Preparation method of cryptocrystalline graphite/polyvinyl alcohol heat-conducting composite material

A heat-conducting composite material and aphanitic graphite technology, applied in heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of poor thermal conductivity of aphanitic graphite/polyvinyl alcohol, etc. Achieve the effects of dense heat conduction effect, increased density, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

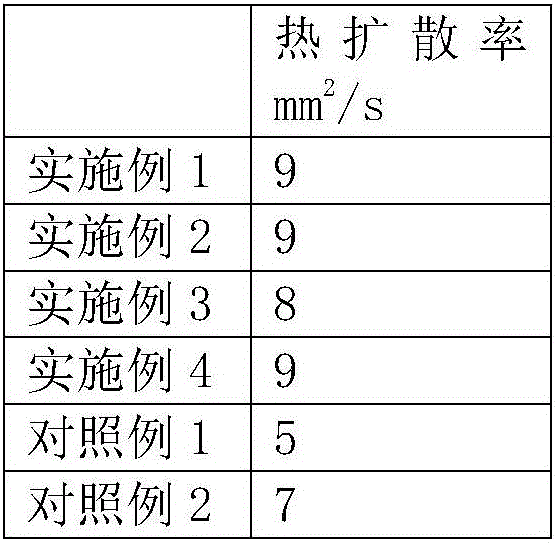

Examples

Embodiment 1

[0024] The preparation method of cryptocrystalline graphite / polyvinyl alcohol heat conduction composite material comprises the following steps:

[0025] In the first step, mix cryptocrystalline graphite, ammonium fluoride, and hydrochloric acid solution with a mass ratio of 6:3:22, heat to 45°C for 3 hours, wash with deionized water until neutral, and dry;

[0026] In the second step, 0.65 parts of sodium bicarbonate, 5 parts of cornstarch and 60 parts of cryptocrystalline graphite are weighed and mixed according to the weight ratio, and wet ball milled at a ball milling rate of 320r / min, and dried so that the moisture content is 1 ± 0.5%;

[0027] The third step is to dissolve polyvinyl alcohol in 95°C water, add the treated cryptocrystalline graphite mixture, mix evenly, and dry in an oven at a drying temperature of 55°C and a drying time of 3 hours; the cryptocrystalline The mass ratio of graphite mixture and polyvinyl alcohol is 1:2;

[0028] The fourth step is pulverizat...

Embodiment 2

[0030] The preparation method of cryptocrystalline graphite / polyvinyl alcohol heat conduction composite material comprises the following steps:

[0031] In the first step, mix cryptocrystalline graphite, ammonium fluoride, and hydrochloric acid solution with a mass ratio of 6:3:22, heat to 40°C for 3 hours, wash with deionized water until neutral, and dry;

[0032] In the second step, 0.5 parts of sodium bicarbonate, 4 parts of cornstarch and 40 parts of cryptocrystalline graphite are weighed and mixed according to the weight ratio, wet ball milled at a ball milling rate of 300r / min, and dried to make the moisture content 1 ± 0.5%;

[0033] The third step is to dissolve polyvinyl alcohol in water at 90°C, add the treated cryptocrystalline graphite mixture, mix evenly, and dry in an oven at a drying temperature of 50°C and a drying time of 3 hours; the cryptocrystalline The mass ratio of graphite mixture and polyvinyl alcohol is 1:2;

[0034] The fourth step is pulverization a...

Embodiment 3

[0036] The preparation method of cryptocrystalline graphite / polyvinyl alcohol heat conduction composite material comprises the following steps:

[0037] In the first step, mix cryptocrystalline graphite, ammonium fluoride, and hydrochloric acid solution with a mass ratio of 6:3:22, heat to 50°C for 3 hours, wash with deionized water until neutral, and dry;

[0038] In the second step, 0.8 parts of sodium bicarbonate, 6 parts of cornstarch and 80 parts of cryptocrystalline graphite were weighed and mixed according to weight ratio, wet ball milled at a ball milling rate of 50 r / min, and dried to make the moisture content 1 ± 0.5%;

[0039] The third step is to dissolve polyvinyl alcohol in water at 100°C, add the treated cryptocrystalline graphite mixture, mix evenly, and dry in an oven at a drying temperature of 60°C and a drying time of 3 hours; the cryptocrystalline The mass ratio of graphite mixture and polyvinyl alcohol is 1:2;

[0040] The fourth step is pulverization and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com