Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

294results about How to "Easy to expand production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

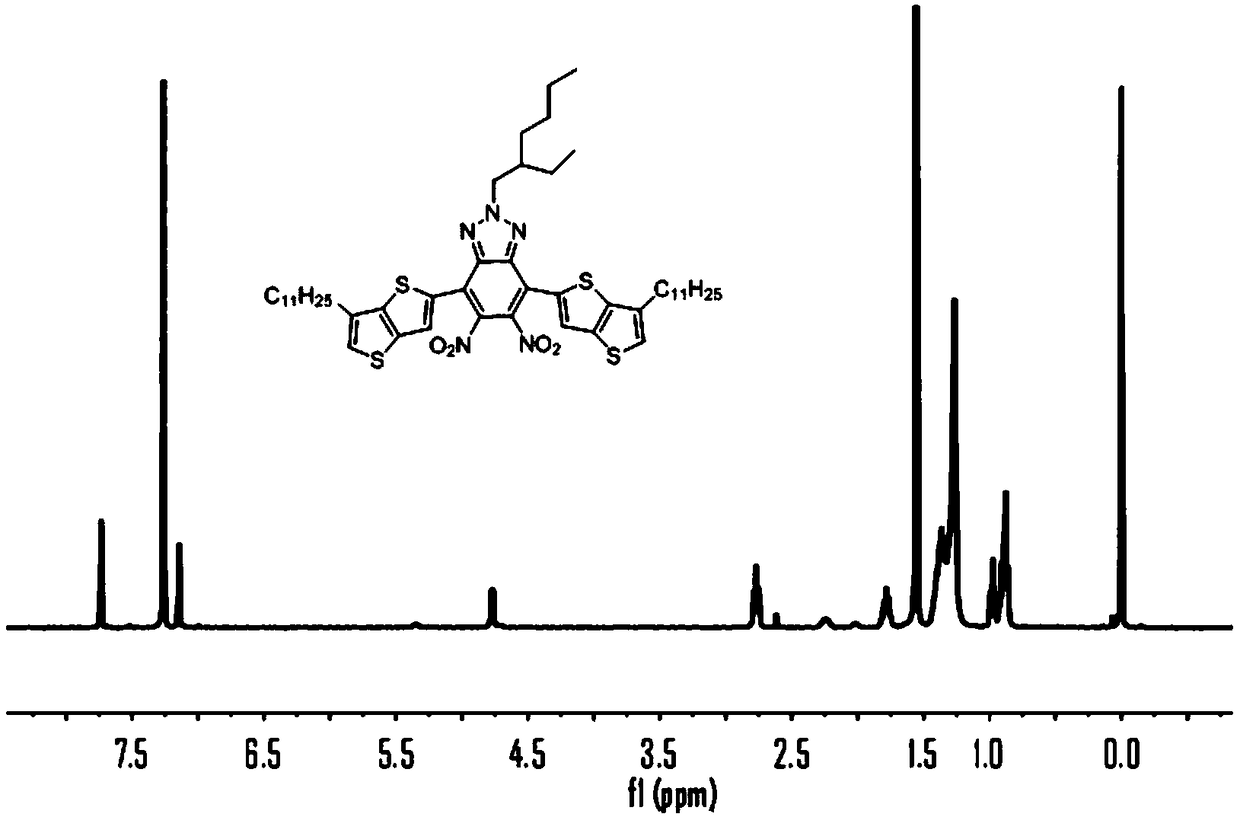

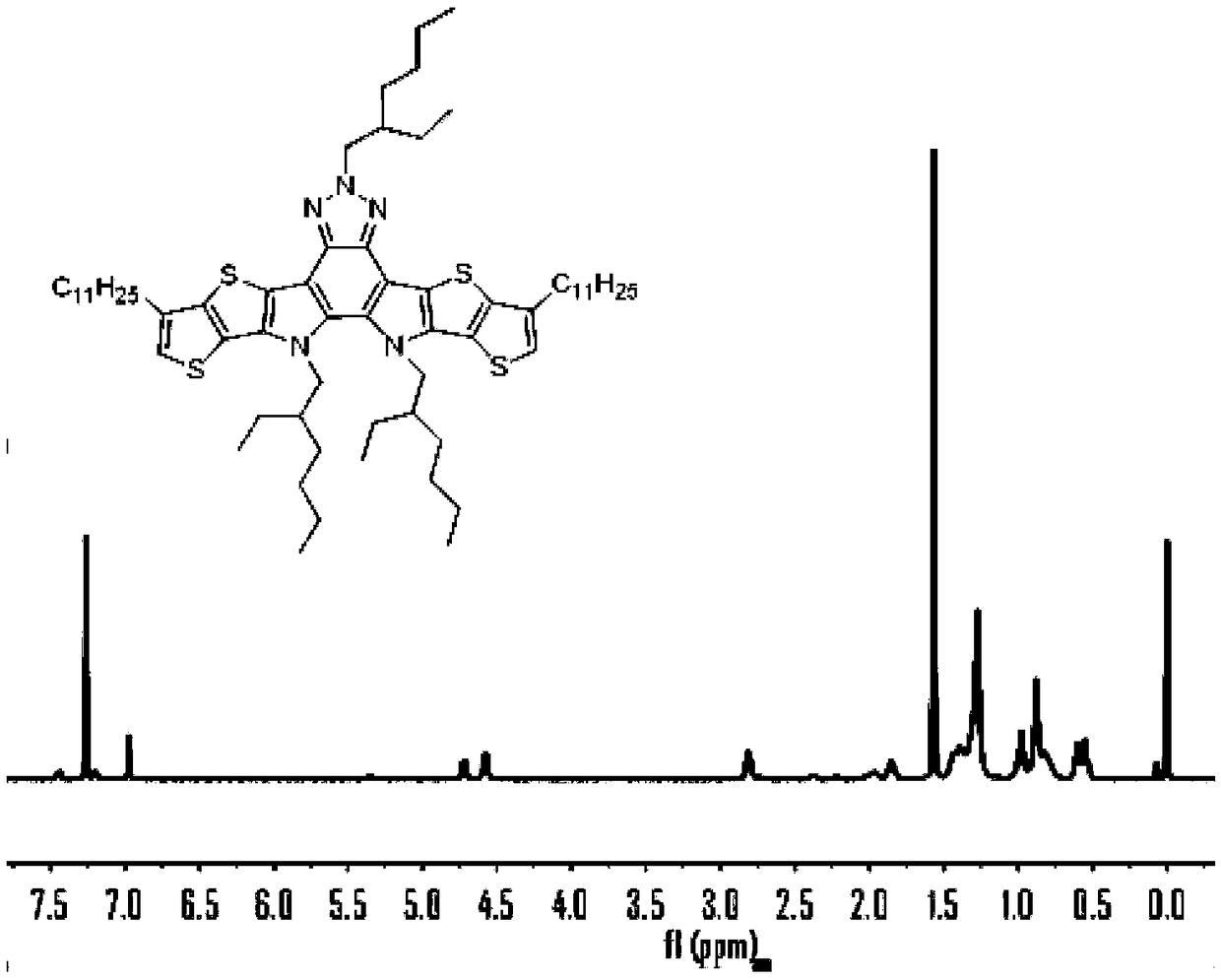

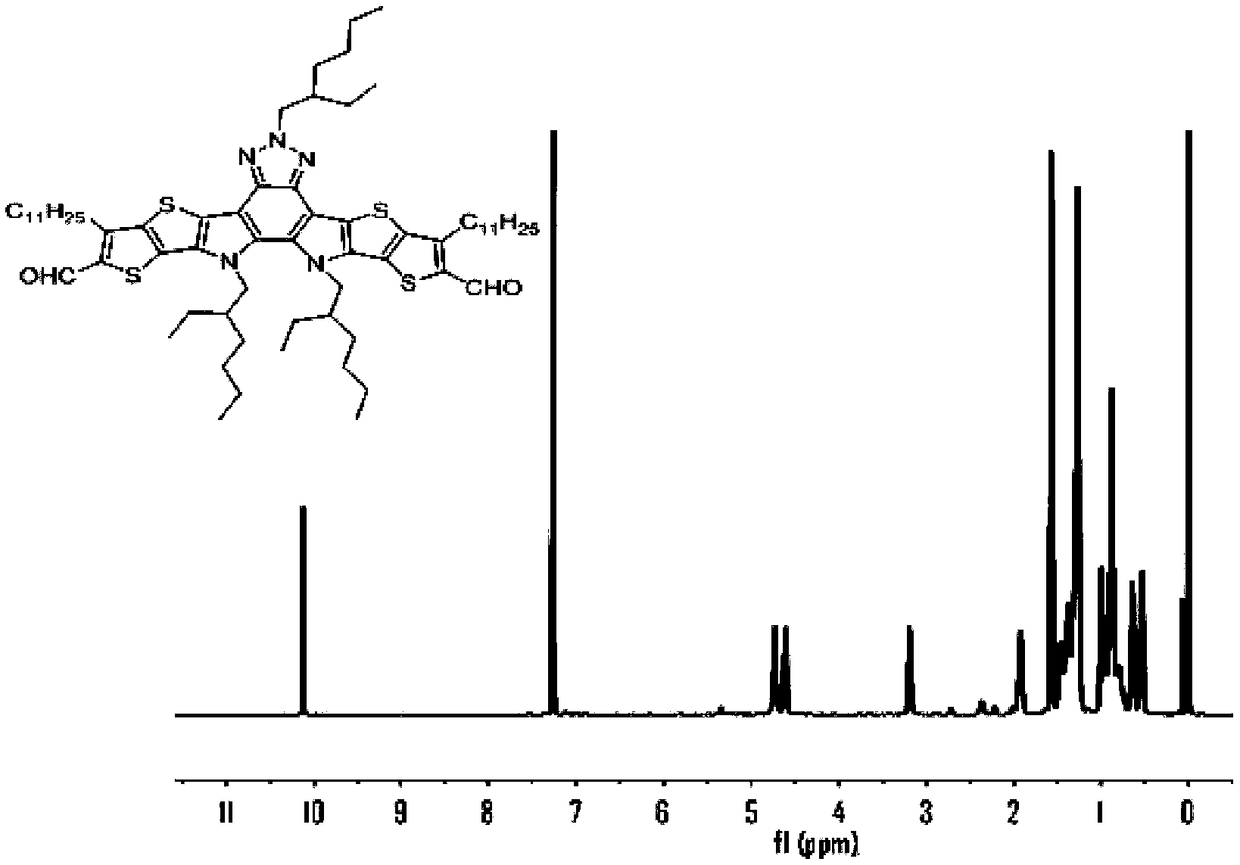

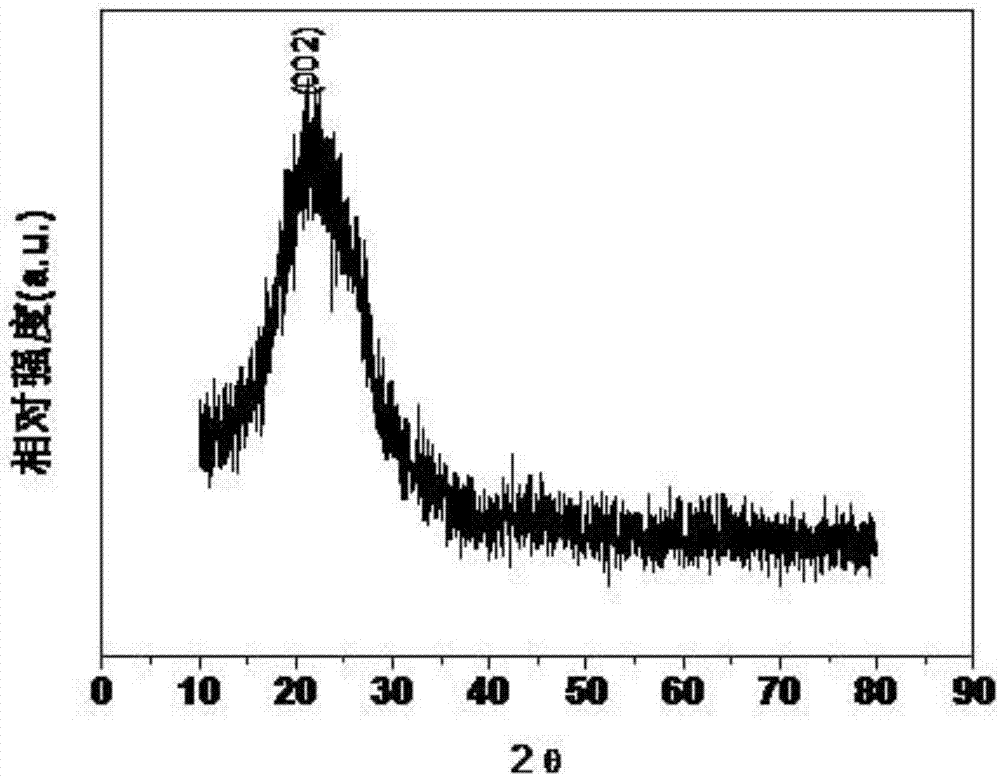

Heptatomic condensed ring benzotriazole receptor and preparation method and application thereof

ActiveCN108948042ADefinite conformationImprove solubilityOrganic chemistrySolid-state devicesSolubilityLoop closing

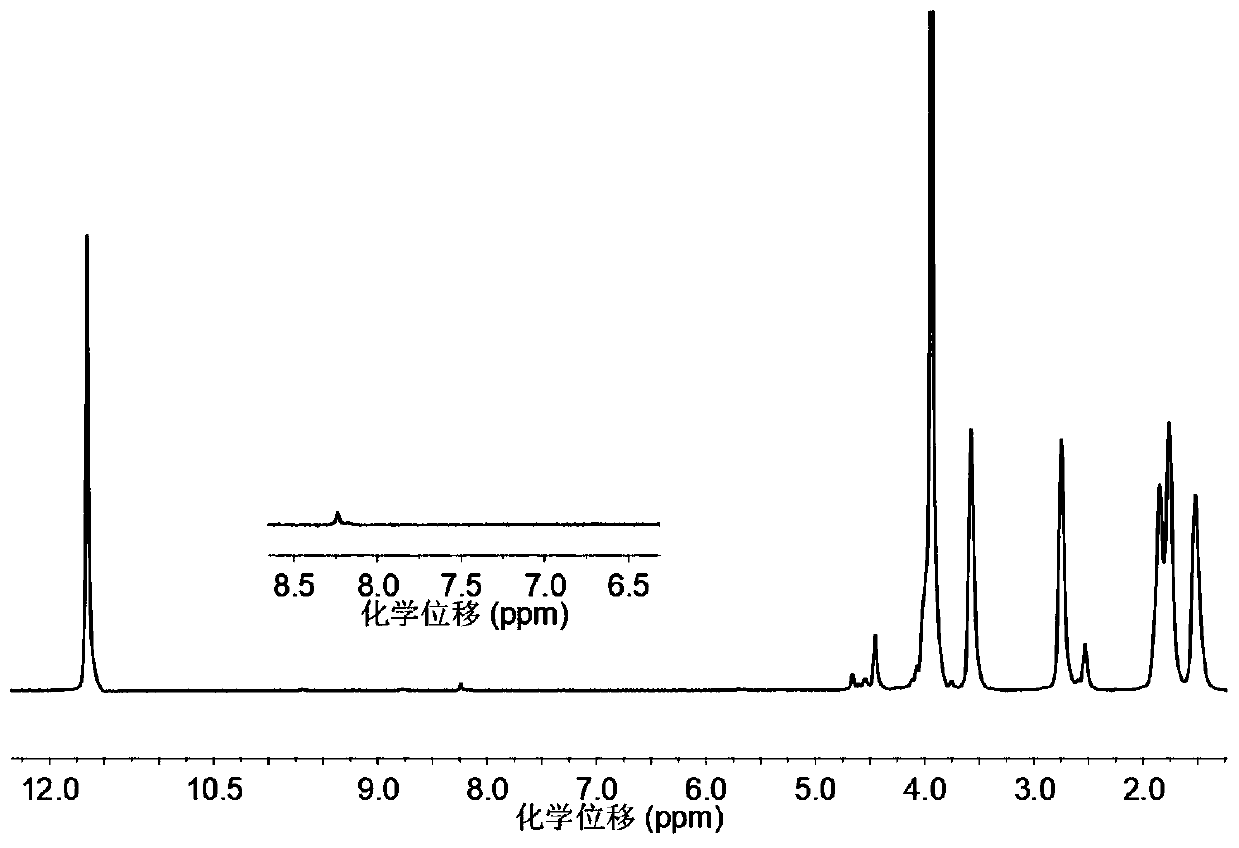

The invention discloses a heptatomic condensed ring benzotriazole receptor micromolecule and a preparation method and application thereof. The compound takes heptatomic condensed ring benzotriazole (B) with an alkyl chain as intercalated nucleus, and cyan group as n-type fullerene receptor material (BIC) of an electrophilic unit. The preparation method comprises the following steps: by taking 4,7-dibromo-5,6-dinitro benzotriazole compound as a raw material, sequentially introducing thienothiophene with an alkyl chain by stille coupling reaction, then performing loop closing, introducing the alkyl chain to N by nucleophilic substitution, introducing aldehyde group via Vilsmeier-Haack, and then introducing a polar conjugation unit by Knoevenage reaction, so as to obtain a BIC compound; the micromolecule forms definite conformation and good solubility, has an electron receptor unit with universality, obtains a high efficiency (PCE of 13%) on a solar cell, and thus is a photovoltaic material full of potential.

Owner:CENT SOUTH UNIV

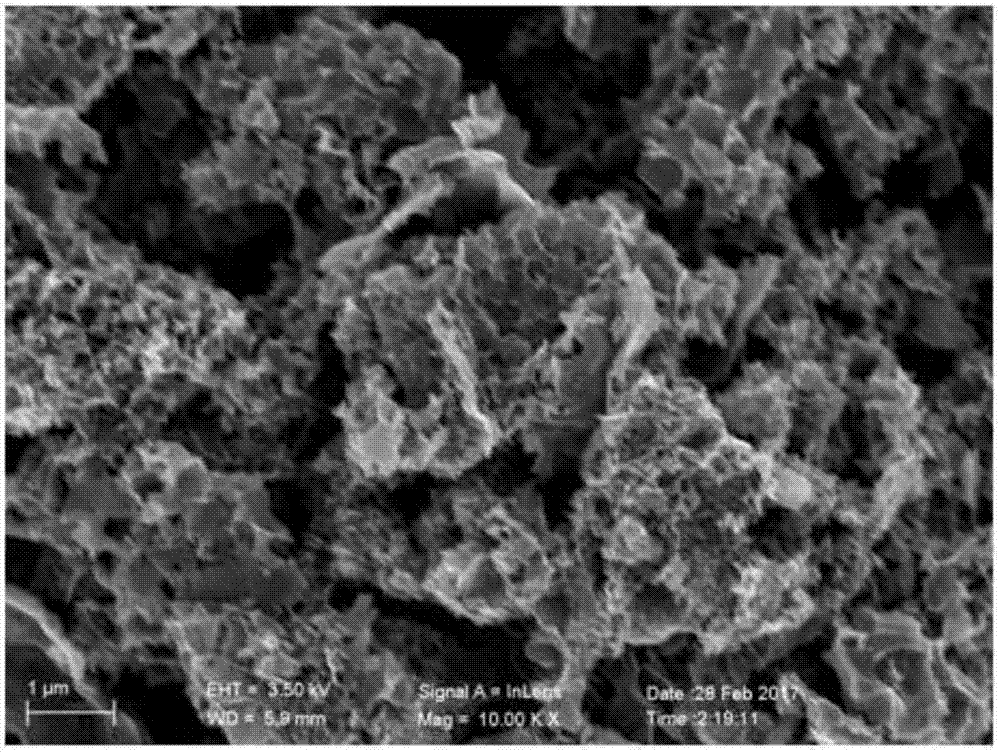

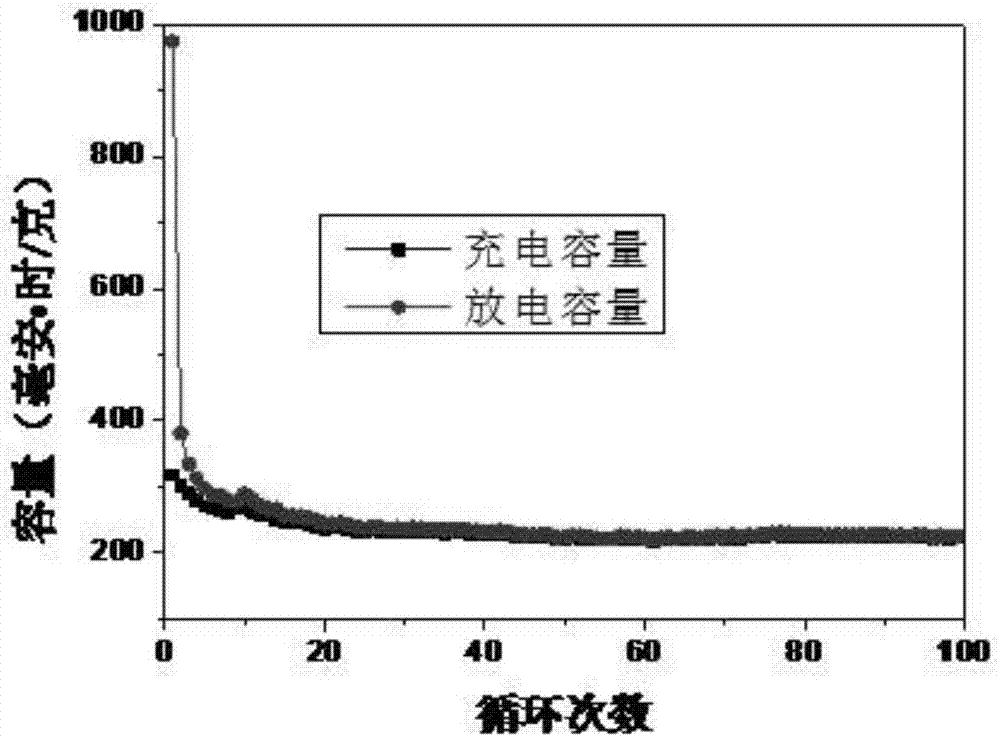

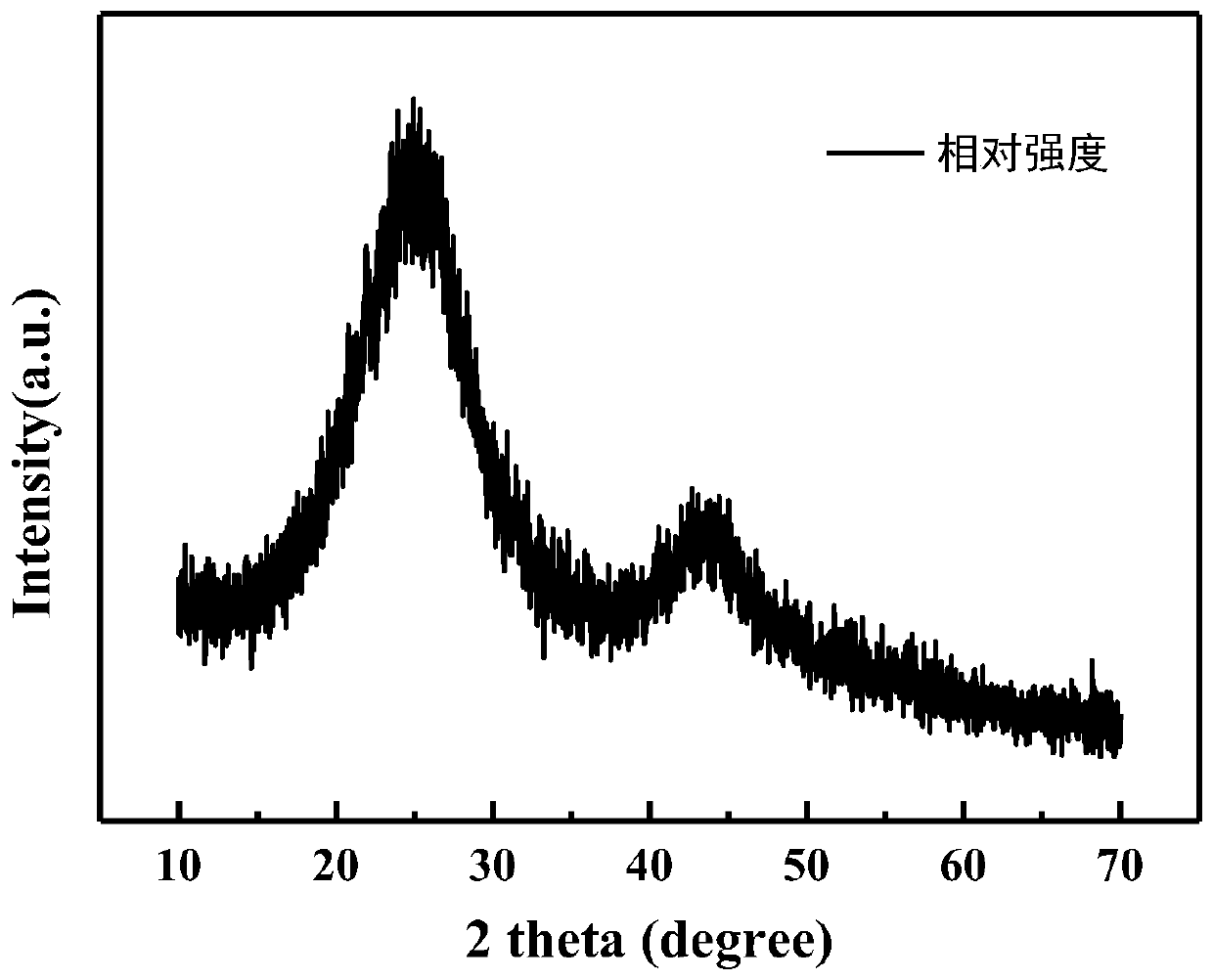

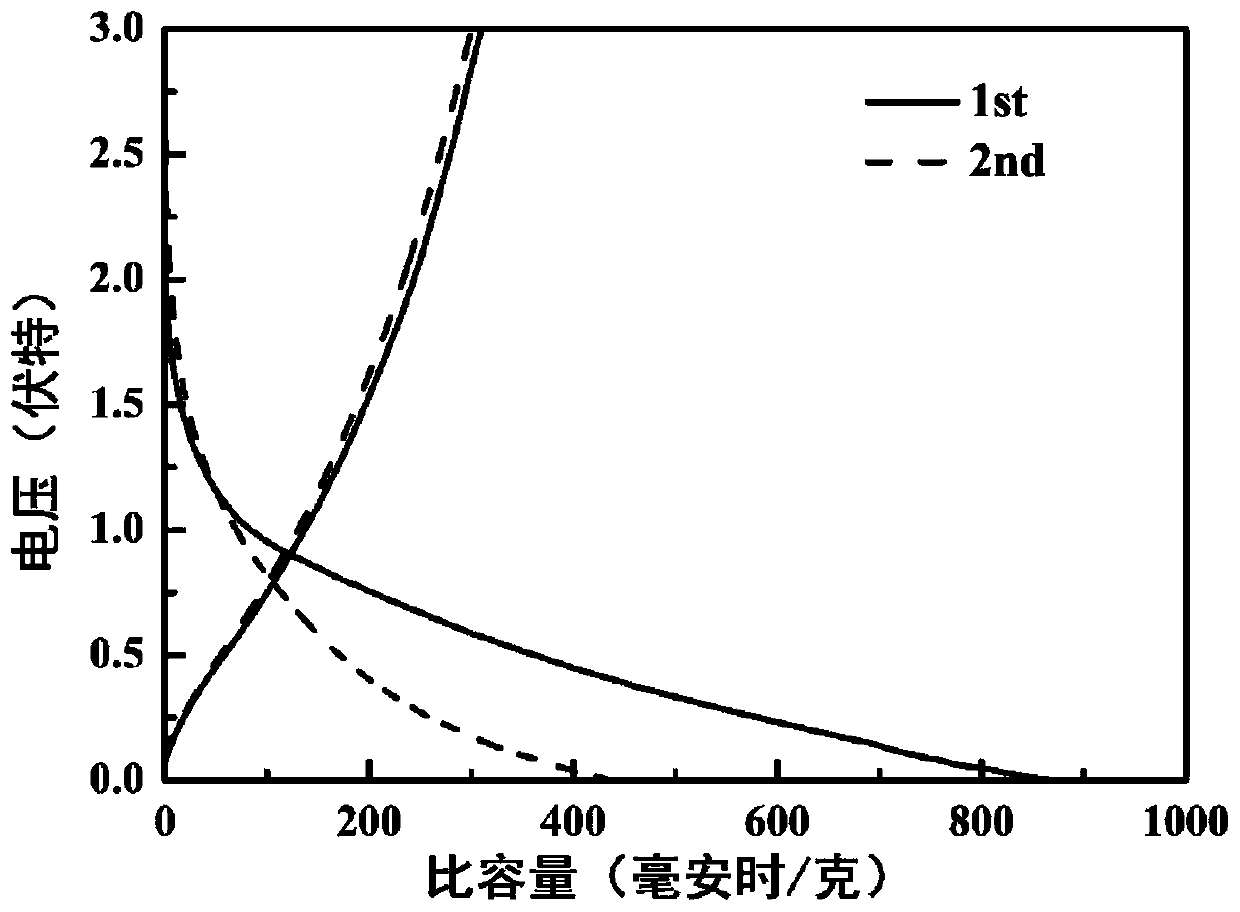

Method for preparing nitrogen-doped porous carbon material used as sodium ion battery cathode

ActiveCN107331867AImprove cycle stabilityOvercome the disadvantage of low specific capacityCell electrodesSecondary cellsPorous carbonSynthesis methods

The invention provides a method for preparing a nitrogen-doped porous carbon material used as a sodium ion battery cathode, and belongs to a method for preparing nitrogen-doped porous carbon. The nitrogen-doped carbon material is controlled and synthesized by regulating and controlling each parameter in the reacting process by means of a simple and feasible high-temperature solid phase reaction method, and is applied to a sodium ion battery cathode material. The method comprises the following steps: dissolving a selected nitrogen source in a solvent to form a transparent solution A; adding a proper amount of carbon source into the solution A, and constantly adding into solvent to sufficiently disperse the nitrogen source under a stirring state; drying the materials in a lyophilizer for 2-12 hours; putting a proper amount of the materials into a crucible, heating to 300-1100 DEG C and insulating for 1-6 hours in a vacuum tube furnace under an argon atmosphere at a speed of 2-8 DEG C / minute; and separating and purifying the generated product to obtain a product. The preparation method has the advantages of low-price and easily available raw materials, simple synthesis method and high controllability of operation steps, and is easy for expanded production. The nitrogen-doped porous carbon material can be used as a sodium ion battery cathode material, and shows excellent electrochemical performance.

Owner:CHINA UNIV OF MINING & TECH

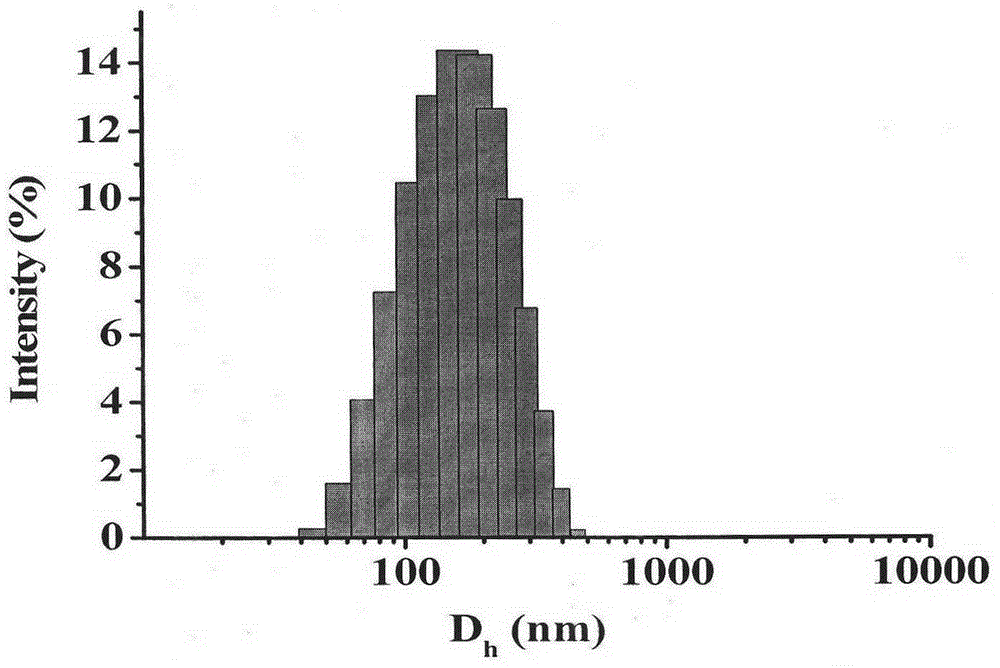

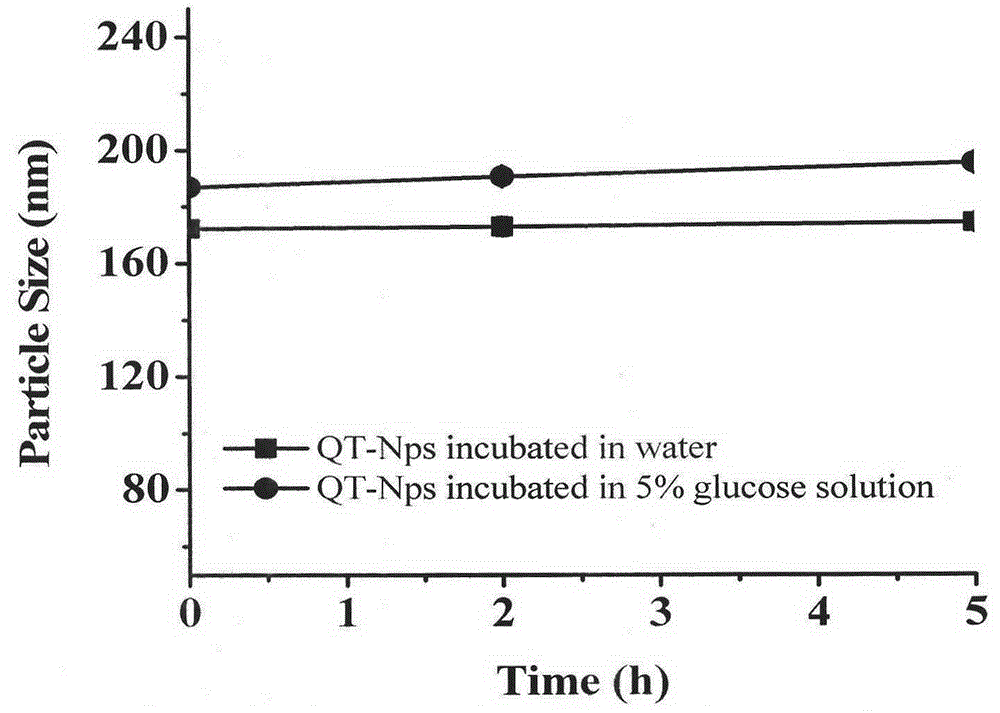

Quercetin nanoparticle and preparation method thereof

ActiveCN105106117AEasy to achieve passive targeting effectEasy to operateOrganic active ingredientsPowder deliverySolubilityHigh pressure homogenization

The invention relates to a quercetin nanoparticle and a preparation method thereof. The quercetin nanoparticle is prepared by using one or two selected from the group consisting of a nanometer precipitation process and a high pressure homogenization process. According to the invention, quercetin is used as a bulk drug, TPGS (vitamin E polyethanediol succinate) is used as a main stabilizing agent, and a mass ratio of the bulk drug to the carrier stabilizing agent is 1: 20 to 10: 1. The prepared quercetin nanoparticle has a small particle size and a high drug loading rate, and when a drug-carrier ratio is 5: 1, the average particle size of the quercetin nanoparticle is 173.21 nm and the drug-loading rate is about 80%; moreover, the prepared quercetin nanoparticle has good stability, the drug exists in crystal form in the nanoparticle, and an obvious slow release effect in vitro is obtained. The quercetin nanoparticle with a high drug loading rate and a small particle size can be prepared by using TPGS, shows obvious slow release effect in vitro, overcomes the problem of poor water-solubility and has good application prospects.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI

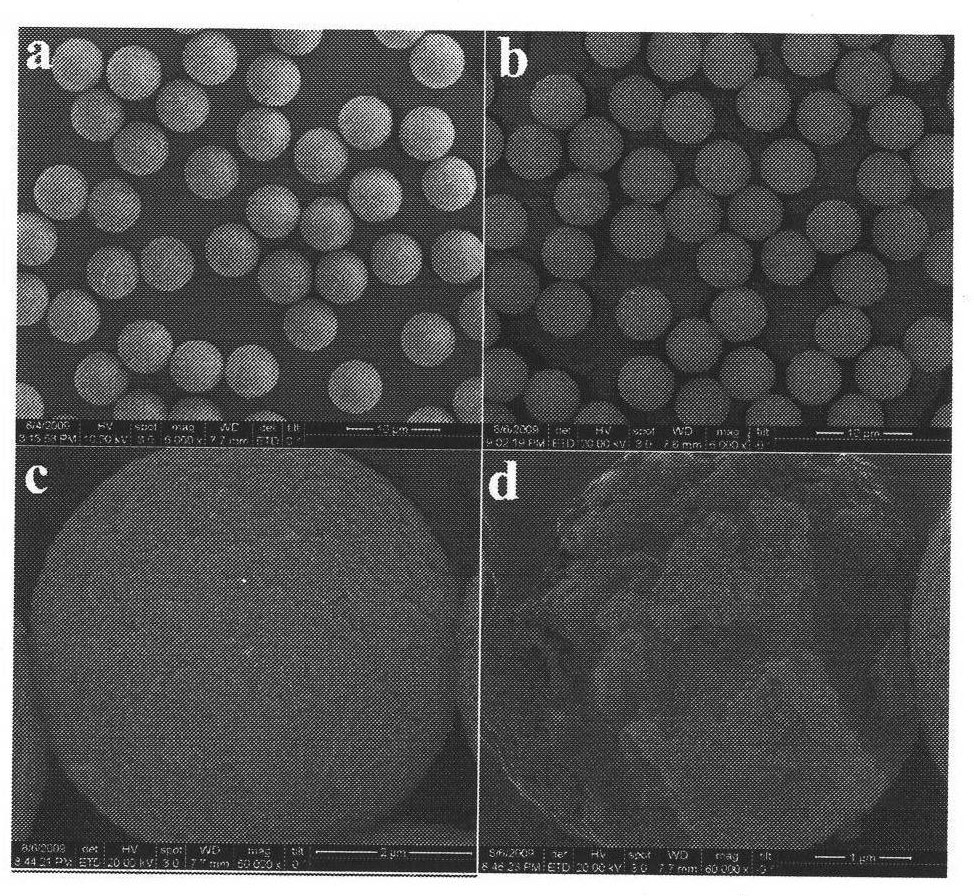

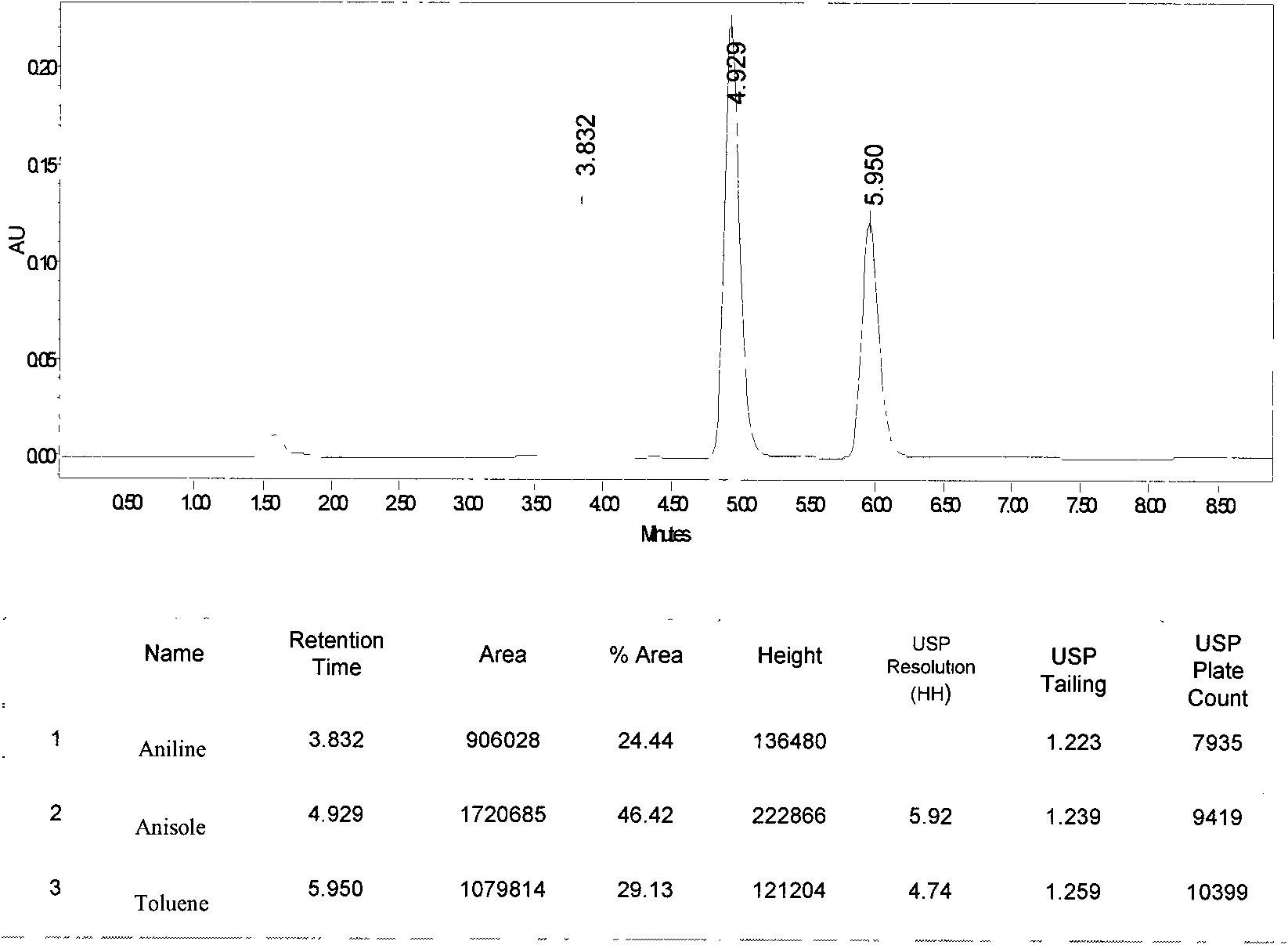

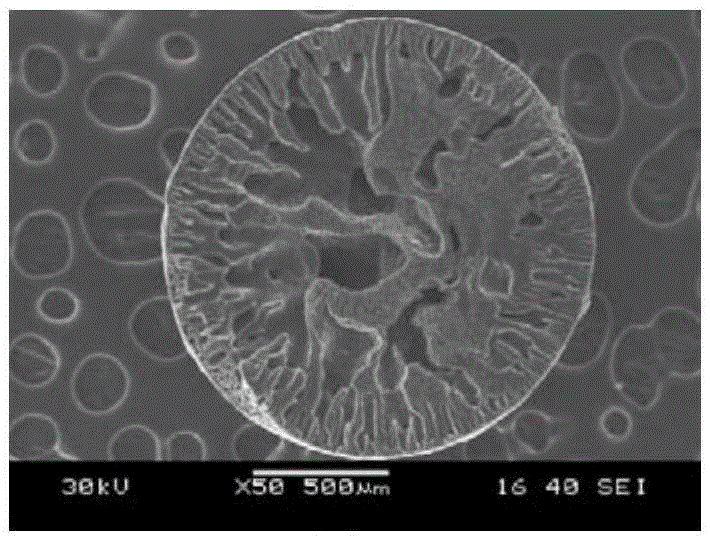

Preparation method of monodisperse porous inorganic microsphere

InactiveCN102133513AUniform sizeAperture size controllableMicroballoon preparationMicrocapsule preparationMicrosphereWastewater

The invention provides a preparation method of a monodisperse porous inorganic microsphere. Functionalized porous polymer microspheres are used as templates; the hydrolysis condensation reaction of an inorganic precursor is controlled to perform in the pores of the microspheres so as to prepare polymer / inorganic substance composite microspheres; and the templates are removed to obtain porous inorganic microspheres. The porous inorganic microspheres provided by the invention has the same size as the templates with no size reduction phenomenon, and the yield is up to above 98%; the inorganic microspheres have stable chemical properties and high mechanical strength, and have potential application value to the fields of chromatography, bioseparation, wastewater treatment, catalyst carrier, immobilized enzyme, etc.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

Preparation method of alkene epoxidation catalyst as well as catalyst prepared thereby

ActiveCN107930610AHigh reactivityReduce surface acidityOrganic chemistryMolecular sieve catalystsComposite oxideKinetic diameter

The invention relates to a preparation method of an alkene epoxidation catalyst. The preparation method of the alkene epoxidation catalyst comprises the following steps: (1) preparing titanium silicongel; (2) performing pore-enlarging treatment on the titanium silicon gel by using organic amine or liquid ammonia, drying and roasting to obtain titanium silicon composite oxide; (3) optionally performing alcohol solution treatment on organic alkali metal salt; and (4) optionally performing gas phase silanization treatment. The pore diameter of the catalyst prepared by the method is adjustable, so that the catalyst has higher activity on epoxidation reaction of olefin molecules with different kinetic diameter; and the catalyst is subjected to two-step modification, the surface acidity of thecatalyst is effectively reduced and the catalyst has higher epoxidation product selectivity.

Owner:WANHUA CHEM GRP

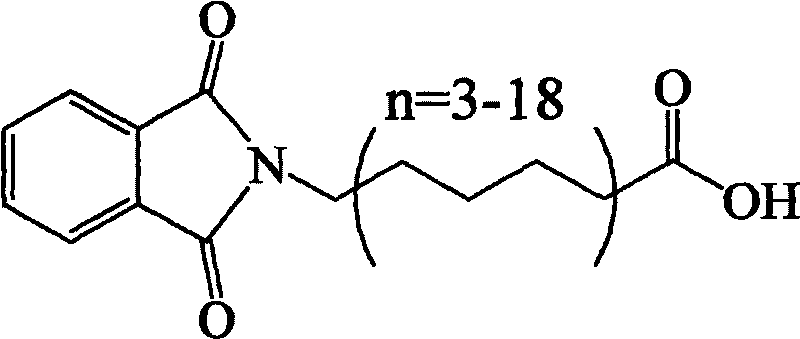

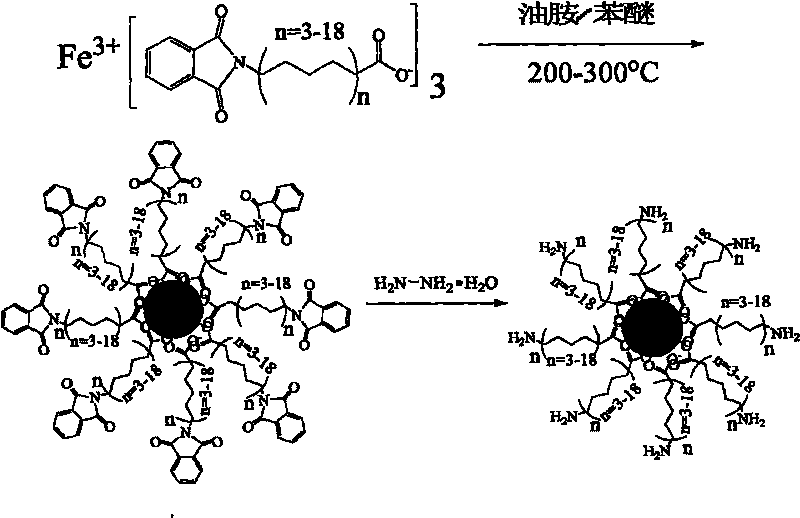

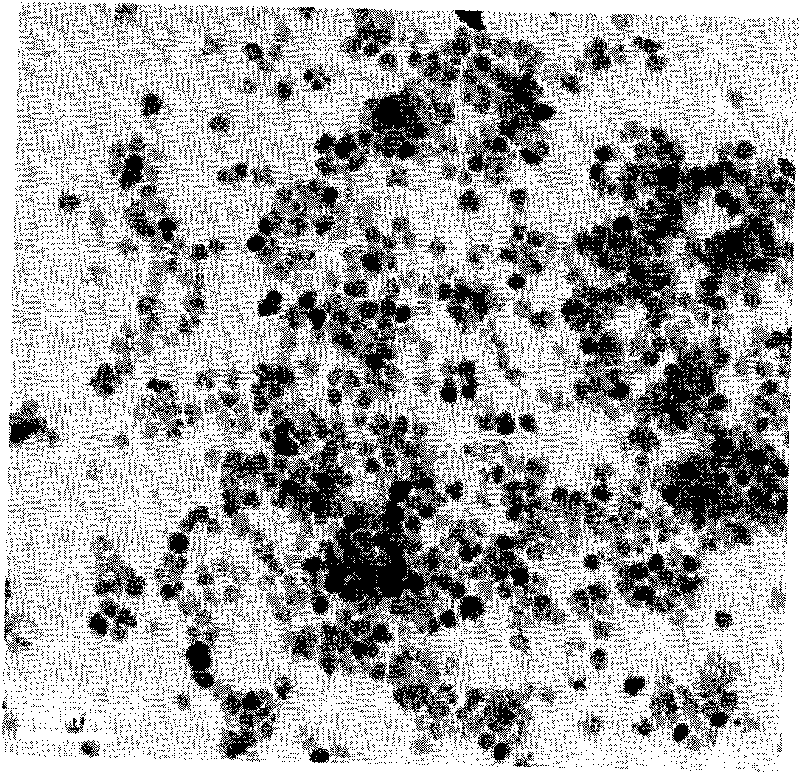

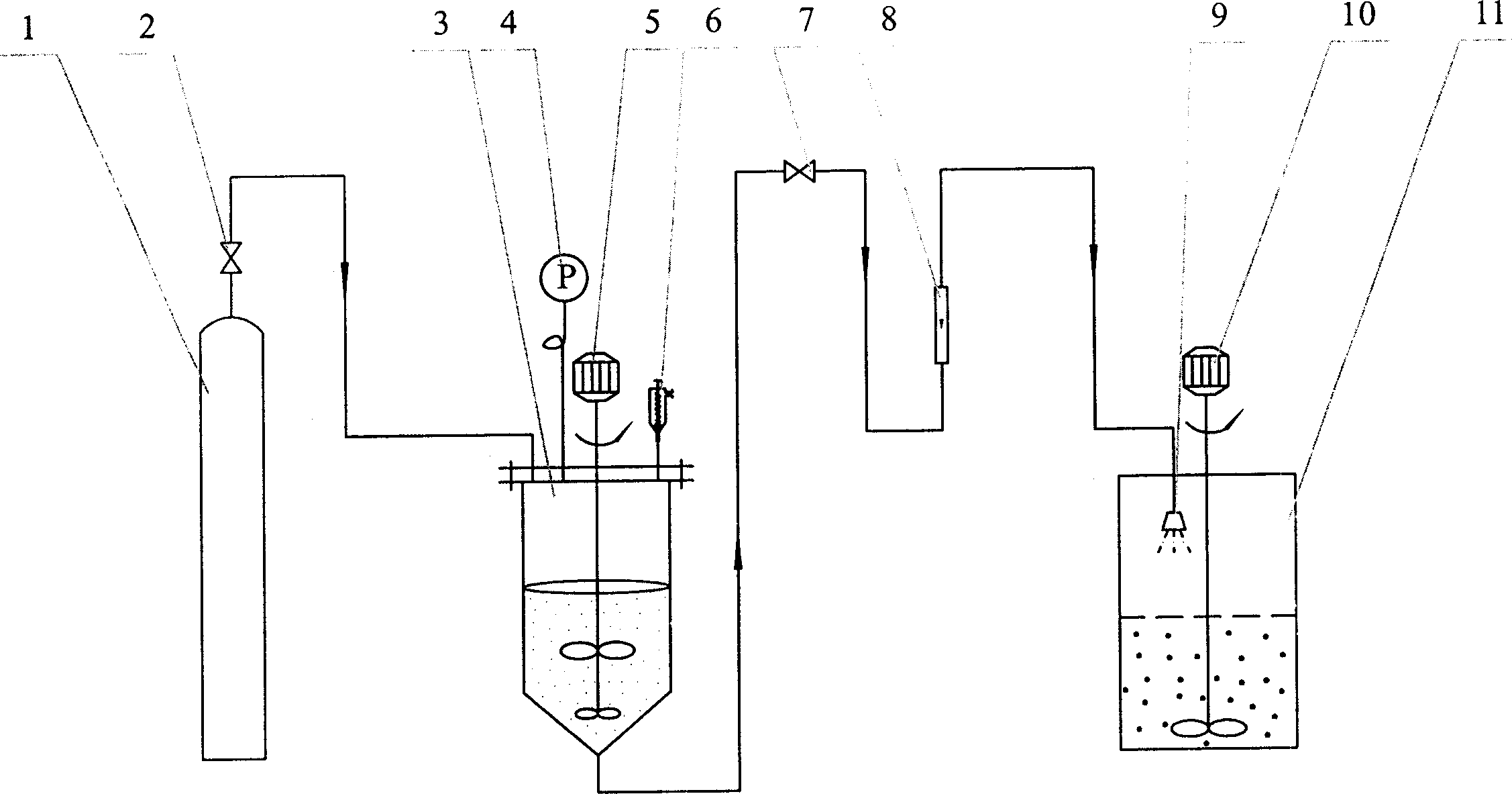

Preparation method of water-soluble ferroferric oxide magnetic nanoparticle with functional amidogen

InactiveCN101697303AImprove magnetic propertiesThe synthesis method is simpleInorganic material magnetismFerroso-ferric oxidesHydrazine compoundMagnetite Nanoparticles

The invention relates to the field of nano materials and discloses a preparation method of a water-soluble ferroferric oxide magnetic nanoparticle with functional amidogen, comprising the following steps of: coordinating carboxyl on n-(1,3-dioxoisoindolin-2-yl) alkyl acid (n is equal to 3-18) with ferrum; pyrolyzing a precursor of n-(1,3-dioxoisoindolin-2-yl) alkyl acid iron at high temperature to obtain an oil-soluble magnetic nanoparticle with lipophilicity and a surface ligand, i.e. the n-(1,3-dioxoisoindolin-2-yl) alkyl acid; then removing phthalic anhydride for protecting amino by a deammoniation protective reagent (hydrazine hydrate) by using a deammoniation protection method, and converting the oil-soluble magnetic nanoparticle into the water-soluble ferroferric oxide magnetic nanoparticle with functional amidogen. The water-soluble ferroferric oxide magnetic nanoparticle with functional amidogen can be excellently dissolved in a water solution and has favorable biocompatibility and paramagnetism.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for plating magnesium alloy based on ionic liquid plating solution

The invention discloses a method for plating a magnesium alloy based on an ionic liquid plating solution, relates to the technical field of magnesium alloy surface treatment, and in particular relates to the plating of the pre-plated magnesium alloy in a plating solution in which deep eutectic solvent serves as a solvent. A plated layer obtained through the method is uniform and compact and can be firmly combined with a matrix, and the whole process has the characteristics of simple process, environmental friendliness and the like.

Owner:合肥金盟工贸有限公司

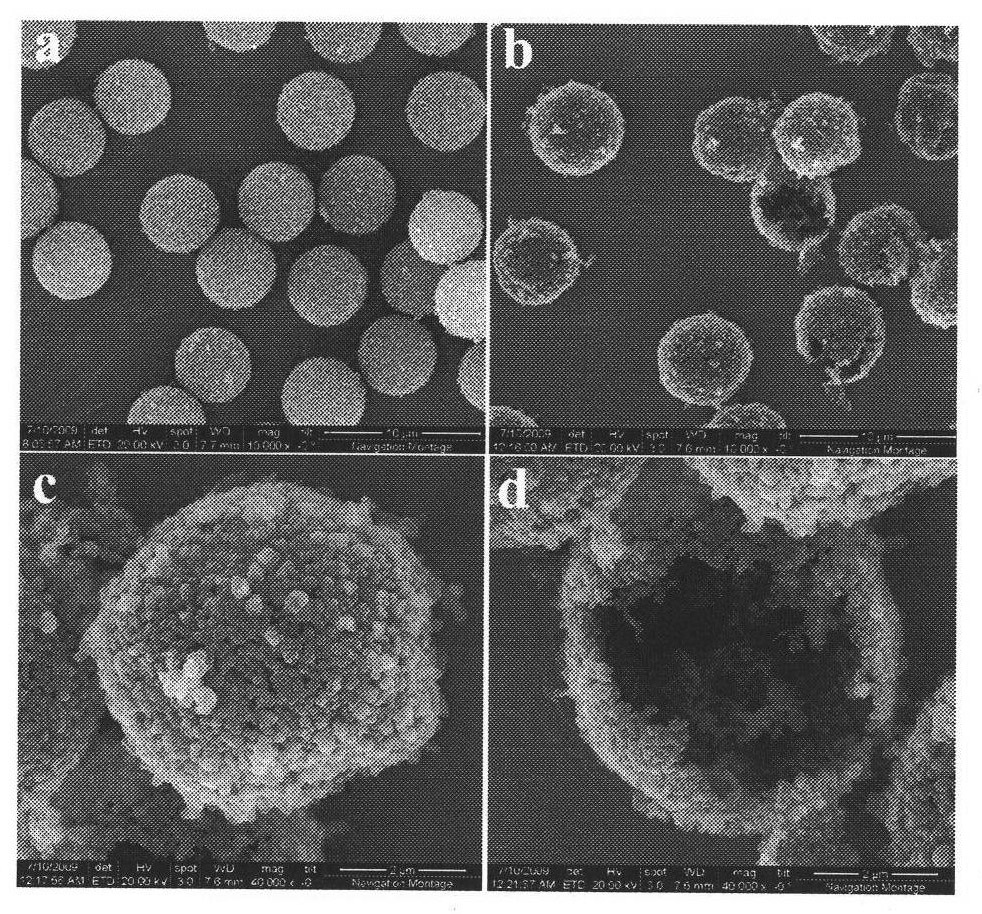

Method for preparing super paramagnetic high polymer homogeneous microball

The present invention provides the making process of homogeneous superparamagnetic polymer microballoon. Nanometer Fe3O4 grain prepared in coprecipitation process has its surface coated with oleophilic layer to form hydrophobic Fe3O4 magnetic fluid, and the magnetic fluid is dissolved in hydrophobic olefin monomer and oil soluble initiator via stirring to form homogeneous dispersive oil phase fluid. The oil phase fluid is crushed and dispersed into homogeneous oil drops in a spouting suspension polymerization process so as to form homogeneous O / W suspension in water phase. Under certain polymerizing temperature, oil drop is cured fast and constant temperature polymerized into homogeneous size superparamagnetic polymer microballoon. The superparamagnetic polymer microballoon has size of about 10 micron, specific saturation magnetic intensity of 15-20 emu / g, homogeneous magnetic content, stable chemical property and latent application in biological separation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

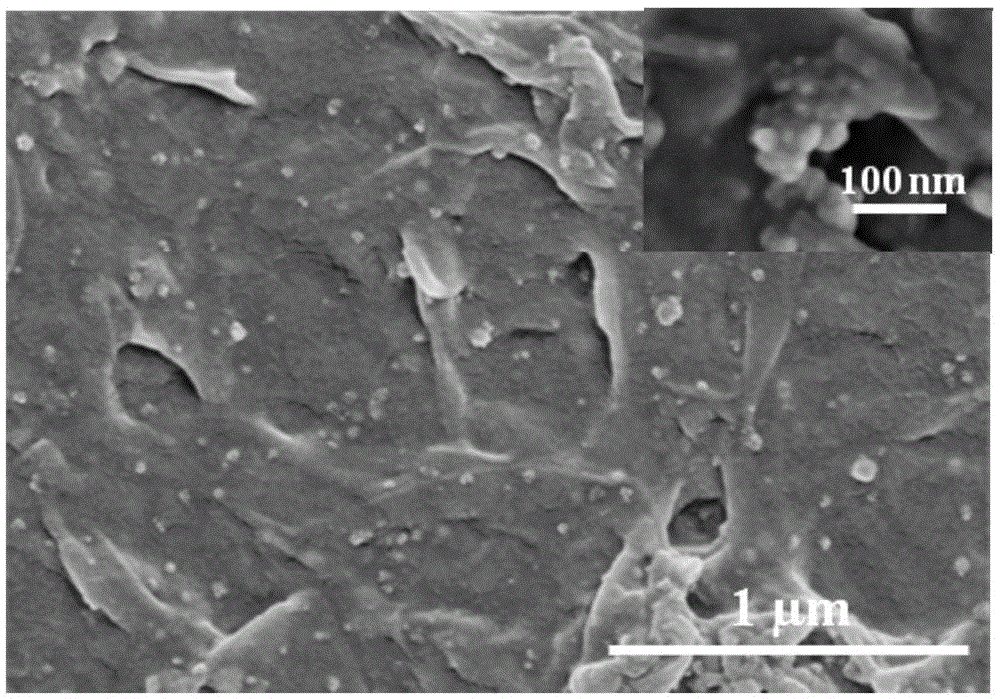

Preparation method of graphene/manganese dioxide composite material

ActiveCN103588198ASolve reunionHigh specific surface areaGrapheneManganese oxides/hydroxidesElectrophoresesOrganic solvent

The invention discloses a preparation method of a graphene / manganese dioxide composite material. The preparation method comprises the following steps: graphite is ultrasonically stripped directly in an organic solvent to obtain a graphene dispersion liquid; a manganese ion salt is added in the obtained graphene dispersion liquid; graphene adsorbs added manganese ions to carry with positive charges; and an electrophoretic deposition method is adopted to prepare the graphene / manganese dioxide composite material. The graphene of the method is prepared by adopting the liquid-phase ultrasonic stripping method, and the oxidizing treatment is not implemented, so that the defects are fewer, and the complete structure of the graphene is retained; the electrophoretic deposition method can be adopted to evenly and controllably deposit the graphene / manganese dioxide composite material on the surface of any three-dimensional conducting matrix. The method has the advantages such as easiness in operation, low production cost, high product uniformity and easiness in control.

Owner:SHANGHAI INST OF TECH

Method for preparing white carbon black by taking rice hull ash as raw material

InactiveCN102079525ADefect-Hard Agglomeration PhenomenonReduce manufacturing costSilicaSilicon dioxideMuffle furnace

The invention relates to a method for preparing white carbon black by taking rick hull ash as a raw material, comprising the following steps of: (a) dissolving and boiling the rice hull ash processed by a sieve with 40 meshes and an NaOH (sodium hydroxide) solution of 1.5-3.5mol / L at a temperature of 90-110 DEG C for 1 hour to 6 hours, wherein the ratio of the rice hull ash to the NaOH solution is 1g:(8-10) mL, cooling and filtering; (b) mixing a filter liquid, 95% ethanol and a surfactant in terms of the ratio of the filter liquid to the 95% ethanol to the surfactant being 1:(8-10):(0.1-0.3), regulating the temperature of a mixture to be 35-45 DEG C, and adding an ammonium chloride solution into the mixture in terms of the mass ratio of the mixture to the ammonium chloride solution with the mass concentration of 20-30% being 1:(0.1-0.3) under a state of stirring; (c) washing a turbid material, suction-filtering, ageing by using a proper amount of the ethanol with the mass fraction of 95% for 2 hours to 5 hours, standing, filtering, and washing and filtering by using the 95% ethanol to obtain a filter cake; and (d) stoving the filter cake, placing in a muffle furnace for roasting at a temperature of 450-600 DEG C for 1 hour to 6 hours to obtain white granular silicon dioxide, and grinding the white granular silicon dioxide to obtain the globular white carbon black. The method has the advantages of low production cost and simple operation, and is easy to control the condition and expand the production.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

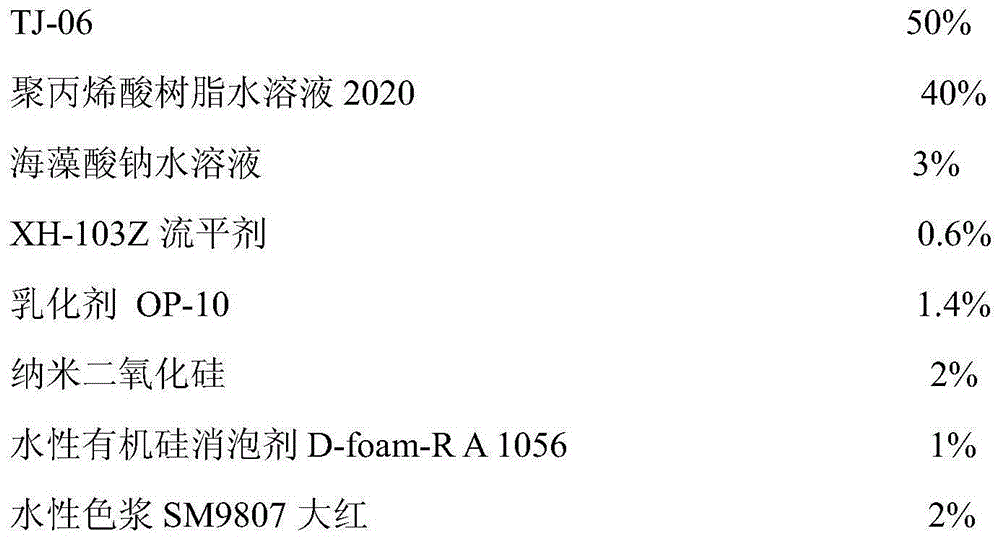

Washable touch screen temporary protection ink as well as preparation method and application thereof

InactiveCN105038401AImprove the disadvantages of insolubleImprove smoothnessInksOther printing apparatusWater basedEmulsion

The invention discloses washable touch screen temporary protection ink as well as a preparation method and application thereof. The washable touch screen temporary protection ink consists of the following raw materials by weight percent: 0 to 50 percent of polyacrylic acid resin solution, 5 to 90 percent of water-based paint resin, 5 to 50 percent of water-soluble macromolecule solution, 0 to 70 percent of polyacrylate emulsion, 1 to 10 percent of packing, 0.1 to 2 percent of pigment and 2 to 5 percent of functional additive, wherein the polyacrylic acid resin solution and the polyacrylate emulsion are not simultaneously equal to 0. When in preparation, a polyacrylic acid solution, the polyacrylate emulsion, a water-based leveling agent and packing are placed into a dispersion machine and uniformly mixed, and then the other components are placed into the dispersion machine to be uniformly mixed to obtain the washable touch screen temporary protection ink. The ink can protect touch screen cover plate glass or an ITO glass surface layer film against damage during a construction process at a high temperature of 200 DEG C; moreover, after the ink is used at 200 DEG C, the ink can fall off in block shapes in 30s to 2min after being soaked in water with the temperature of 50 DEG C.

Owner:SOUTH CHINA UNIV OF TECH

Molecular sieve film and preparation method thereof

InactiveCN101962196AGood repeatabilitySimple and fast operationPretreated surfacesMolecular-sieve and base-exchange phosphatesIn situ crystallizationMolecular sieve

The invention relates to a molecular sieve film and a preparation method thereof, in particular to an aligned nano laminar AFI or CHA type molecular sieve film and an in-situ preparation method thereof based on layer-by-layer film coating and vapor-phase transfer. The molecular sieve film is composed of nano laminar AFI or CHA type molecular sieve crystals in aligned arrangement. The method comprises the following steps: successively coating two film-coating liquids on a glass sheet support, and then carrying out in-situ crystallization by vapor-phase transfer. The layer-by-layer film-coating preparation method does not need the introduction of crystal seeds or the aging of a synthesis liquid, has the advantages of convenient operation and high film-forming repeatability and can realize the industrial expanded production easily. By simultaneously combining vapor-phase transfer to carry out crystallization, the invention greatly reduces the preparation cost of the molecular sieve film and is beneficial to the cyclic utilization of the template agent.

Owner:NANJING UNIV OF TECH

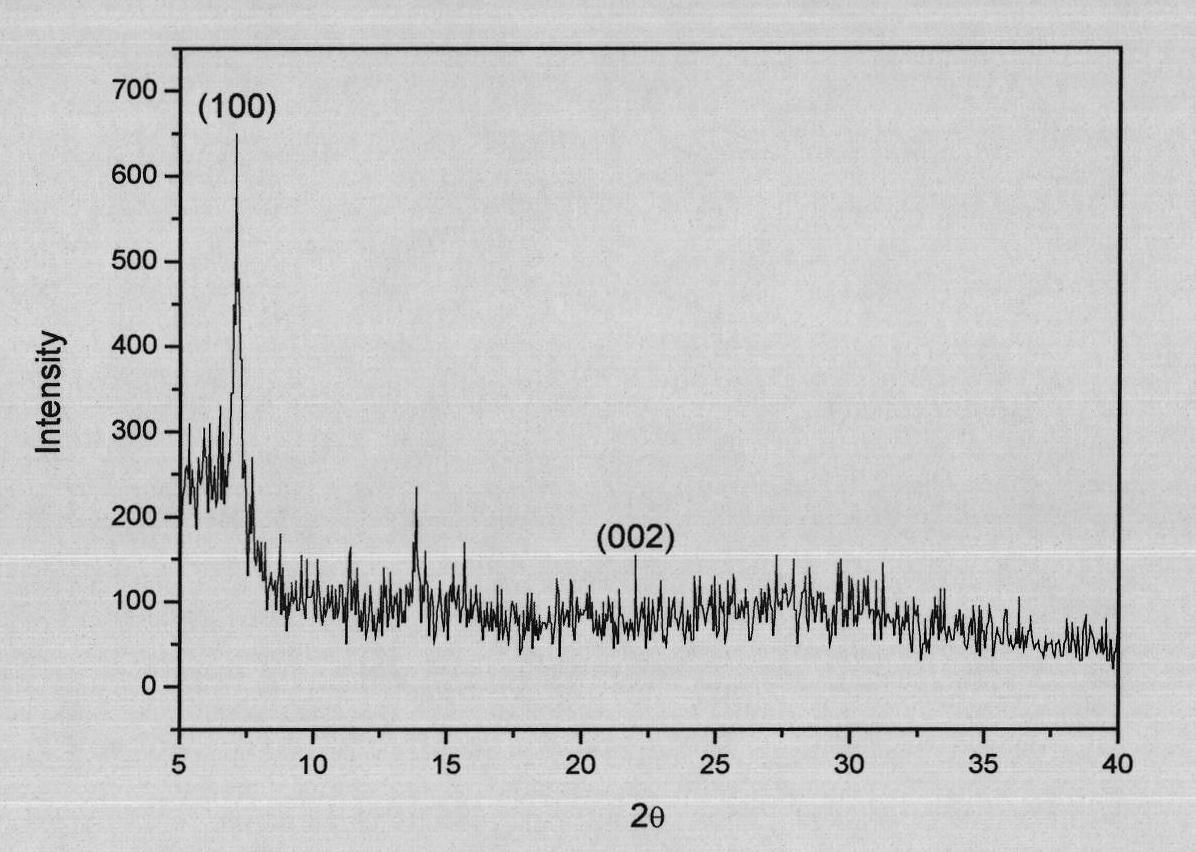

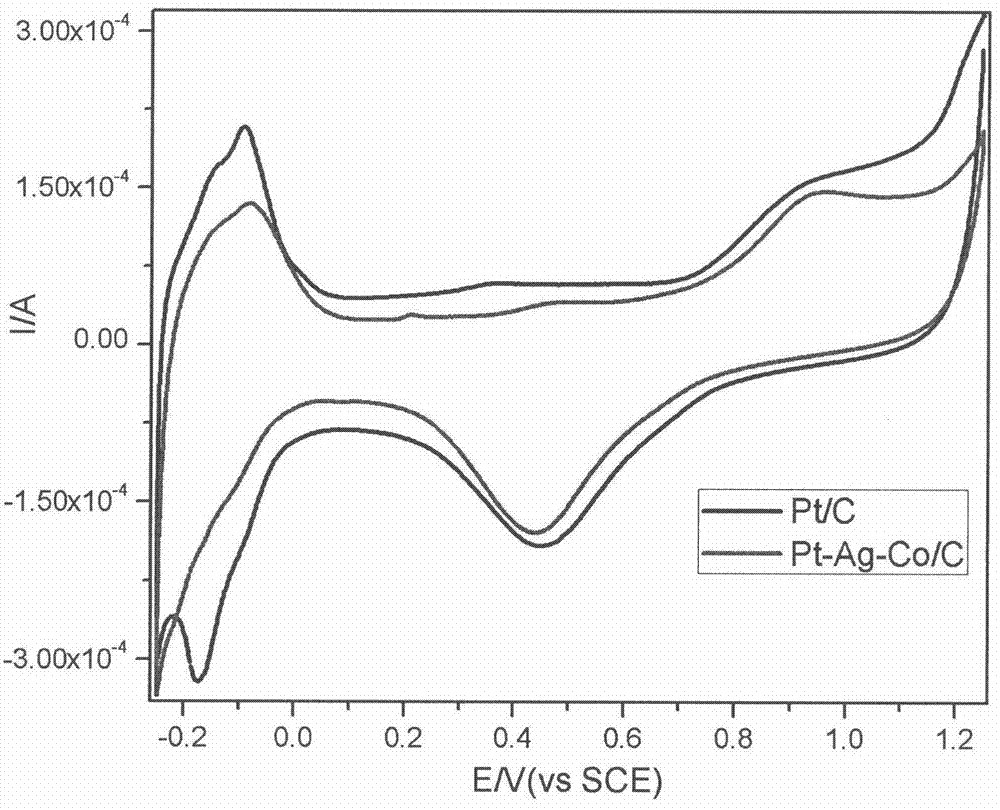

Preparation method of Pt-Ag-Co/C catalyst

InactiveCN104707625ASimple preparation processLow costCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystIn situ chemical reduction

The invention relates to a preparation method of a proton exchange membrane fuel cell carbon-supported metal electrocatalyst. The active component of the electrocatalyst is Pt-Ag-Co, an atom ratio of Pt:Ag:Co is 20:1:0.01-1:20:0.01, and the mass percentage content of the active component is 10-50%. The preparation method comprises the following steps: 1, dissolving processed carbon powder in an alcohol solvent, carrying out ultrasonic treatment to obtain a uniform slurry, adding an Ag and Co precursor solution to the slurry, and mixing; 2, reducing a mixed solution obtained in step 1 by sodium borohydride for 10-24h, washing, and drying to obtain Ag-Co / C; 3, dissolving the Ag-Co / C by alcohol, and carrying out ultrasonic treatment to obtain a slurry; and 4, processing a Pt precursor through an in situ chemical reduction homogeneous precipitation process to prepare complexing ions, processing to prepare a colloid, and carrying out reduction deposition on the colloid in the slurry obtained in step 3 by using a reducing agent formaldehyde in order to prepare the Pt-Ag-Co / C catalyst. The method has the advantages of simple process, low cost and easy enlarged production, and the catalyst has good catalysis activity, and has better durability than commercial Pt / C electrocatalysts and binary Pt-Ag / C electrocatalysts.

Owner:NANJING UNIV OF TECH

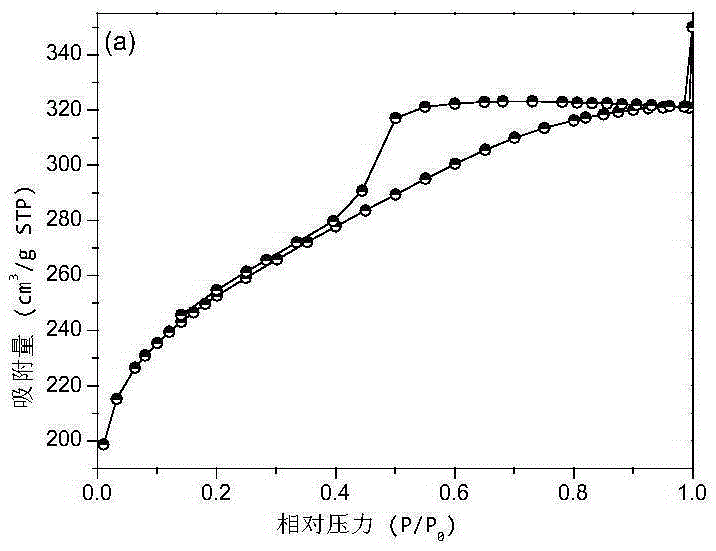

Preparation method of millimeter-scale hierarchical pore carbon balls

The invention discloses a preparation method of millimeter-scale hierarchical pore carbon balls. Macromolecule-based spherical activated carbon is prepared with a nonsolvent induced phase separation method in a membrane separation field, and balling obtained through suspension polymerization of phenolic resin is replaced; millimeter-scale spherical macromolecule-based precursors with very narrow particle size distribution are obtained through an injection pump extrusion process; a few of added pore forming agents form a rich pore structure; a little of added phenolic resin has a structure support action, and excellent sphericity degree and strength are kept; the prepared porous carbon balls have rich pore structures and high mesoporous content. The millimeter-scale hierarchical pore carbon balls are simple to prepare, and the preparation method has the advantages of simplicity and controllability in operation, low cost, easiness in industrial production expansion and the like; the prepared millimeter-scale hierarchical pore carbon balls have wide application prospect in the fields of catalysis, separation, restoring of polluted environment and the like.

Owner:NANJING UNIV OF SCI & TECH

Bio-based flame-retardant curing agent for epoxy resin as well as preparation method and application thereof

The invention relates to a bio-based flame-retardant curing agent for epoxy resin as well as a preparation method and application thereof. The flame-retardant curing agent is prepared by reacting phytic acid and poly-amino compounds in one step, and has the effects of a flame retardant and a curing agent. When the bio-based flame-retardant curing agent is used for the epoxy resin, excellent thermal properties and insulating property of the epoxy resin are maintained, and the curing agent has excellent flame-retardant property. The bio-based flame-retardant curing agent is wide in application,and is particularly applied to the field of electronics and electrical appliances.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Antrodia cultivating method capable of improving content of triterpene

InactiveCN105766382APromote growthShorten the maturation periodCultivating equipmentsMushroom cultivationCulture mediumsAntrodia

The invention discloses an antrodia cultivating method.The method comprises the steps of strain culture medium manufacturing, strain isolation and expanding propagation, carrier cultivating, inoculation, mycelial growth and sporocarp growth.The antrodia cultivating method has the advantages that due to the cultivating method is simple and capable of achieving industrialization and standardized production, so that expanded production is promoted, the production cost is lowered, and the cultivating time is short.Low-density wood is adopted as a bacteria bed, mycelial growth is promoted, hyphae can easily form sporocarp, and meanwhile strains can better adapt to bacteria bed growth by improving the strains, so that the fruiting rate can be improved by about 80%, and economic benefits can be improved.The obtained antrodia sporocarp and wild antrodia sporocarp DNA detection equal rate can reach 99%, and the effect is good.The cultivating method can enable the content of triterpene of the antrodia sporocarp can reach 8.6%, the content of polysaccharide can reach 4.8%, and the content of effective elements can be improved.

Owner:FUJIAN HUASHEN ANTRODIA CAMPHORATA BIOTECH CO LTD

Au-Pd alloy electroplating solution as well as preparation method and electroplating process thereof

The embodiment of the invention discloses an Au-Pd alloy electroplating solution which comprises an Au salt, a Pd salt, a chelating agent and conducting salts. The Au-Pd alloy electroplating solution comprises the following components: 0.1-20g / l of Au salt based on the content of a single substance Au, 0.1-15 g / L of Pd salt based on the content of a single substance Pd, 30-300 g / L of chelating agent and10-30 g / L of conducting salt, wherein based on the content of metal substance, the mass ratio of gold salt to palladium salt is (0.5-20):1. In addition, the invention also discloses the preparation method and the electroplating process of the Au-Pd alloy electroplating solution. By using the Au-Pd alloy electroplating solution and electroplating process thereof, the process is simple, and an obtained Au-Pd alloy electroplating layer has the advantages of high electrical conductivity, strong wear resistance and corrosion resistance, metal white or light golden yellow appearance, and the like.

Owner:RAMBO NANOTECH SHENZHEN

Method for using biomass porous carbon as potassium ion battery cathode

ActiveCN109742384AThe synthesis method is simpleHigh operational controllabilityCell electrodesSecondary cellsSynthesis methodsPorous carbon

The invention discloses a method for using biomass porous carbon as a potassium ion battery cathode. Firstly, a biomass precursor is evenly mixed with specific salt, a pollution-free molten salt carbonization method is adopted to prepare a three-dimensional classification porous carbon material, a carbonization temperature and a ratio of the specific salt to a biomass raw material in a reaction process are regulated and controlled to obtain the porous carbon material, and the porous carbon material is used as the potassium ion battery cathode. The porous carbon cathode material is prepared bya molten salt carbonization method which comprises the following steps that: 1) cleaning and smashing the biomass raw material into precursor powder; 2) carrying out ball milling and mixing on the precursor and the specific salt particles; and 3) after a product in 2) is coated with salt powder, rising the temperature to 500-1200DEG C at a rate of 1-10DEG C / min under air, keeping the temperature for 3-6h, and washing, separating and purifying the generated product to obtain a target product. The synthesis method is simple and is free from pollution, operation steps can be easily controlled, scale production is realized, and realizability is high. The obtained porous carbon material is used as the potassium ion battery cathode and has excellent electrochemical performance and good cycling stability.

Owner:CHINA UNIV OF MINING & TECH

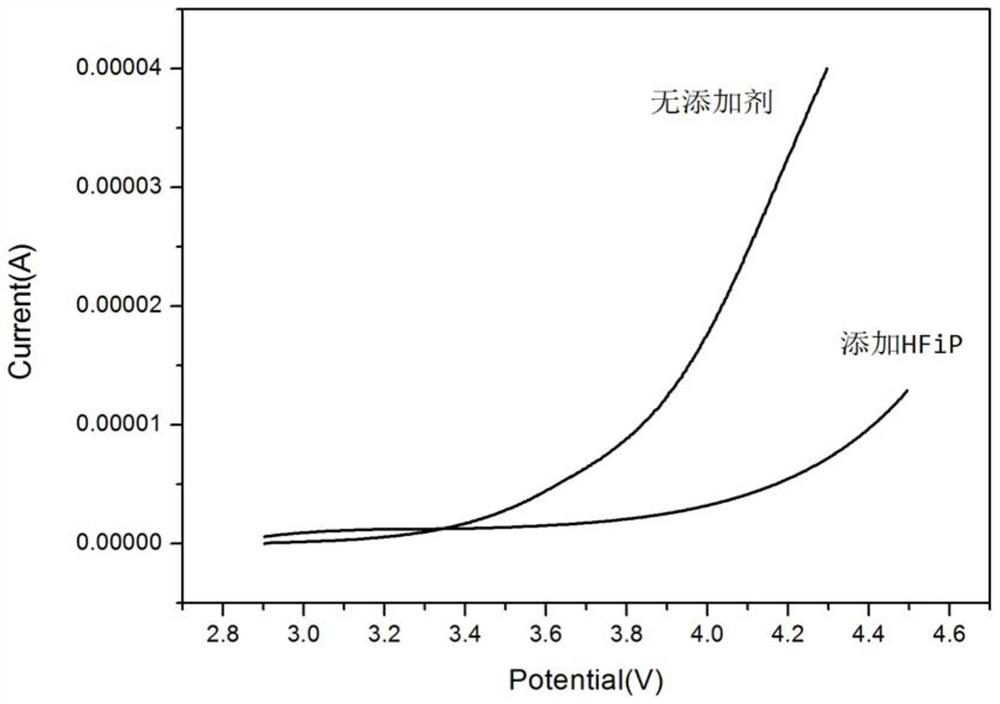

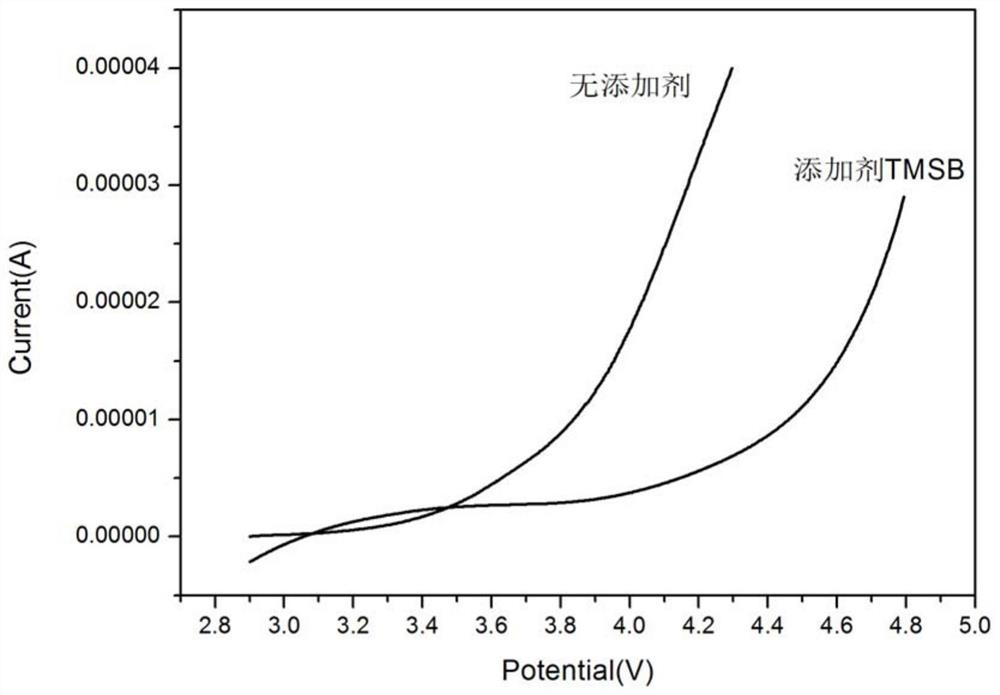

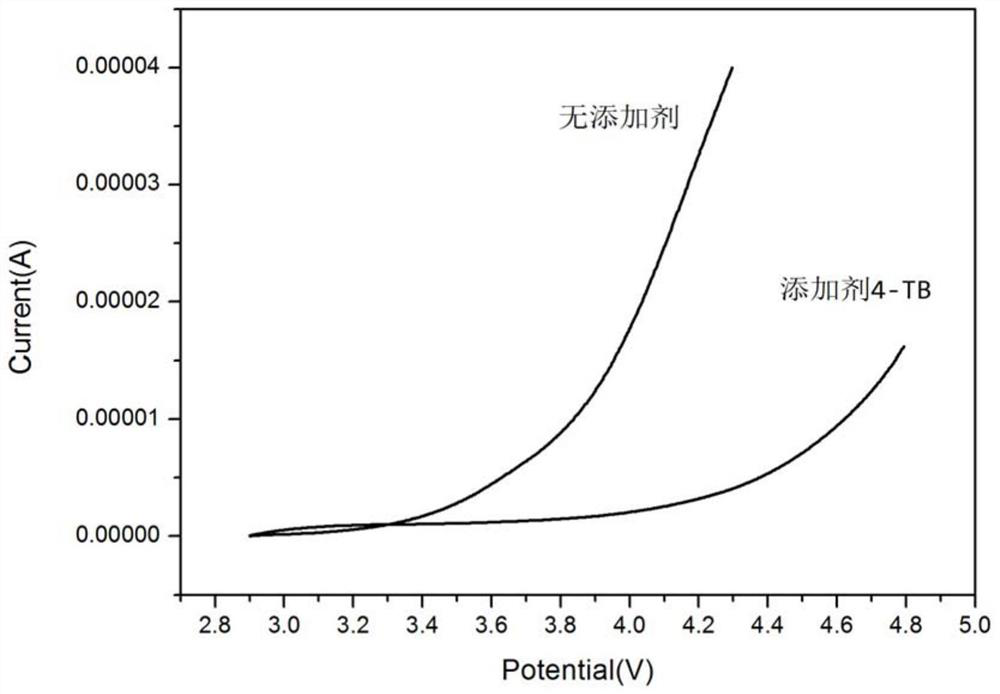

High-voltage polymer electrolyte and preparation method of solid-state battery thereof

PendingCN111816915ADesign has not changedSimple methodFinal product manufactureSecondary cells servicing/maintenancePolymer electrolytesInterfacial impedance

The invention relates to a high-voltage polymer electrolyte and a preparation method of a solid-state battery thereof, and the preparation method of the high-voltage polymer electrolyte comprises thefollowing steps: (1) dissolving a polymer in a solvent at normal temperature or by heating at the temperature of 25-120 DEG C; (2) dissolving a certain proportion of lithium salt into the mixture, wherein the mass of the lithium salt accounts for 100%-200% of the mass of the polymer; (3) adding a high-voltage additive into the mixture, uniformly stirring, then pouring the mixture into a membrane or coating the membrane with the mixture, and carrying out blast heating and drying to obtain a high-voltage-resistant composite high-voltage polymer electrolyte membrane, wherein the mass of the high-voltage additive accounts for 1%-10% of the mass of the polymer. The high-voltage polymer electrolyte is prepared by adding the high-voltage-resistant additive, has relatively low interface impedanceand relatively high ionic conductivity, and is beneficial to improving the energy density, the power density and the safety of the solid-state battery.

Owner:TIANJIN SPACE POWER TECH CO LTD

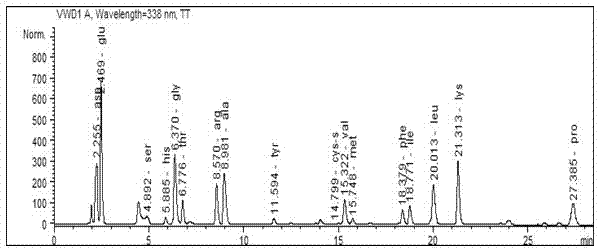

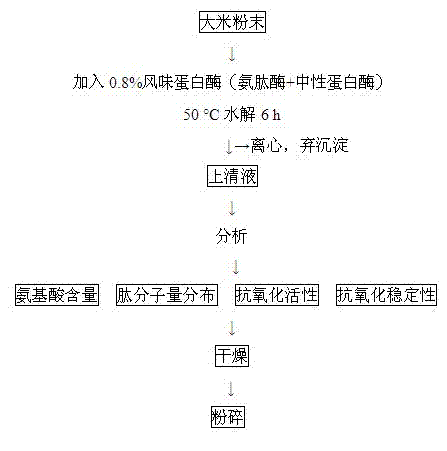

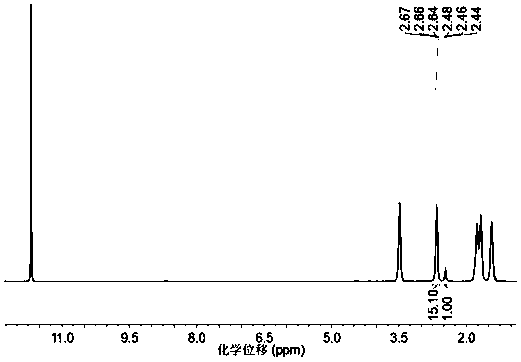

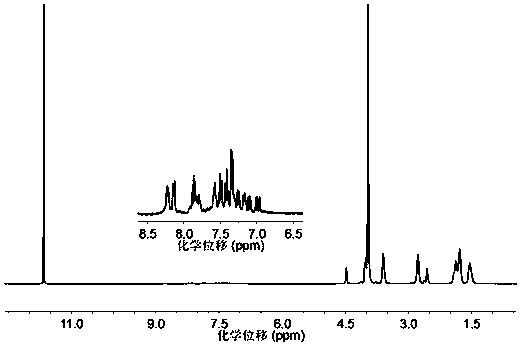

Application of bacillus subtilis amino-peptidase in preparing flavor functional nutrient rice

The invention discloses an application of bacillus subtilis amino-peptidase in preparing flavor functional nutrient rice, belonging to the technical field of enzyme preparations and food additives. A bacillus subtilis Zj016 amino-peptidase broth is subject to centrifugation, clarification, condensation, desalination and freeze drying to obtain a solid enzyme. By adding neutral protease and amino-peptidase according to a certain proportion to carry out enzymolysis on rice, the free amino acid content of the enzymatic nutrient rice is remarkably increased. By analyzing the DPPH elimination capability, superoxide radical elimination capability, hydroxy free radical elimination capability and reducing power and the like of a hydrolyzate obtained after the enzymolysis of the nutrient rice, after the protein in the rice is enzymolysized into high-proportion micro-molecular peptide, the antioxidant activity of the nutrient rice is greatly increased, and the stability of the antioxidant activity is high. According to the invention, the enzymolysis processing of the nutrient rice is combined with the flavor functional processing organically, thus the effect of strengthening the flavor and function factors of the nutrient rice is achieved. The invention has a wide application prospect in developing the flavor functional nutrient rice.

Owner:JIANGNAN UNIV

Guangdong Jun Blue glaze prepared from commonly used raw materials in ceramics factory and preparation method of Guangdong Jun Blue glaze

The invention belongs to the preparation field of traditional Guangdong Jun glaze in Foshan Shiwan art ceramics, and discloses a Guangdong Jun Blue glaze prepared from commonly used raw materials in a ceramics factory and a preparation method of the Guangdong Jun Blue glaze. The method comprises the following steps: using common glaze raw materials widely applied in the existing ceramics factory such as feldspar, quartz, limestone, calcined talc, black clay, cattle and sheep ashes and chemical toners CuO, CoO, Fe2O3 and the like to replace the lead-containing traditional raw materials such as ramulus mori ashes, miscellaneous wood ashes, straw ashes, canal mud, jade powder, carnelian cobble, copper ore, yellow stone, star cinnabar, graphite and Lion mountain ashes which are complex or expensive in treatment, or nearly exhausted, or large in toxicity to the environment. The Guangdong Jun glaze disclosed by the invention is wide in raw material resource, low in cost, simple in preparation process, and unnecessary to renovate the equipment, the obtained Guangdong Jun glaze formula is simple in composition, smooth in glaze, high in stability, and has the color characteristics of the Guangdong Jun glaze.

Owner:FOSHAN UNIVERSITY

Phosphorus-containing intrinsic flame-retardant thermoplastic nylon elastomer and preparation method thereof

ActiveCN110183649AGood flame retardant efficiency and durabilityNo migration issuesElastomerPolymer science

The invention discloses a phosphorus-containing intrinsic flame-retardant thermoplastic nylon elastomer and a preparation method thereof. The phosphorus-containing intrinsic flame-retardant thermoplastic nylon elastomer is a nylon elastomer represented by the following structural general formula [I] obtained by the melt copolymerization reaction of a carboxyl-terminated nylon pre-polymer, a hydroxyl-terminated polyether polyol and a phosphorus-containing diol monomer, or is a nylon elastomer represented by the following structural general formula [II] obtained by the melt copolymerization reaction of a carboxyl-terminated phosphorus-containing nylon pre-polymer and a hydroxyl-terminated polyether polyol. The nylon elastomer is a multi-block copolymer, a phosphorus-containing reactive flameretardant is copolymerized and embedded in the molecular chain of the thermoplastic nylon elastomer, the effective flame retardancy at a low content can be realized, the durability is good, no migration problem exists, the ratio of a soft segment, a hard segment and the flame retardant can be adjusted, and demands of different mechanical properties of different application fields are satisfied under the premise of high efficiency flame retardant. The preparation method is simple, the raw materials are easily available, and the expanding production is favorable.

Owner:SICHUAN UNIV

Lignin/microcrystalline cellulose complex, reinforced polylactic acid 3D printing material and preparation method thereof

ActiveCN109054323AGood compatibilityGood thermoplasticityAdditive manufacturing apparatusPlasticizerMicrocrystalline cellulose

In order to overcome the defects and shortcomings of poor compatibility between cellulose and a polymer matrix, frequent hole blocking in printing, difficulty in printing of lignin / polymer 3D printingmaterial and the like, common cellulose is subjected to acidolysis by using an inorganic acid solution; then the cellulose is modified by a silane coupling agent and lignin in an alcohol solution, toobtain the lignin / microcrystalline cellulose compound. The compound serving as a reinforcing material and PLA serving as a base material are blended with an inorganic nano material, a toughening agent, a plasticizer and the like, and the reinforced polylactic acid 3D printing material with good mechanical property and 3D printing property is prepared by melt extrusion blending and wiredrawing moulding. The mechanical property of the 3D printing material provided by the invention is better than that of common polylactic acid printing materials; according to a test by an FDM type 3D printer, the 3D printing material is completely applicable to the FDM rapid prototyping technology, and the printed product has high glossiness and wood-texture appearance and can be applied to the printing of furniture, toys, artwork, model design and the like.

Owner:SOUTH CHINA AGRI UNIV +1

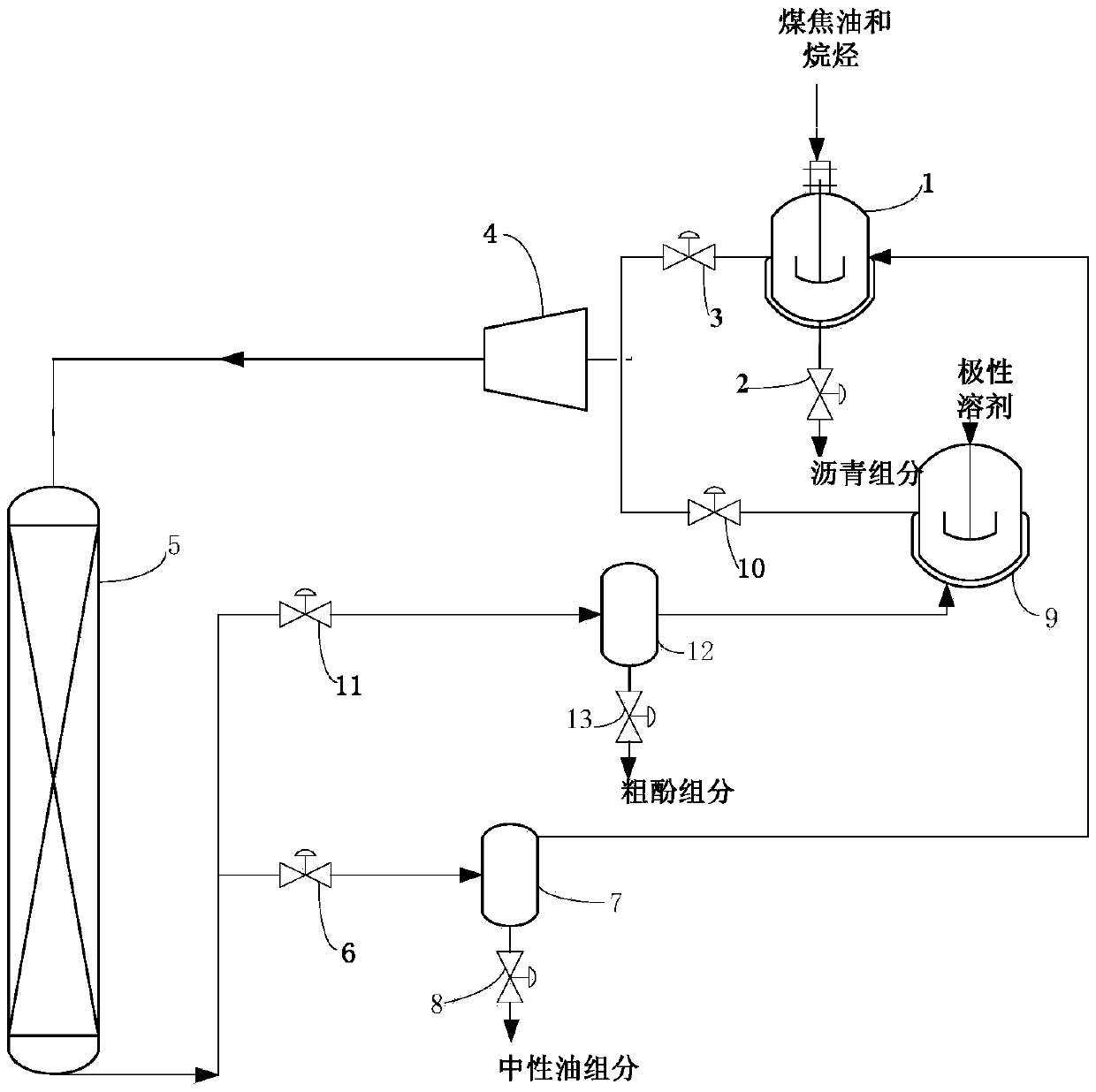

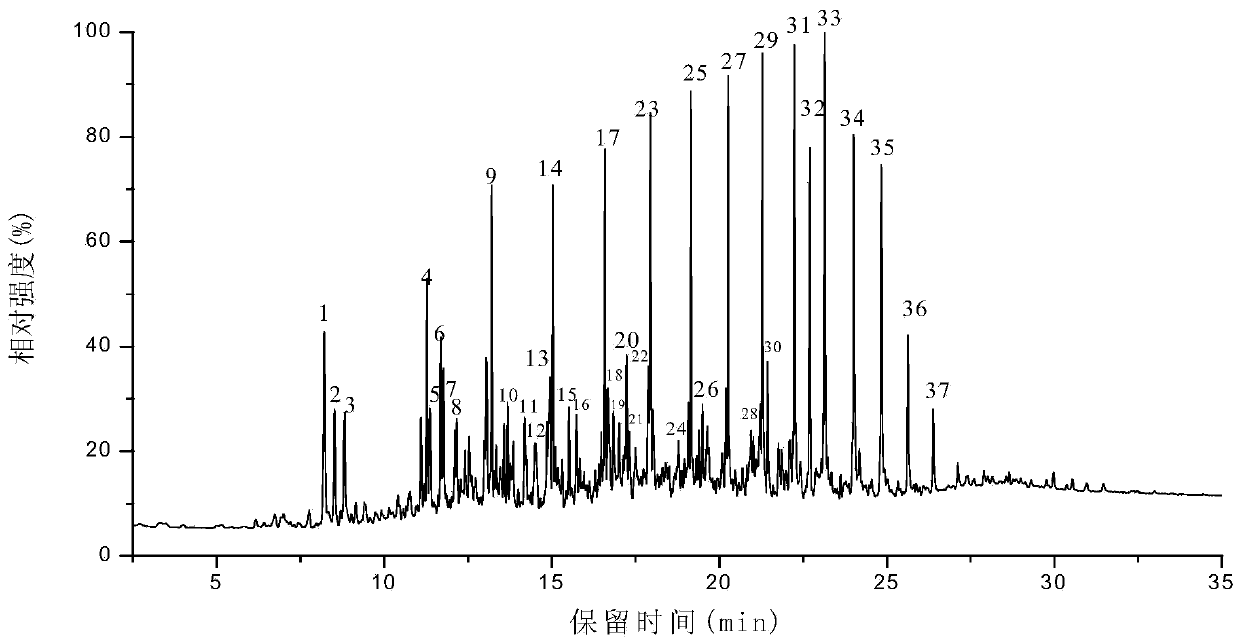

Method for solvent extraction-column chromatography separation of coal tar, and apparatus thereof

InactiveCN103289717AAchieve separationAchieve enrichmentTar working-up by solvent extractionAlkaneDecomposition

The invention discloses a method for solvent extraction-column chromatography separation of coal tar, and an apparatus thereof. The method comprises the following steps: respectively placing C5-C7 alkane as a solvent and coal tar in a solvent extraction system, heating, stirring, allowing the obtained solution to stand for completing extraction, allowing the obtained extract liquid to enter a chromatography column system filled with a silica gel filler, carrying out cycle elution on the chromatography column system with an extraction solvent as an eluant, carrying out cycle extraction and column chromatography elution several times to obtain a raffinate (soft asphalt) in the extraction system and neutral oil in a concentration kettle, changing the eluant to ethyl acetate or toluene, and carrying out cycle elution several times to obtain crude phenols in the concentration kettle. The method for separating coal tar is environmentally-friendly, and does not generate wastewater, waste residues or waste gases; and the whole apparatus is in a relatively closed pipeline, so the contact of easy-oxidation and easy-decomposition substances with air is reduced.

Owner:NORTHWEST UNIV(CN)

Compressed air inhaler for pulmonary application of liposomal powder aerosols and powder aerosols suitable therefor

InactiveCN1338956AEasy to expand productionLow toxicityMaterial nanotechnologyPowder deliveryActive agentLiposome

The invention relates to a compressed air inhaler for the pulmonary application of a liposomal powder aerosol that carries active agents or is uncharged. The aim of the invention is to provide an inhaler by means of which the pulmonary application of especially liposomes that carry active agents is possible without forced breathing manoeuvres and by means of which the active agent can be transferred to the desired place of action in a sufficient amount without the active agent escaping. To this end, said compressed air inhaler comprises a receptacle (20) for the aqueous dispersion of liposomes. The liposomes carrying the active agents are dispersed in water in said receptacle. The receptacle is connected to an anatomising nozzle (1) and to a drying unit (17) via a device that doses liquids (19), whereby the drying unit can be an atomising chamber for spray drying the liposomes. An outlet (18) and a mouth piece are joined to said drying unit. The anatomising nozzle (1) is provided with separate supply channels (14, 16) for the compressed air and the dispersion of the liposomes. The invention also relates to a novel powder aerosol consisting of liposomes or nanoparticles.

Owner:马克思-德布鲁克-分子医学中心 +1

Device and process for separating coal tar components

InactiveCN105368473ASimple structureSmall footprintTar working-up by distillationTar working-up by solvent extractionAlkaneSolenoid valve

Provided are a device and process for separating coal tar components. Coal tar and alkane of C5-C8 undergo mixed extraction in an extractor and still standing and a first solenoid valve is opened to discharge an asphalt component; alkane chromatographic column elution and separation of C5-C8 are performed: the mixture of the coal tar components where the asphalt component is removed and alkane of C5-C8 are sent into a chromatographic column to be separated; mixed liquid obtained through chromatographic column separation enters a first distillation tower to be distilled to obtain a neutral oil component and alkane of C5-C8, and the neutral oil component is discharged; polar solvent chromatographic column elution and separation are performed; a polar solvent is pressurized through a pressure pump and then enters the chromatographic column to undergo elution and separation and then enters a second distillation tower to be separated to obtain a crude phenol component and the polar solvent, and the separation of the coal tar components is finished. The process is a green separation process, and no waste water, waste residue or waste gas is generated. The operation conditions of the process are mild, simple and convenient, and the process and the device are low in cost and small in investment.

Owner:NORTHWEST UNIV(CN)

Method for preparing antibacterial composite membrane, antibacterial composite membrane prepared from method and application thereof to field of water treatment

ActiveCN106268362AAvoid gatheringAvoid churnSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSilanesReverse osmosis

The invention relates to the technical field of separating membranes and discloses a method for preparing an antibacterial composite membrane, the antibacterial composite membrane prepared from the method and application thereof to field of water treatment. The method for preparing the antibacterial composite membrane comprises a step (1) of mixing macromolecules containing multiple hydroxyl groups, a silane coupling agent containing sulfhydryl groups, acid, aldehyde and solvent, and preparing a coating liquid; a step (2) of coating a nanofiltration membrane or a reverse osmosis membrane with the coating liquid to perform thermo-crosslinking reaction, and obtaining a composite membrane with the surface provided with a crosslinking layer; a step (3) of contacting the crosslinking layer of the composite membrane with an aqueous solution of silver nitrate; and a step (4) of performing heating treatment on the composite membrane obtained through the step (3). The method for preparing the antibacterial composite membrane has the advantages that (1) the method is simple, expanded production is performed easily; (2) in-situ reduction is performed, and gathering of nano-silver is prevented; (3) nano-silver particles can be fixed to a macromolecule layer through interaction of sulfhydryl groups, and the loss of nano-silver in the membrane operation process is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

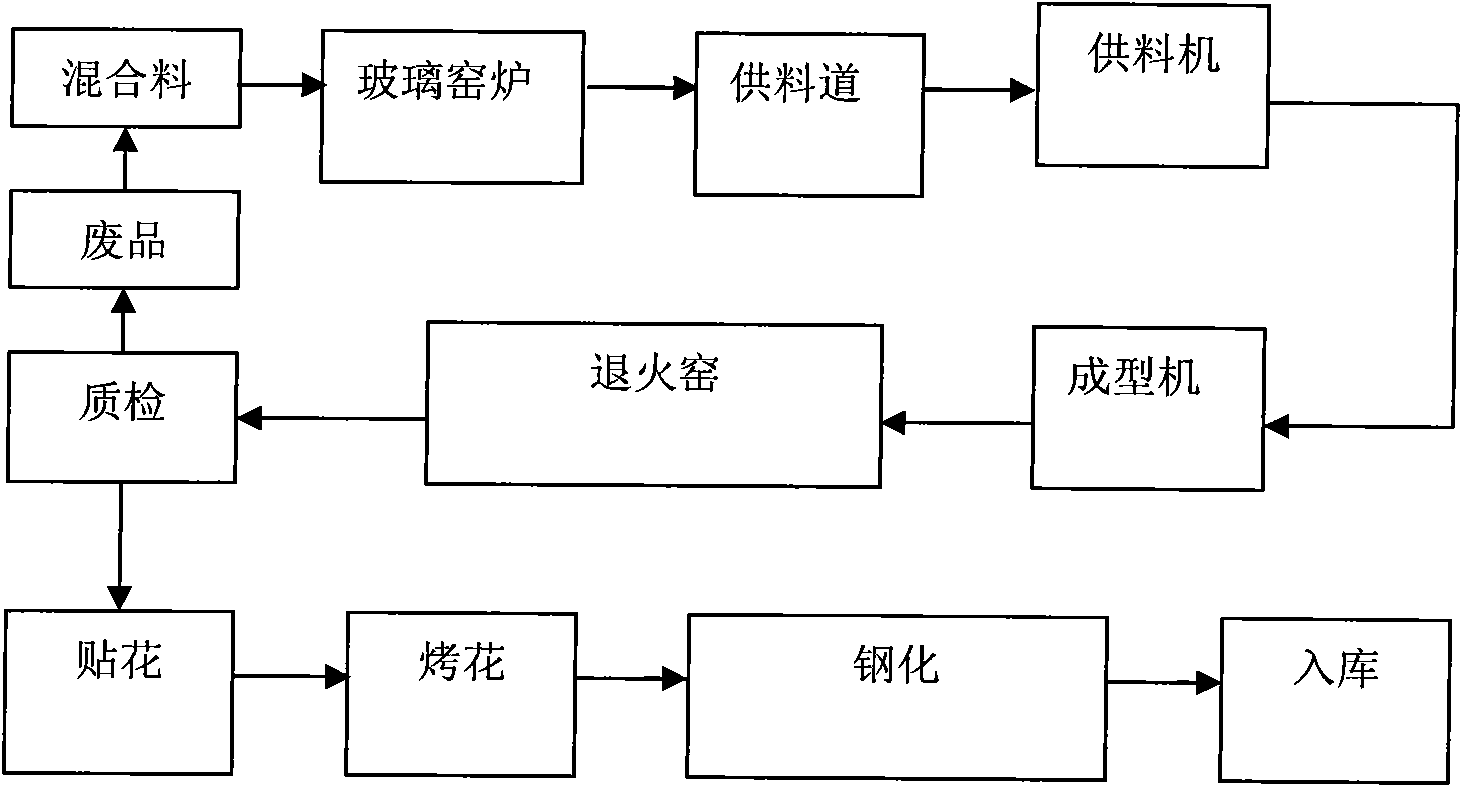

Glass ceramic and preparation method thereof

The invention relates to a glass ceramic and a preparation method thereof, comprising the following raw materials by weight parts: 75-100 weight parts of quartz sands, 10-30 weight parts of lithium feldspar, 30-60 weight parts of feldspar, 25-45 weight parts of sodium carbonate, 2-8 weight parts of sodium nitrate, 2-6 weight parts of barium carbonate, 5-15 weight parts of fluorite powders, 5-10 weight parts of borax, 10-30 weight parts of sodium fluosilicate and 10-20 weight parts of calcite; the method comprises the following steps of: mixing the raw materials and sending the mixture in a glass furnace; melting the mixture as glass melt at the temperature of 1400-1600 DEG C; sending the glass melt into a material supply machine by a material supply passage; sending the glass melt into a forming machine for forming by the material supply machine; sending the formed product into an annealing furnace for annealing; subsequently inspecting the quality of the annealed product; returning the unqualified product to the raw material; and conducting the operations of applique, enamel firing and steeling to the qualified product so as to prepare the finished products. Compared with the prior art, the method has the advantages of low expansion heat-resistance performance, high hardness, being not easy to be scraped or cracked, environmental protection and the like.

Owner:JINGDEZHEN COKING IND GRP CO LTD

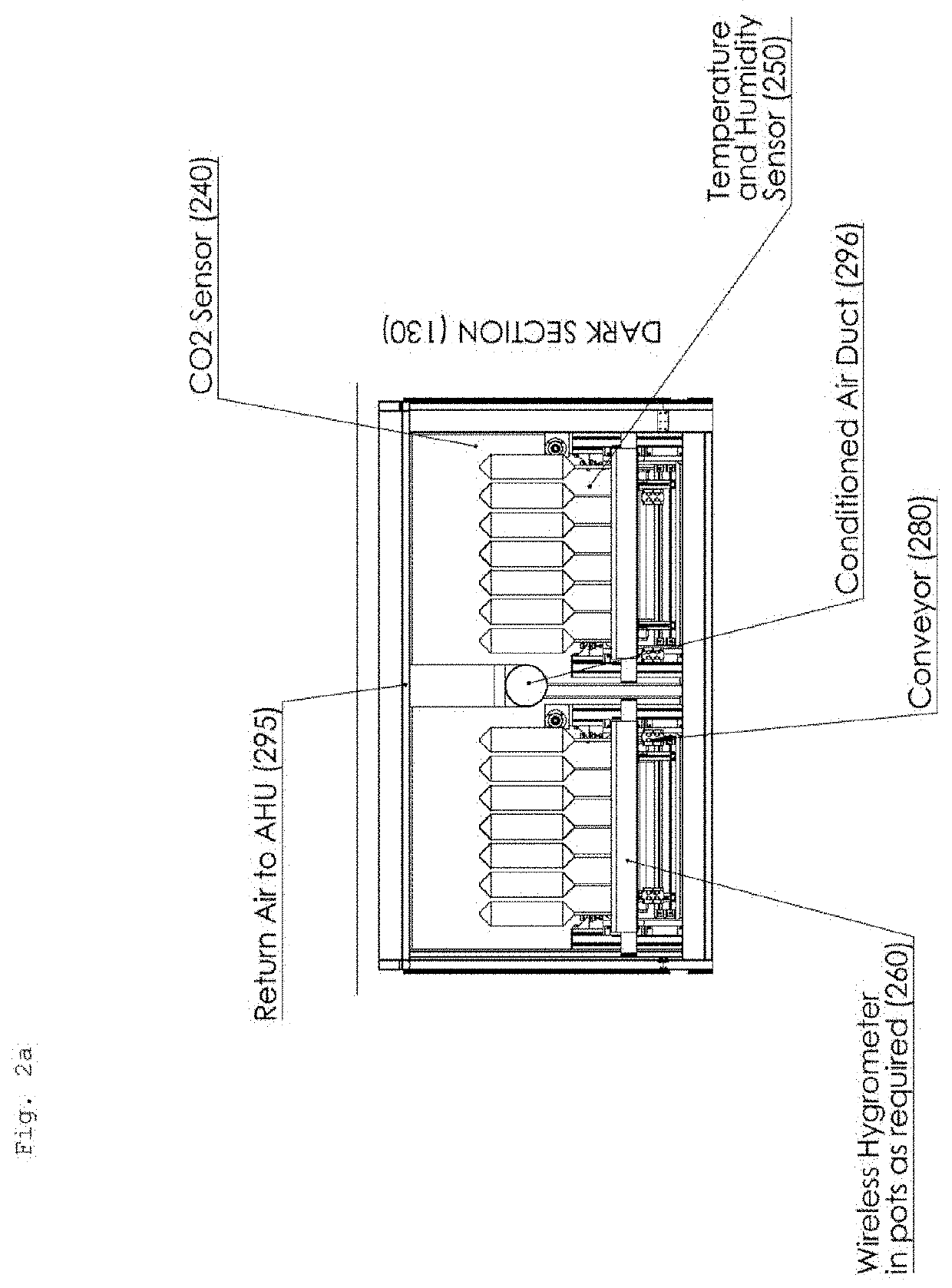

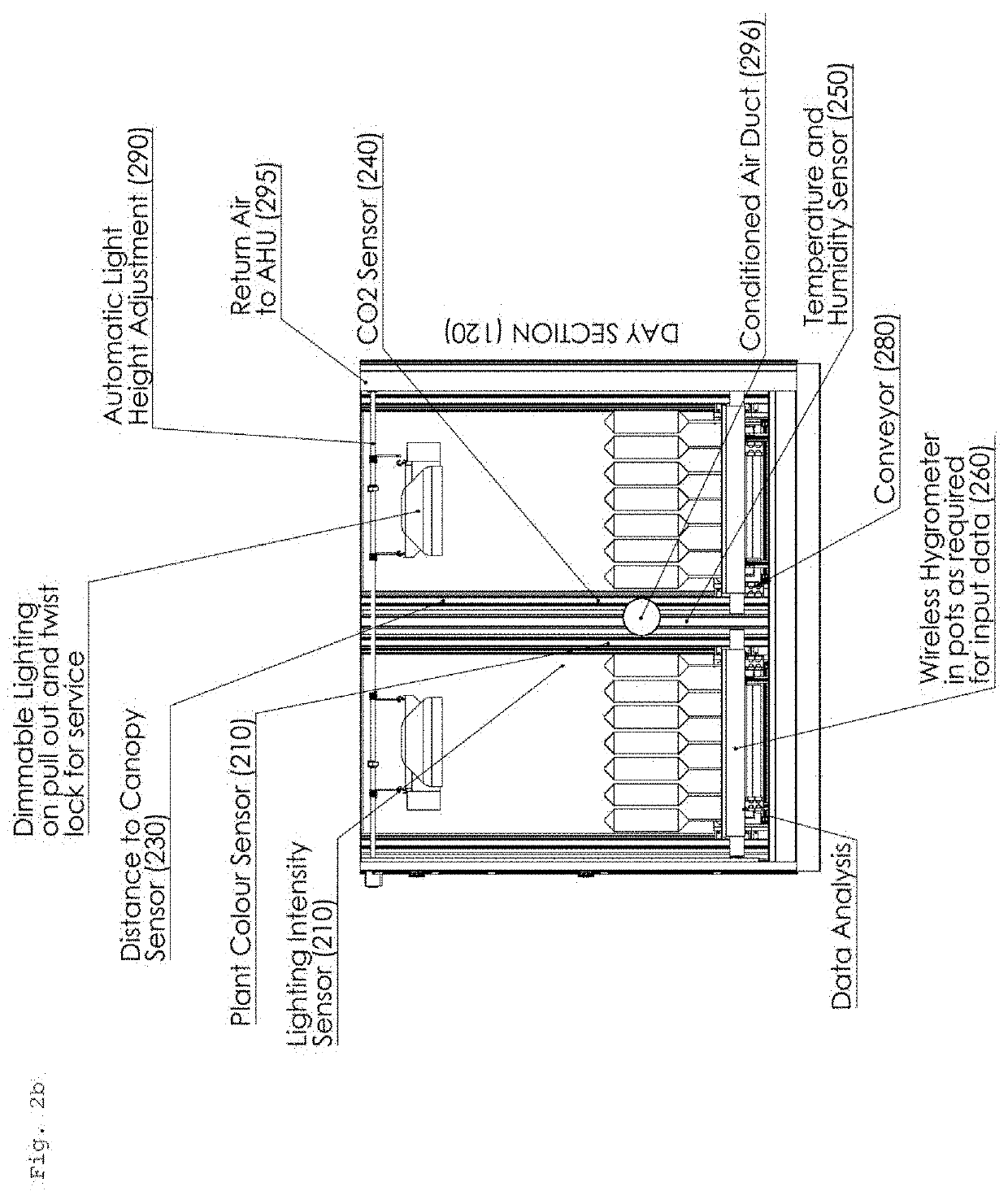

Systems, methods and apparatus for optimal growth of plants

InactiveUS20190335676A1Easily harvestOptimal growth parameterGreenhouse cultivationWeather influencing devicesEcologyOptimal growth

The present invention relates to systems, methods and apparatus for multi-dimensional conveyor which allows for the planting, growing and harvesting of plants and plant material in a manner which optimizes yield, allows for consistency, allows production and harvesting to be automated, and allows production to proceed in conditions which may be most favorable to biologic activities associated with plant products. The entire apparatus can be constructed of lightweight, cost-effective materials, which afford mass-production and mass-array into vast automatic growing operations.

Owner:CONCEPTS TO SOLUTIONS

Genetically engineered duckweed

InactiveCN1272762AEasy to expand productionIncrease production capacityFused cellsFermentationGenetically engineeredGenetic engineering

Methods and compositions for the efficient transformation of duckweed are provided. Preferably, the methods involve transformation by either ballistic bombardment or Agrobacterium. In this manner, any gene or nucleic acid of interest can be introduced and expressed in duckweed plants. Transformed duckweed plants, cells, tissues are also provided. Transformed duckweed plant tissue culture and methods of producing recombinant proteins and peptides from transformed duckweed plants are also disclosed.

Owner:NORTH CAROLINA STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com