Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

A spray gun and molten iron technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve problems such as long time for slag removal, easy corrosion of molten iron tanks, high iron loss, etc., to reduce mechanical damage, reduce wear speed, and reduce erosion wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

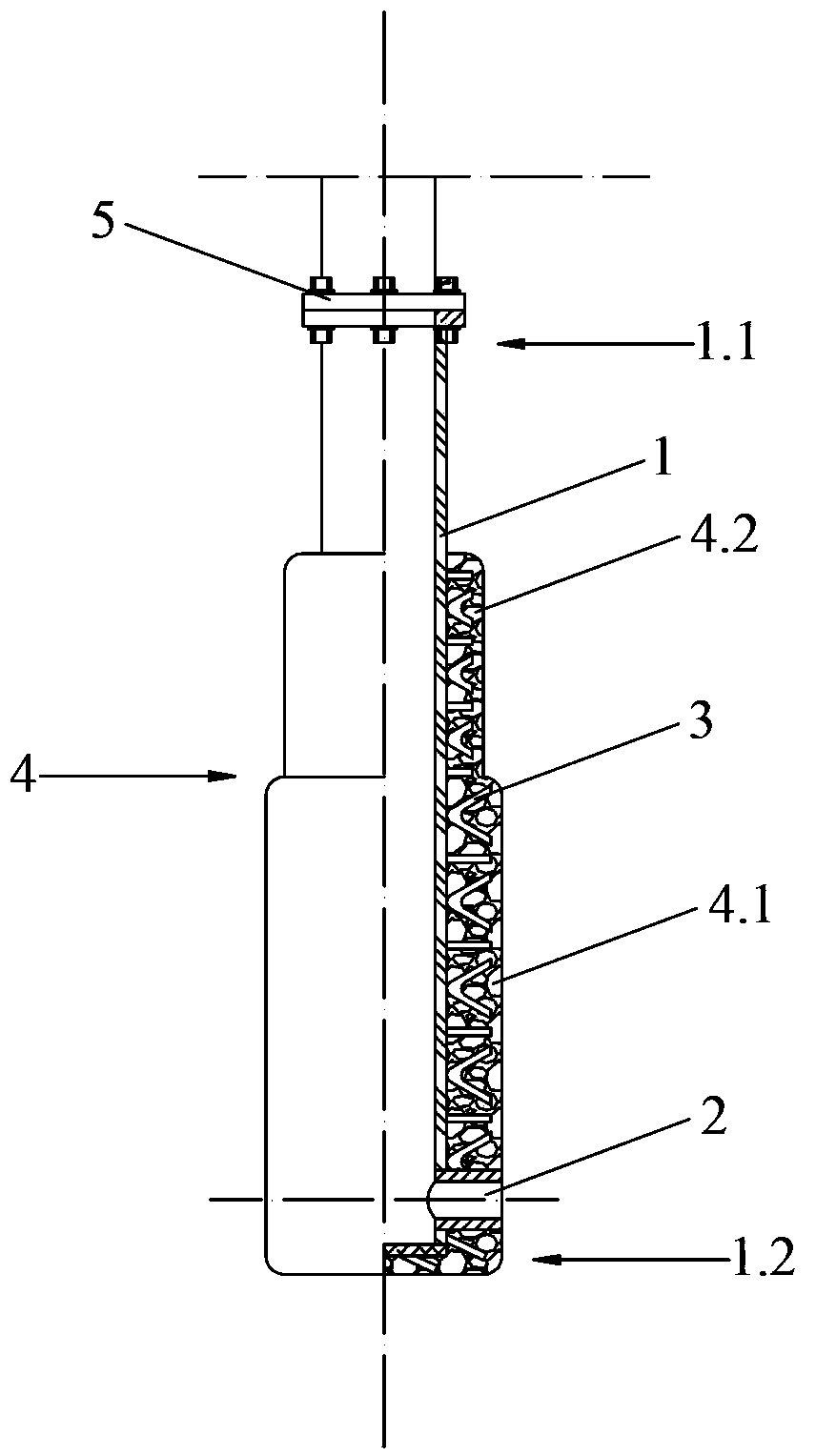

[0032] Such as figure 1 As shown, an air blowing slag gathering spray gun for assisting molten iron slag removal includes a gun barrel 1 having an open end 1.1 and a closed end 1.2. The central axis is symmetrically provided with a spout 2, the central axis of the spout 2 is perpendicular to the central axis of the gun barrel 1, and the ratio of the inner diameter of the spout 2 to the inner diameter of the gun barrel 1 is 0.50:1. The nozzle 2 is made of ordinary carbon steel seamless pipe, which is welded vertically and radially symmetrically along the axis of the barrel 1.

[0033] V-shaped anchors 3 are evenly arranged on the outer side of the closed end 1.2 of the gun barrel 1 and the outer side of the pipe wall connected to the closed end 1.2, and the V-shaped anchors 3 are covered with a refractory castable layer 4 . The V-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com