Phosphorus-containing intrinsic flame-retardant thermoplastic nylon elastomer and preparation method thereof

A nylon elastomer, intrinsic flame retardant technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

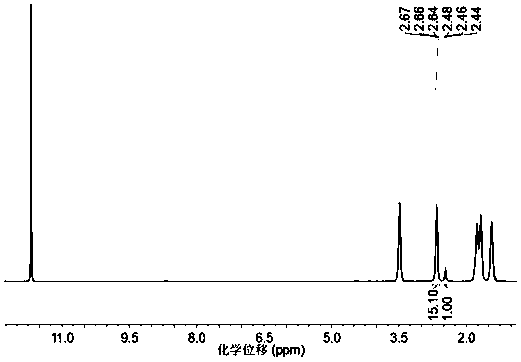

[0053] Add 30g of caprolactam, 2.35g of adipic acid and 1.2ml of water together into a polymerization container, raise the temperature to 240°C for 4 hours under the protection of nitrogen, and carry out the ring-opening polycondensation of caprolactam, and then remove the water in the later stage of the reaction to obtain carboxyl-terminated Nylon prepolymer.

[0054] Add 13.69g of polyethylene glycol (Mn=1000), 0.78g of DOPO-HQ and 0.14g of catalyst tetrabutyl titanate to the above polymerization vessel, raise the temperature to 240°C for 2h under the protection of nitrogen, then raise the temperature to 260°C for 1h , and finally raised the temperature to 280°C and slowly vacuumed to 100Pa to react for 2h. The obtained product was extracted with boiling water for 8 hours, and the water was changed every hour; then the product was pre-dried in a blast oven, and finally dried in a vacuum oven at 80°C for 12 hours.

[0055] The limiting oxygen index LOI of the phosphorus-cont...

Embodiment 2

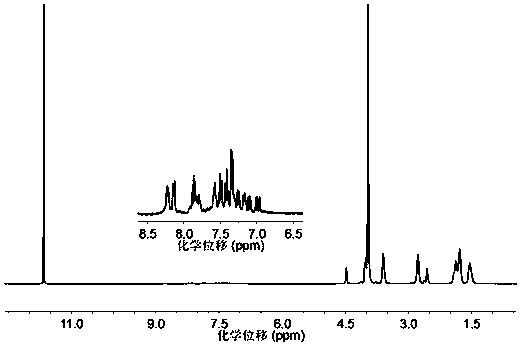

[0057] 30g of caprolactam, 2.35g of adipic acid and 1.2ml of water were added together into a polymerization container, and the ring-opening polycondensation of caprolactam was carried out according to the method of Example 1 to prepare a carboxy-terminated nylon prepolymer.

[0058] Add 12.88g of polyethylene glycol (Mn=1000), 1.04g of DOPO-HQ and 0.13g of catalyst tetrabutyl titanate into the above polymerization container, carry out esterification polycondensation and post-treatment according to the method of Example 1.

[0059] The limiting oxygen index LOI of the phosphorus-containing intrinsically flame-retardant thermoplastic nylon elastomer is 30.0, can pass the UL-94 vertical burning V-0 level, and the elongation at break and tensile strength can reach 608% and 32.37MPa respectively.

Embodiment 3

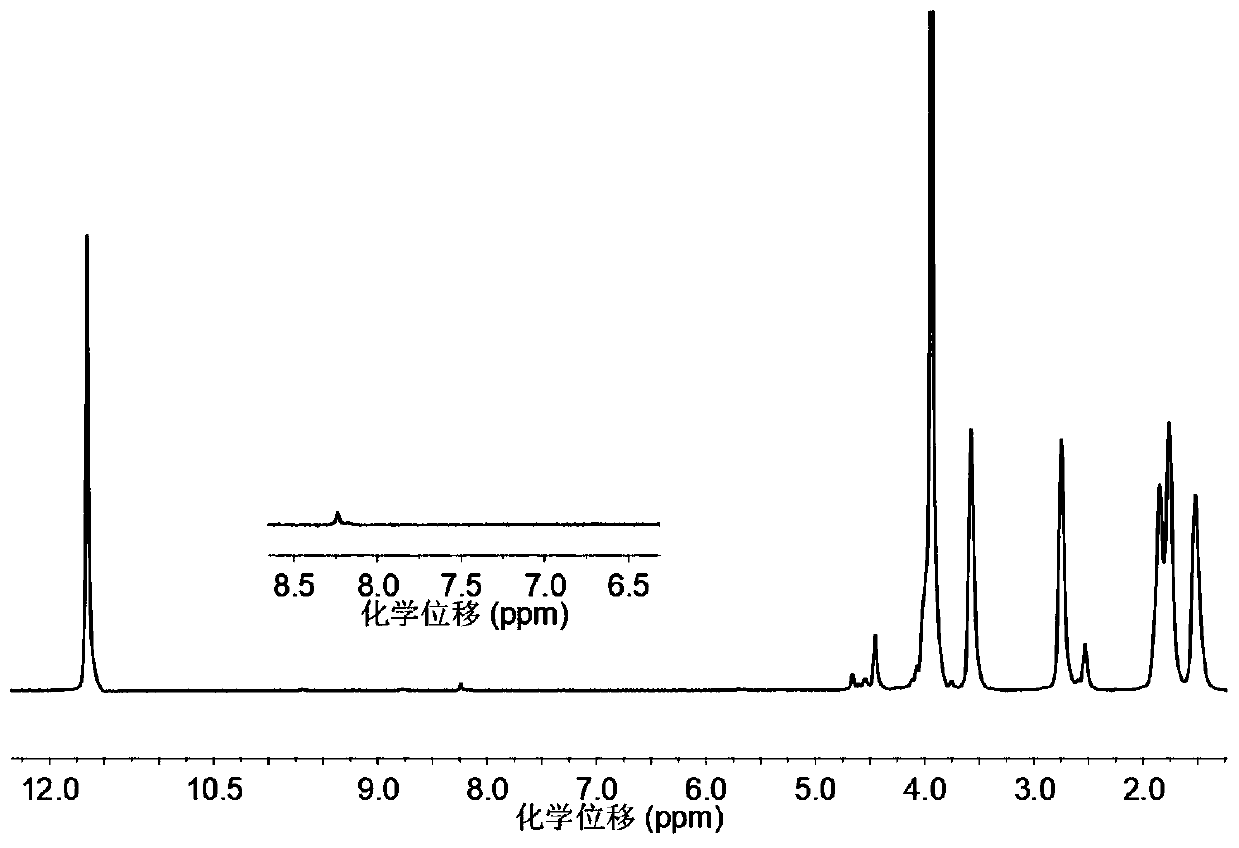

[0061] 30g of caprolactam, 2.35g of adipic acid and 1.2ml of water were added together into a polymerization container, and the ring-opening polycondensation of caprolactam was carried out according to the method of Example 1 to prepare a carboxy-terminated nylon prepolymer.

[0062] Add 12.08g of polyethylene glycol (Mn=1000), 1.31g of DOPO-HQ and 0.12g of catalyst tetrabutyl titanate into the above polymerization container, carry out esterification polycondensation and post-treatment according to the method of Example 1.

[0063] The limiting oxygen index LOI of the phosphorus-containing intrinsically flame-retardant thermoplastic nylon elastomer is 32.5, can pass the UL-94 vertical burning V-0 level, and the elongation at break and tensile strength can reach 468% and 27.33 MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com