Graphene with high density and high electrochemical specific capacity, as well as preparation method and application thereof

A graphene and electrochemical technology, applied in the field of graphene preparation, can solve the problems of limited graphene volume specific capacity, difficulty in preparing density, and low product density, so as to improve the mass specific electrochemical capacity, avoid graphene loss, increase Agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare sulfuric acid intercalated graphite oxide according to the literature method and expand and exfoliate at 300°C to prepare expanded graphene: mix 80mL concentrated sulfuric acid and 1g sodium nitrate in an ice-water bath, stir for 10min, add 2g graphite powder (3000 mesh), stir for 1h, slowly Add 6g of potassium permanganate, stir for 20min, transfer to a 37°C water bath and stir for 10h, then add 150mL of deionized water at room temperature, stir for 0.5h, continue to add water to 500mL, add 30% hydrogen peroxide, until the cloudy liquid turns bright yellow, After stirring for 2 hours, let it stand overnight, remove the supernatant, wash with deionized water for 4 times, dry and obtain sulfuric acid intercalated graphite oxide with a sulfur content of 4 wt%, and then expand the sulfuric acid intercalated graphite oxide at 300°C Peel off to obtain expanded graphene with a rolling density of about 0.38g / cm 3 .

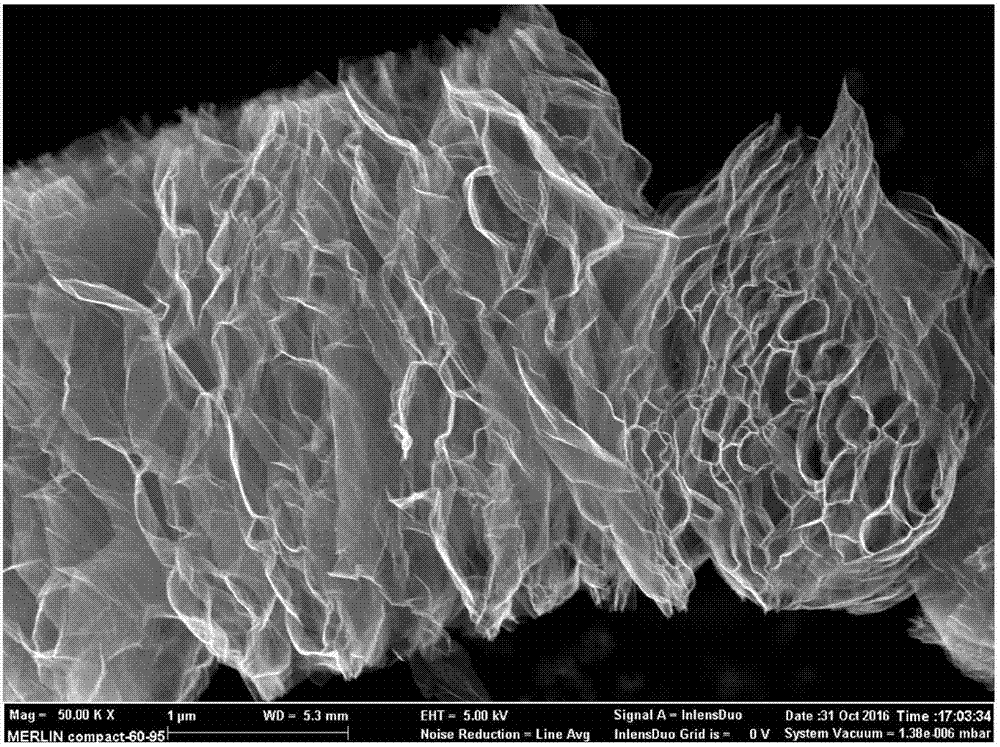

[0033] The obtained expanded graphene is placed in ...

Embodiment 2

[0036] Prepare expanded graphene by the method of embodiment 1, the gained expanded graphene is placed in molten CH under the protection of inert atmosphere 3 In COSK, conduct solid-liquid separation after heat treatment at 200°C for 300 minutes, wash the product with deionized water until neutral after cooling, and dry it in a blast drying oven at 50°C to obtain a tap density of about 1.1g / cm 3 high-density graphene.

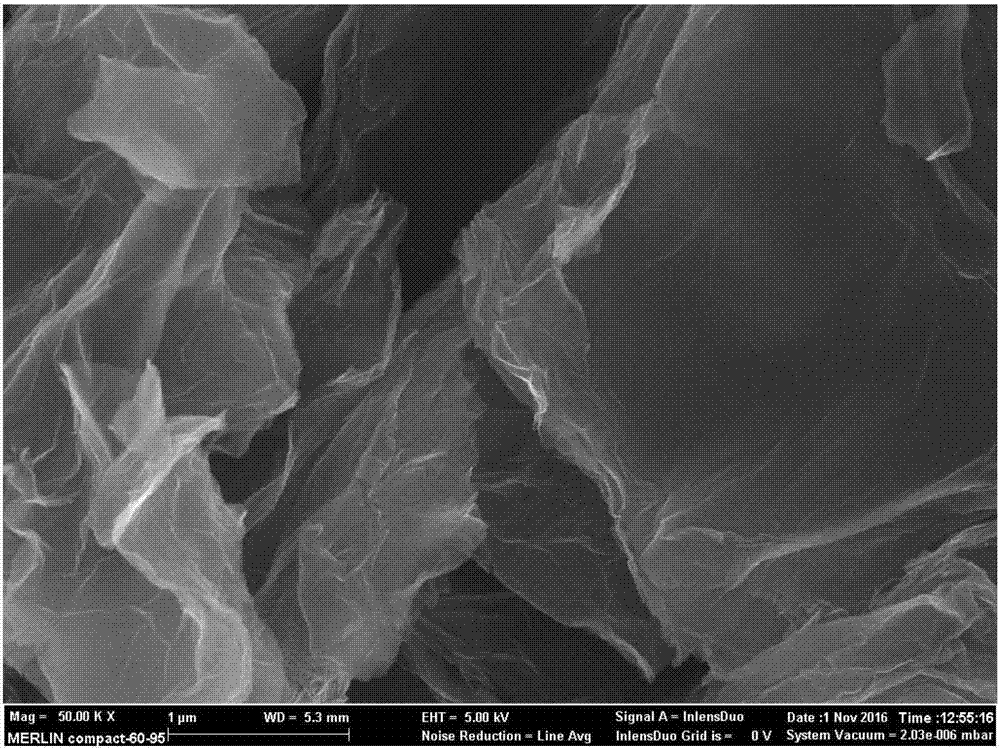

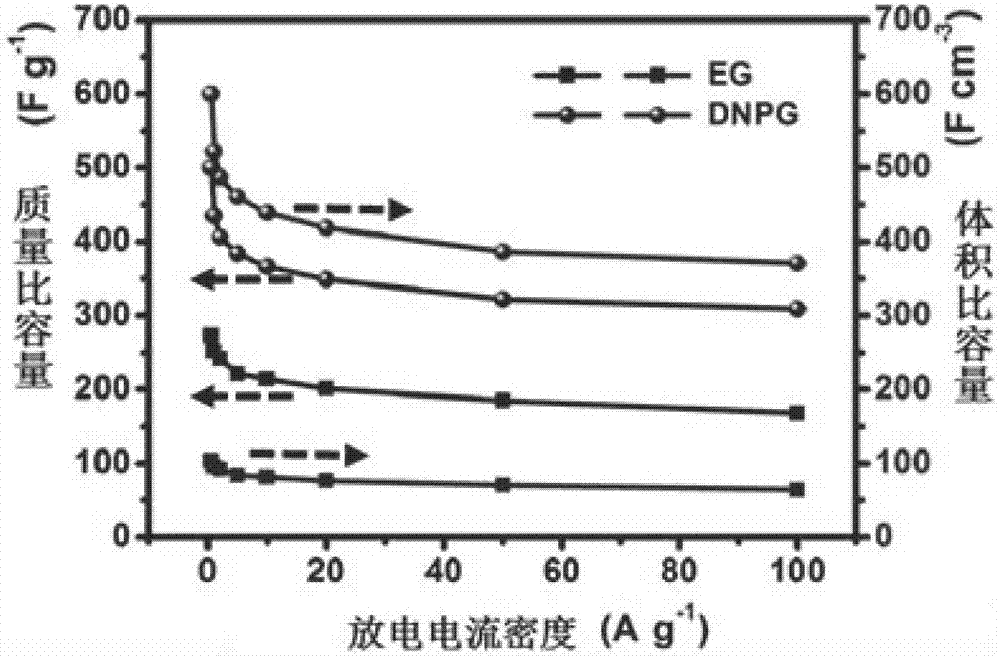

[0037] Figure 5 The SEM image of the high-density graphene product prepared in Example 2 shows that the separated sheets in the expanded graphene raw material have densely overlapped together. The above SEM image shows that the graphene raw material with loose and well-developed pore structure is transformed into very dense micron-scale graphene particles after high temperature treatment in ionic liquid. The S content of high-density graphene is about 5.3% as measured by XPS. Image 6 When the high-density graphene (DSG) product prepared for Example 2 is us...

Embodiment 3

[0039] Prepare graphene oxide and chemically reduce graphene according to the literature method: mix 80mL concentrated sulfuric acid and 1g sodium nitrate in an ice-water bath, stir for 10min, add 2g graphite powder (3000 mesh), stir for 1h, slowly add 6g potassium permanganate , stirred for 20 minutes, transferred to a 37°C water bath and stirred for 10 hours, then added 150mL deionized water at room temperature, continued to stir for 0.5h, added water to 500mL, and then added 30% hydrogen peroxide until the cloudy liquid was bright yellow, stirred for 2 hours and left for a while In the evening, remove the supernatant, centrifuge and wash 15 times with 2% dilute hydrochloric acid, ultrasonically disperse in aqueous solution, and reduce with hydrazine hydrate to obtain chemically reduced graphene, whose roll density is about 0.6g / cm 3 .

[0040] The obtained chemically reduced graphene was placed in molten sodium borohydride under the protection of an inert atmosphere, and so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com