Method for preparing super paramagnetic high polymer homogeneous microball

A technology of superparamagnetic and manufacturing methods, which is applied in the field of manufacturing magnetic polymer microspheres, can solve problems such as the inability to synthesize uniform magnetic microspheres, magnetic polymer microspheres, etc., achieve easy expansion of production, uniform distribution of magnetic content, and avoid collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

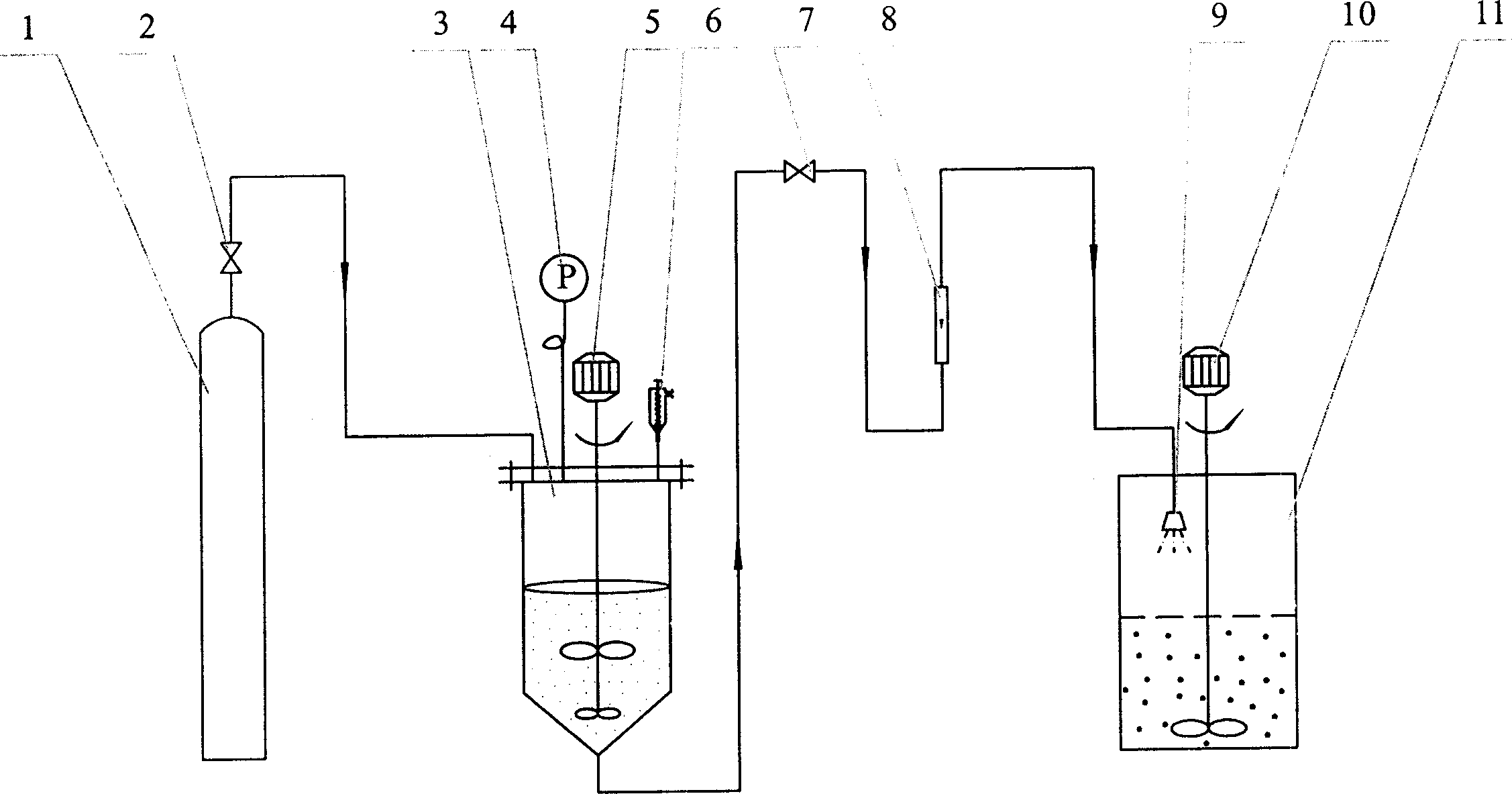

[0047] The upper end of the oil phase storage tank 3 of the jet-flow suspension polymerization reaction device is connected with the nitrogen cylinder 1 through the first regulating valve 2, and connected with the spray nozzle 9 at the upper end of the polymerization reactor 11 through the second regulating valve 7 and the flow meter 8 The upper end of the oil phase storage tank 3 is equipped with a pressure gauge 4, a motor 5 and a safety valve 6, and the motor 5 drives the agitator to rotate; the polymerization reactor 11 is installed with a paddle agitator driven by the motor 10, and the upper end is installed with an automatically adjustable sprayer. For the nozzle 9, the distance between the nozzle 9 and the liquid surface of the water phase in the reaction kettle 11 can be adjusted to obtain droplets with different particle sizes; the diameter of the nozzle (9) is 10-100 μm.

[0048] 2. Improved co-precipitation method to produce hydrophobic Fe 3 o 4 Ferrofluid:

Embodiment 2

[0050] Add 0.098mol FeCl to a 1-liter stirred reactor filled with 800ml distilled water 2 4H 2 O and 0.196 mol FeCl 3 ·6H 2 O, heat up to 90°C, pour 30-40ml NH 3 ·H 2 O aqueous solution, after 2 minutes, start to press 0.5ml·min -1 Add about 20ml of stearic acid dropwise at a high speed until a clear supernatant is seen, continue to keep the temperature for 40min, and pour off the supernatant to obtain a black mass of Fe coated with stearic acid. 3 o 4 ferrofluid.

Embodiment 3

[0052] Add 0.25mol FeSO to a 1-liter stirred reactor filled with 500ml distilled water 4 ·7H 2 O, 0.49mol FeCl 3 ·6H 2 O, heat up to 70°C, pour 0.4mol Na 2 CO 3 50-60ml of aqueous solution, add 15ml of oleic acid dropwise within 30min, after the supernatant becomes clear, raise the temperature to 80°C for 1 hour, pour off the supernatant to obtain Fe 3 o 4 ferrofluid.

[0053] 3. Manufacture of superparamagnetic polymer homogeneous microspheres by jet-flow suspension polymerization:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com