Preparation method of monodisperse porous inorganic microsphere

A monodisperse, microsphere technology, applied in the field of monodisperse porous inorganic microspheres and their preparation, can solve problems such as wide particle size distribution, and achieve the effects of controllable pore size, low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

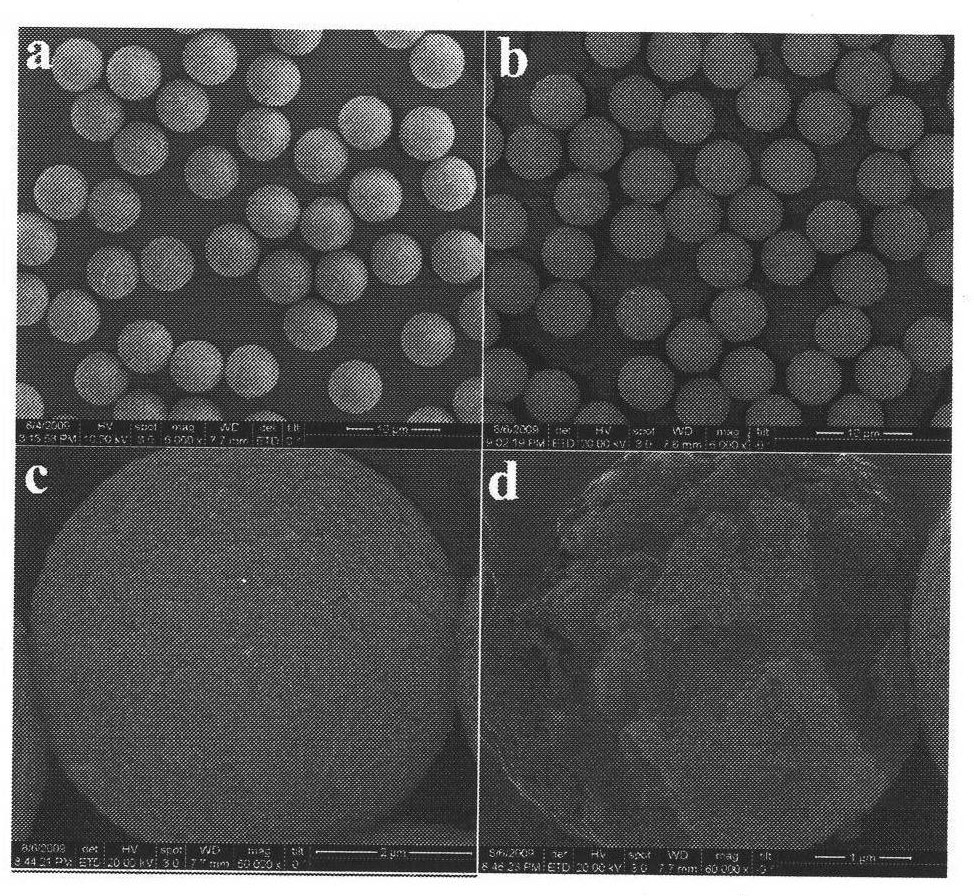

Embodiment 1

[0035] Take 3.68g of porous polyglycidyl methacrylate / ethylene glycol dimethacrylate [P(GMA / EGDMA)] copolymerized microspheres (5μm) in a 250mL three-necked bottle, add 120mL of water, and ultrasonicate for 20min to make the balls completely Spread out. Then 4g of ethylenediamine (EDA) was added, and the reaction was heated at 80°C for 12h. The obtained microspheres were repeatedly washed with water, and then washed with ethanol several times, and dried in a vacuum oven at 50°C.

Embodiment 2

[0037] Take 4.0g of porous P(GMA / EGDMA) microspheres (10μm) in a 250mL three-necked bottle, add 120mL of water, and disperse the balls completely by ultrasonication for 20min. Then 5g of ammonia water was added, and the reaction was heated at 80°C for 12h. The obtained microspheres were repeatedly washed with water, and then washed with ethanol several times, and dried in a vacuum oven at 50°C.

[0038] 2. Synthesis of porous silica microspheres:

Embodiment 3

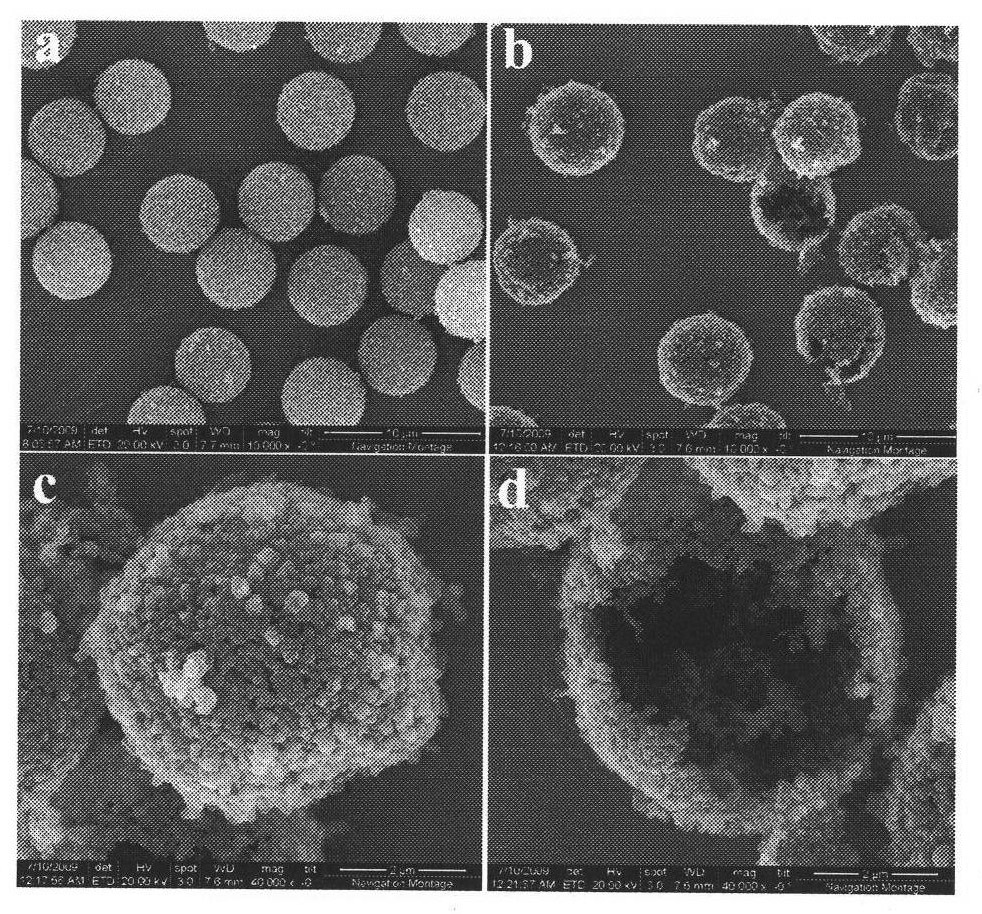

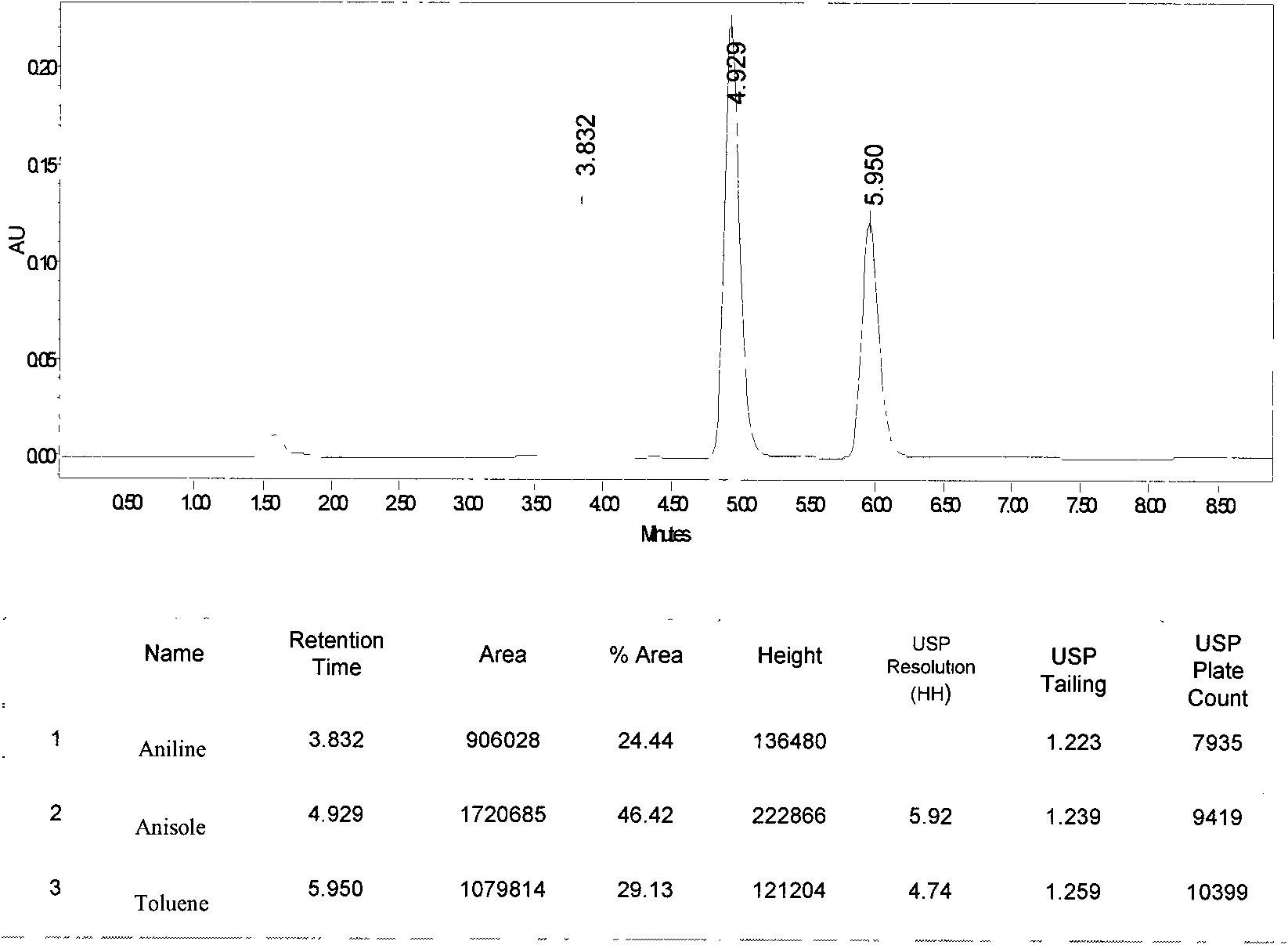

[0040] Take 0.2 g of the porous microspheres of Example 1 in a 500 mL three-neck flask, add 40 mL of deionized water, 200 mL of isopropanol, 0.5 mL of tetrabutylammonium bromide and 1 mL of 28% ammonia water, and then sonicate for 10 min. 5 mL of isopropanol solution containing 10% tetraethyl orthosilicate (TEOS) was added dropwise into the reaction system within 1 h, and reacted at room temperature for 24 h. The obtained polymer / silica composite microspheres were repeatedly washed with ethanol and acetone, and then dried in a vacuum oven at 50°C. The dried polymer / silica composite microspheres were placed in a muffle furnace, and the temperature was raised to 600°C step by step, and kept at this temperature for 6 hours to burn, and finally 5 μm porous silica microspheres were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com