Stirring device for PE blown film raw material particle machining

A technology of blowing film and stirring device, applied in the field of PE blowing film, can solve the problem of uneven stirring of raw material particles, and achieve the effect of promoting mixing, promoting stirring and improving automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

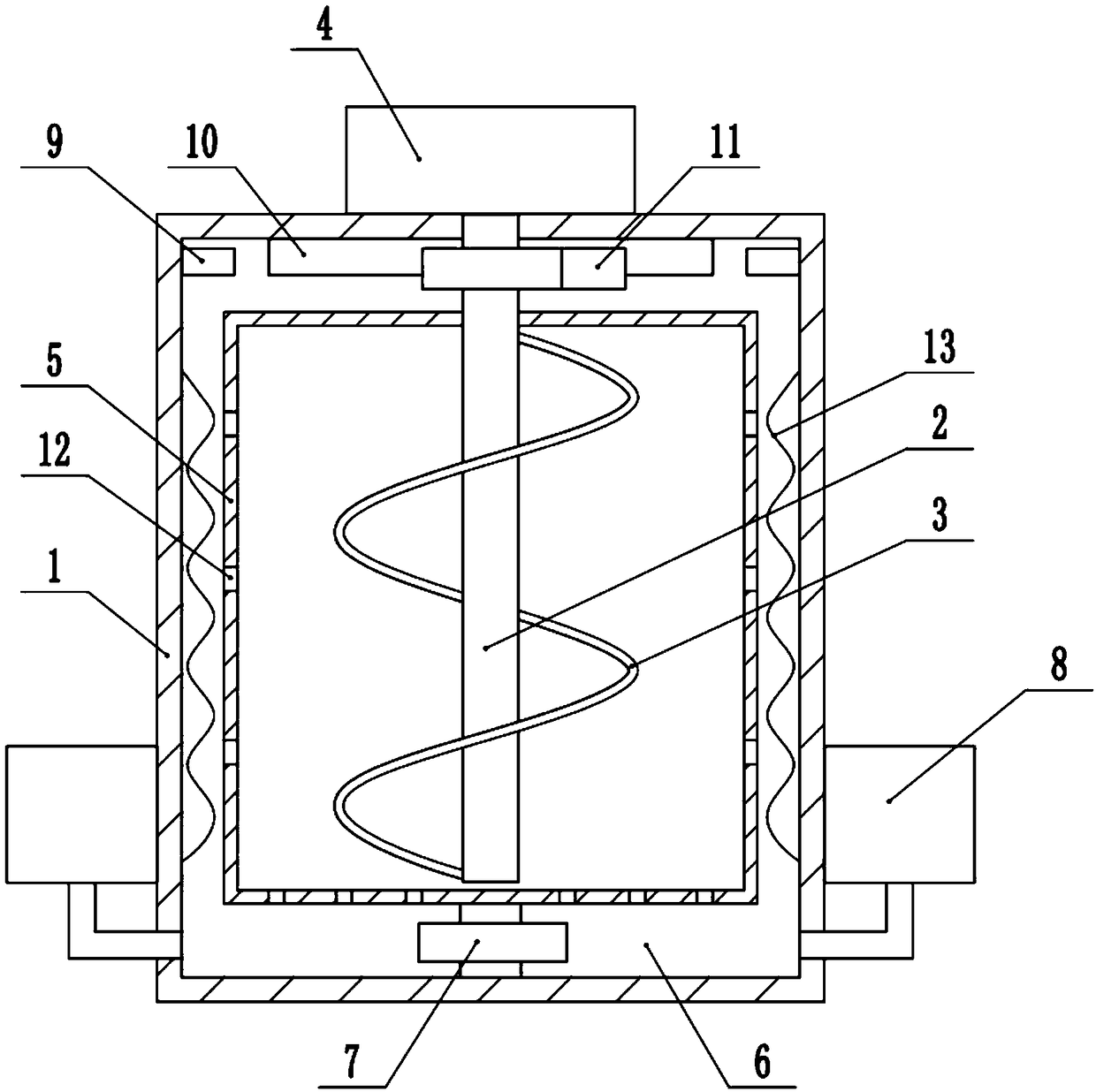

[0023] Embodiment one is basically as attached figure 1 Shown:

[0024] The agitating device for processing PE blown film raw material particles includes an outer box body 1, a stirring shaft 2 is rotatably connected to the outer box body 1, and a spiral stirring blade 3 is fixed on the stirring shaft 2, and the outer box body 1 is fixed A motor 4 for driving the stirring shaft 2 to rotate is connected, and an inner box 5 for loading raw material particles is connected to the outer box 1 for rotation, and the inner box 5 is made of aluminum material. The top centers of the outer box body 1 and the inner box body 5 are provided with a connected feed port and a connected discharge port (not shown in the figure), and the feed port and the discharge port are all arranged in a circular shape. In the embodiment, the connection mode between the feed port and the feed port, and the discharge port and the discharge port adopts a soft cloth bag, which can not only play the role of mate...

Embodiment 2

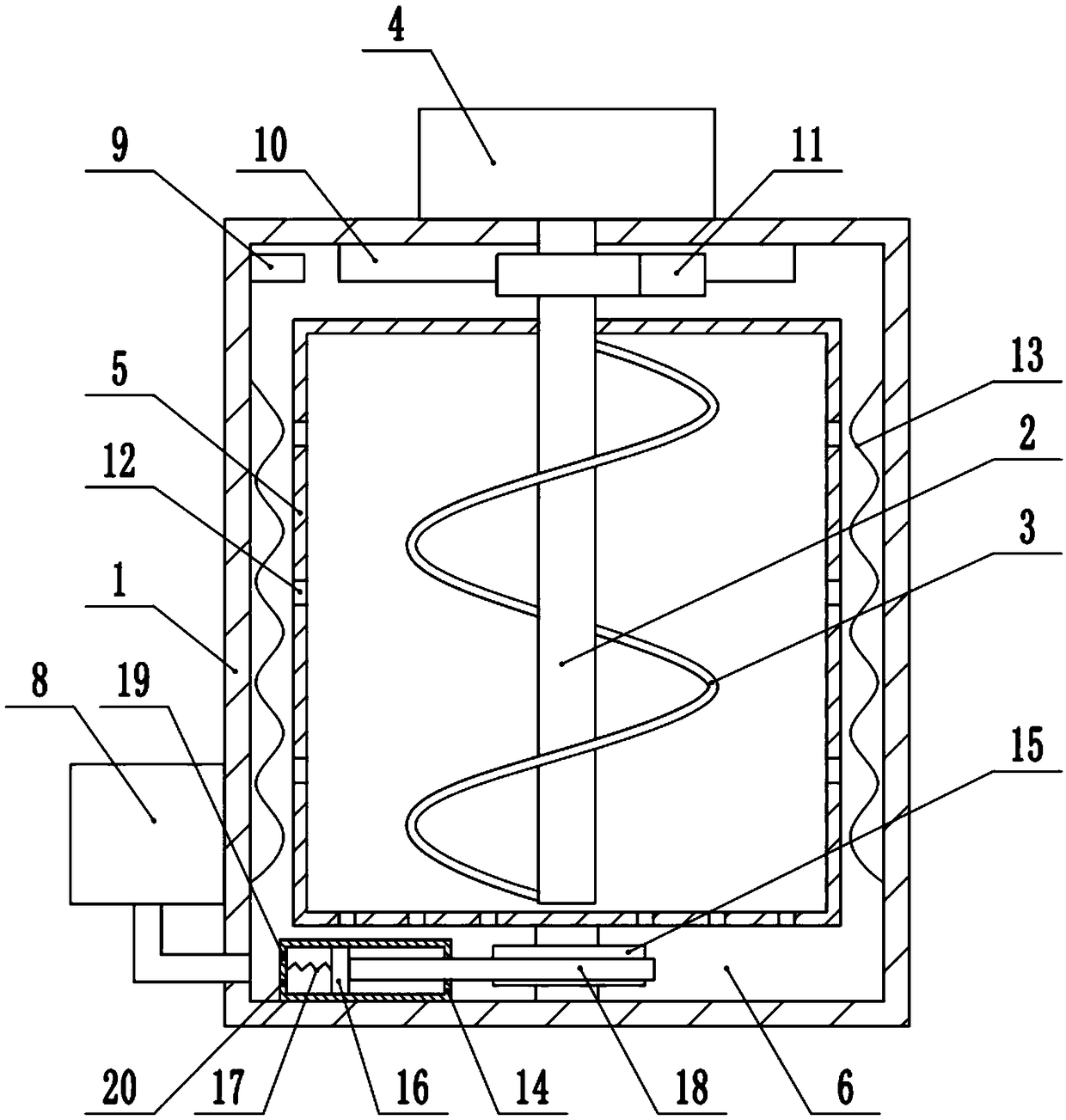

[0029] Embodiment two is basically as attached figure 2 Shown:

[0030]The difference between this embodiment and Embodiment 1 is that the driving mechanism includes a cylinder 14 and a gear 15 rotatably connected in the cavity 6, the gear 15 forms a coaxial connection with the inner box 5, and a piston 16 is slidably connected in the cylinder 14 , an elastic member 17 is connected between the piston 16 and the cylinder body 14. In this embodiment, the elastic member 17 is a spring. 19 and air outlet 20, the aperture of air inlet 19 is far greater than the aperture of air outlet 20, and check valve (not shown) is all provided with in air inlet 19 and air outlet 20, and the check valve at air inlet 19 places is The cavity 6 leads to the cylinder body 14 in one direction, and the one-way valve at the air outlet 20 leads the cylinder body 14 to the cavity 6 in one direction.

[0031] During specific implementation, the stirring shaft 2 forwardly rotates to drive the first rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com