Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

376 results about "Multiblock copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

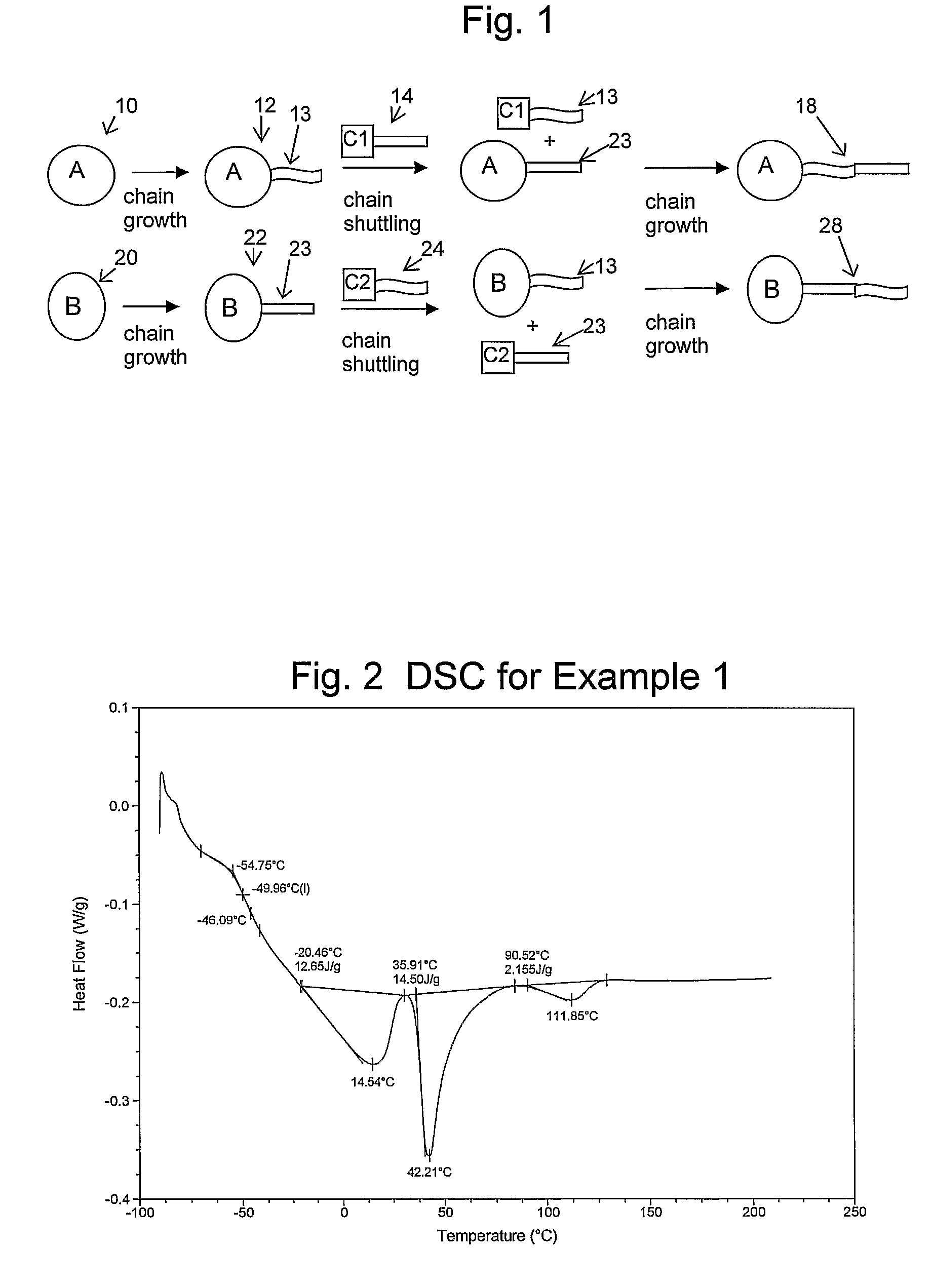

Catalyst composition comprising shuttling agent for ethylene multi-block copolymer formation

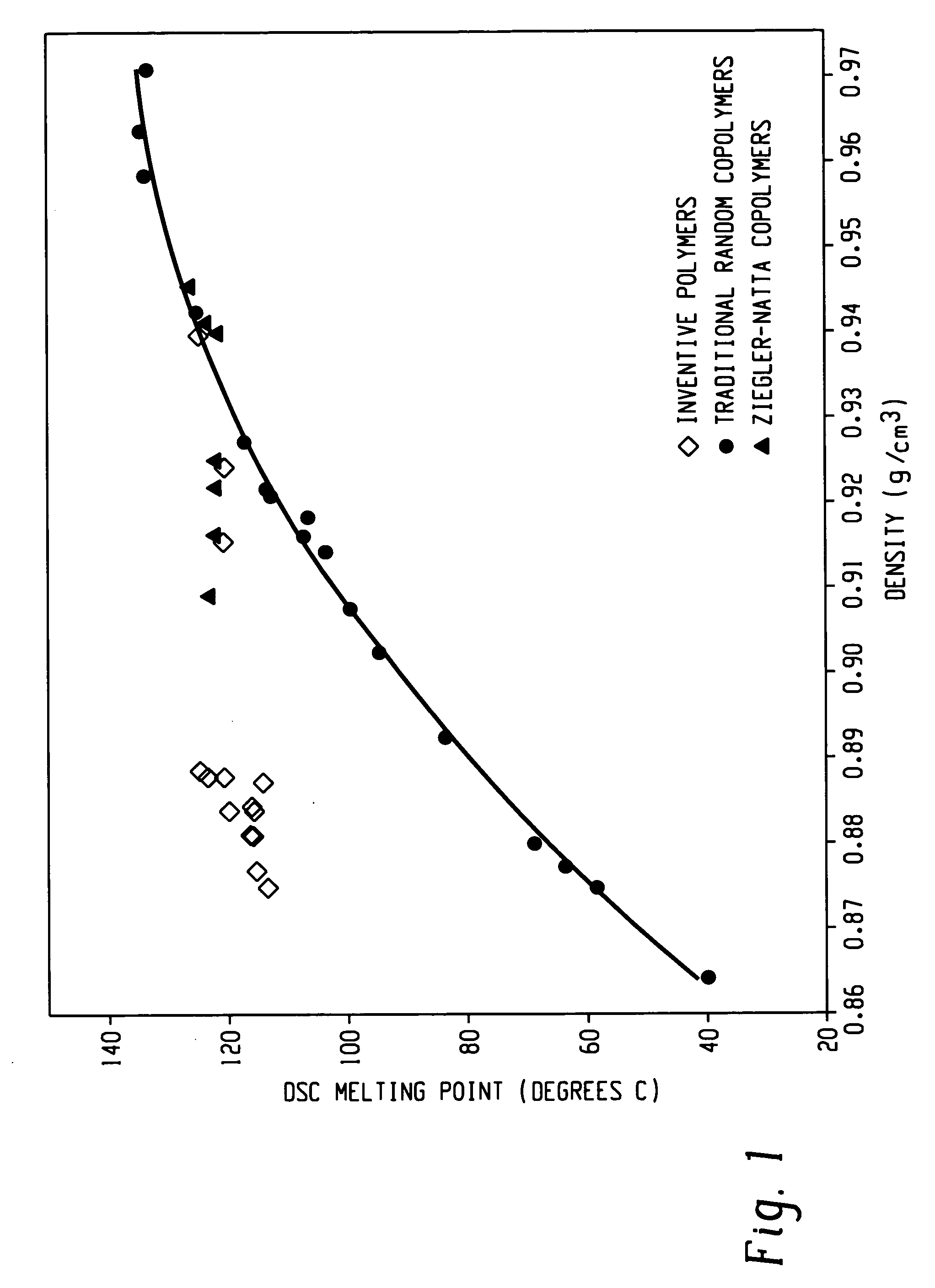

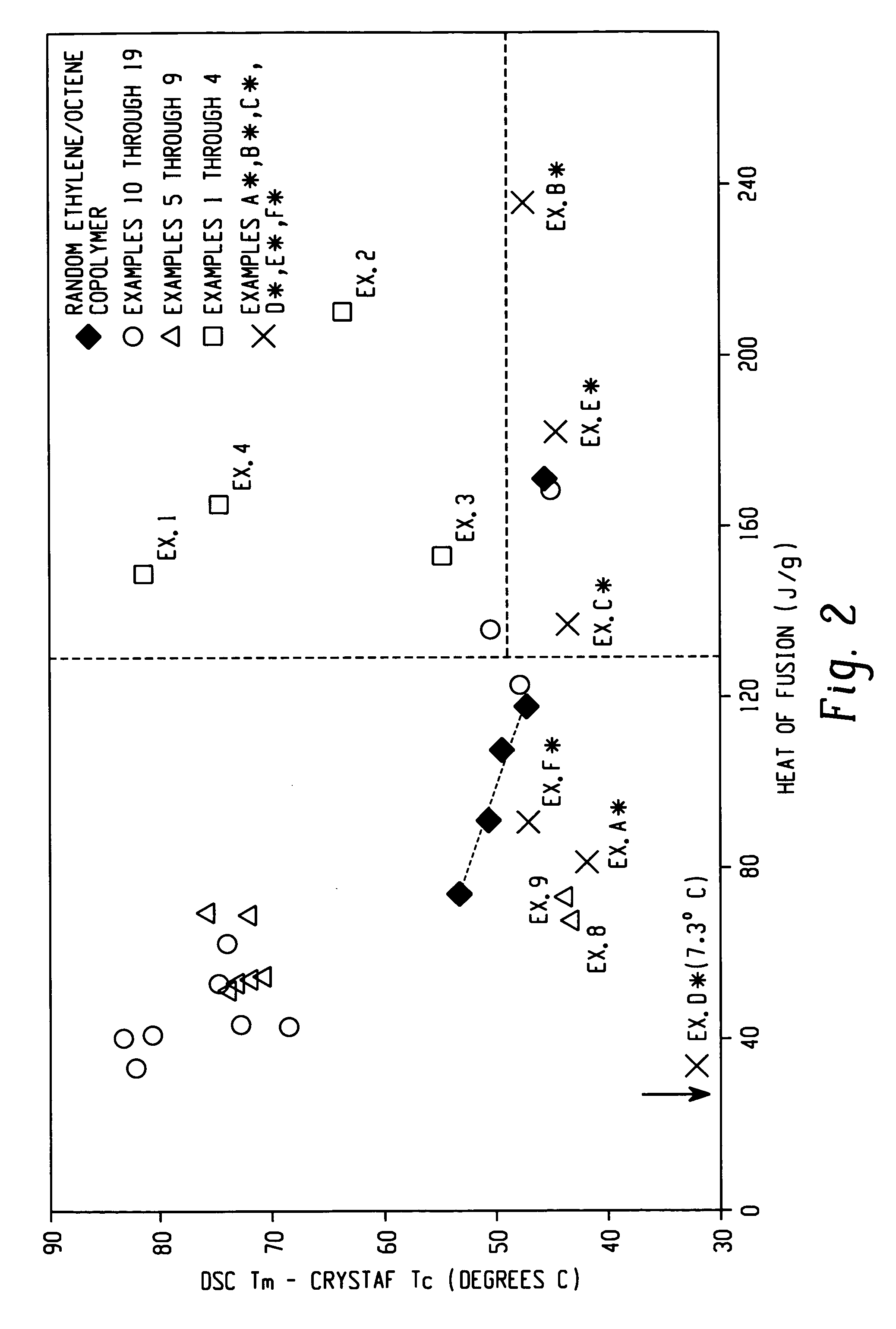

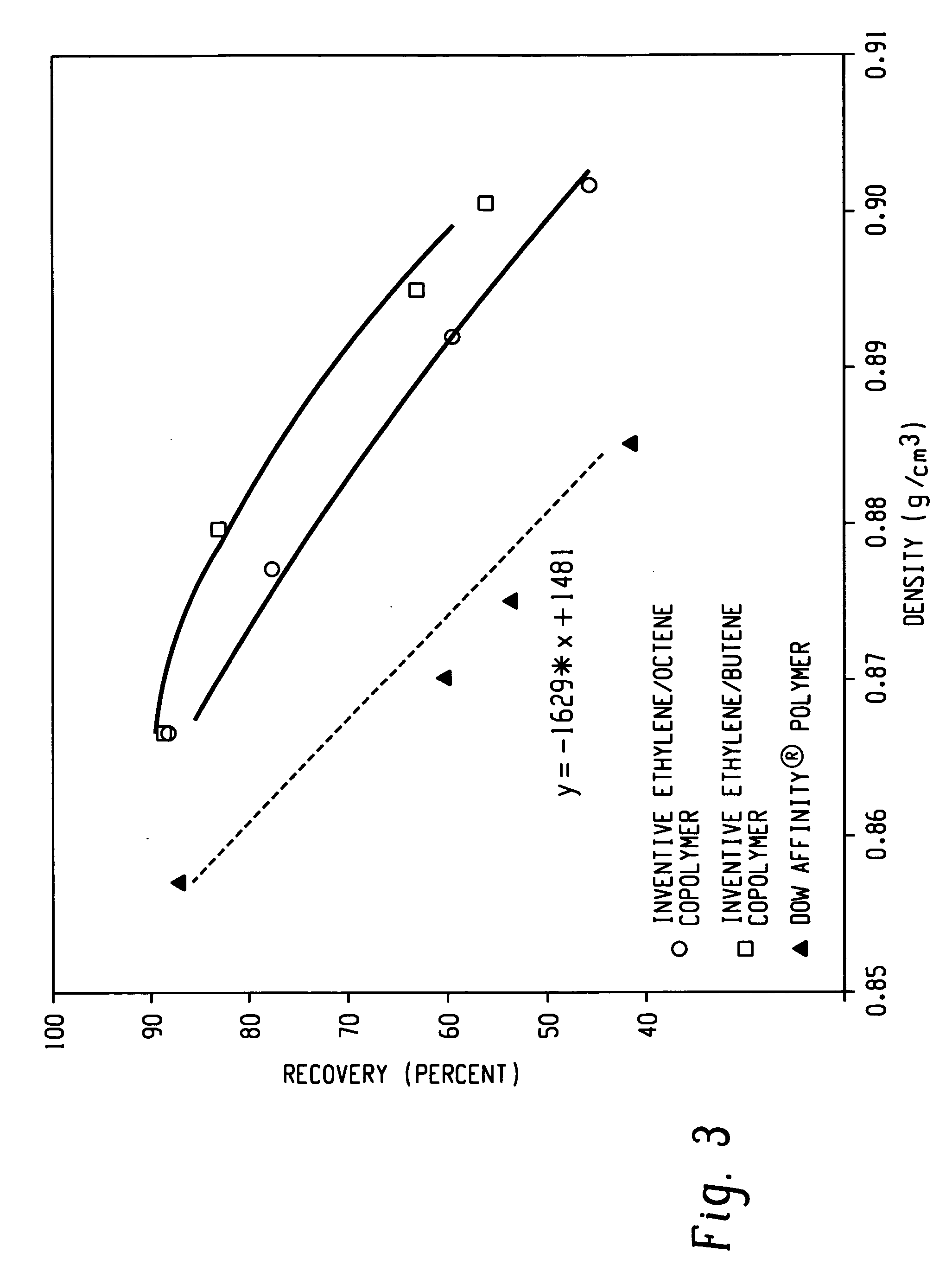

ActiveUS7858706B2Improve efficiencySynthetic resin layered productsThin material handlingOlefin polymerizationPolymerization catalysts

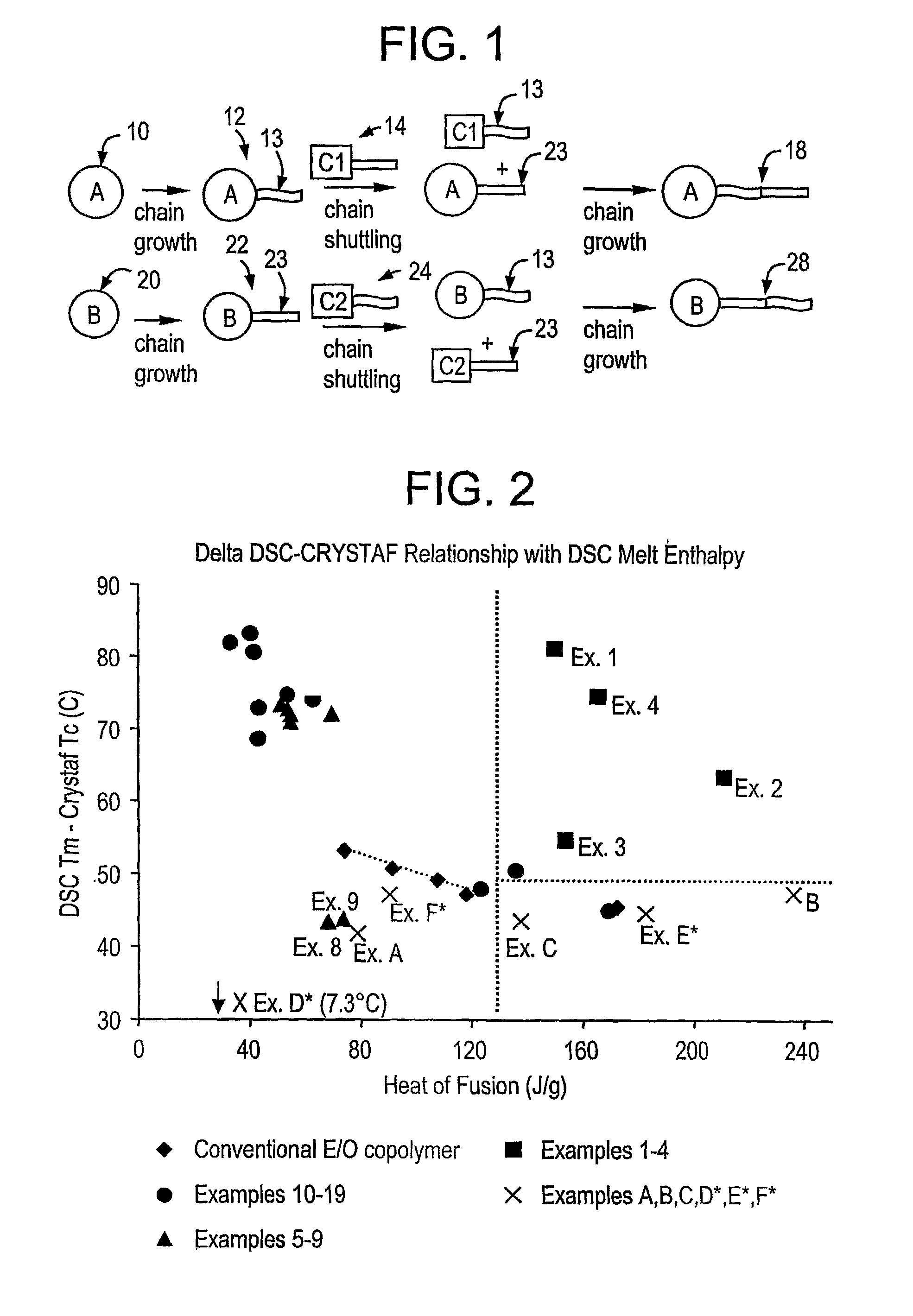

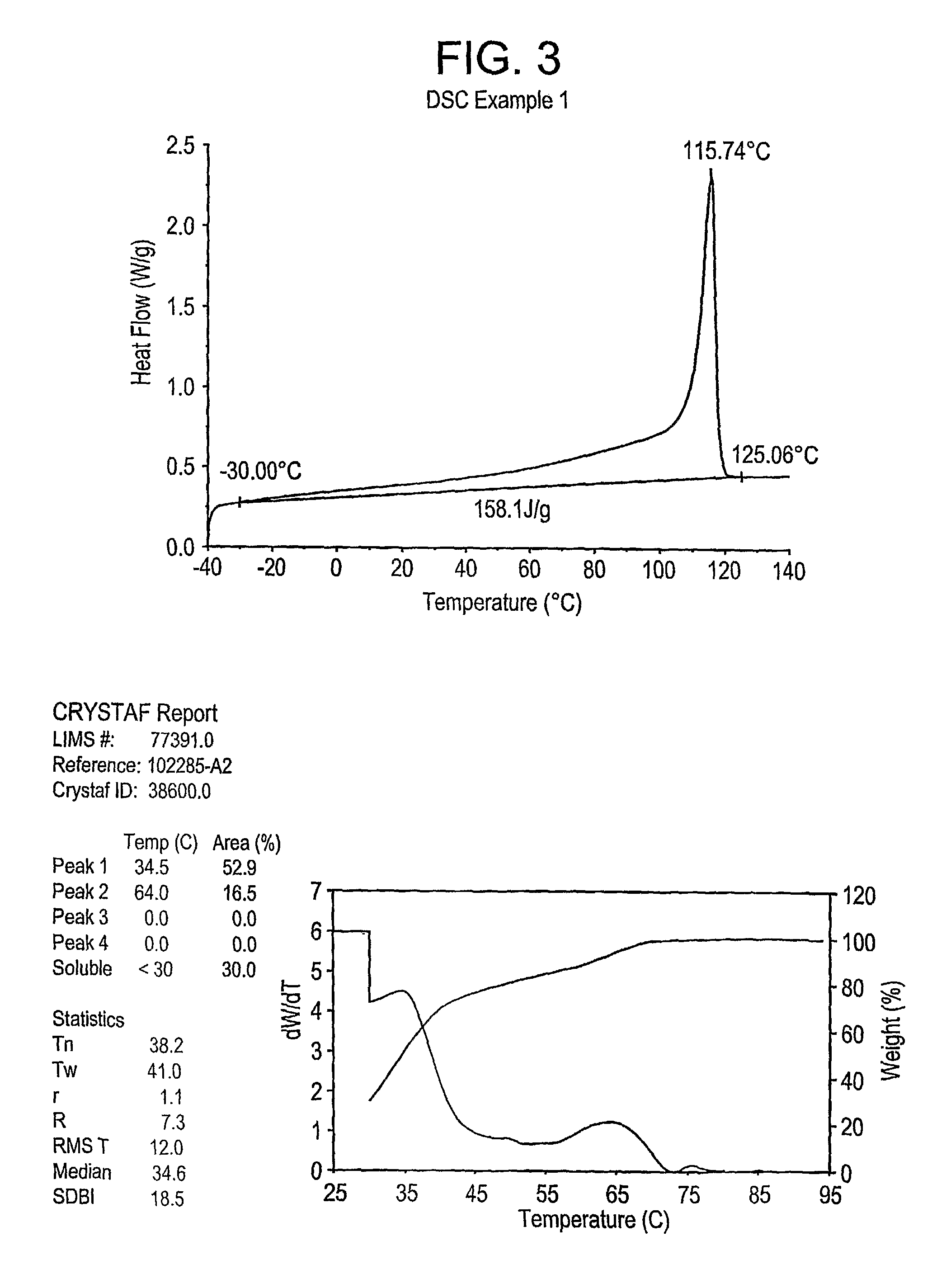

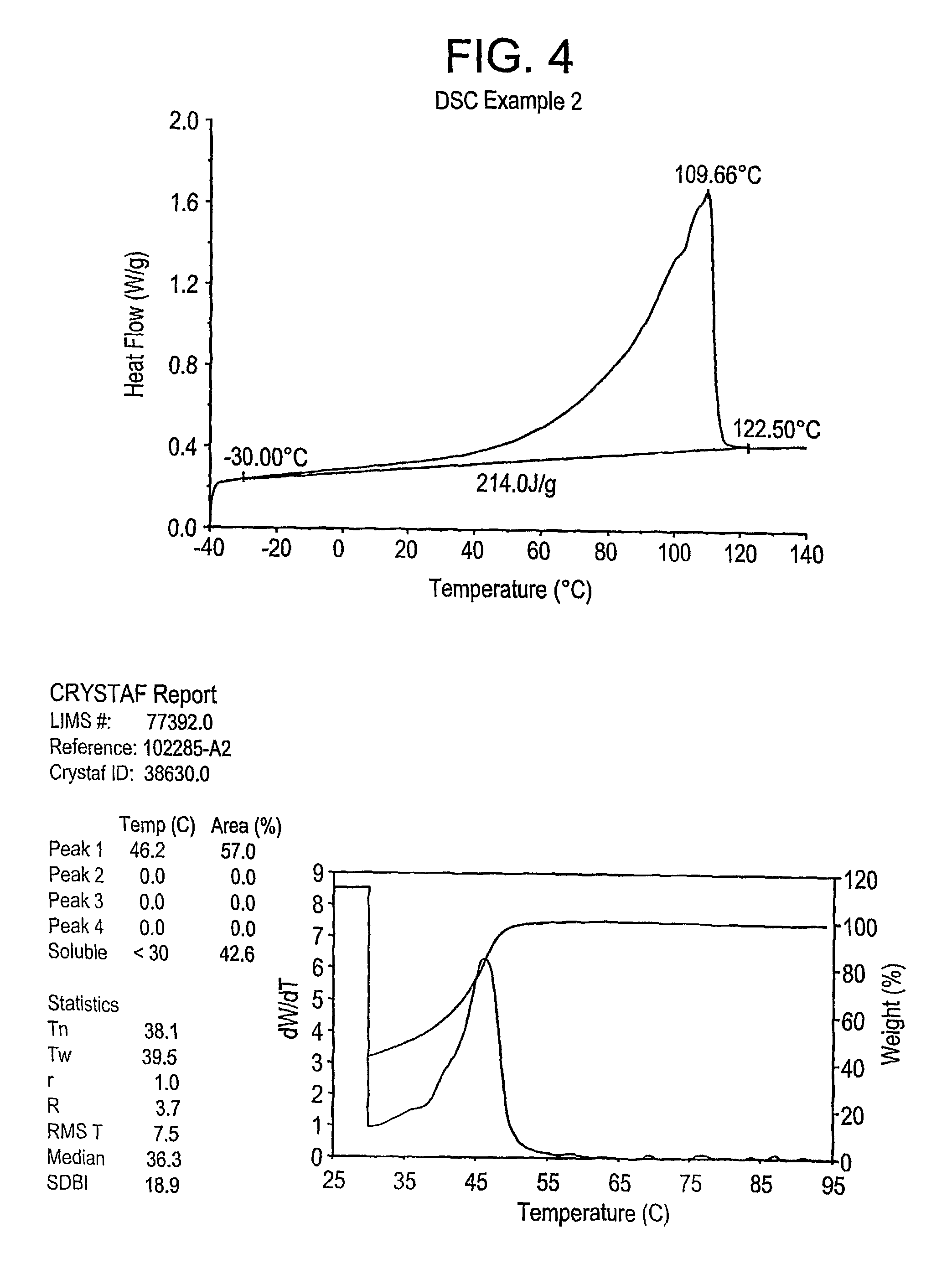

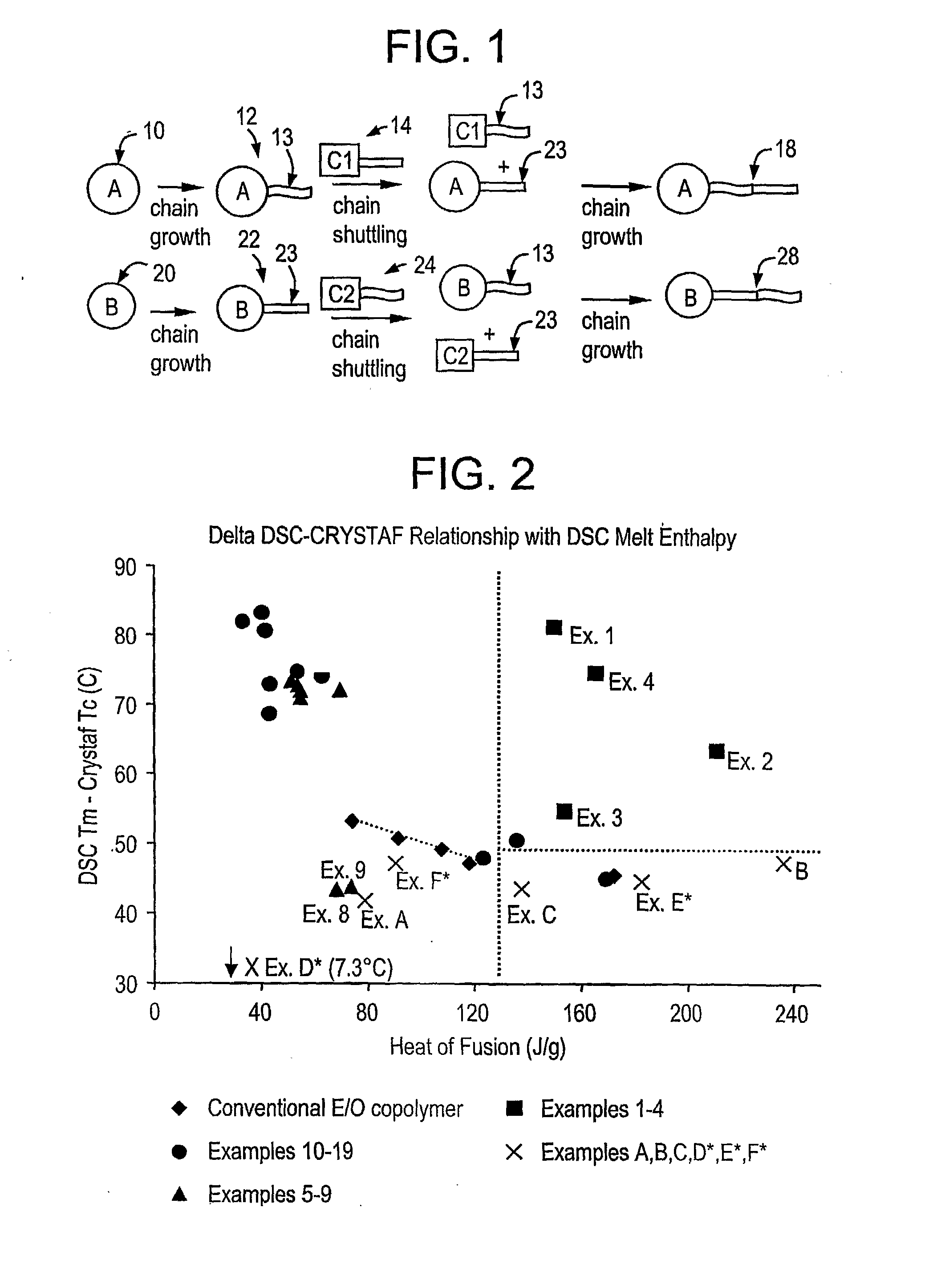

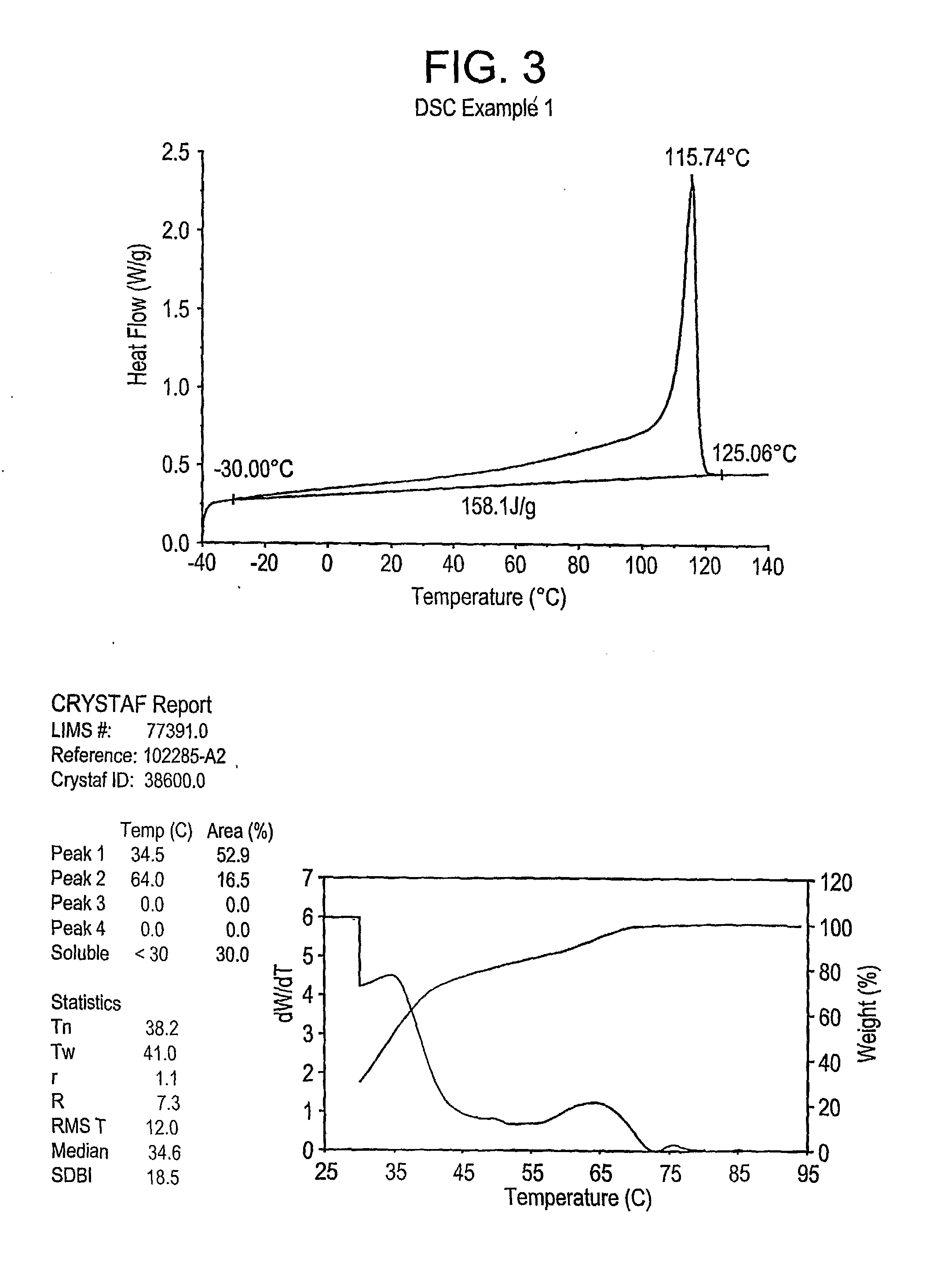

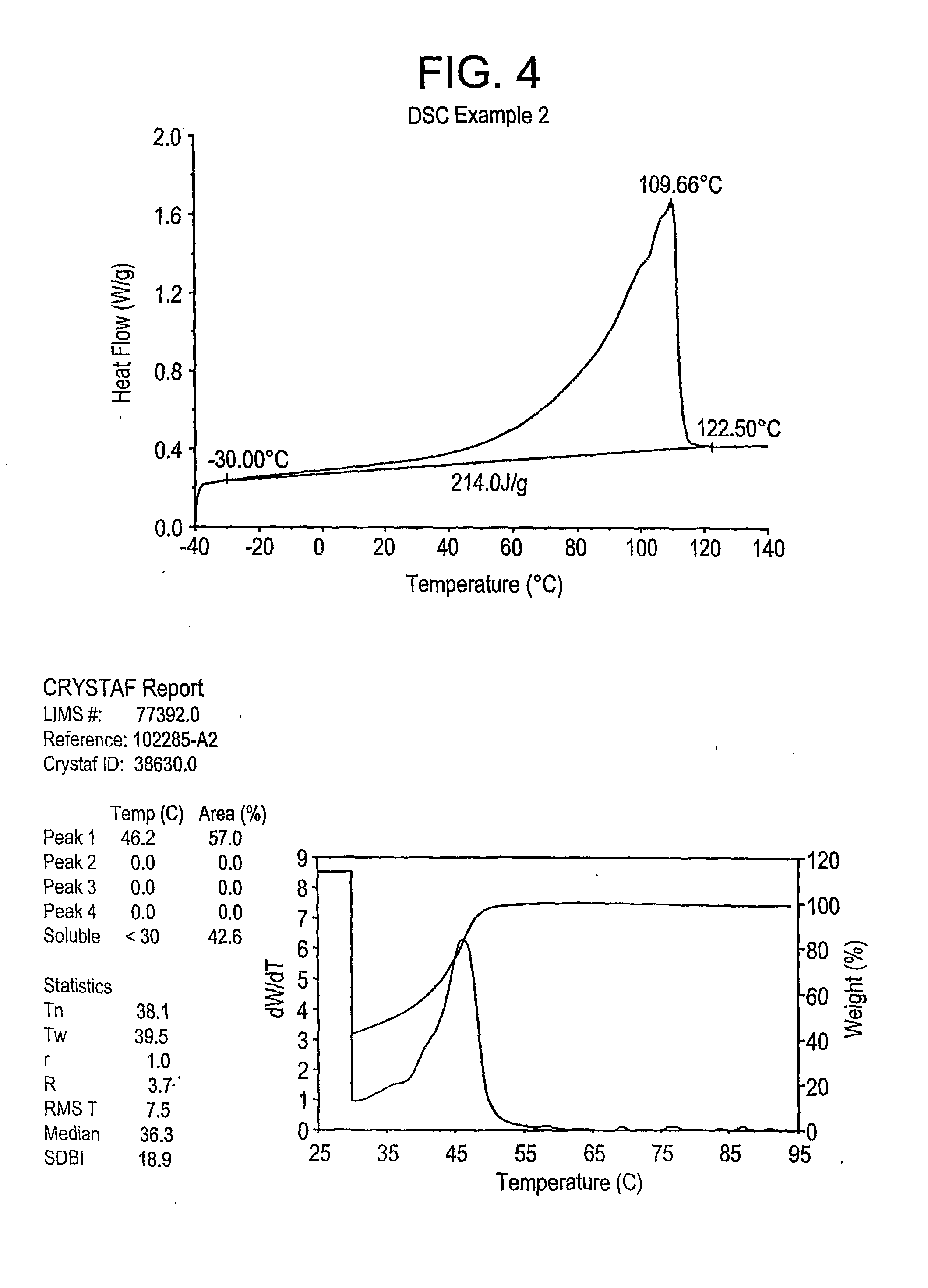

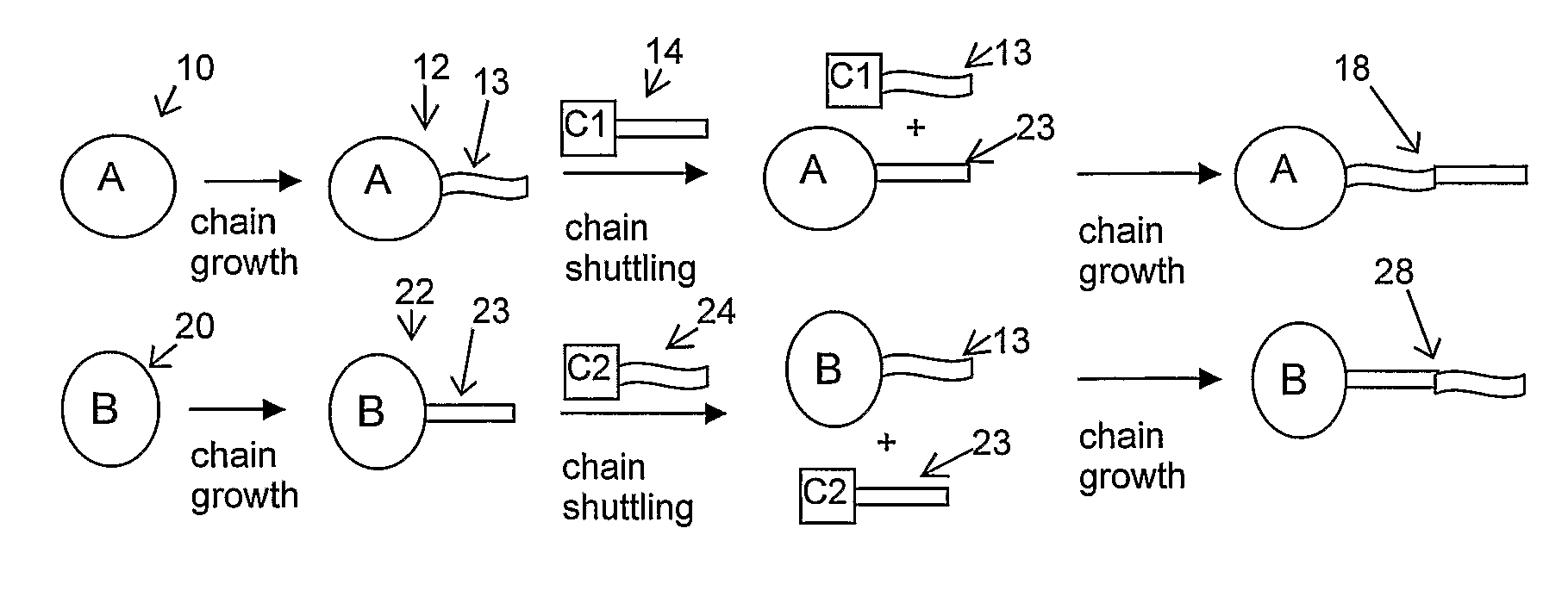

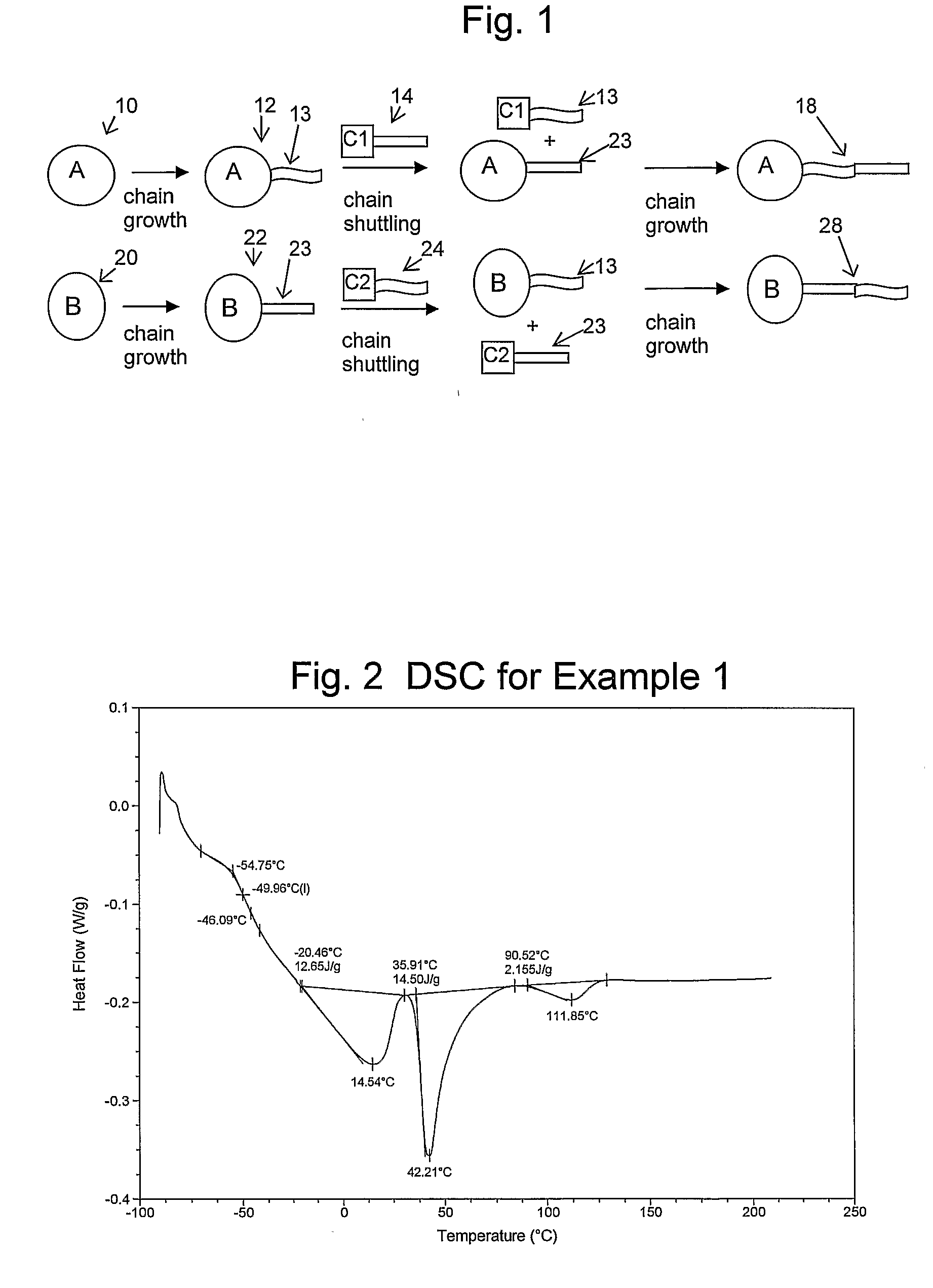

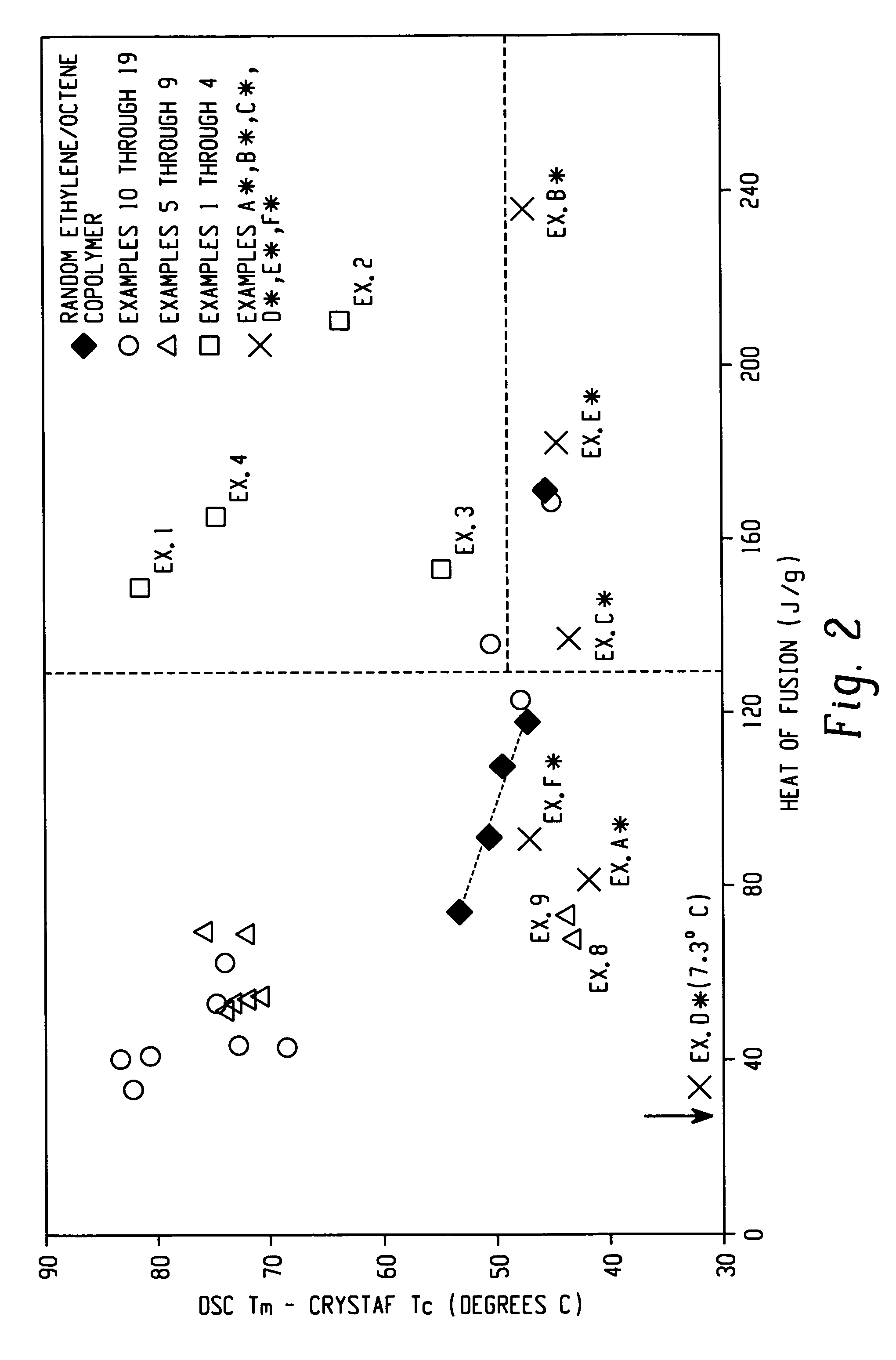

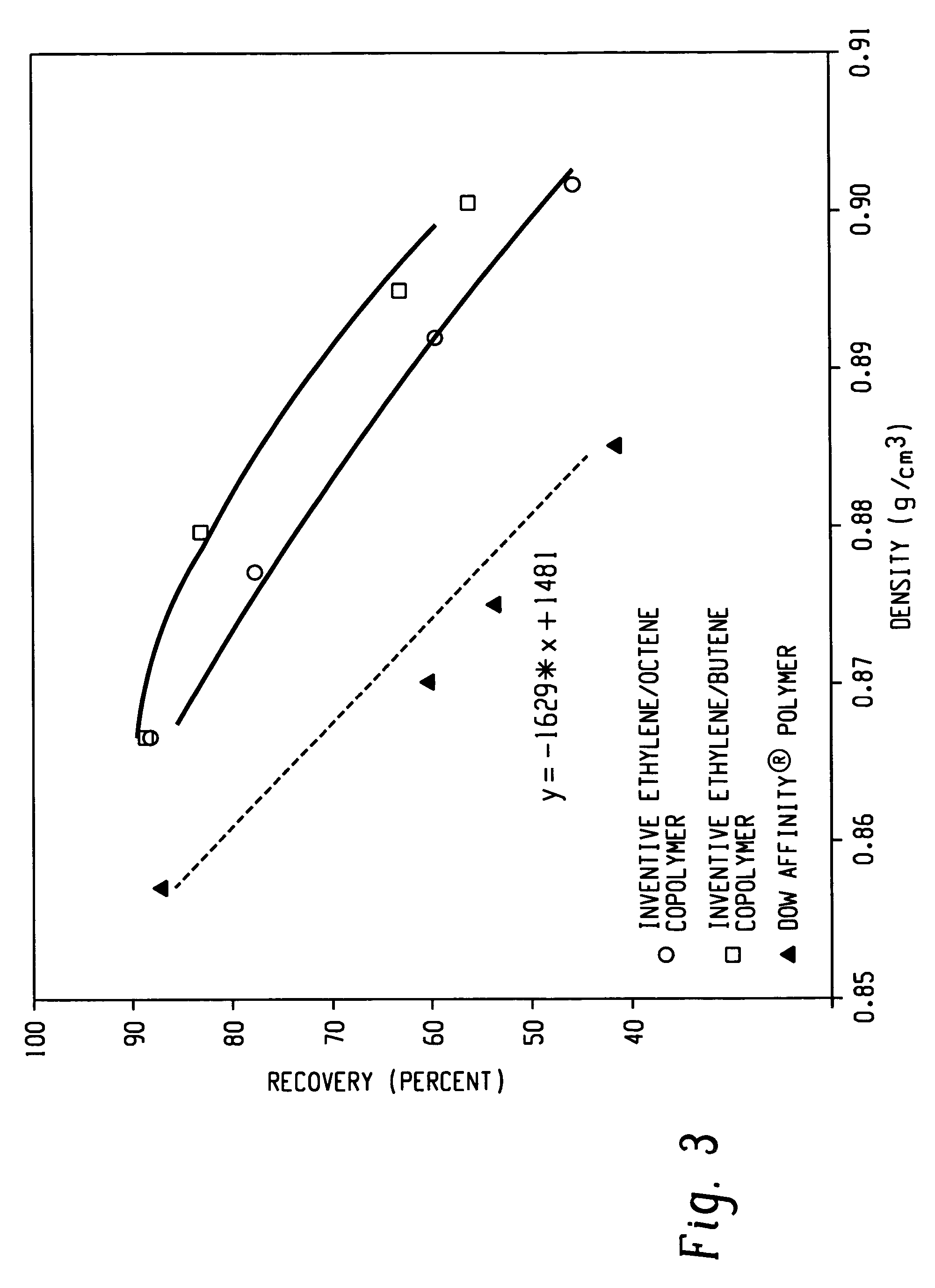

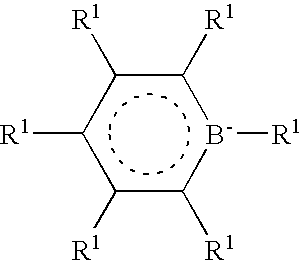

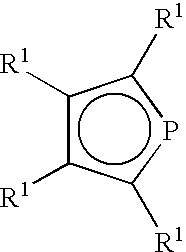

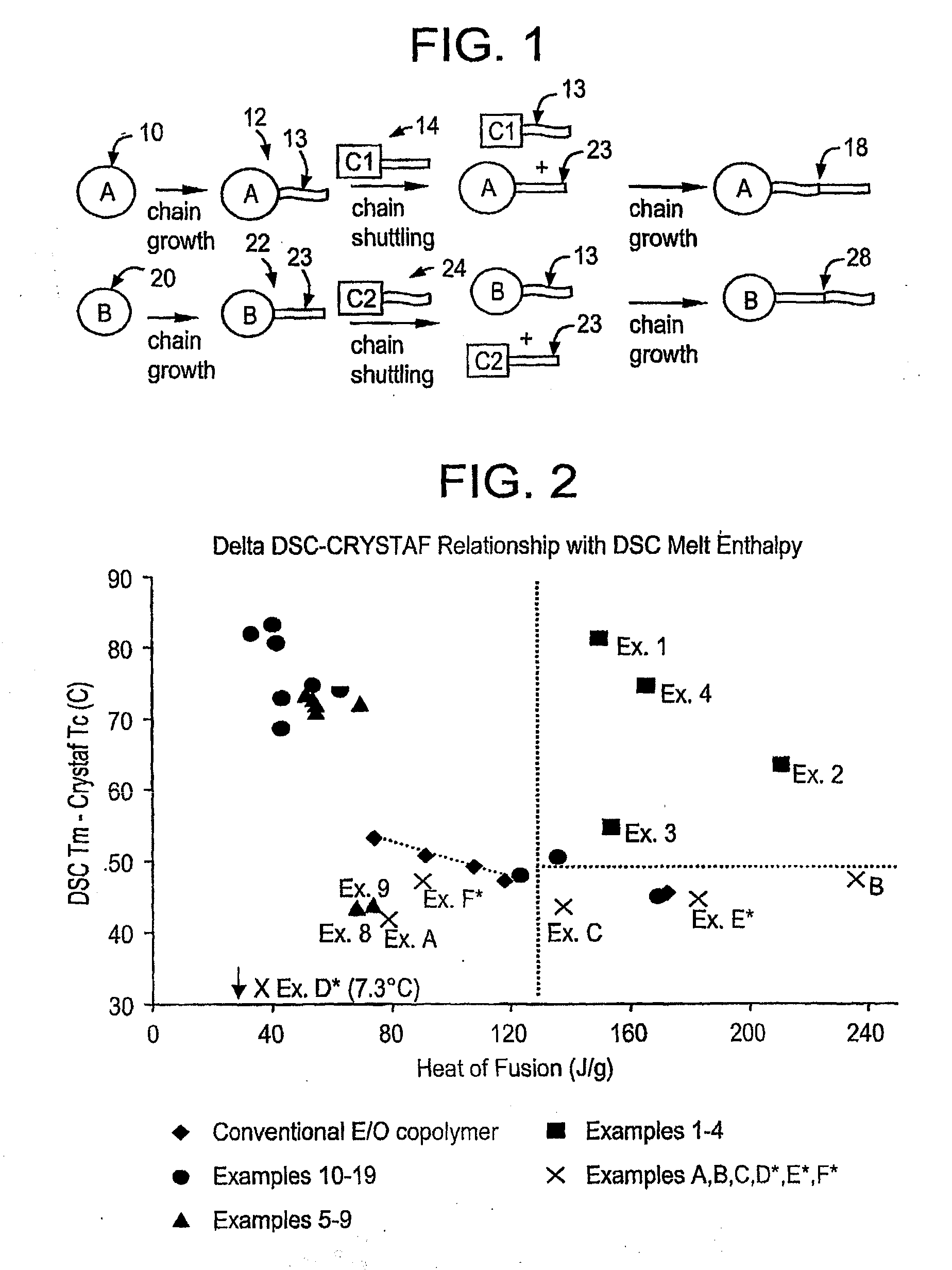

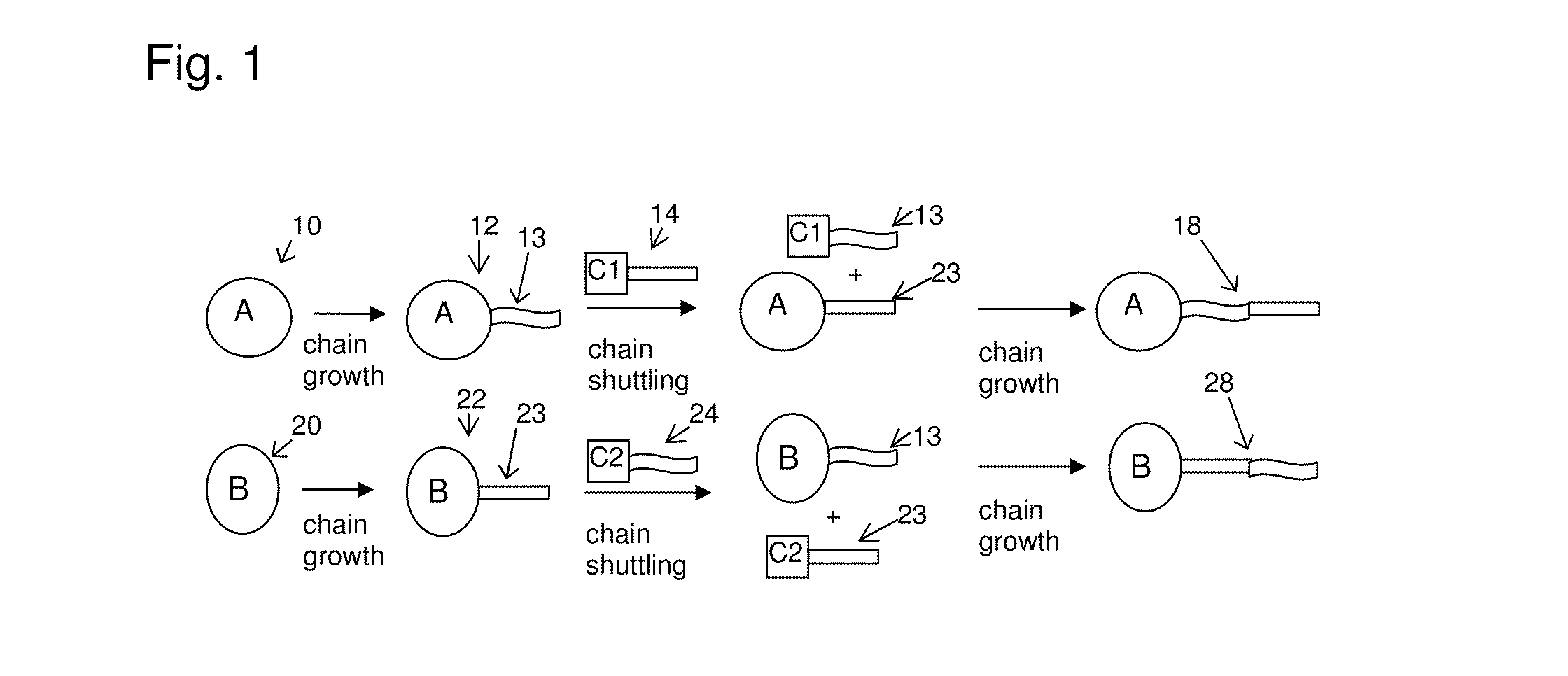

A composition for use in forming a multi-block copolymer, said copolymer containing therein two or more segments or blocks differing in chemical or physical properties, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Catalyst composition comprising shuttling agent for ethylene multi-block copolymer formation

ActiveUS20070167578A1Improve efficiencySynthetic resin layered productsThin material handlingOlefin polymerizationPolymerization catalysts

A composition for use in forming a multi-block copolymer, said copolymer containing therein two or more segments or blocks differing in chemical or physical properties, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Catalyst Composition Comprising Shuttling Agent for Higher Olefin Multi-Block Copolymer Formation

ActiveUS20080311812A1Improve efficiencyHigh monomer conversion rateWoven fabricsNon-woven fabrics4-Methyl-1-penteneOlefin polymerization

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

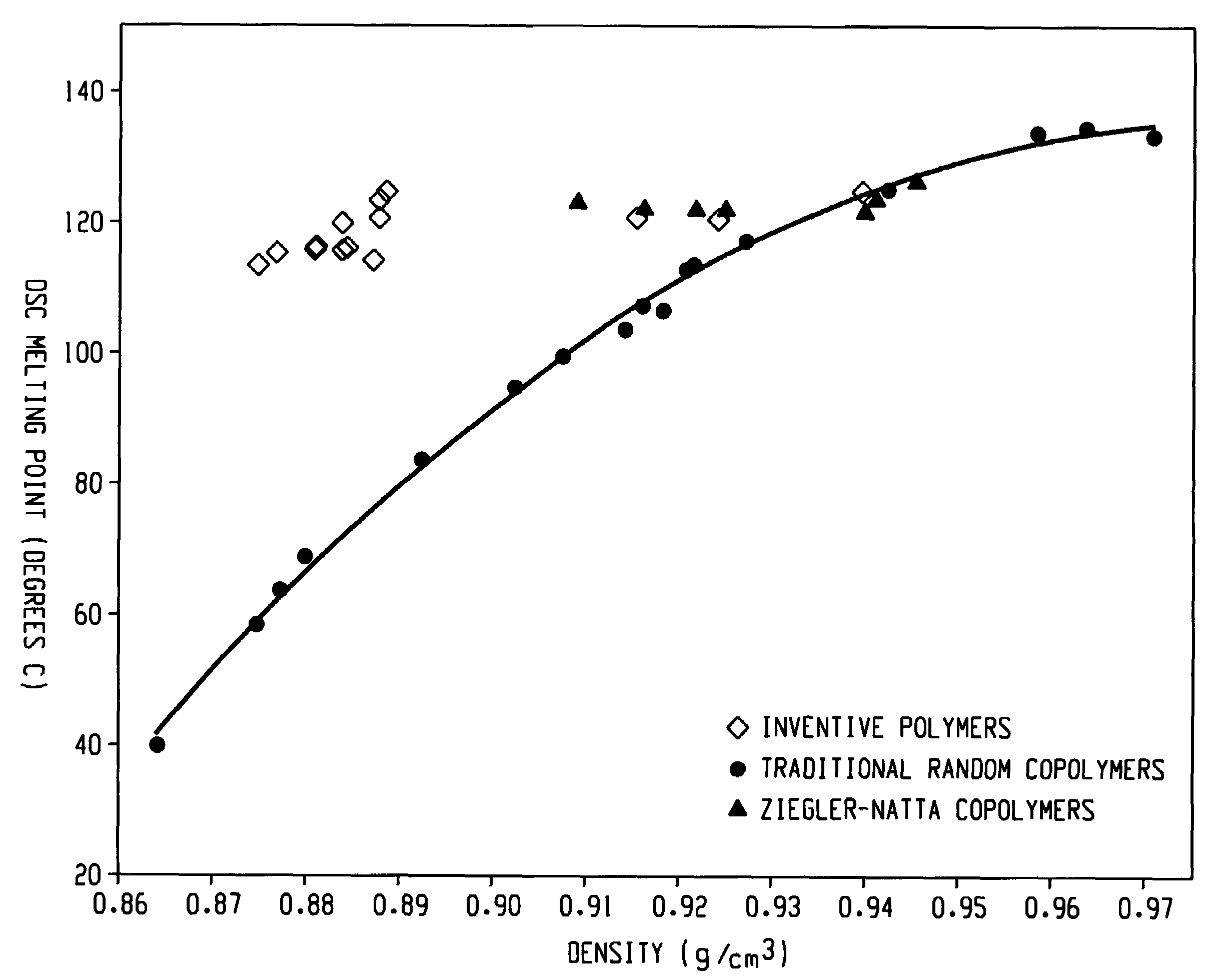

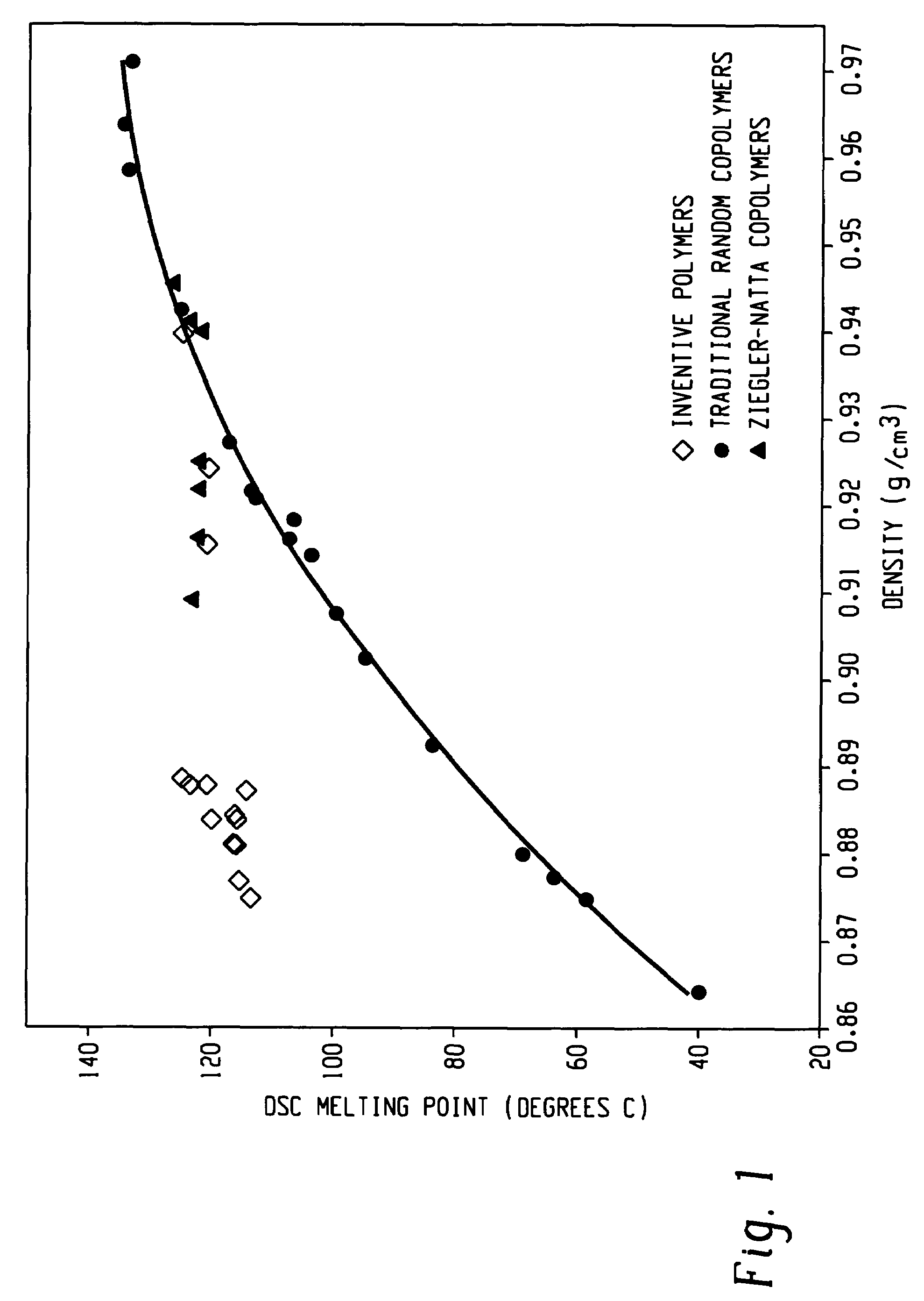

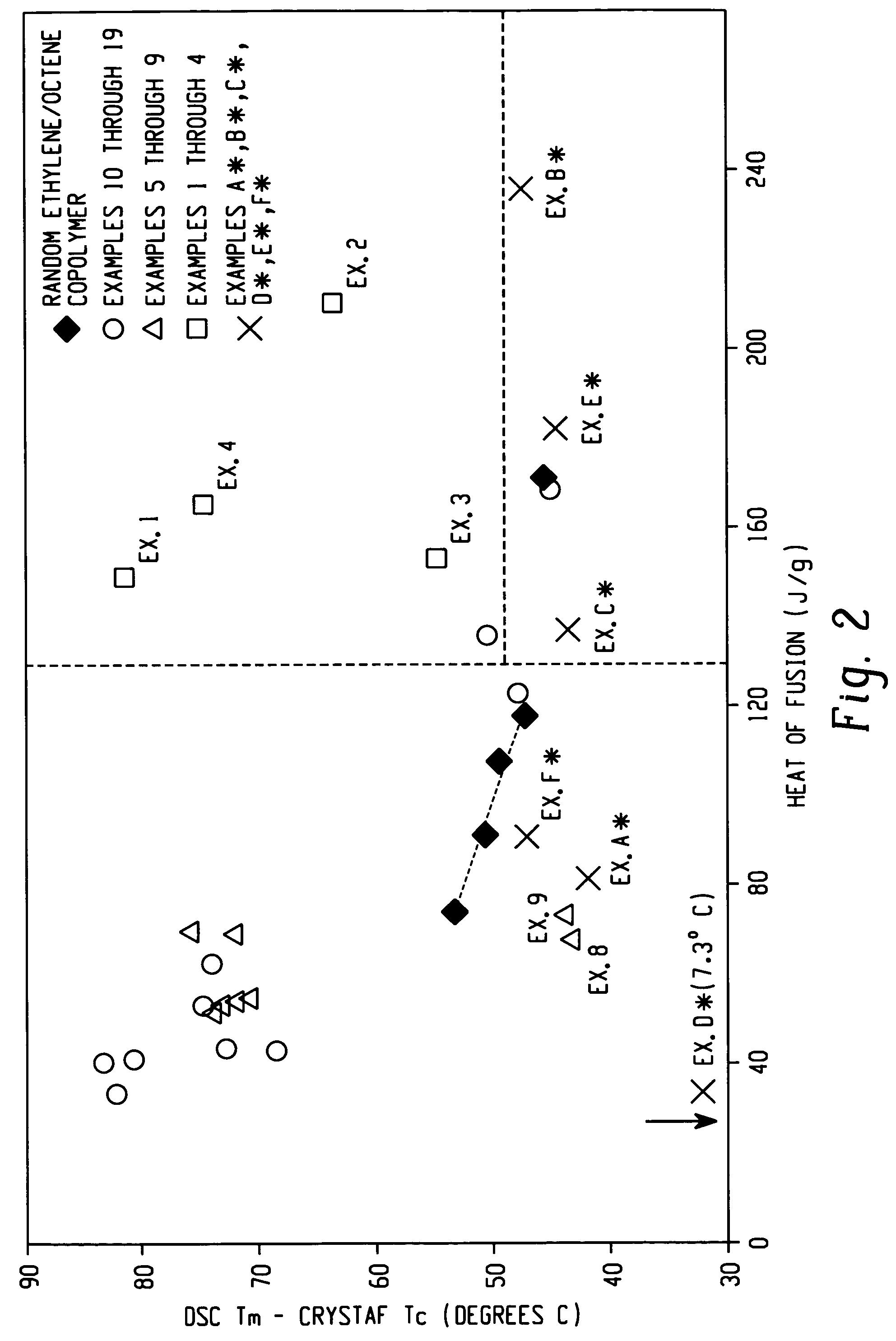

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6169151B1Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolymer science

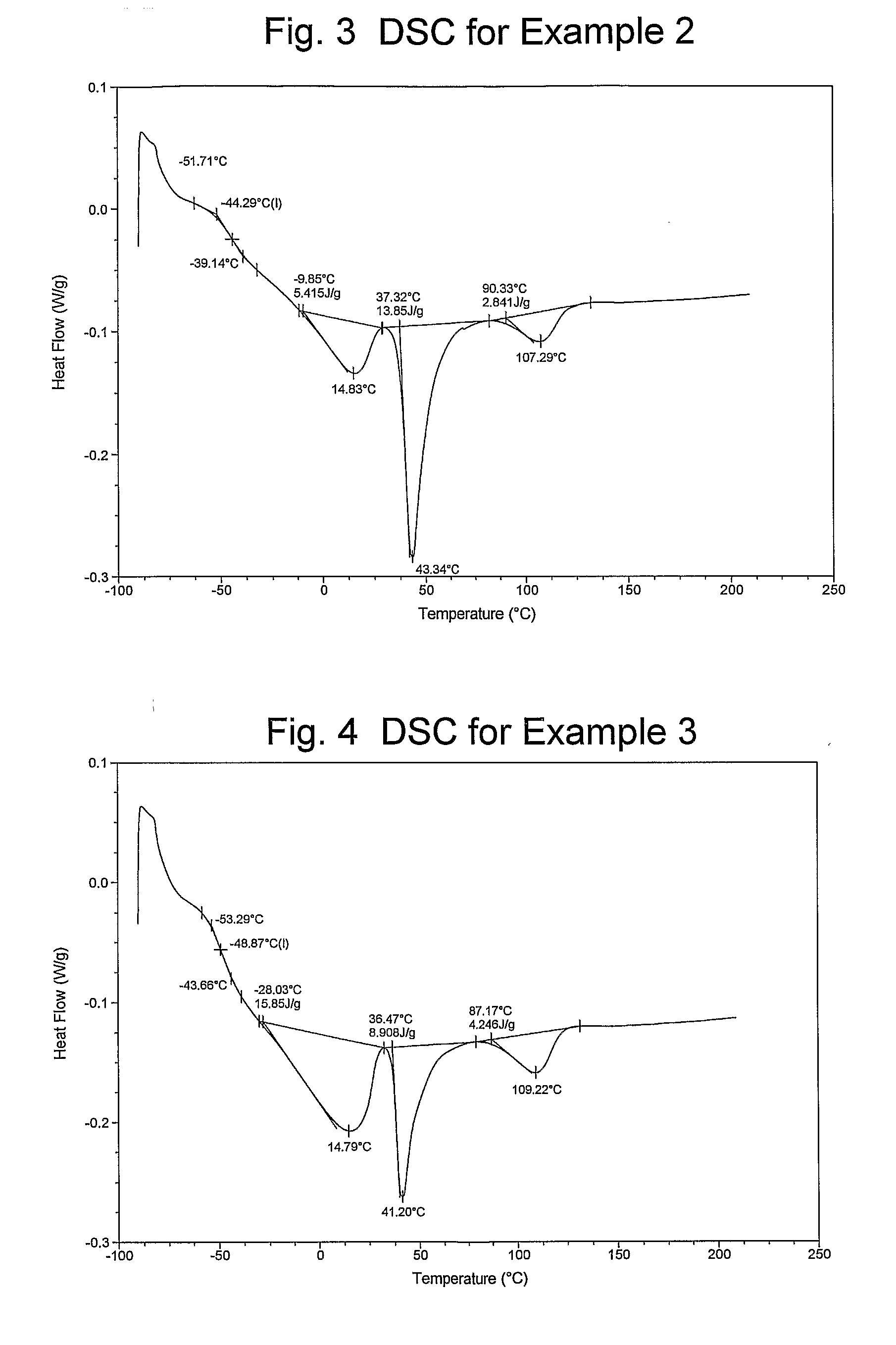

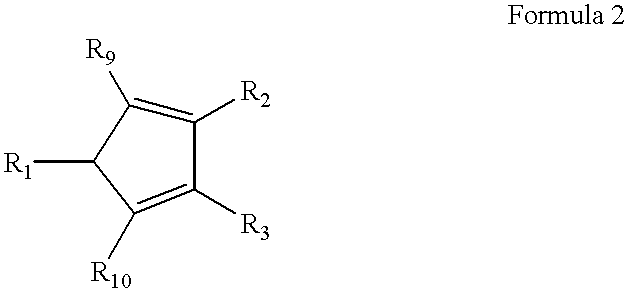

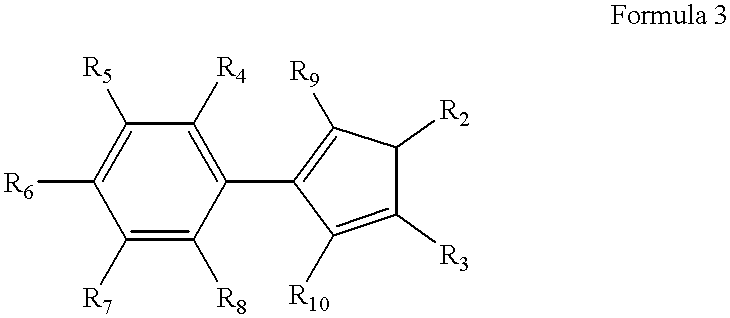

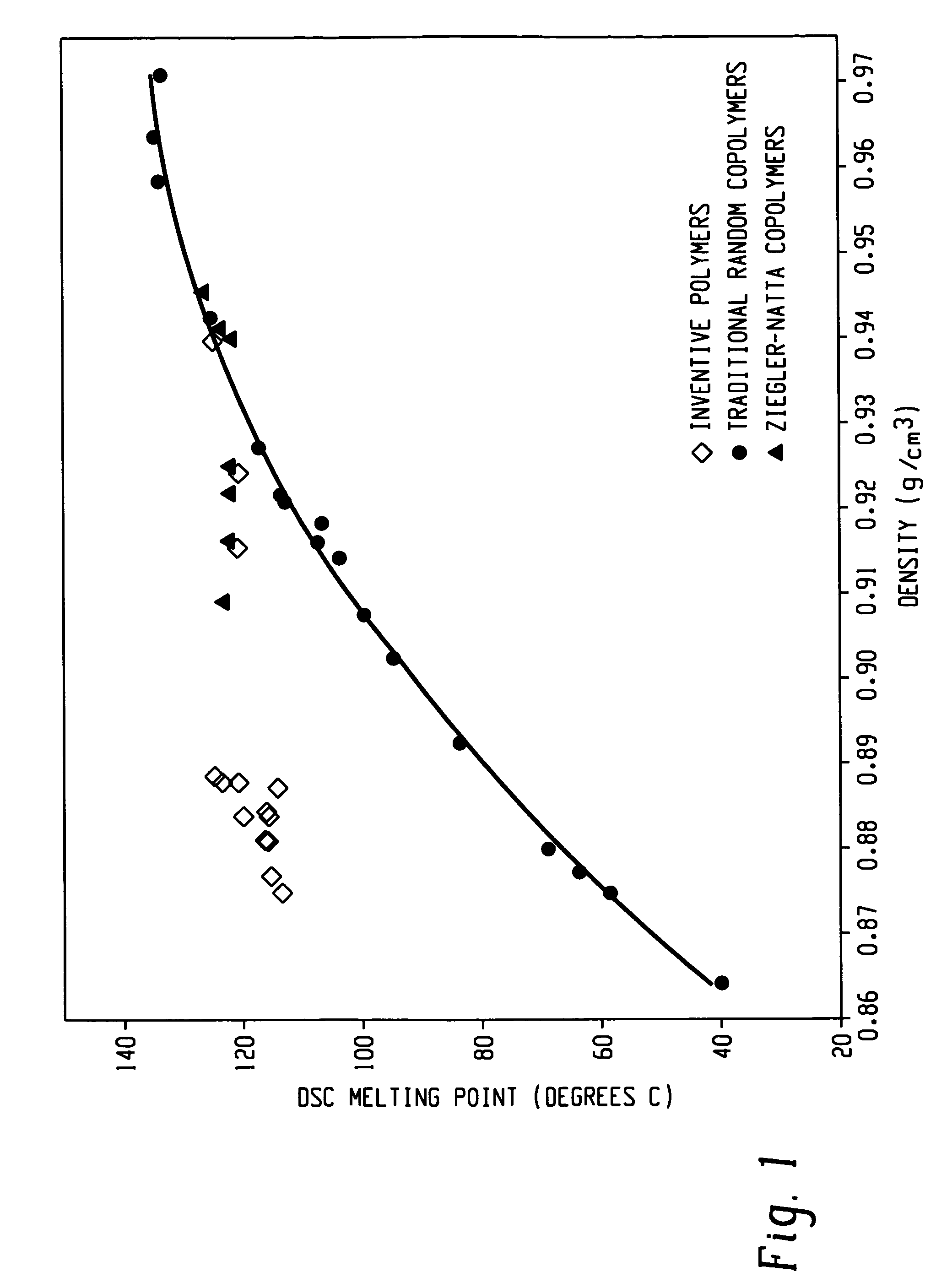

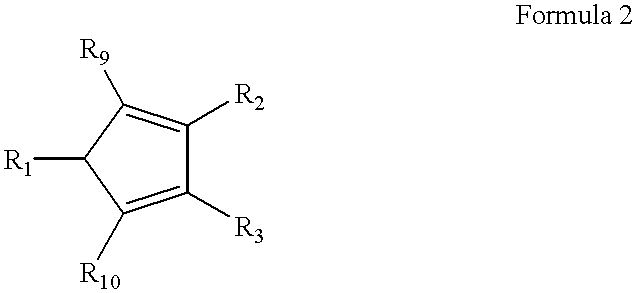

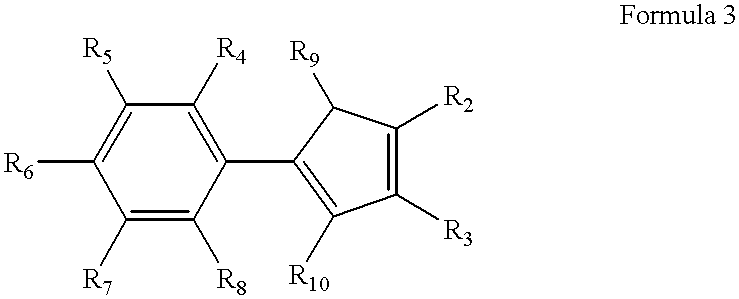

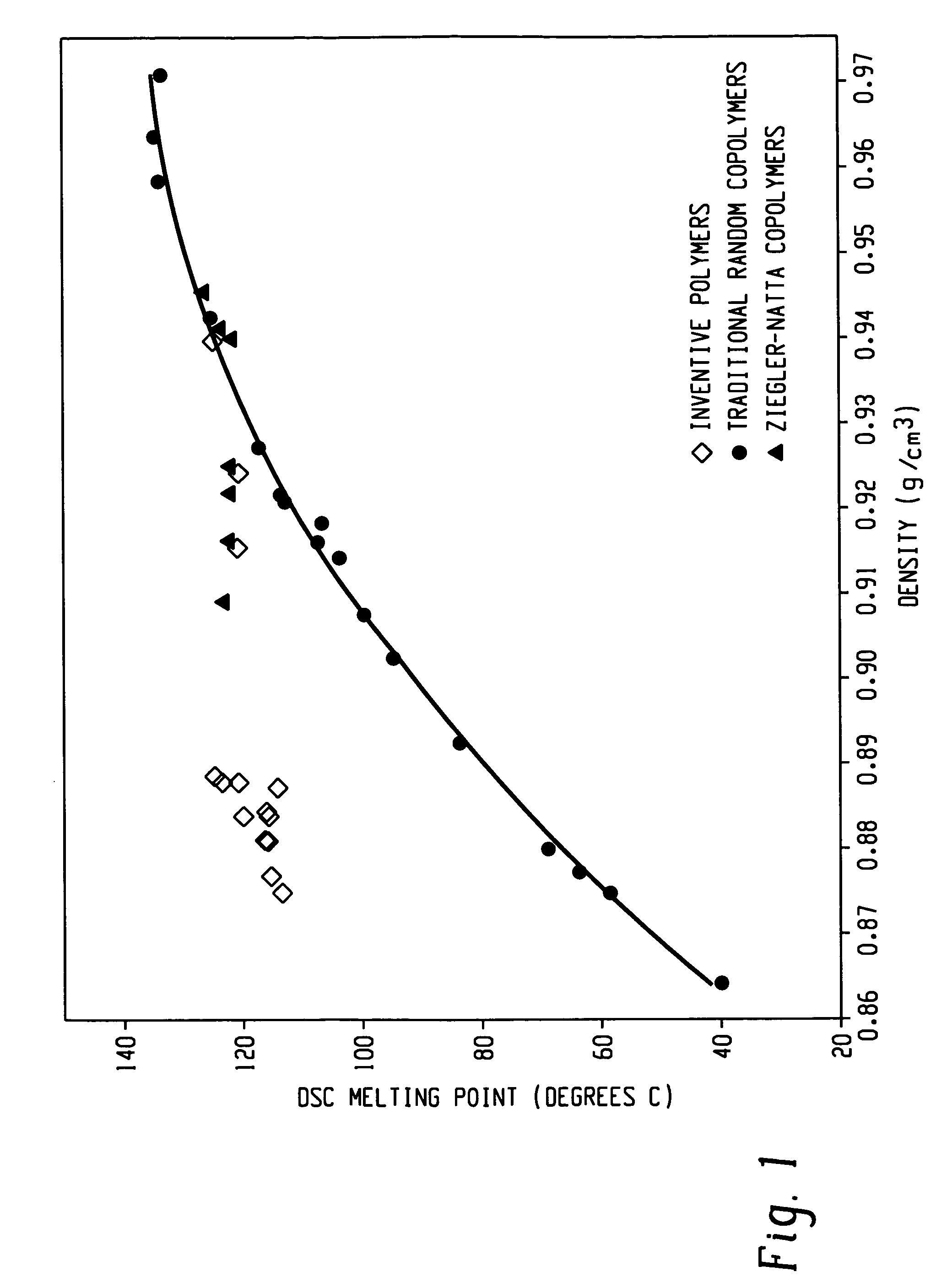

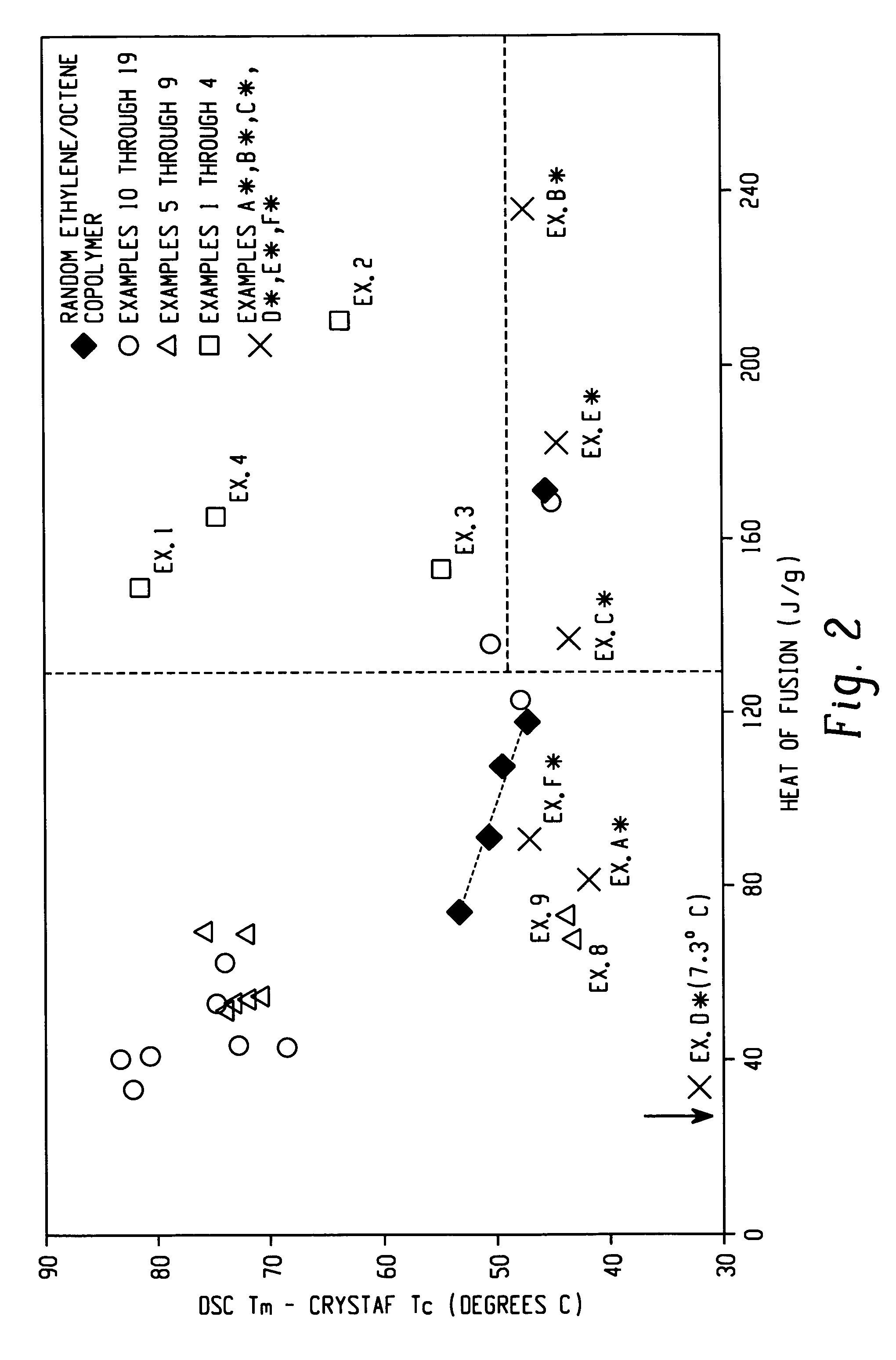

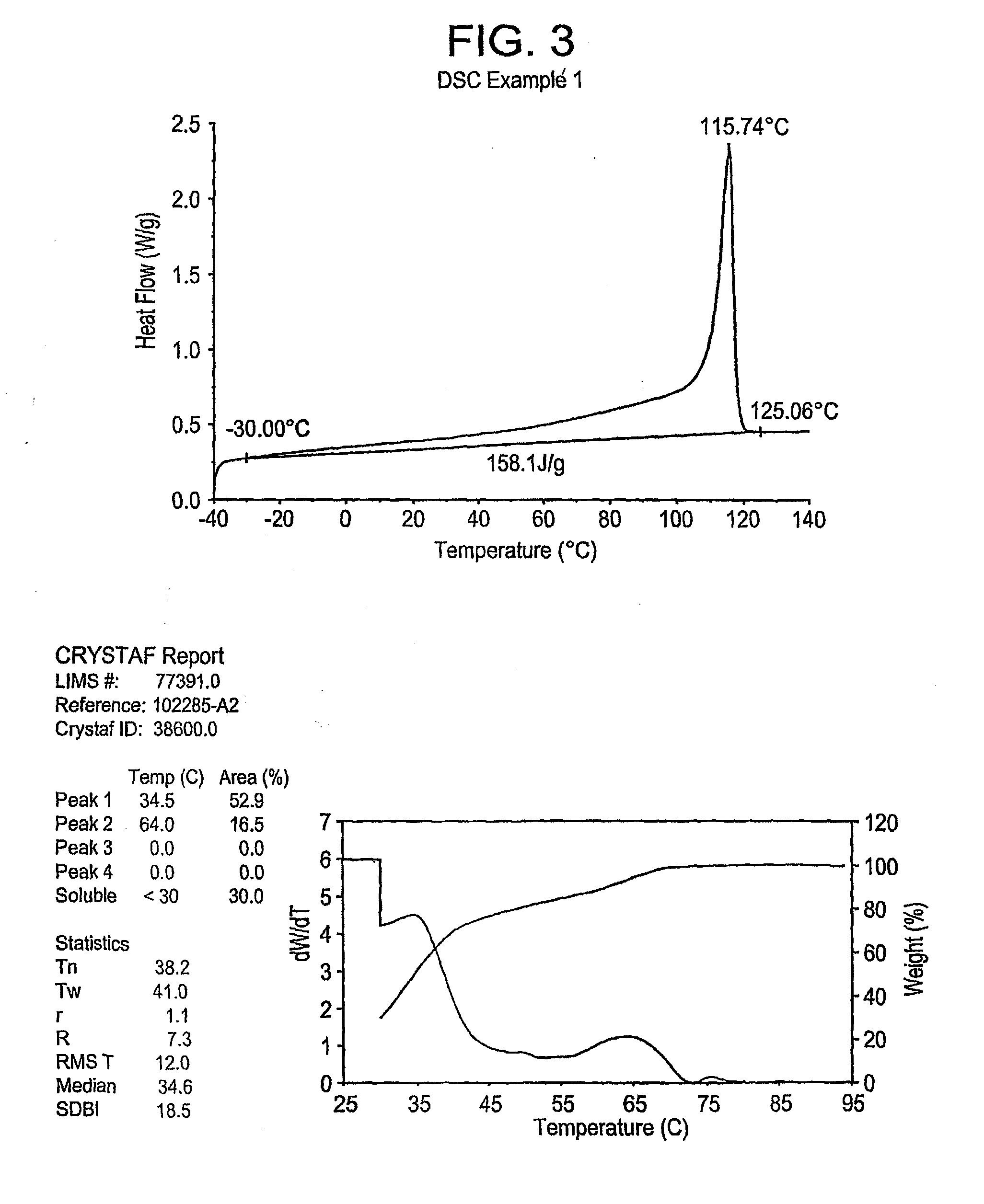

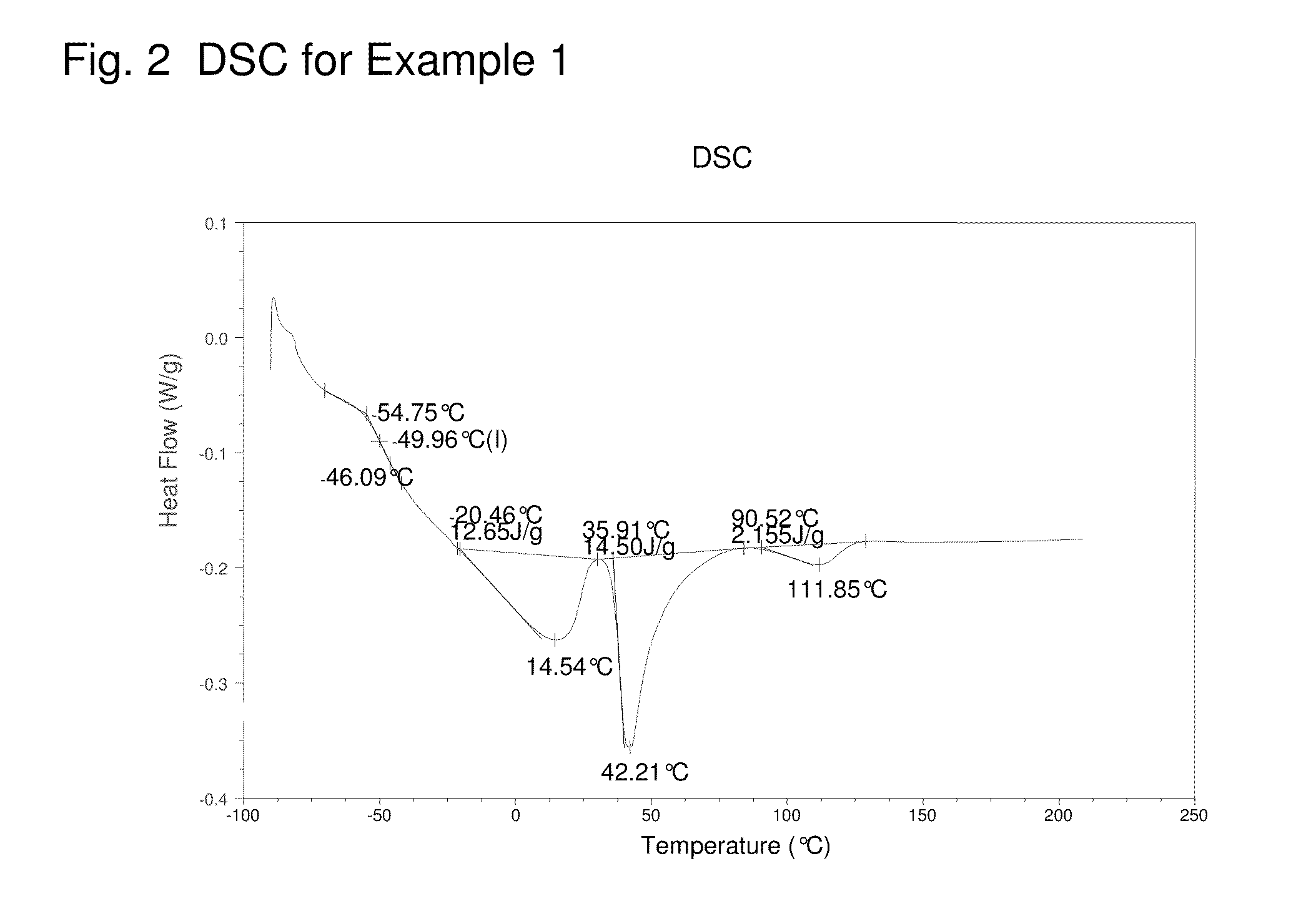

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

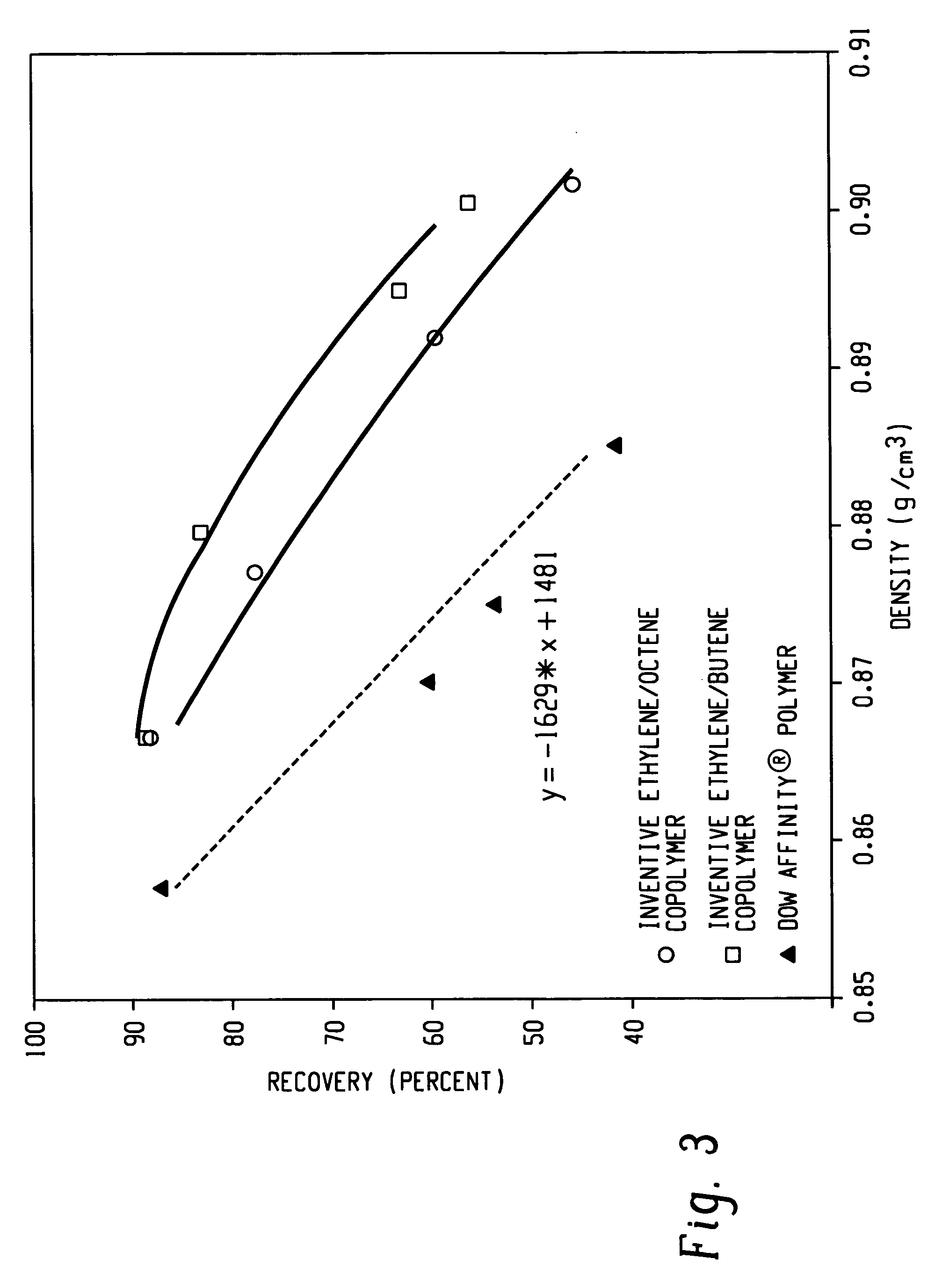

Anti-blocking compositions comprising interpolymers of ethylene/alpha-olefins

Owner:DOW GLOBAL TECH LLC

Foams made from interpolymers of ethylene/alpha-olefins

Foamable compositions and foams comprise at least an ethylene / α-olefin interpolymer. The foam has a density from greater than 150 to about 500 kg / m3. The foamable compositions further comprise a blowing agent and a crosslinking agent. The ethylene / α-olefin interpolymers are a multi-block copolymer comprising at least one soft block and at least one hard block. Methods of making the foamable compositions and foams; and foamed articles made from the foams are also described.

Owner:DOW GLOBAL TECH LLC

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6518378B2Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerPolyolefin

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:BP AMOCO CORP +1

Anti-blocking compositions comprising interpolymers of ethylene/alpha-olefins

Owner:DOW GLOBAL TECH LLC

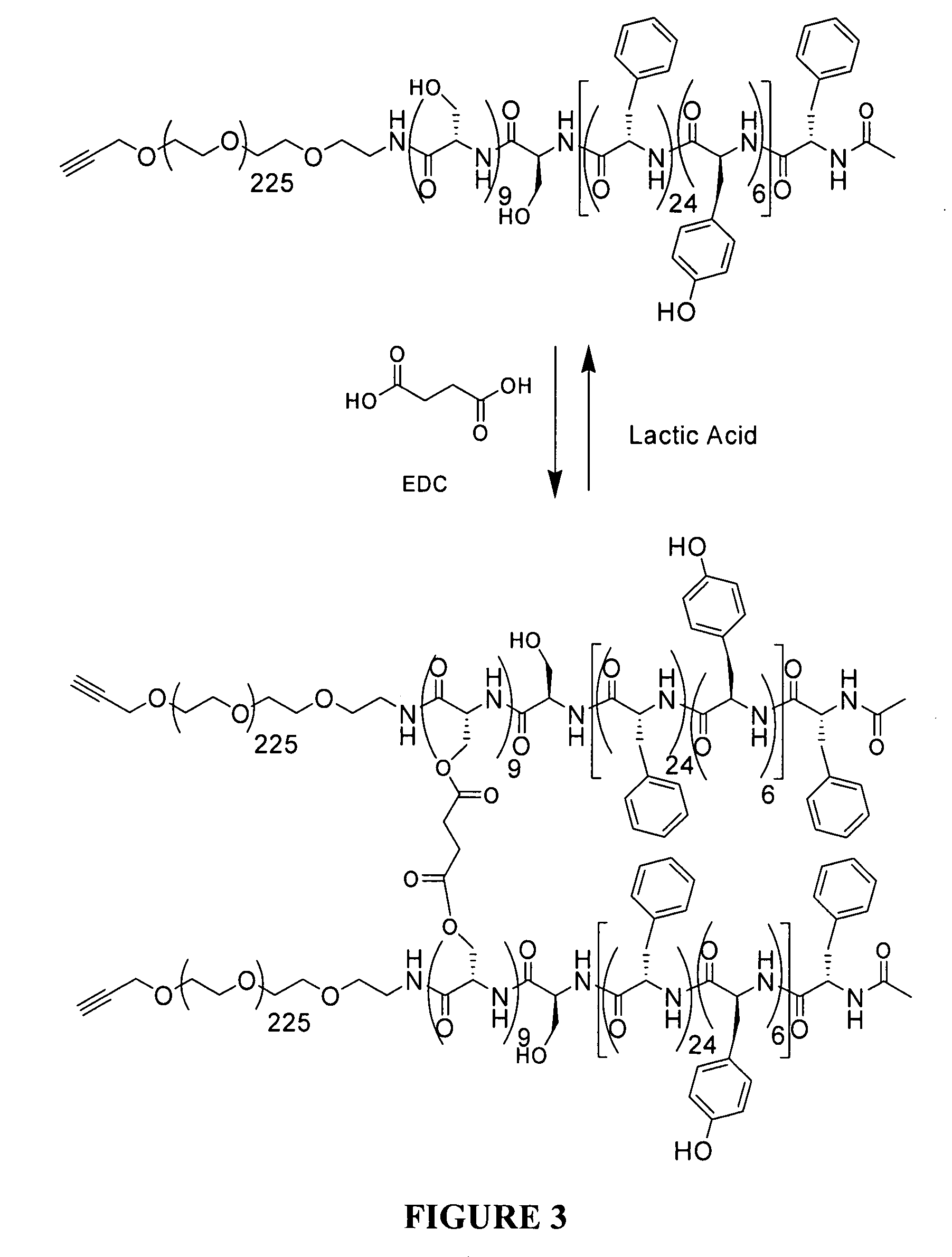

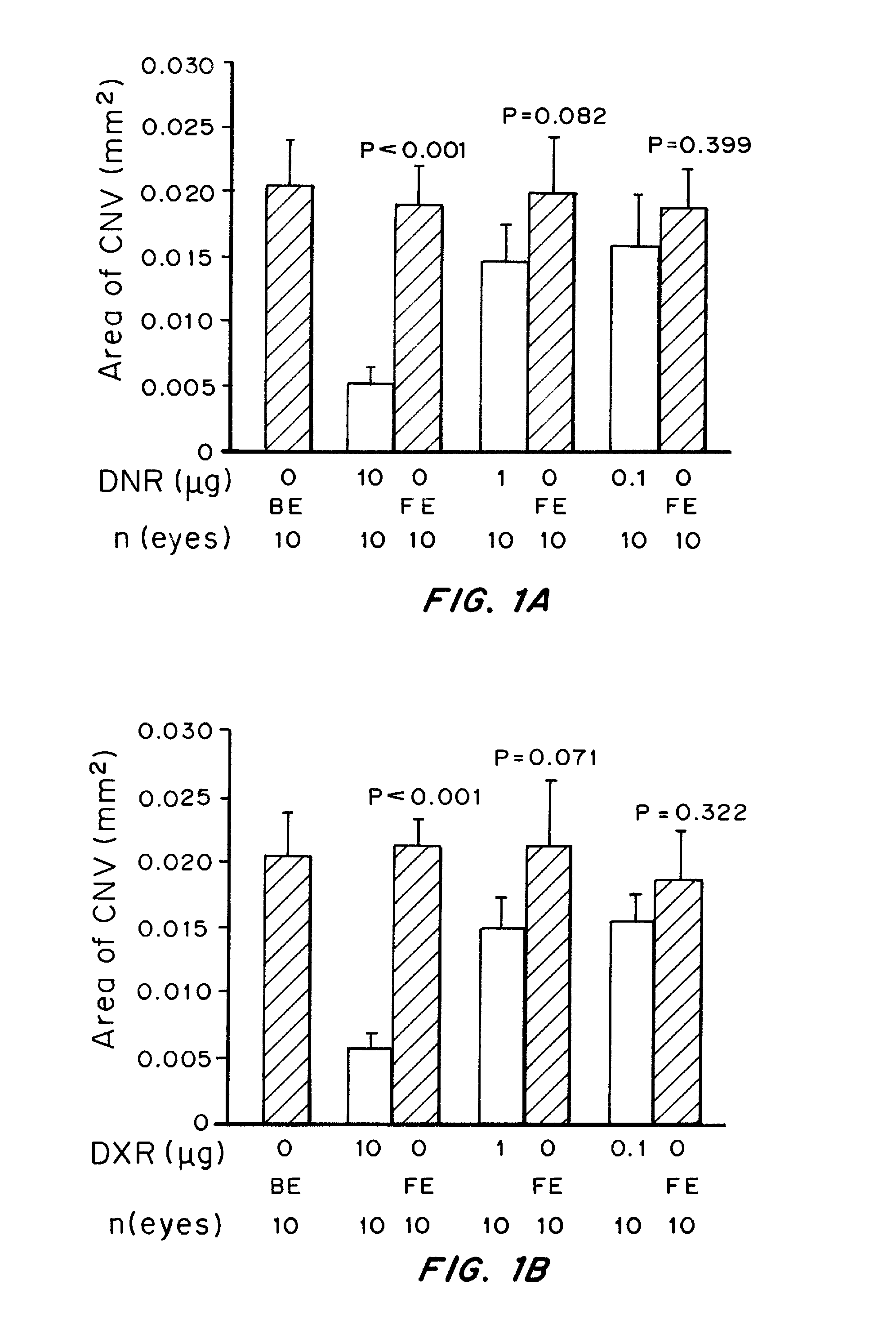

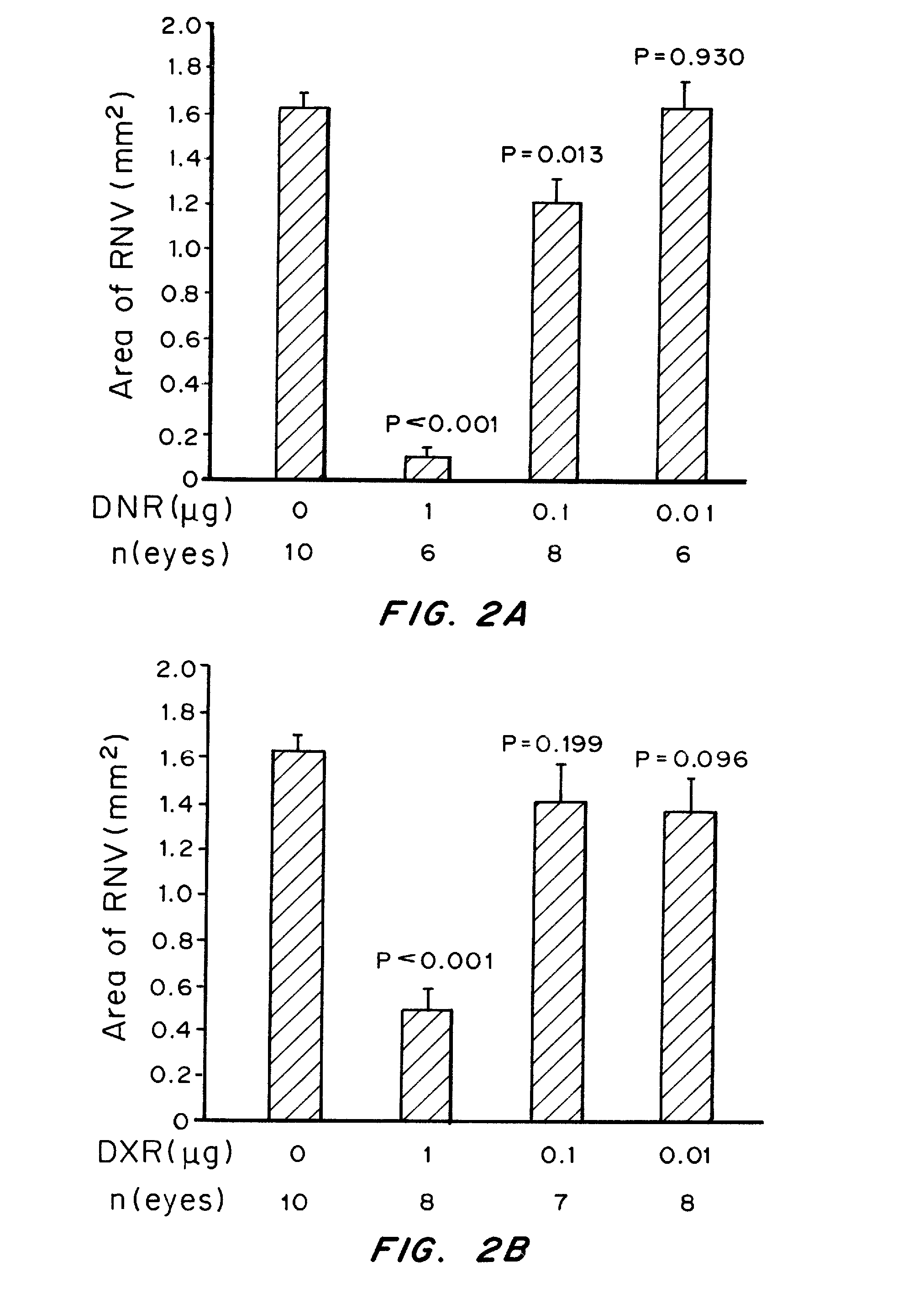

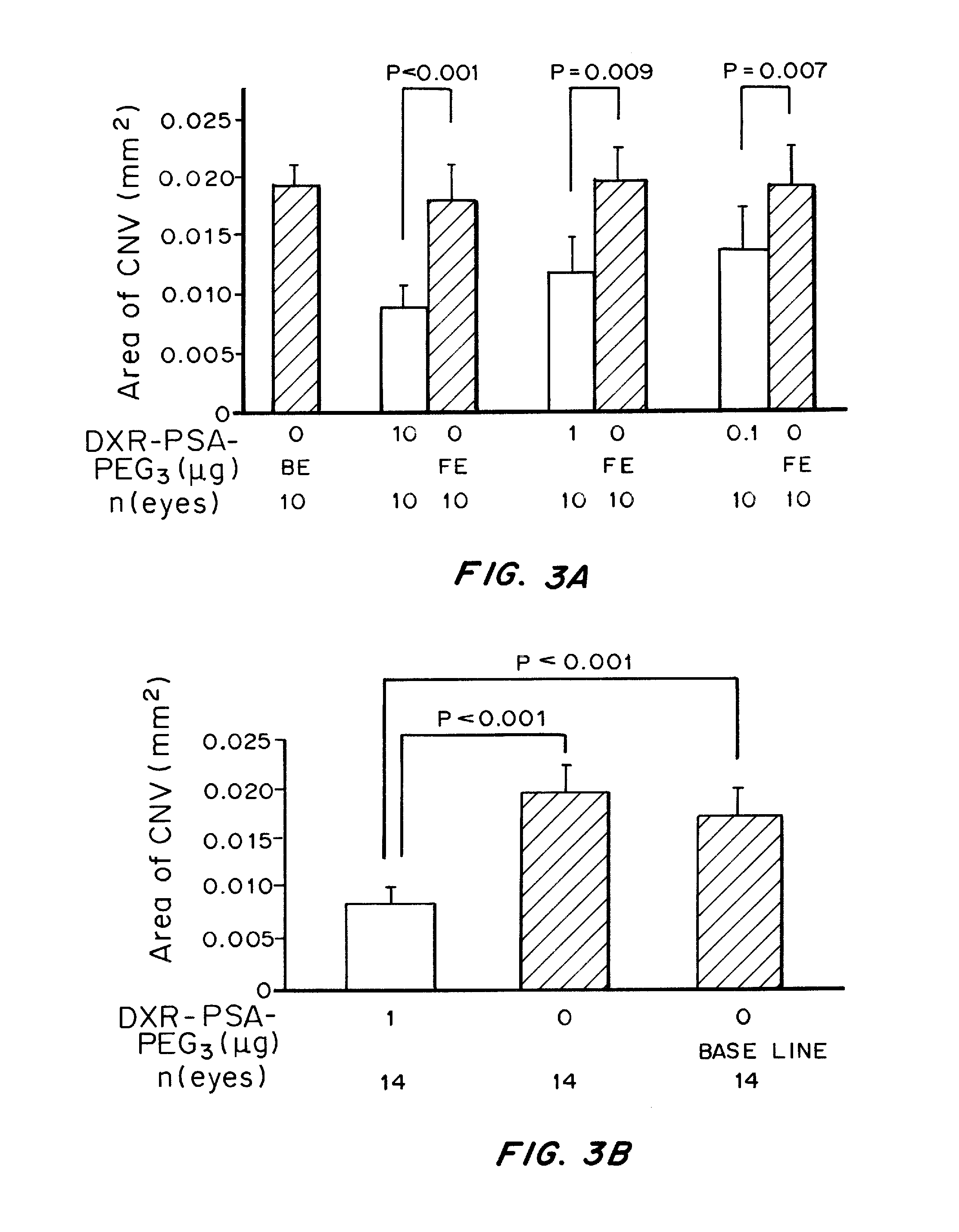

Non-Linear Multiblock Copolymer-Drug Conjugates for the Delivery of Active Agents

ActiveUS20130272994A1Improve propertiesControlled drug and drug release profilePowder deliverySenses disorderUveitisDisease

Non-linear multiblock copolymer-drug conjugates for the treatment and prevention of diseases and disorders of the eye are provided. The polymer-drug conjugates can form nanoparticles, microparticles, and implants that are capable of effectively delivering therapeutic levels of one or more active agents for an extended period of time. Administration to the eye of an active agent in the form of a non-linear multiblock copolymer-drug conjugate produces decreased side effects when compared to administration of the active agent alone. Also provided are methods of treating intraocular neovascular diseases, such as wet age-related macular degeneration as well as diseases and disorders of the eye associated with inflammation, such as uveitis.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

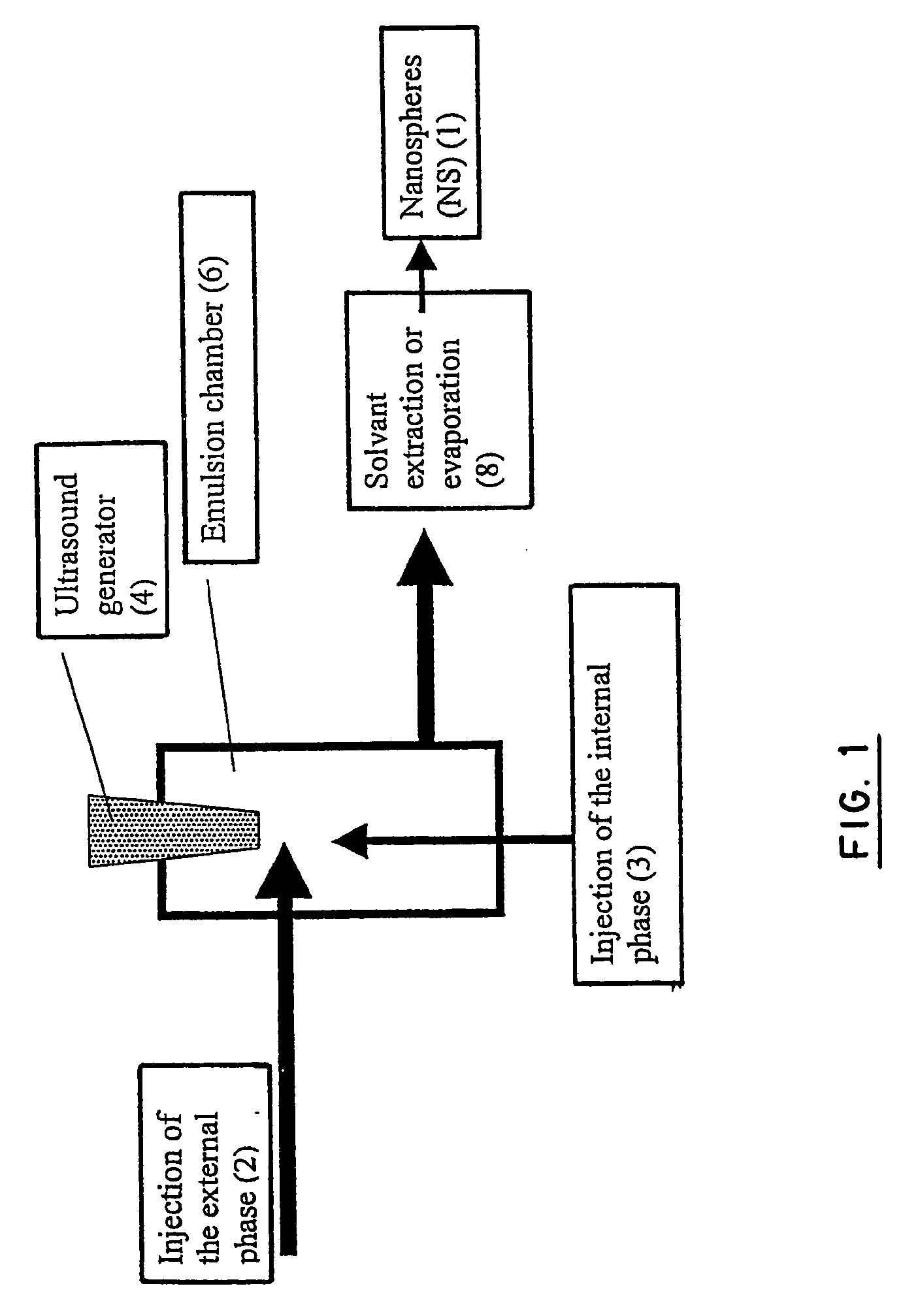

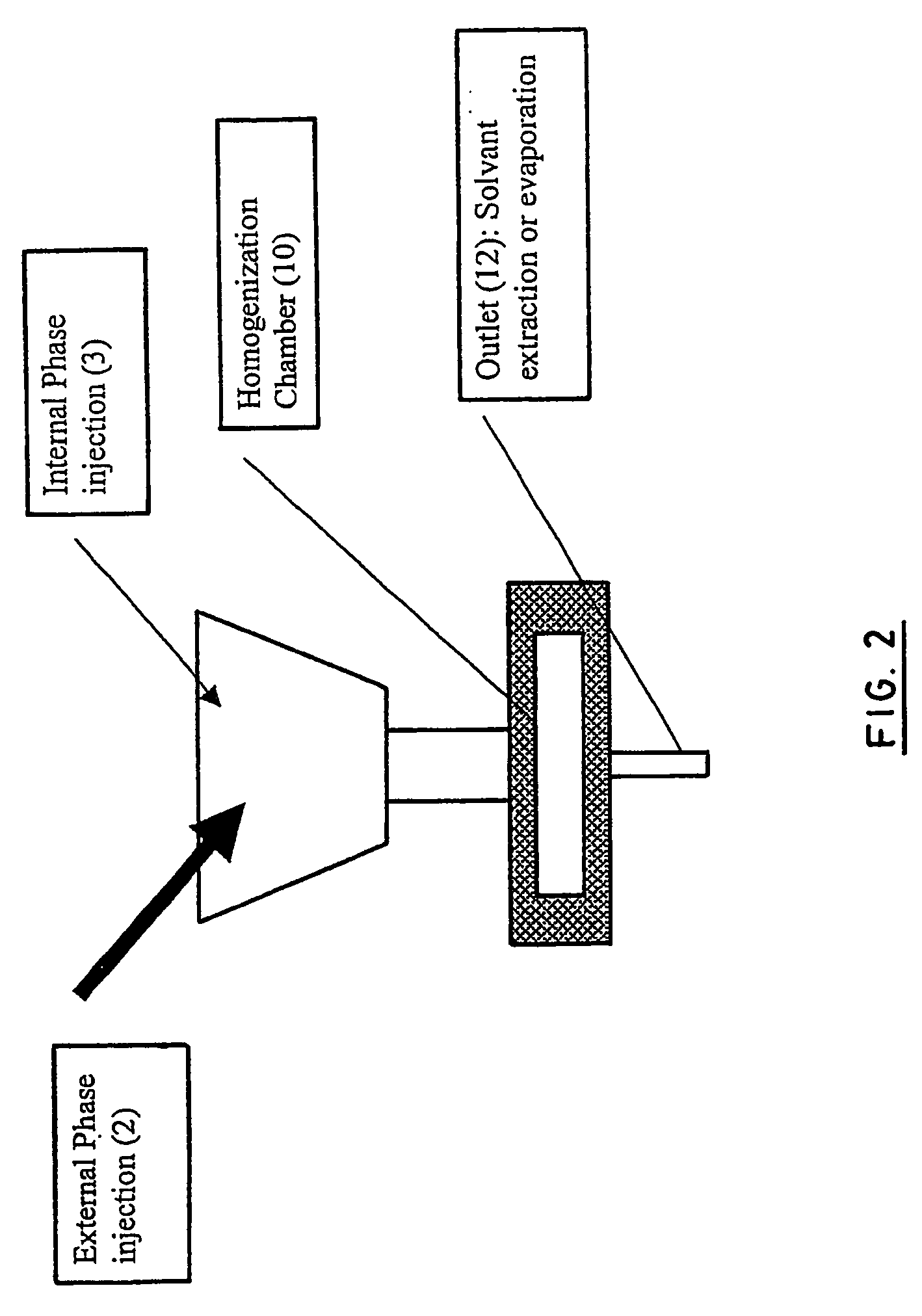

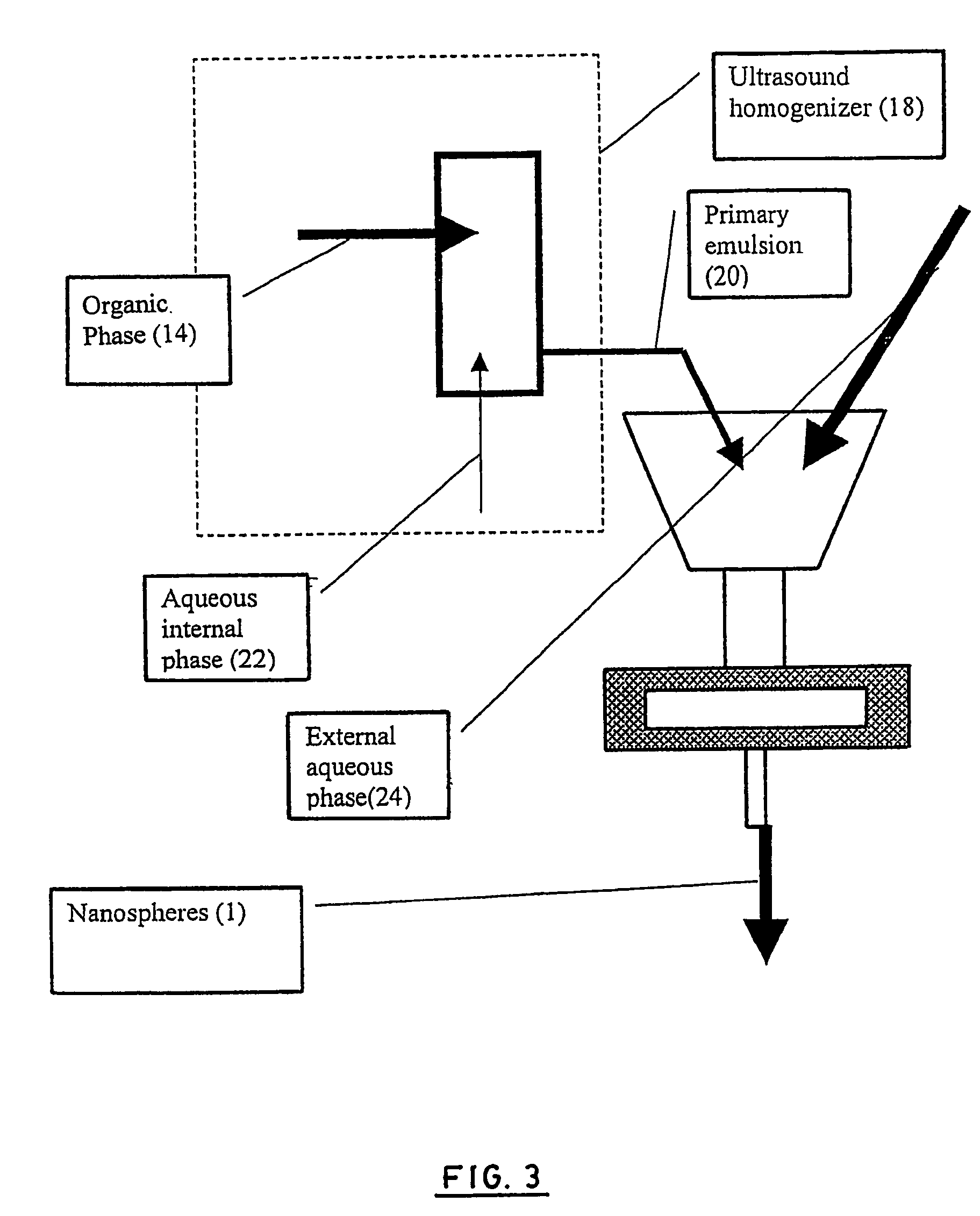

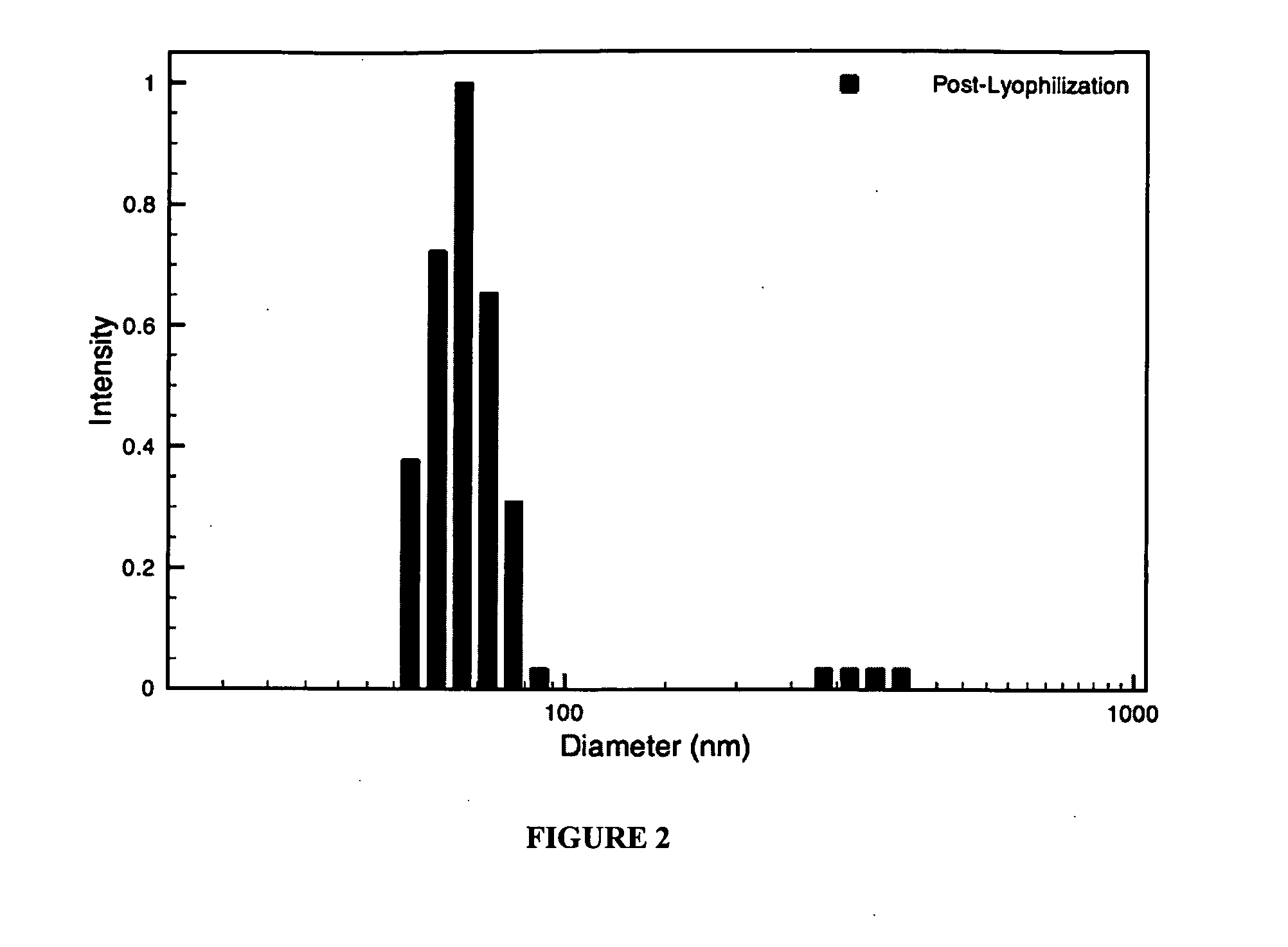

Stealthy polymeric biodegradable nanospheres and uses thereof

InactiveUS20060165987A1Maintain stable propertiesImprove drug deliverySynthetic resin layered productsCellulosic plastic layered productsPolyesterDrug compound

Disclosed herein are stealthy polymeric biodegradable nanospheres each comprising: (i) a polyester-polyethylene multiblock copolymer; (ii) optionally a polyester entangled with the multiblock copolymer to give rigidity to the nanospheres; and (iii) optionally a pharmaceutical compound incorporated therein. Also disclosed is the use of such nanospheres for the preparation of a medicament having a long-term and non-toxic release of a pharmaceutical compound into a mammal, and the method for preparing a stealthy polymeric biodegradable nanospheres.

Owner:VALORISATION RECH SOC & COMMANDITE

Catalyst composition comprising shuttling agent for higher olefin multi-block copolymer formation

ActiveUS7951882B2Improve efficiencyWoven fabricsNon-woven fabricsOlefin polymerization4-Methyl-1-pentene

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

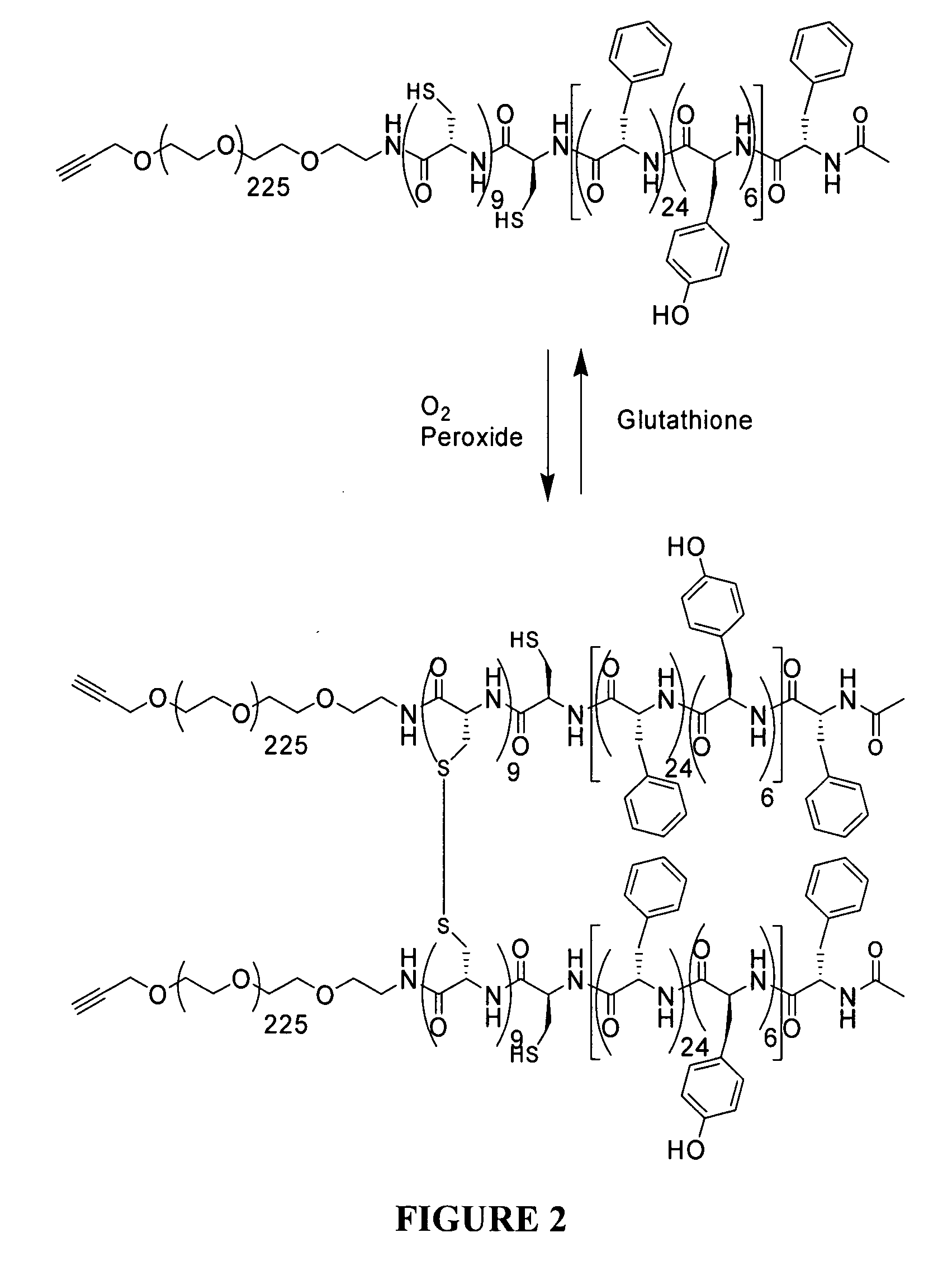

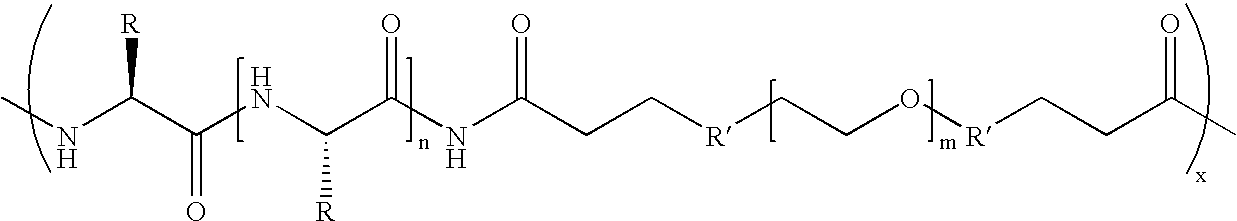

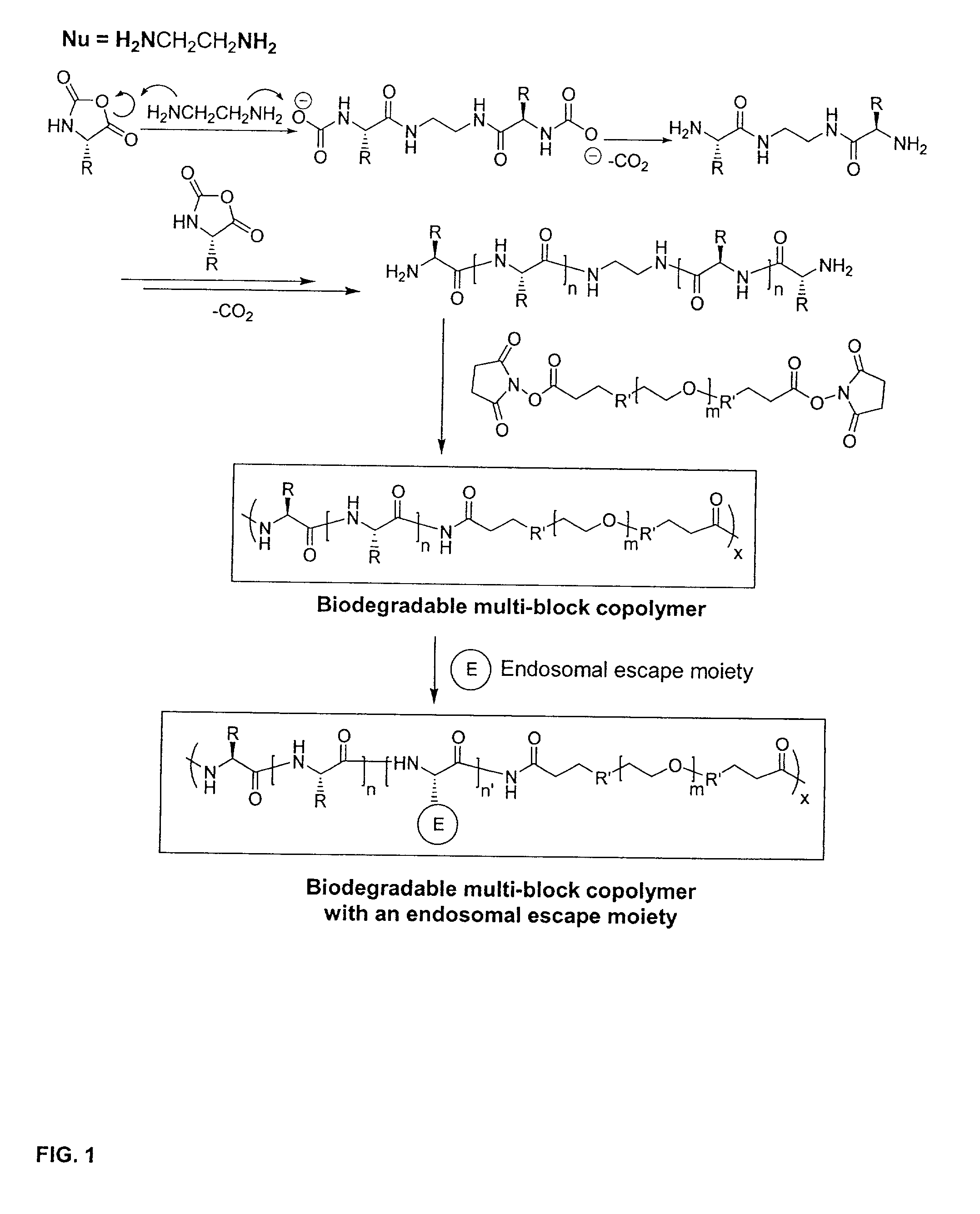

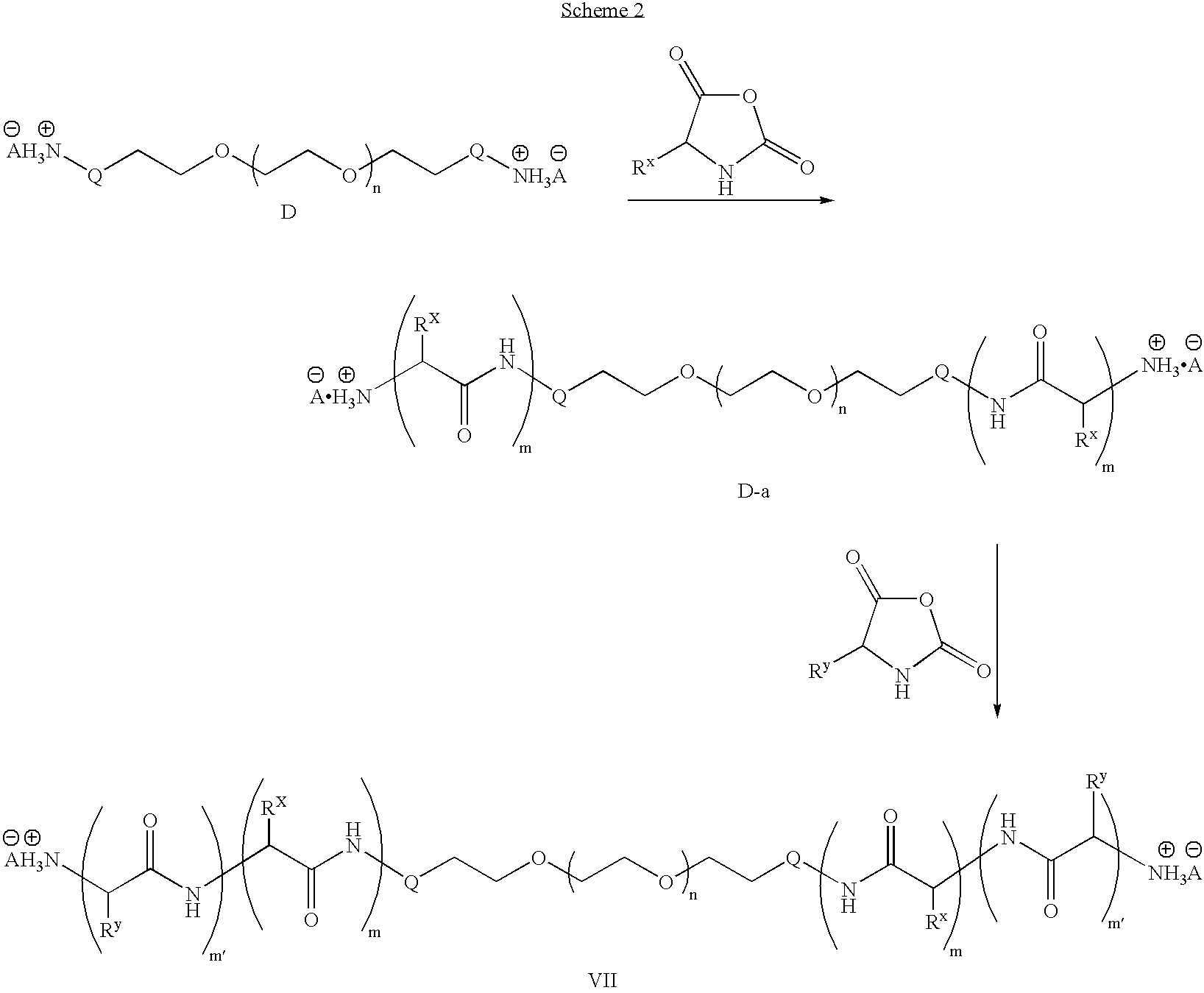

Biodegradable multi-block copolymers of poly(amino acid)s and poly(ethylene glycol) for the delivery of bioactive agents

InactiveUS20030147958A1Easy to chargeSmall sizePowder deliveryGenetic material ingredientsCarbamateHydrophilic polymers

This patent discloses the synthesis of a multi-block copolymer containing poly(amino acids) (PAA) and a hydrophilic polymer which are degradable under physiological conditions. Control over the degradation rate of the obtained copolymers is achieved by introducing ester, amide or urethane groups as a biodegradable linkage connecting the PAA and the hydrophilic polymer. The biodegradable multi-block copolymers display high transfection efficiency in plasmid delivery with low cytotoxicity.

Owner:EXPRESSION GENETICS INC

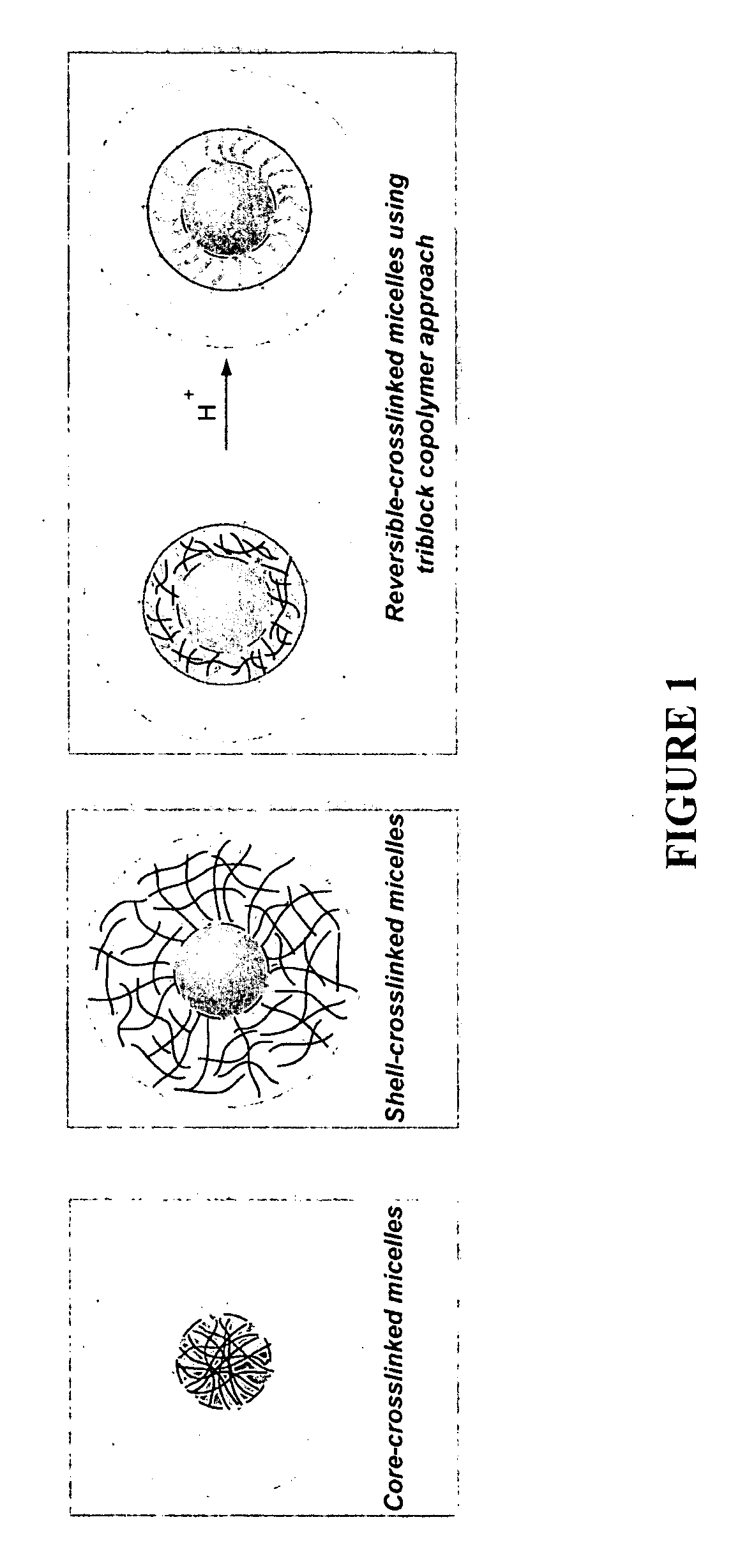

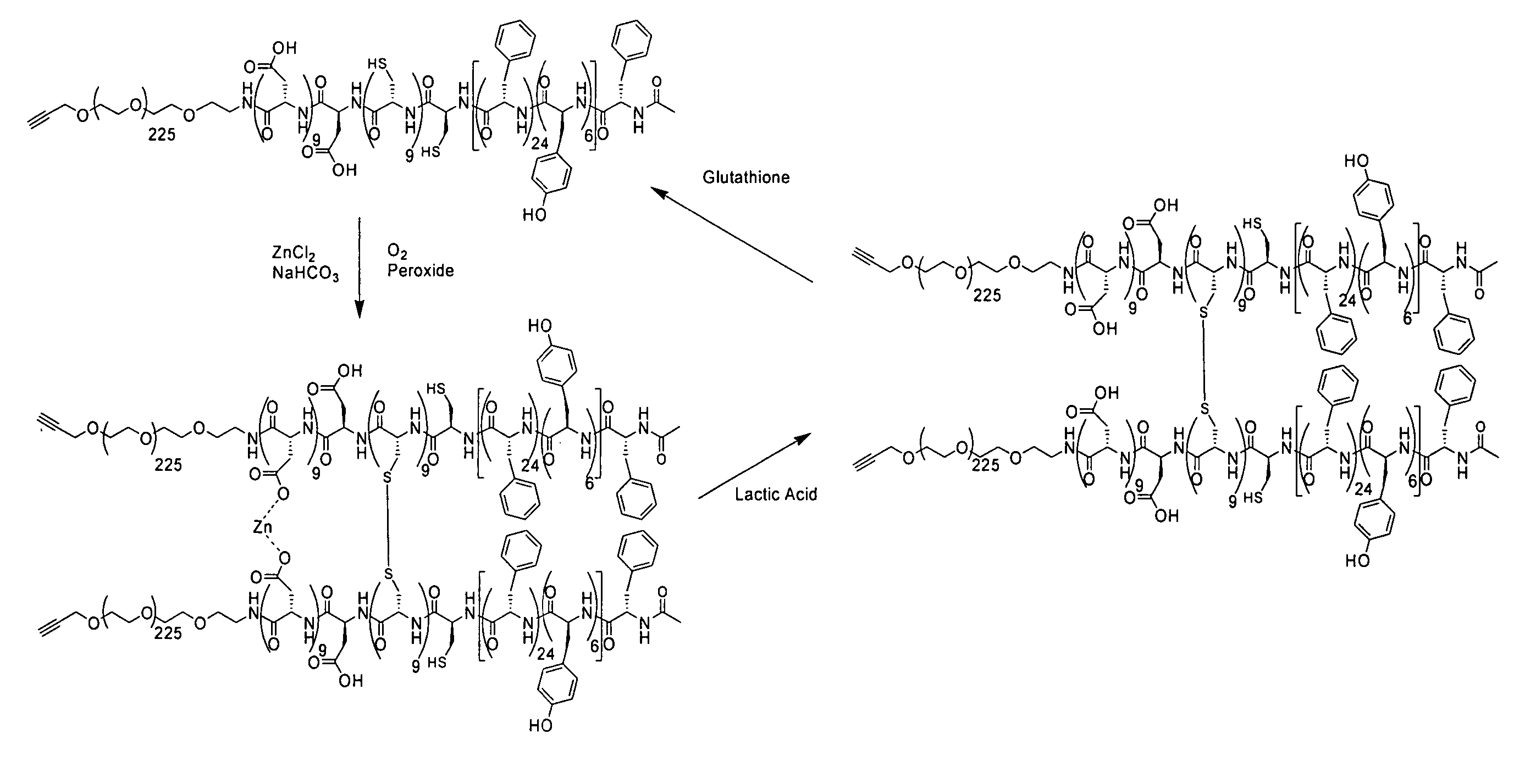

Polymeric micelles for drug delivery

Owner:INTEZYNE TECH INC

Hybrid block copolymer micelles with mixed stereochemistry for encapsulation of hydrophobic agents

Owner:INTEZYNE TECH INC

Essentially gas-impermeable thermoplastic elastomer

A thermoplastic elastomer (“TPE”) which is oxygen-permeable is provided with excellent barrier properties against oxygen by melt-blending with a liquid polyisobutene oil plasticizer in an amount insufficient to render the plasticized elastomer tacky. If made tacky, enough detackifier is used to allow the product to be formed into a removable seal. The TPE may be a conventional thermoplastic vulcanizate or a block copolymer of a vinylaromatic compound, typically styrene, and a conjugated diene, typically butadiene or isoprene, or mixtures thereof; the block may be a diblock, triblock or higher block, but the preferred polyblock copolymer is a triblock with styrene end-blocks and a butadiene / isoprene mid-block. Preferably the diene mid-block is hydrogenated to provide a poly(lower)monoolefin mid-block. When the TPE is a TPV, some or all of the mineral oil used to make the TPV processable may also be substituted with the polyisobutene plasticizer. The elastomeric product is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:AVIENT CORP

Foams made from interpolymers of ethylene/α-olefins

Foamable compositions and foams comprise at least an ethylene / α-olefin interpolymer. The foam has a density from greater than 150 to about 500 kg / m3. The foamable compositions further comprise a blowing agent and a crosslinking agent. The ethylene / α-olefin interpolymers are a multi-block copolymer comprising at least one soft block and at least one hard block. Methods of making the foamable compositions and foams; and foamed articles made from the foams are also described.

Owner:DOW GLOBAL TECH LLC

Catalyst composition comprising shuttling agent for ethylene copolymer formation

ActiveUS7915192B2Improve efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChain walkingOlefin polymerization

A composition for use in forming a multi-block copolymer from a single polymerizable monomer, said copolymer containing therein two or more segments or blocks differing in branching index, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first olefin polymerization catalyst, (B) a second olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, at least one of catalyst (A) or catalyst (B) being capable of forming a branched polymer by means of chain walking or reincorporation of in situ formed olefinic polymer chains, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

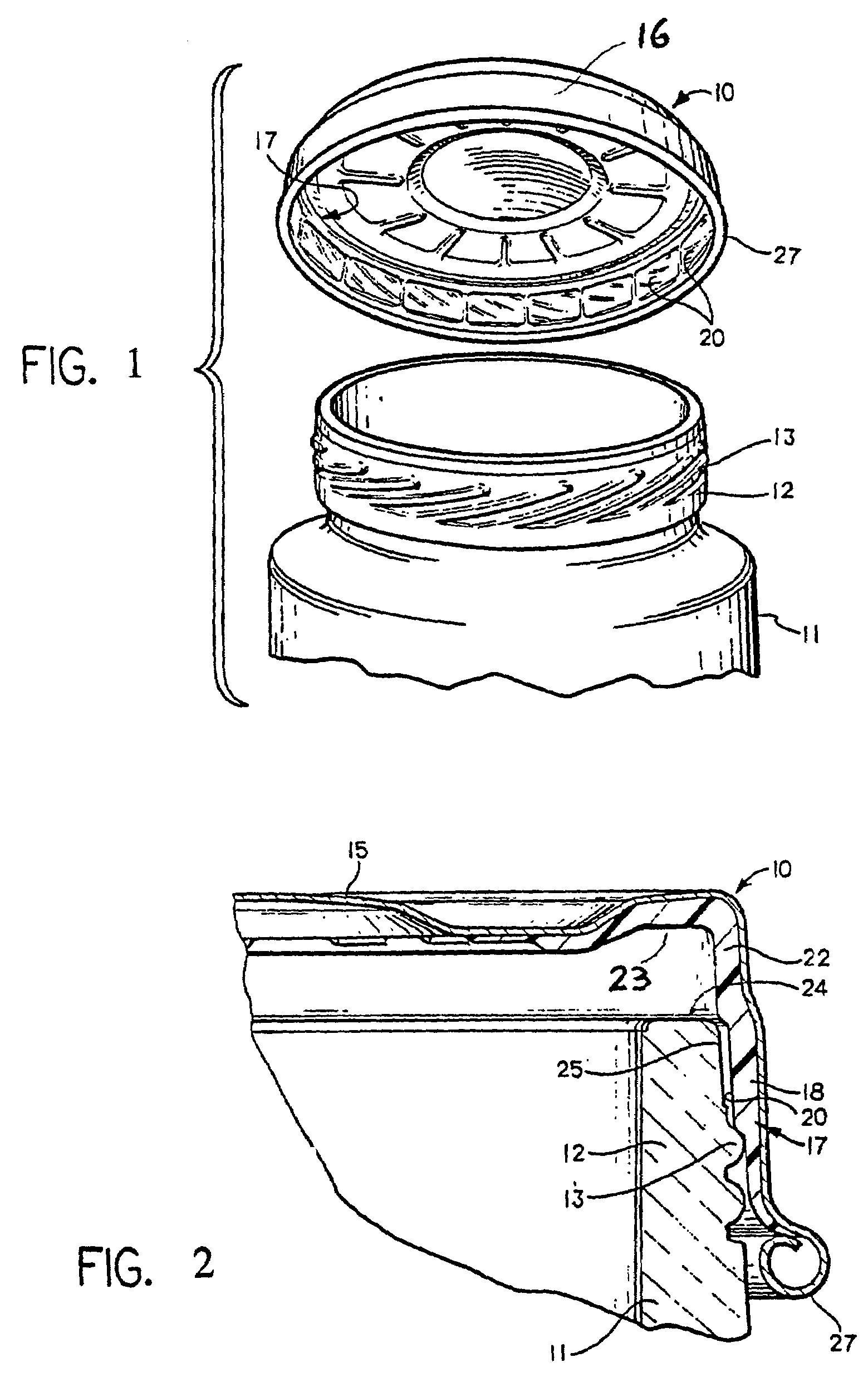

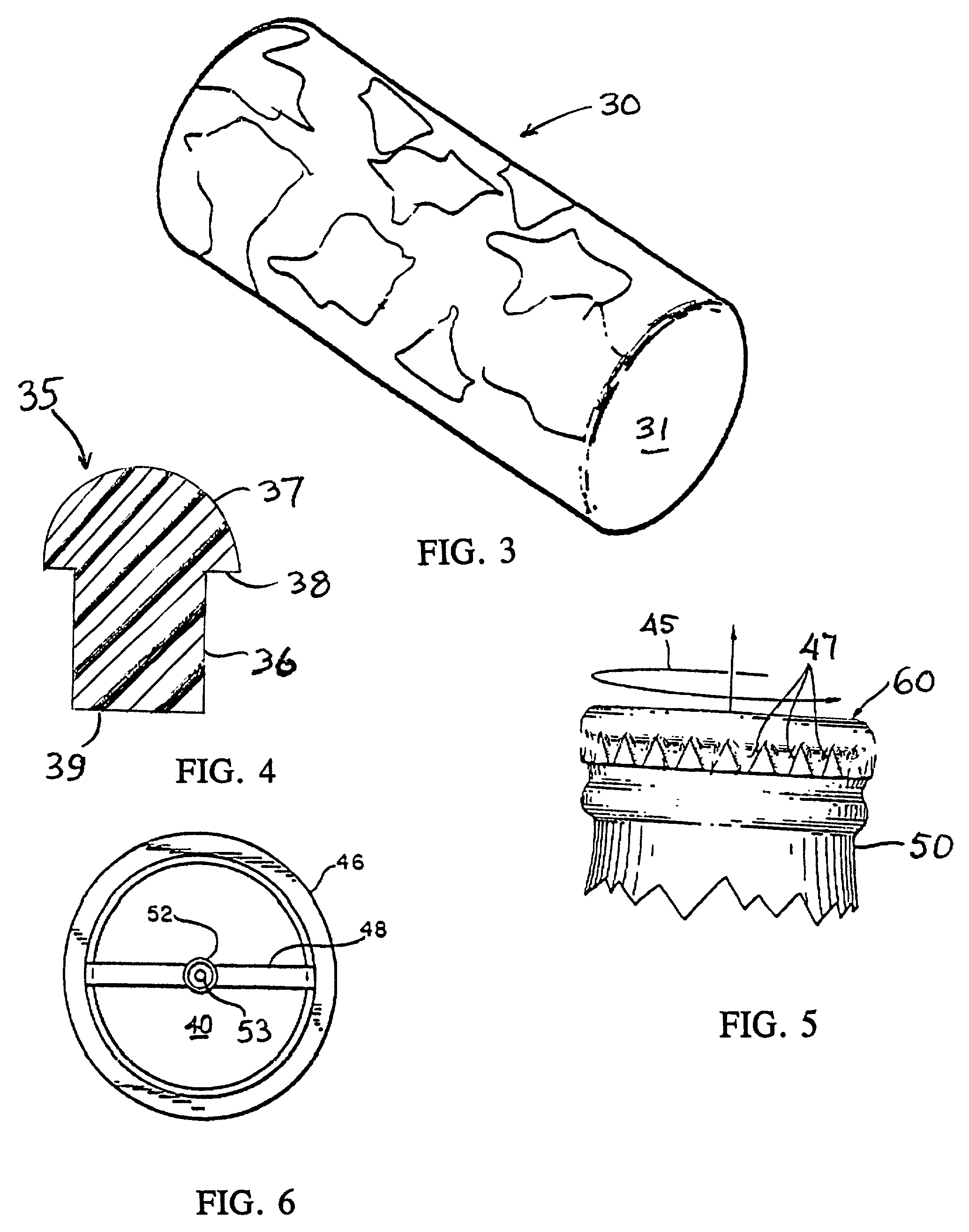

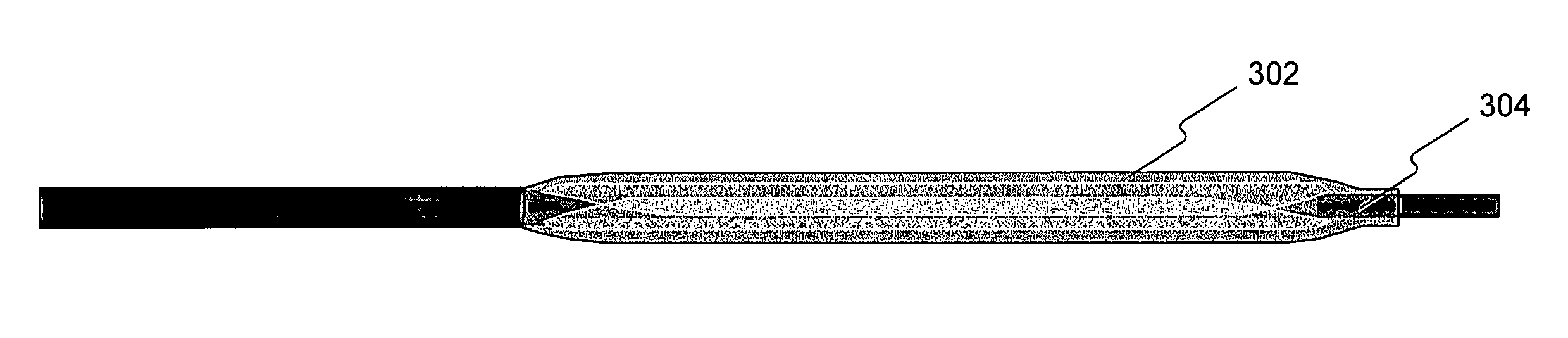

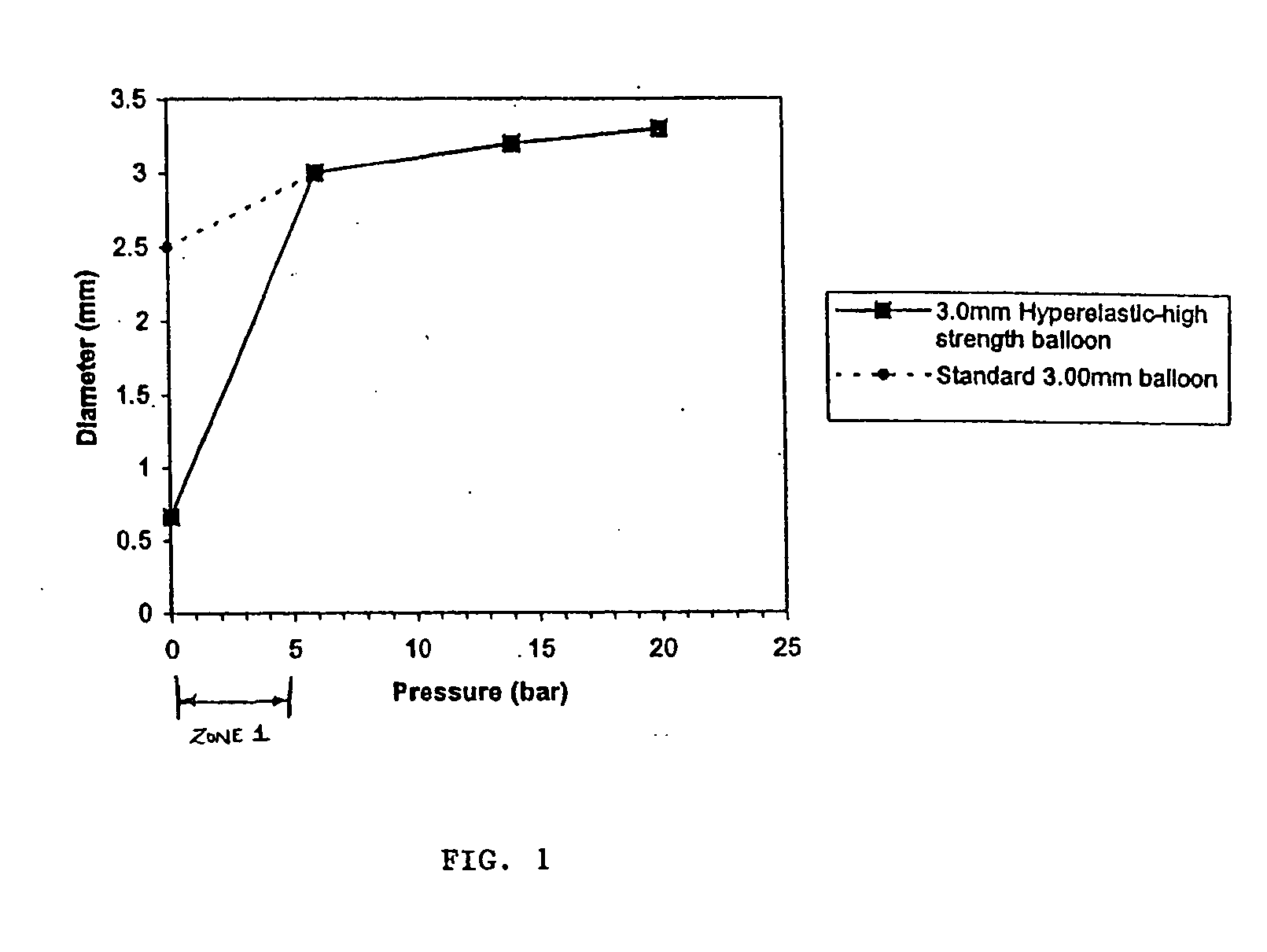

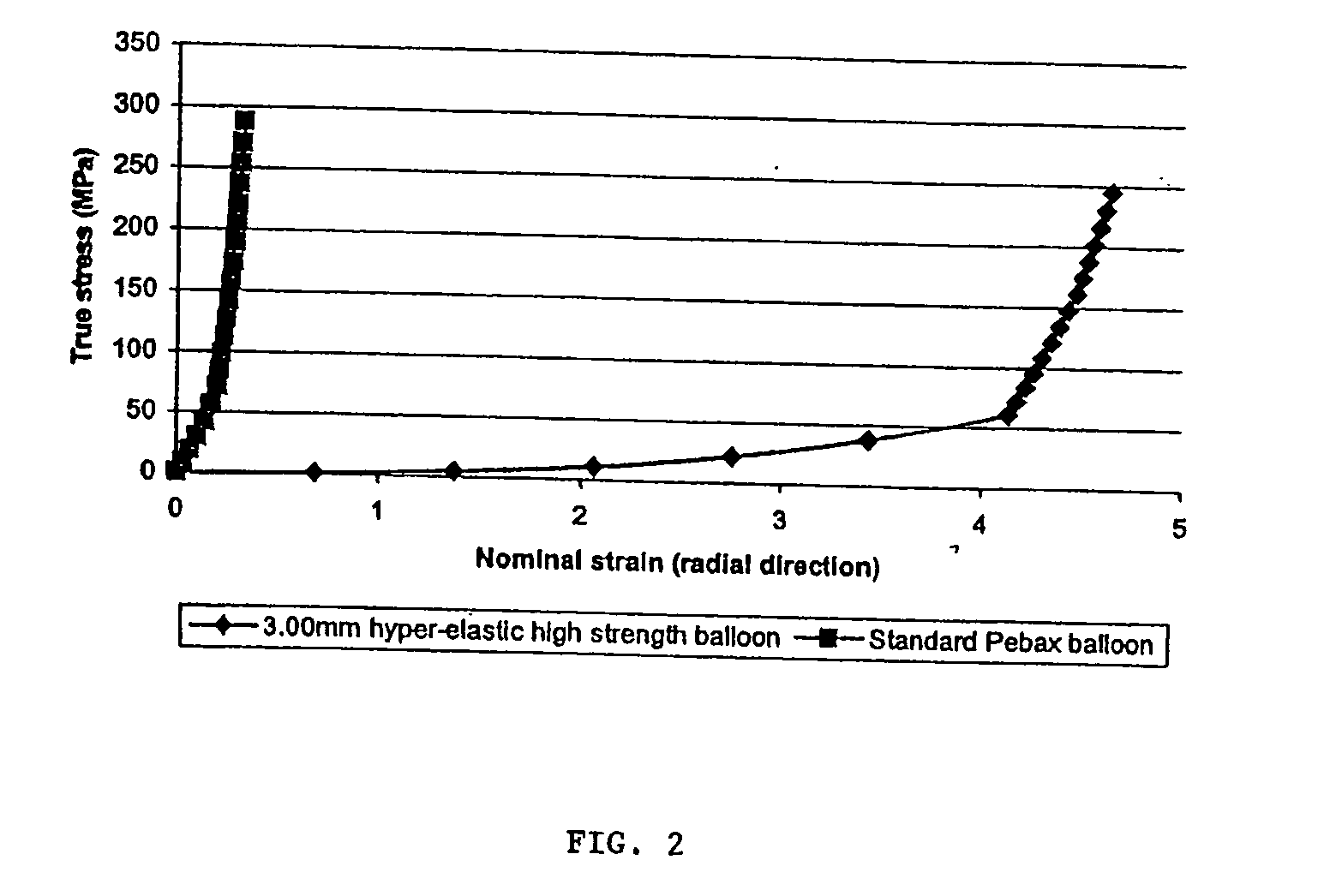

Process for producing a hyper-elastic, high strength dilatation balloon made from multi-block copolymers

InactiveUS20050098914A1Increase elasticityLow profileCatheterThin material handlingHyper elasticUltimate tensile strength

A self-wrapping dilatation balloon comprising a multiblock copolymer having high elasticity and elastic recovery from nominal strains greater than about 30% is described. Also described herein, is a polymeric extrudate for making a dilatation balloon comprising a multiblock copolymer having tensile strength in the range of about 50 MPa to about 450 MPa, strain at break in the range of about 50% to about 600% and substantially complete elastic recovery from nominal strains of at least about 30%. The extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. Also described herein is a process for producing a polymeric extrudate for use as a dilatation balloon. The process comprises extruding a multiblock copolymer mixture or composition to form an extrudate. The extruding is done such that the extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. After extrusion, the process optionally comprises the steps of drawing and coagulating the extrudate.

Owner:VARMA ASHISH +5

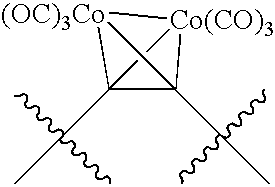

Synthesis of hybrid block copolymers and uses thereof

ActiveUS20060172914A1Peptide/protein ingredientsGroup 8/9/10/18 element organic compoundsPolymer scienceMultiblock copolymer

Owner:INTEZYNE TECH INC

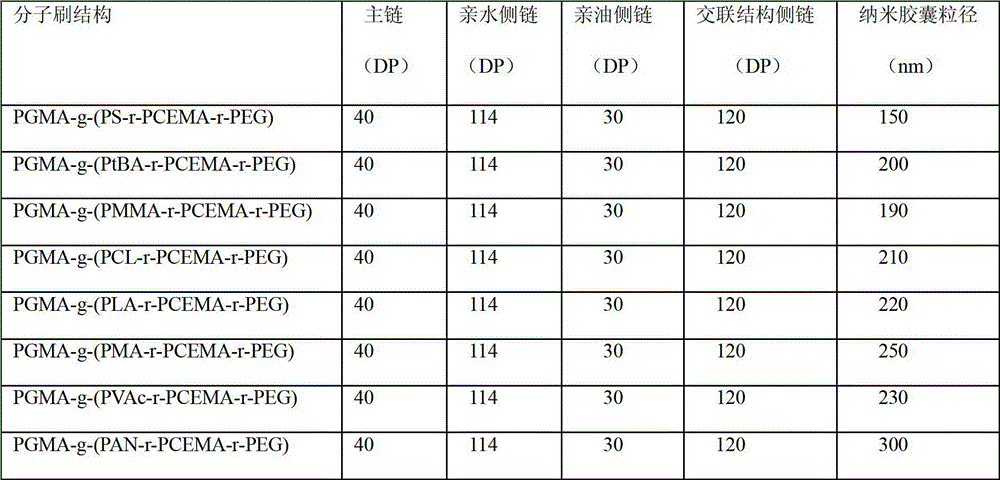

Amphiphilic ternary polymer brush and nano capsule

ActiveCN102911370AEasy to adjust and control the sizeThe particle size is easy to adjust and controllableMicroballoon preparationMicrocapsule preparationPolymer scienceSide chain

The invention discloses an amphiphilic ternary polymer brush and a nano capsule. The amphiphilic ternary polymer brush has the following general formula, wherein A is polymer main chain, B is lipophilic polymer side chain, C is photo-crosslinked polymer side chain, D is hydrophilic polymer side chain, and the side chains B, C and D are randomly grafted onto the main chain A; and the nano capsule is prepared through dispersing the amphiphilic ternary polymer brush into an oil-water two-phase system, and then performing light crosslinking reaction or reaction initiated by light. The amphiphilic ternary polymer brush solves the difficulty that the particle size of the capsule can not be adjusted and controlled effectively by using the conventional segmented copolymers, and the size of the prepared photo-crosslinked nano capsule is easily adjusted and controlled; the nano capsule prepared by the emulsion self-assembly method is simple in operation and easy to use in large-scale preparation; the prepared hollow nano capsule is large in casting quantity; the photo-crosslinked nano capsule provided by the invention is stable, and according to the light crosslinking method, nontoxicity and safety are reliazed, and the environmental protection is realized. The amphiphilic ternary polymer brush has the following general formula: A-g-(B-r-C-r-D).

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Methods for the preparation of a poly(arylene ether) polysiloxane multiblock copolymer, multiblock copolymers produced thereby, and associated compositions and articles

A poly(arylene ether)-polysiloxane multiblock copolymer is prepared by the reaction of a hydroxy-diterminated poly(arylene ether), a hydroxyaryl-diterminated polysiloxane, and an aromatic diacid chloride. This synthesis overcomes disadvantages of known syntheses of poly(arylene ether)-polysiloxane block copolymers. The poly(arylene ether)-polysiloxane multiblock copolymer is useful for improving the melt processibility of poly(arylene ether) compositions.

Owner:SABIC GLOBAL TECH BV

Catalyst Composition Comprising Shuttling Agent for Ethylene Multi-Block Copolymer Formation

ActiveUS20110118416A1Improve efficiencySynthetic resin layered productsThin material handlingOlefin polymerizationPolymerization catalysts

A composition for use in forming a multi-block copolymer, said copolymer containing therein two or more segments or blocks differing in chemical or physical properties, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining:(A) a first metal complex olefin polymerization catalyst,(B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and(C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Catalyst composition comprising shuttling agent for higher olefin multi-block copolymer formation

A process for preparing polymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, by contacting propylene, 4-methyl-1-pentene, or other C4-8 α-olefins and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining:(A) a first metal complex olefin polymerization catalyst,(B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and(C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Multiblock copolymer films, methods of making same, and uses thereof

A method for forming an isoporous graded film comprising multiblock copolymers and isoporous graded films. The films have a surface layer and a bulk layer. The surface layer can have at least 1×1014 pores / m2 and a pore size distribution (dmax / dmin)) of less than 3. The bulk layer has an asymmetric structure. The films can be used in filtration applications.

Owner:CORNELL UNIVERSITY +1

Degradation type marine anti-fouling material, preparation method and application thereof

InactiveCN102731745ATo achieve the purpose of anti-pollutionModulation of affinity/hydrophobicityAntifouling/underwater paintsPaints with biocidesXylylenePolyol

The present invention discloses a degradation type marine anti-fouling material, a preparation method and an application thereof. According to the present invention, a polyol with a characteristic of controllable degradation, isocyanate and a chain extender react to form a multi-block copolymer, wherein the multi-block copolymer can be degraded in seawater so as to flush a new surface, such that adhered marine organisms fall down; the multi-block copolymer can be applicable for preparation of a marine anti-fouling coat; the composition and the ratio of the polymers are adjusted to control crystallinity, and hydrophilicity / hydrophobicity of the polyol so as to effectively regulate degradation properties; with introductions of the isocyanate and the chain extender, excellent mechanical property and adhesion of the polyurethane are combined under the premise of assurance of controllable degradation performance; the degradation type marine anti-fouling material of the present invention can be dissolved in conventional xylene or an alcohol solvent, has good surface self-renewal performance and good mechanical properties, and does not contain any anti-fouling agents; and the method of the present invention has characteristics of simple process and low cost, and is suitable for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Amphipathic ternary molecular brush polymer constructed multichannel nanocapsule

ActiveCN103059312AEasy to adjust and control the sizeSolve the problem of no channelMicroballoon preparationMicrocapsule preparationEmulsionSide chain

The invention discloses an amphipathic ternary molecular brush polymer and a nanocapsule. The amphipathic ternary molecular brush polymer has a general formula shown below, wherein A is a main polymer chain, B is a side lipophilic macromolecular chain, C is a side macromolecular chain with a hydrophilic chemical cross-linking structure, D is a side lipophilic macromolecular chain, and the side chains B, C and D are randomly grafted to the main chain A. The nanocapsule is obtained by dispersing the amphipathic ternary molecular brush polymer in an oil and water two-phase system for a chemical cross-linking reaction. The amphipathic ternary molecular brush polymer constructed multichannel nanocapsule, disclosed by the invention, solves the problem that a traditional segmented copolymer is difficult to adjust and control multiple channels of the nanocapsule efficiently; and the channel structure and size of the prepared nanocapsule are easy to adjust and controllable. As an emulsion self-assembling method is adopted for preparing the nanocapsule, simple operation is obtained and the nanocapsule is easy to prepare in a large scale; the prepared hollow nanometer nanocapsule covering amount is great; and the nanocapsule disclosed by the invention has a steady structure after hydrophilic chemical cross-linking. A-g-(B-r-C-r-D).

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

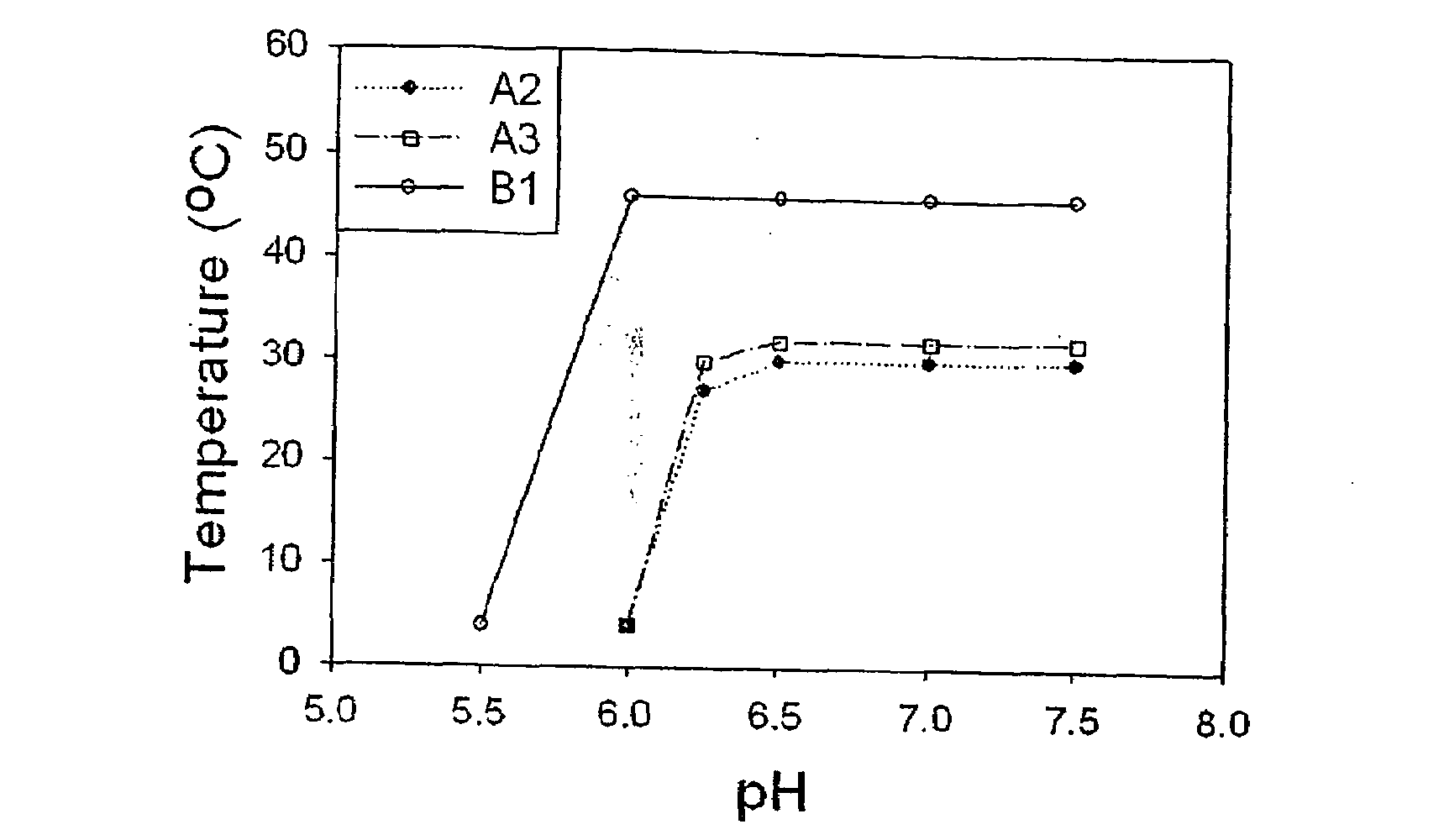

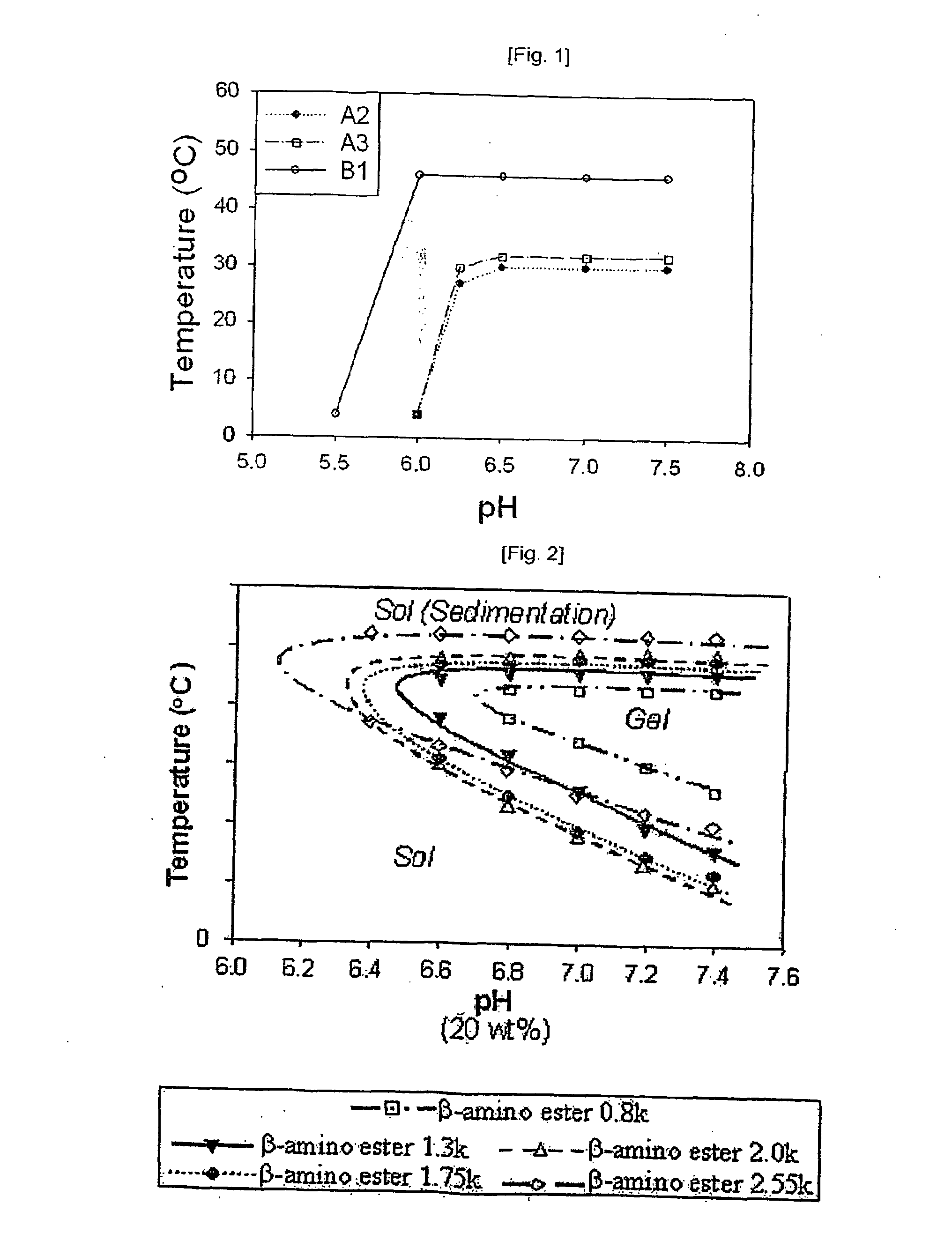

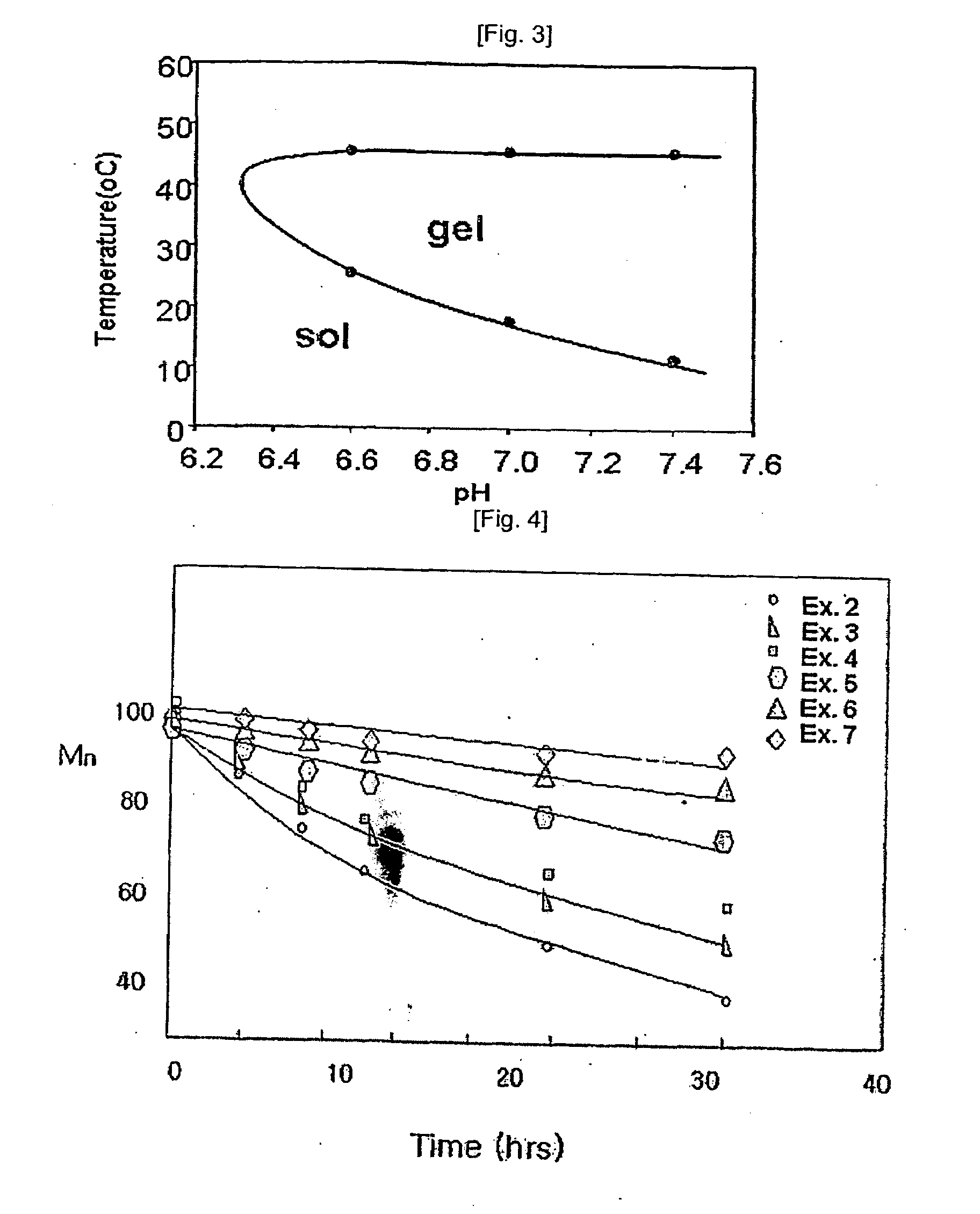

Temperature and Ph Sensitive Block Copolymer and Polymeric Hydrogels Using the Same

ActiveUS20080293827A1Good pH sensitivityHigh temperature sensitivityPharmaceutical non-active ingredientsAmino estersPolyethylene glycol

Disclosed is a block copolymer formed by coupling the following components with each other: (a) a copolymer (A) of a polyethylene glycol (PEG) type compound with a biodegradable polymer; and (b) at least one oligomer (B) selected from the group consisting of poly(β-amino ester) and poly(amido amine). A method for preparing the same block copolymer, and a polymeric hydrogel type drug composition comprising the temperature and pH-sensitive block copolymer and a physiologically active substance that can be encapsulated with the block copolymer are also disclosed. The multiblock copolymer is obtained by copolymerization of a pH-sensitive poly(β-amino ester) and / or poly(amido amine) type oligomer, a hydrophilic and temperature-sensitive polyethylene glycol type compound and a hydrophobic and biodegradable polymer. Therefore, the block copolymer can form a polymeric hydrogel structure due to its amphiphilicity resulting from the combination of a hydrophilic group and a hydrophobic group in the copolymer and ionization characteristics depending on pH variations, and thus can be used as a drug carrier for target-directed drug delivery depending on pH variations in the body.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Hyper-elastic, high strength dilatation balloon made from multi-block copolymers

InactiveUS20050118370A1Increase elasticityLow profileSynthetic resin layered productsCatheterHyper elasticHigh intensity

A self-wrapping dilatation balloon comprising a multiblock copolymer having high elasticity and elastic recovery from nominal strains greater than about 30% is described. Also described herein, is a polymeric extrudate for making a dilatation balloon comprising a multiblock copolymer having tensile strength in the range of about 50 MPa to about 450 MPa, strain at break in the range of about 50% to about 600% and substantially complete elastic recovery from nominal strains of at least about 30%. The extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. Also described herein is a process for producing a polymeric extrudate for use as a dilatation balloon. The process comprises extruding a multiblock copolymer mixture or composition to form an extrudate. The extruding is done such that the extrudate has phase-separated microdomains that are macroscopically aligned in parallel, perpendicular, transverse or a combination thereof. After extrusion, the process optionally comprises the steps of drawing and coagulating the extrudate.

Owner:MEDTRONIC VASCULAR INC

Biodegradable branched aromatic polyester-aliphatic polyester multi-block polymer

The invention relates to a biodegradable branched aromatic polyester-aliphatic polyester multi-block polymer and a preparation method thereof. By combining excellent biological degradability of aliphatic polyester, excellent mechanical property, thermal performance and stability of aromatic polyester and improved physical and mechanical performances of branched aliphatic polyester, the invention provides the biodegradable branched aromatic polyester-aliphatic polyester multi-block polymer. The multi-block polymer is a branched multi-block copolymer comprising an chain segment I and a chain segment II, or a branched multi-block polymer comprising the chain segment I and a chain segment III, or a branched multi-block polymer comprising the chain segment I, the chain segment II and a chain segment III. According to the multi-block polymer, the defects of the aliphatic polyester in performance are overcome; and the multi-block polymer has the advantages of high viscosity of fused mass, high strength of the fused mass, excellent stability and the like.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com