Lamp for vehicles

A technology for lamps and vehicles, applied in the direction of headlights, vehicle parts, vehicle lighting systems, etc., can solve the problems of large curvature of lens order 6s, poor appearance of lamps, lack of transparency, etc., and achieve the effect of strong light uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] First, an embodiment of the present invention will be described.

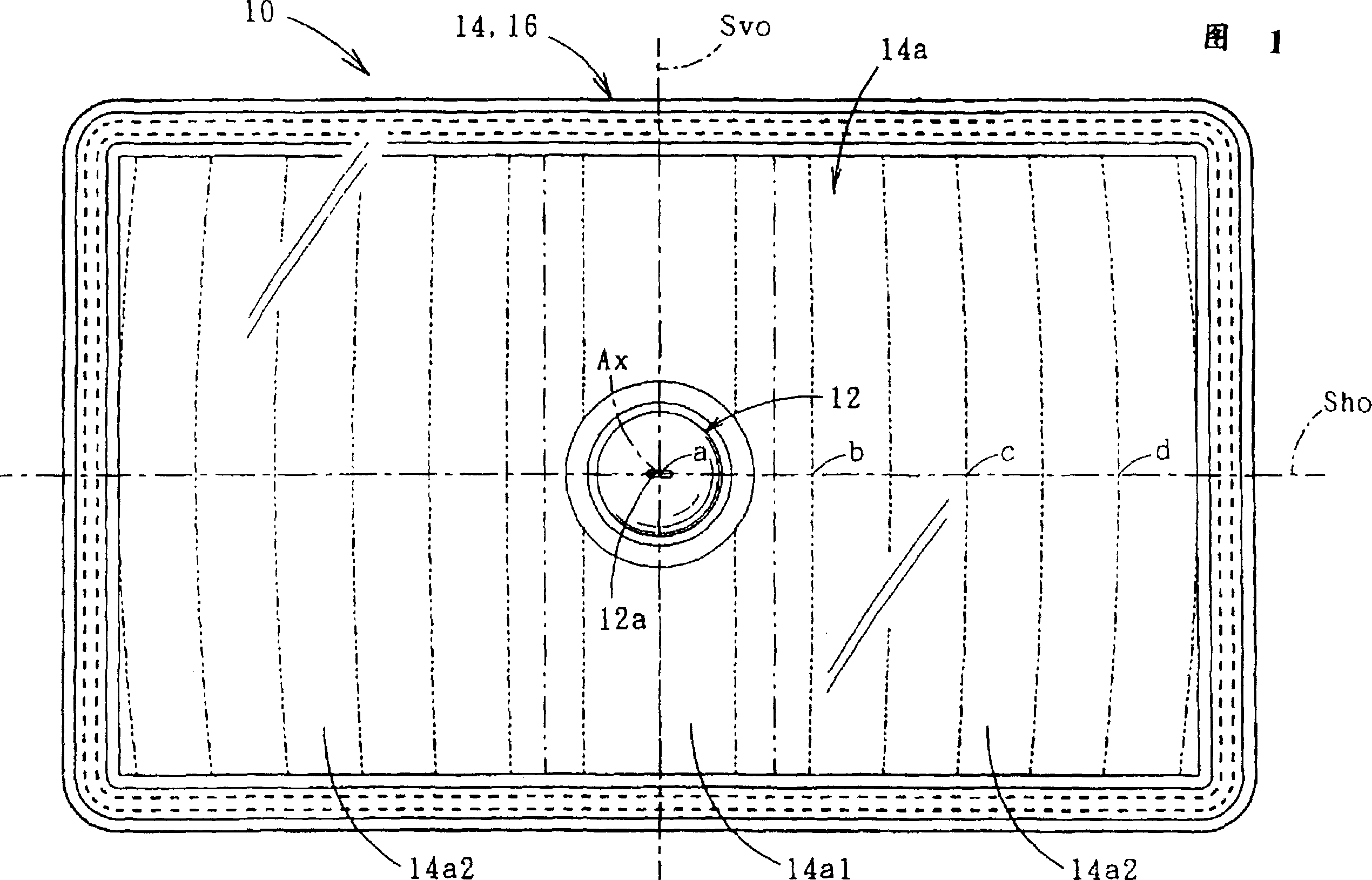

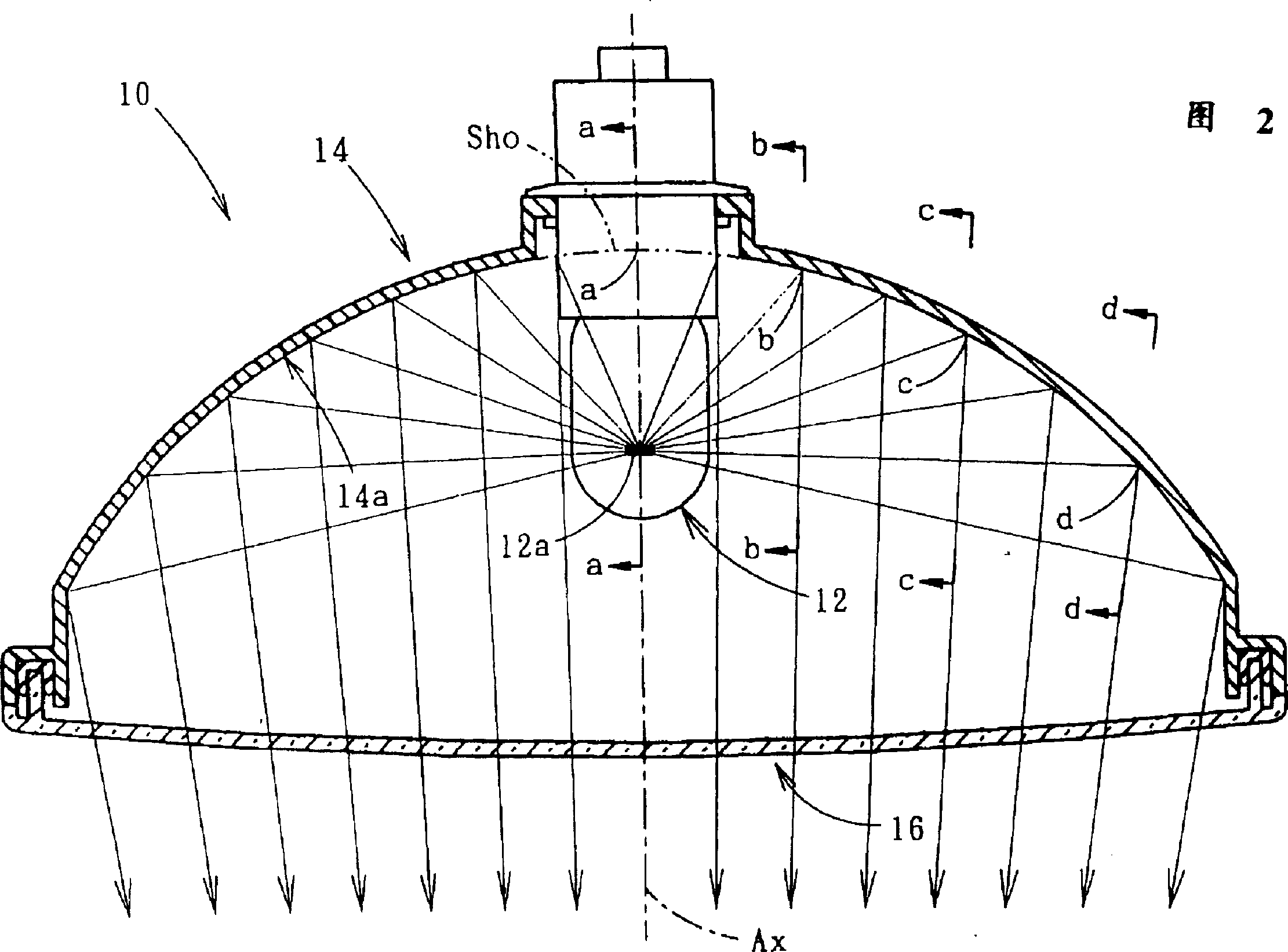

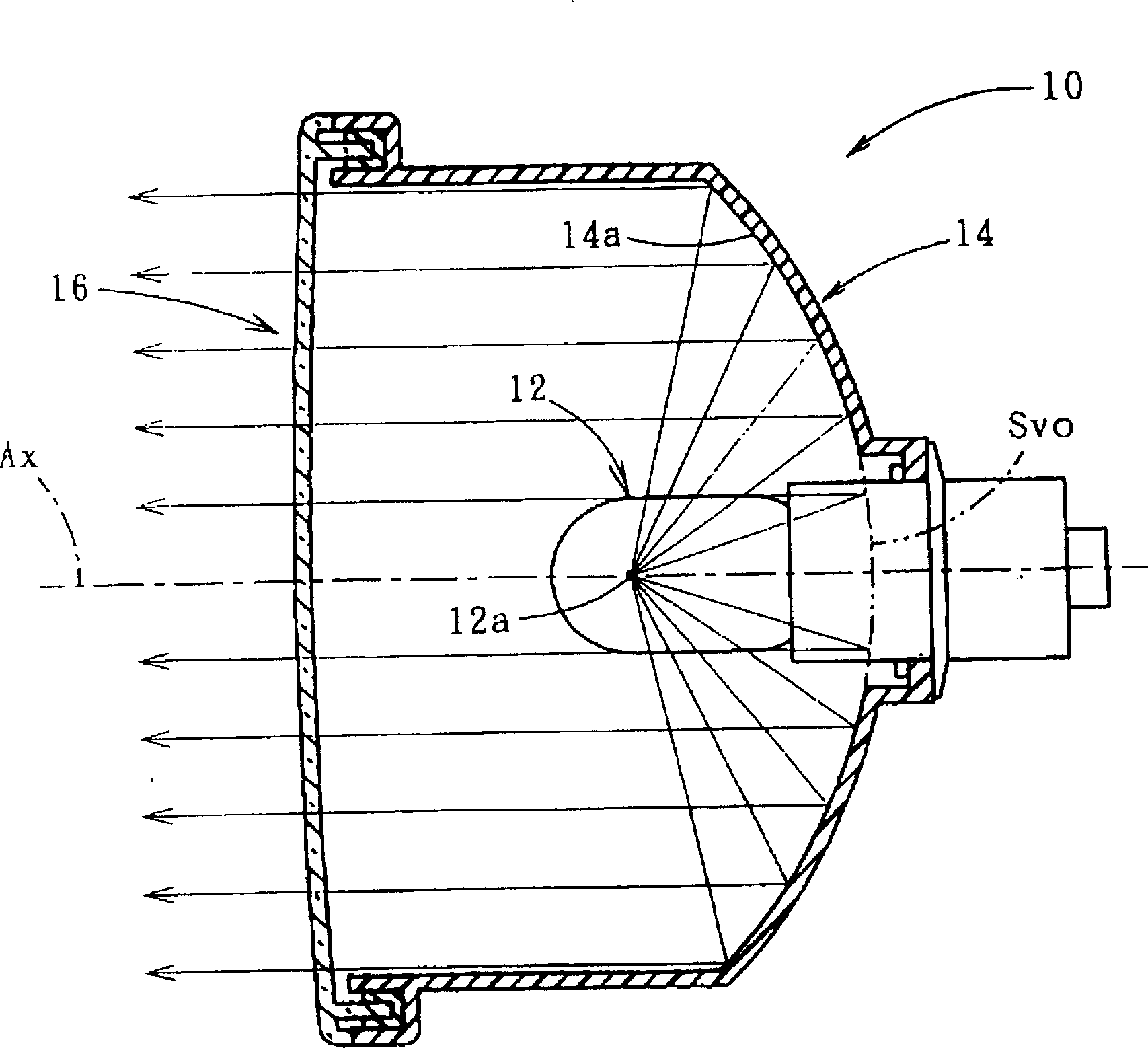

[0038] Fig. 1 is the front view that shows the vehicle lamp 10 of present embodiment, Fig. 2 and image 3 Its front section view and side section view.

[0039] As shown in the figure, the vehicle lamp 10 is a tail light arranged at the rear end of the vehicle body, which includes a reflector 14 inserted with a light source bulb 12, and is arranged in front of the reflector 14 (that is, the front of the lamp and the rear of the vehicle body). , hereinafter the same) the headlight glass 16.

[0040] The light source bulb 12 as its light source 12a is centered on a reference axis Ax extending in the front-rear direction and extends in a horizontal direction perpendicular to the reference axis Ax, and has a so-called C-6 filament.

[0041] The reflector 14 has a reflective surface 14a that reflects light emitted from the light source 12a forward, and the reflective surface 14a has a laterally long rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com