Preparation method of palladium-cobalt/carbon nitride composite material and product and application thereof

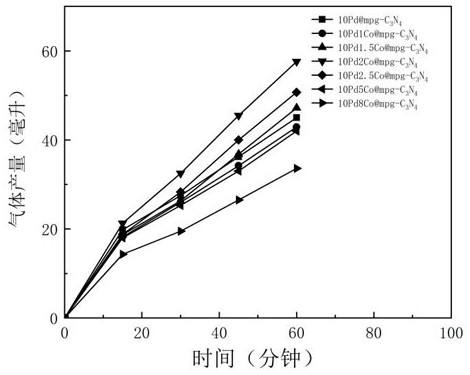

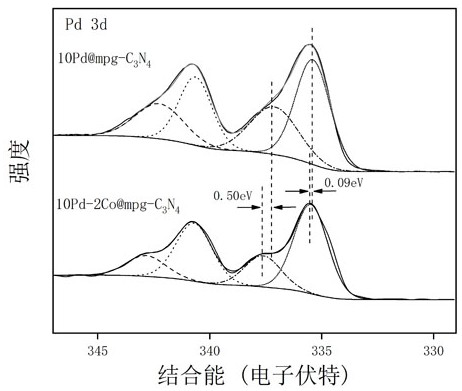

A technology of composite materials and carbon nitride, which is applied in the direction of nitrogen compounds, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve the problems of increasing the cost of catalysts and restricting the application of catalysts, so as to improve the aggregation degree and excellent photocatalytic production. Hydrogen performance, effect of enhancing electron density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of palladium cobalt / carbon nitride composite material, utilizes hard template method and sub-step impregnation reduction method to prepare a kind of palladium cobalt / carbon nitride composite material with heterojunction structure, prepares according to the following steps:

[0031] a. Preparation of mesoporous graphite phase carbon nitride: 5g of cyanamide 50% aqueous solution was added dropwise to 7.5g of Ludox HS40 silica sol under vigorous stirring, fully stirred and evaporated to dryness in a water bath at 65°C to obtain The solid was calcined in a tube furnace under the protection of nitrogen, the heating rate was 2.3°C / min, and it was kept at 550°C for 4 hours. After natural cooling, a yellow solid was obtained; after grinding the obtained solid, an excess of 4mol / L ammonium bifluoride solution was added and stirred for 48 hours to remove Si0 2 Template, the obtained solid is washed and dried to obtain light yellow mesoporous graphite phase carbon nitride; ...

Embodiment 2

[0036] A kind of palladium cobalt / carbon nitride composite material, similar to embodiment 1, is prepared according to the following steps:

[0037] a. Preparation of mesoporous graphite phase carbon nitride: 5g of cyanamide 50% aqueous solution was added dropwise to 7.5g of Ludox HS40 silica sol under vigorous stirring, fully stirred and evaporated to dryness in a water bath at 65°C to obtain The solid was calcined in a tube furnace under the protection of nitrogen, the heating rate was 2.3°C / min, and the temperature was kept at 600°C for 4 hours. After natural cooling, a dark yellow solid was obtained; after grinding the obtained solid, an excess of 4mol / L ammonium bifluoride solution was added and stirred for 48 hours to remove Si0 2 Template, the obtained solid is washed and dried to obtain yellow mesoporous graphite phase carbon nitride;

[0038] b. Loading of palladium-cobalt metal nanoparticles: take 100 mg of the prepared mesoporous graphite phase carbon nitride and u...

Embodiment 3

[0040] A kind of palladium cobalt / carbon nitride composite material, similar to embodiment 1, is prepared according to the following steps:

[0041] a. Preparation of mesoporous graphite phase carbon nitride: 5g of cyanamide 50% aqueous solution was added dropwise to 7.5g of Ludox HS40 silica sol under vigorous stirring, fully stirred and evaporated to dryness in a water bath at 65°C to obtain The solid was calcined in a tube furnace under the protection of nitrogen, the heating rate was 2.3°C / min, and it was kept at 550°C for 4 hours. After natural cooling, a yellow solid was obtained; after grinding the obtained solid, an excess of 4mol / L ammonium bifluoride solution was added and stirred for 48 hours to remove Si0 2 Template, the obtained solid is washed and dried to obtain light yellow mesoporous graphite phase carbon nitride;

[0042] b. Loading of palladium-cobalt metal nanoparticles: Take 100 mg of the prepared mesoporous graphite phase carbon nitride and ultrasonicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com