Burst-resistant brown paper and making method thereof

A kind of kraft paper and burst-resistant technology, which is applied in papermaking, pulp bleaching, textiles and papermaking, etc. It can solve the problems of packaged items falling out, poor burst resistance, paper rupture, etc., and achieves extended service life, good water absorption, and improved The effect of burst resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

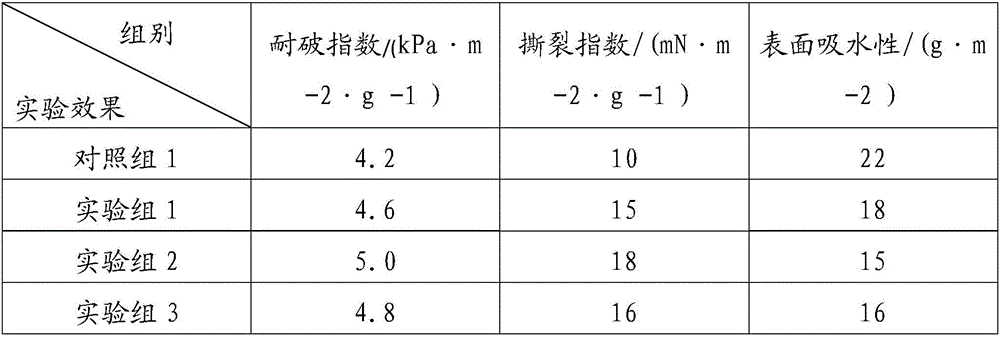

Examples

Embodiment 1

[0021] A kind of preparation method of break-resistant kraft paper comprises the following steps:

[0022] (1) 70 parts of coniferous bark, 60 parts of broad-leaved bark, 50 parts of waste paper, 20 parts of cotton fiber, 30 parts of sandalwood bark, 15 parts of bamboo, 26 parts of bagasse, 15 parts of wool and 30 parts of grass are mixed and pulverized, Mixture A is obtained after pulverization;

[0023] (2) Pour mixture A into a digester for cooking, the cooking temperature is 150 degrees Celsius, and the cooking time is 50 minutes;

[0024] (3) Pour the cooked mixture A into the bleaching tank, add 5 parts of aluminum sulfate to the bleaching tank, stir and mix evenly, and the soaking time of the mixture A is 90 minutes.

[0025] (4) Pour the mixed slurry obtained in step 3 into a high-concentration deslagging machine, and sieve the fibers and particles in the mixed slurry;

[0026] (5) Pour the slurry sieved in step 4, 5 parts of talcum powder, 8 parts of calcium carbona...

Embodiment 2

[0030] A kind of preparation method of break-resistant kraft paper comprises the following steps:

[0031] (1) 60 parts of coniferous bark, 50 parts of broad-leaved bark, 40 parts of waste paper, 15 parts of cotton fiber, 22.5 parts of sandalwood bark, 12.5 parts of bamboo, 22 parts of bagasse, 11.5 parts of wool and 25 parts of grass are mixed and pulverized, Mixture A is obtained after pulverization;

[0032] (2) Pour mixture A into a cooker for cooking, the cooking temperature is 125 degrees Celsius, and the cooking time is 45 minutes;

[0033] (3) Pour the cooked mixture A into the bleaching tank, add 7.5 parts of aluminum sulfate to the bleaching tank, stir and mix evenly, and the soaking time of the mixture A is 75 minutes.

[0034] (4) Pour the mixed slurry obtained in step 3 into a high-concentration deslagging machine, and sieve the fibers and particles in the mixed slurry;

[0035] (5) Pour the slurry sieved in step 4, 7.5 parts of talcum powder, 11.5 parts of calc...

Embodiment 3

[0039] A kind of preparation method of break-resistant kraft paper comprises the following steps:

[0040] (1) 50 parts of coniferous bark, 40 parts of broad-leaved bark, 30 parts of waste paper, 10 parts of cotton fiber, 15 parts of sandalwood bark, 10 parts of bamboo, 18 parts of bagasse, 8 parts of wool and 20 parts of grass are mixed and pulverized,

[0041] Mixture A is obtained after pulverization;

[0042] (2) Pour mixture A into a cooker for cooking, the cooking temperature is 100 degrees Celsius, and the cooking time is 40 minutes;

[0043] (3) Pour the cooked mixture A into the bleaching tank, add 10 parts of aluminum sulfate into the bleaching tank, stir and mix evenly, and the soaking time of the mixture A is 60 minutes.

[0044] (4) Pour the mixed slurry obtained in step 3 into a high-concentration deslagging machine, and sieve the fibers and particles in the mixed slurry;

[0045] (5) Pour the slurry screened in step 4, 10 parts of talcum powder, 15 parts of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com