Method for preparing of composition for surface treatment of metal, surface-treated steel sheet using same and method for manufacturing same

A technology for metal surface treatment and surface treatment of steel plates, applied in metal material coating technology, electrolytic coating, electrophoretic plating, etc., can solve the problems of coating peeling, coating performance degradation, organic film thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

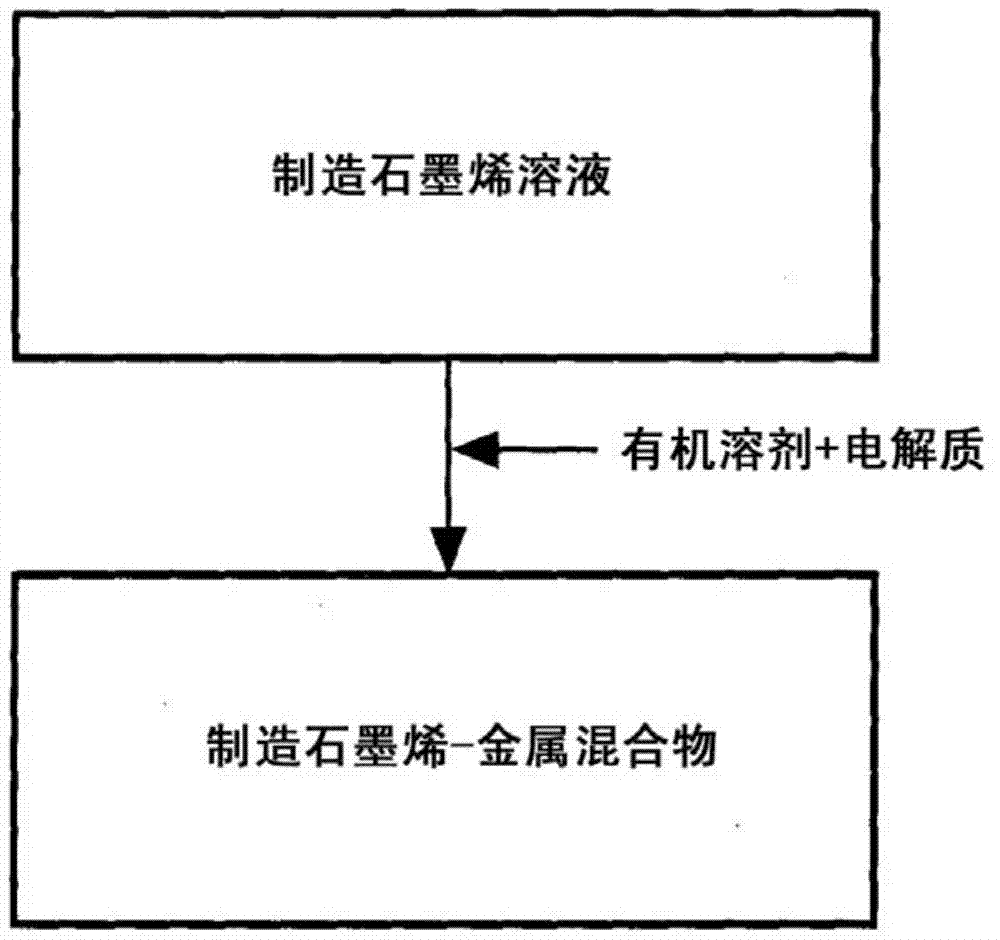

Method used

Image

Examples

Embodiment Construction

[0024] The inventors of the present invention replaced the existing methods of coating coatings or organic thin films, and additionally utilized graphene, which is the main axis of the future industry, to produce a composition capable of surface treatment, and found that after utilizing the composition coating graphene layer In the case of the present invention, it is possible to exhibit more improved performances such as adhesion and corrosion resistance, thereby completing the present invention.

[0025] Graphene is composed of carbon atoms and is a thin film formed with a thickness of one atom. Carbon is a two-dimensional planar structure of honeycombs connected in a hexagonal shape. It has very excellent characteristics in terms of electrical conductivity, thermal conductivity, and mechanical strength. Material.

[0026] Coating the graphene on the surface of the base steel plate to form a graphene layer can give the inherent characteristics of graphene, so compared with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com