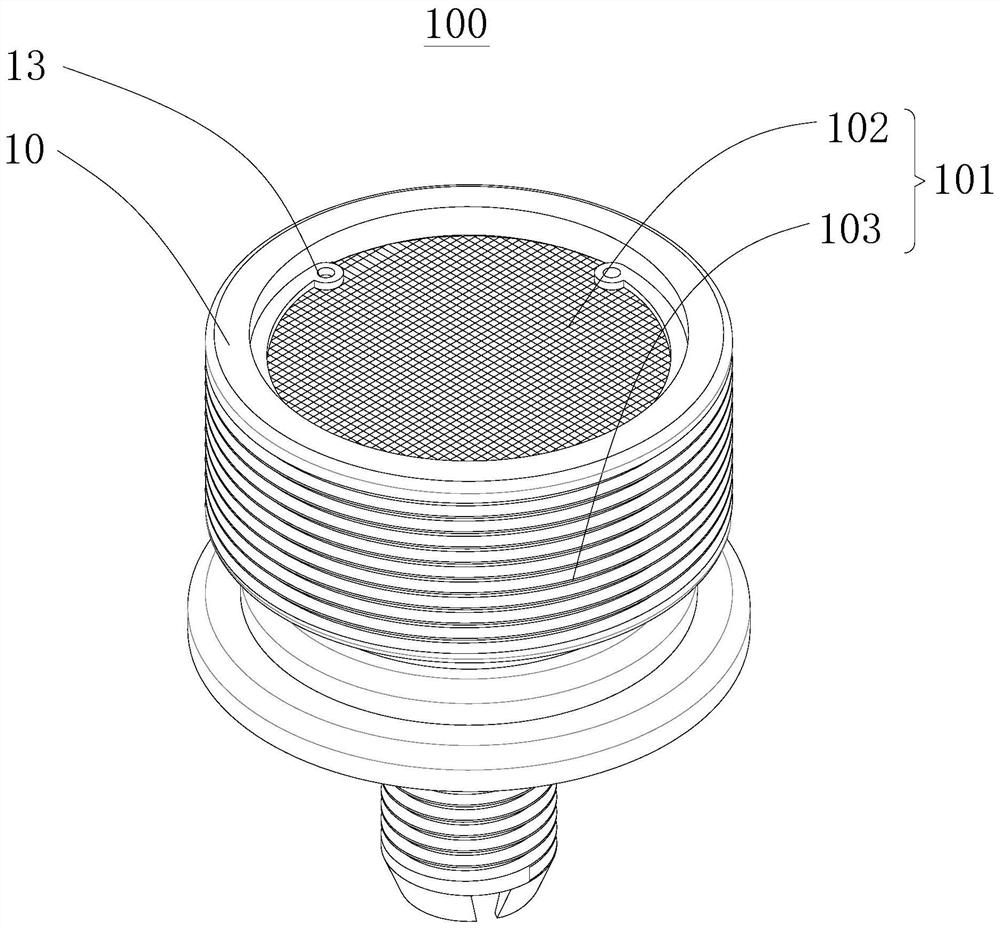

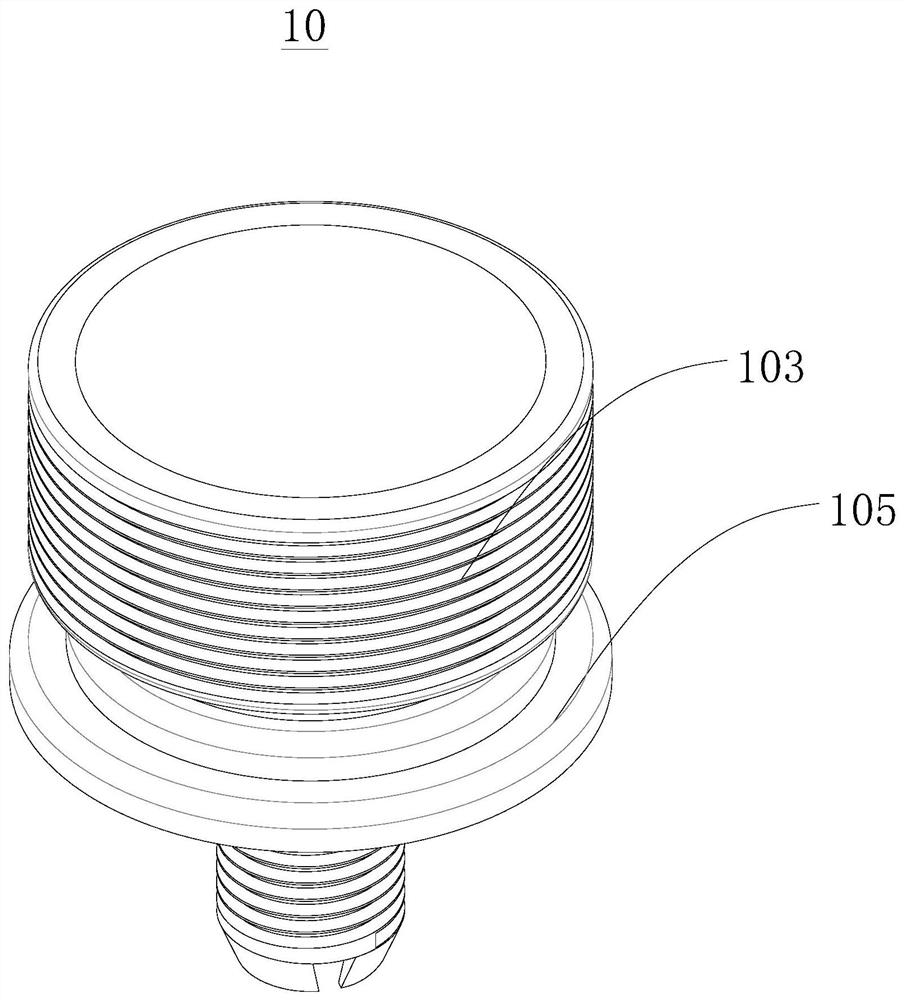

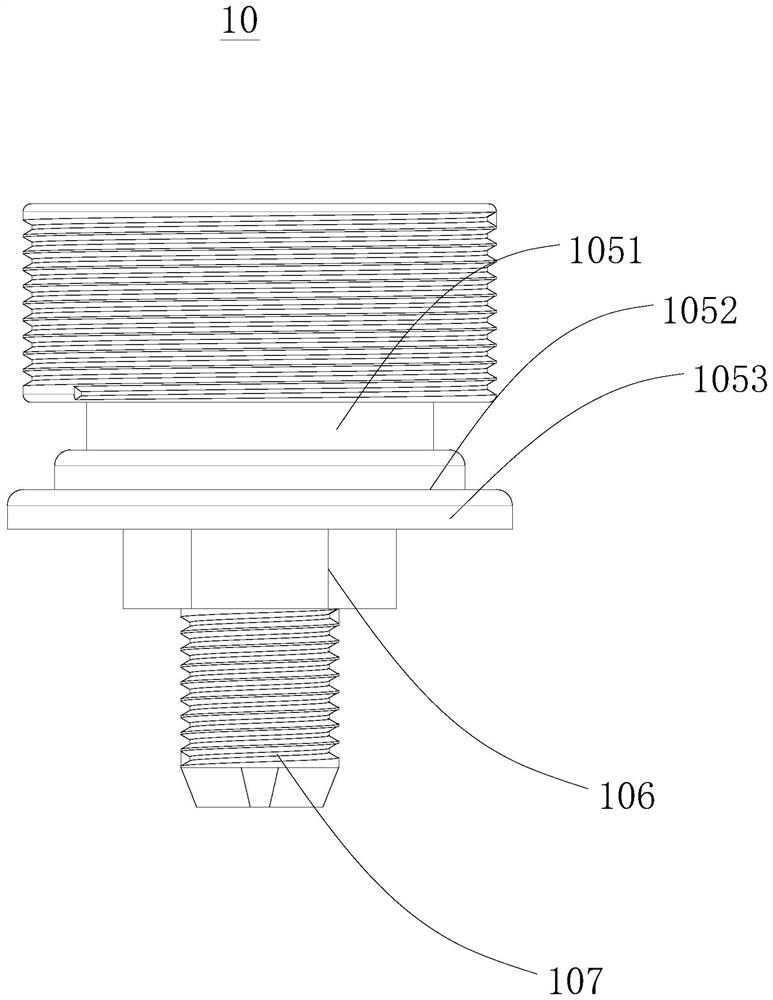

[0051] Please refer to figure 1 , figure 1 An explosion schematic diagram of the fuel-saving joint 100 provided by the embodiment of the present invention. The fuel-saving joint 100 includes a joint body 10 , a magnetic plate assembly 11 and a filter screen assembly 12 . The joint body 10 has an accommodating chamber 101 , the filter screen assembly 12 is embedded in the accommodating chamber 101 , and partitions the accommodating chamber 101 to form a first accommodating chamber 102 and a second accommodating chamber 103 . The magnetic chip assembly 11 includes a magnetic chip body 111 and a sandwich layer 112. The sandwich layer 112 is arranged in the second accommodation cavity 103, and cooperates with the second accommodation cavity 103 to form a magnetic chip housing for accommodating the magnetic chip body 111. cavity, the magnetic chip body 111 is embedded in the magnetic chip accommodating cavity. Both the magnetic sheet body 111 and the sandwich layer 112 have notc...

Embodiment 2

[0074] This embodiment provides a fuel-saving device, which includes the fuel-saving joint 100 and the fuel-saving tube in Embodiment 1, and the fuel-saving joint 100 and the fuel-saving tube are connected to each other. It has all the advantages of the fuel-efficient street.

[0075] Effect example

[0076] In the actual use process, according to the inspection report of motor vehicle exhaust pollution in Taizhou City, the car using the fuel economizer (purchased on June 1, 2003), the current mileage: 182797 (km), in September 2020 After installing the fuel saver on the 13th, it is practical for commuting to and from get off work every day. On January 9, 2021, I went to Taizhou Vehicle Inspection Center for testing. The following is the report obtained by the inspection center:

[0077] Hydrocarbon (HC) measured value: 0.01, less than the national limit of 1.6 (g / km);

[0078] The measured value of carbon monoxide (CO): 0.78, which is less than the national limit of 8.0 (g / k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com