Phosphorus-containing intrinsically flame-retardant thermoplastic nylon elastomer and preparation method thereof

A nylon elastomer and intrinsic flame retardant technology, which is applied in the field of flame retardant polymer elastomer and its preparation, can solve the problems such as no nylon elastomer, and achieve the requirements of excellent thermal stability, efficient flame retardant mechanical properties, Flame retardant efficiency and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

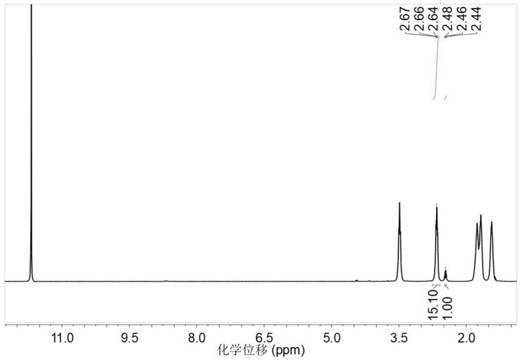

[0053] Add 30g of caprolactam, 2.35g of adipic acid and 1.2ml of water together into a polymerization container, raise the temperature to 240°C for 4 hours under the protection of nitrogen, and carry out the ring-opening polycondensation of caprolactam, and then remove the water in the later stage of the reaction to obtain carboxyl-terminated Nylon prepolymer.

[0054] Add 13.69g of polyethylene glycol (Mn=1000), 0.78g of DOPO-HQ and 0.14g of catalyst tetrabutyl titanate to the above polymerization vessel, raise the temperature to 240°C for 2h under the protection of nitrogen, then raise the temperature to 260°C for 1h , and finally raised the temperature to 280°C and slowly vacuumed to 100Pa to react for 2h. The obtained product was extracted with boiling water for 8 hours, and the water was changed every hour; then the product was pre-dried in a blast oven, and finally dried in a vacuum oven at 80°C for 12 hours.

[0055] The limiting oxygen index LOI of the phosphorus-cont...

Embodiment 2

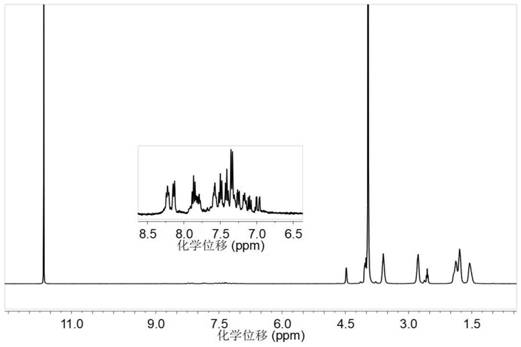

[0057] 30g of caprolactam, 2.35g of adipic acid and 1.2ml of water were added together into a polymerization container, and the ring-opening polycondensation of caprolactam was carried out according to the method of Example 1 to prepare a carboxy-terminated nylon prepolymer.

[0058] Add 12.88g of polyethylene glycol (Mn=1000), 1.04g of DOPO-HQ and 0.13g of catalyst tetrabutyl titanate into the above polymerization container, carry out esterification polycondensation and post-treatment according to the method of Example 1.

[0059] The limiting oxygen index LOI of the phosphorus-containing intrinsically flame-retardant thermoplastic nylon elastomer is 30.0, can pass the UL-94 vertical burning V-0 level, and the elongation at break and tensile strength can reach 608% and 32.37MPa respectively.

Embodiment 3

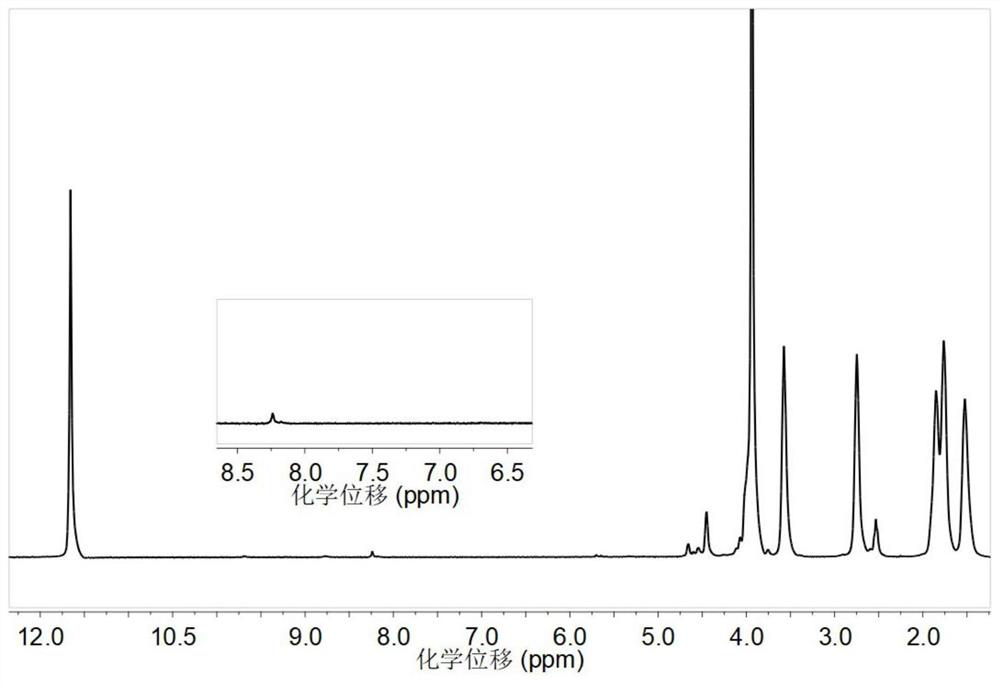

[0061] 30g of caprolactam, 2.35g of adipic acid and 1.2ml of water were added together into a polymerization container, and the ring-opening polycondensation of caprolactam was carried out according to the method of Example 1 to prepare a carboxy-terminated nylon prepolymer.

[0062] Add 12.08g of polyethylene glycol (Mn=1000), 1.31g of DOPO-HQ and 0.12g of catalyst tetrabutyl titanate into the above polymerization container, carry out esterification polycondensation and post-treatment according to the method of Example 1.

[0063] The limiting oxygen index LOI of the phosphorus-containing intrinsically flame-retardant thermoplastic nylon elastomer is 32.5, can pass the UL-94 vertical burning V-0 level, and the elongation at break and tensile strength can reach 468% and 27.33 MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com