Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Contribute to energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

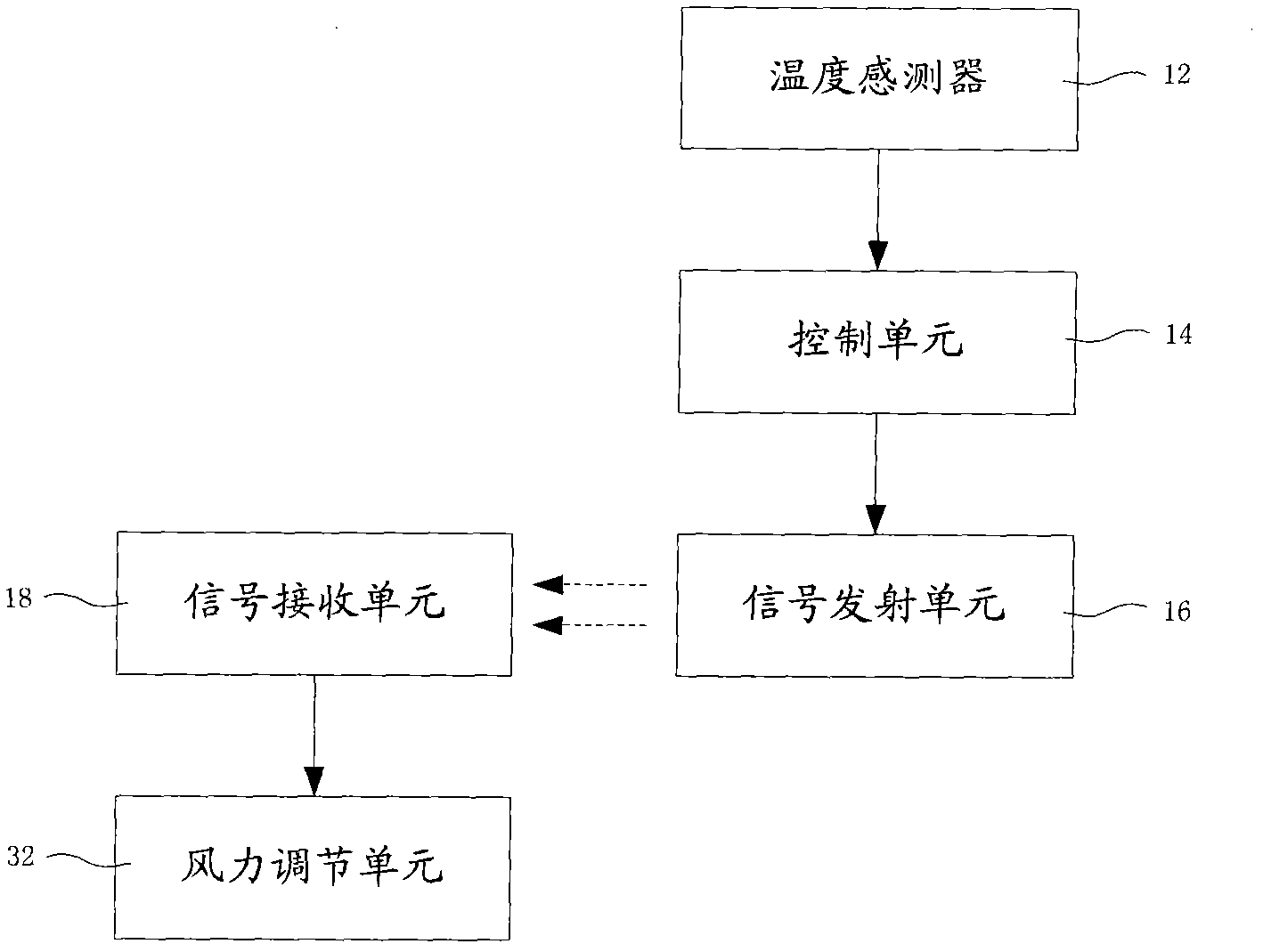

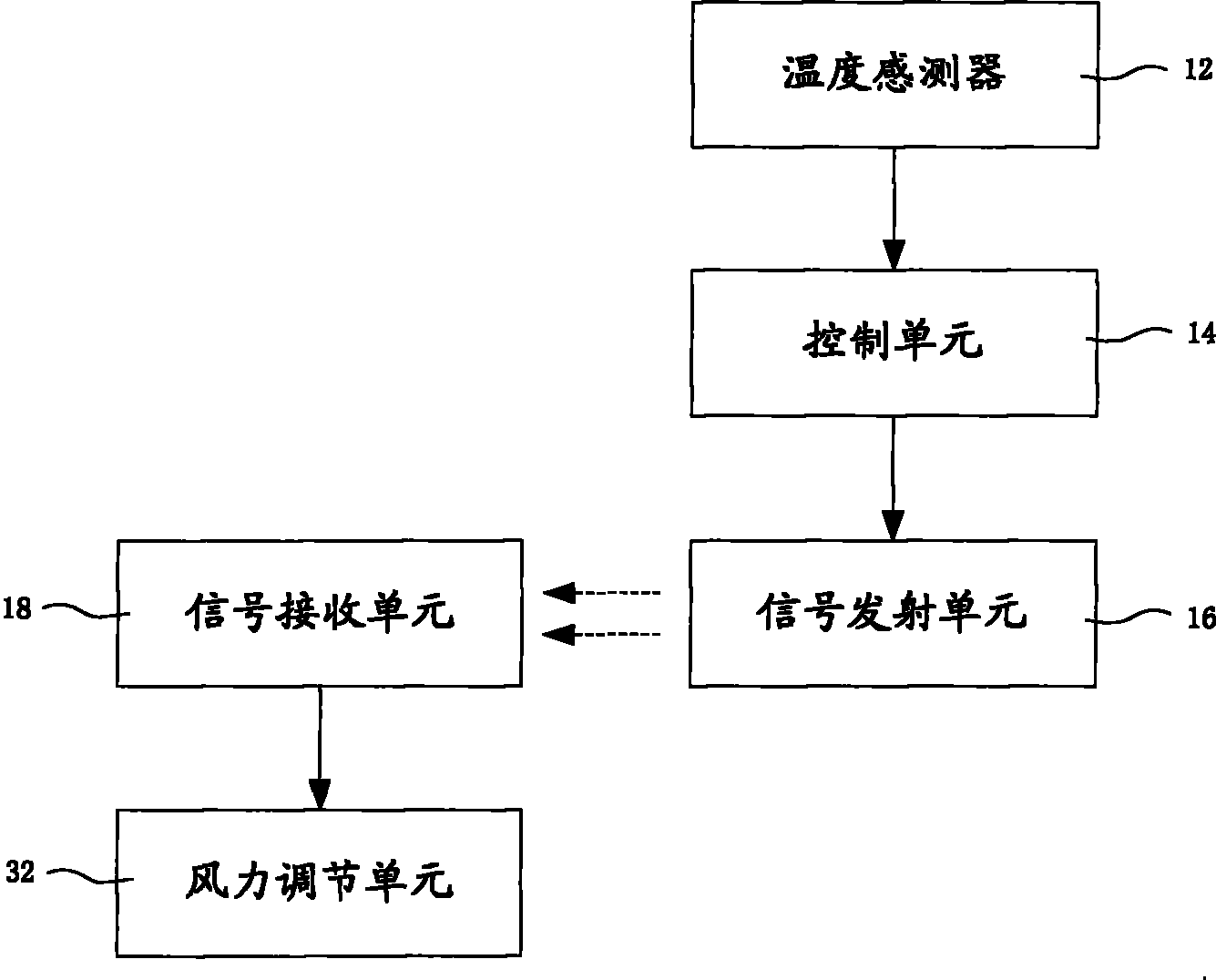

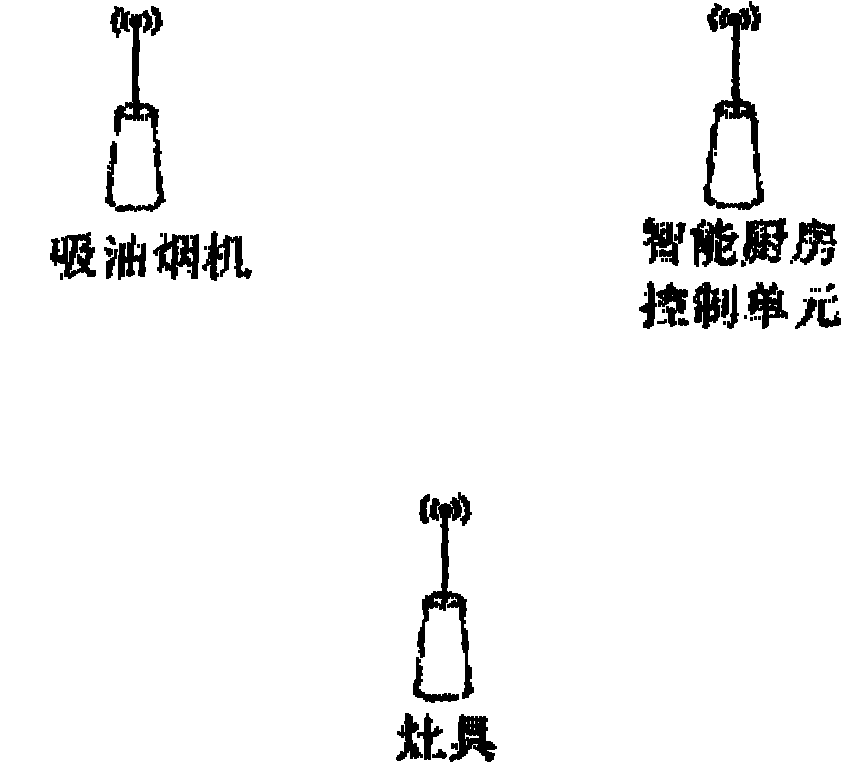

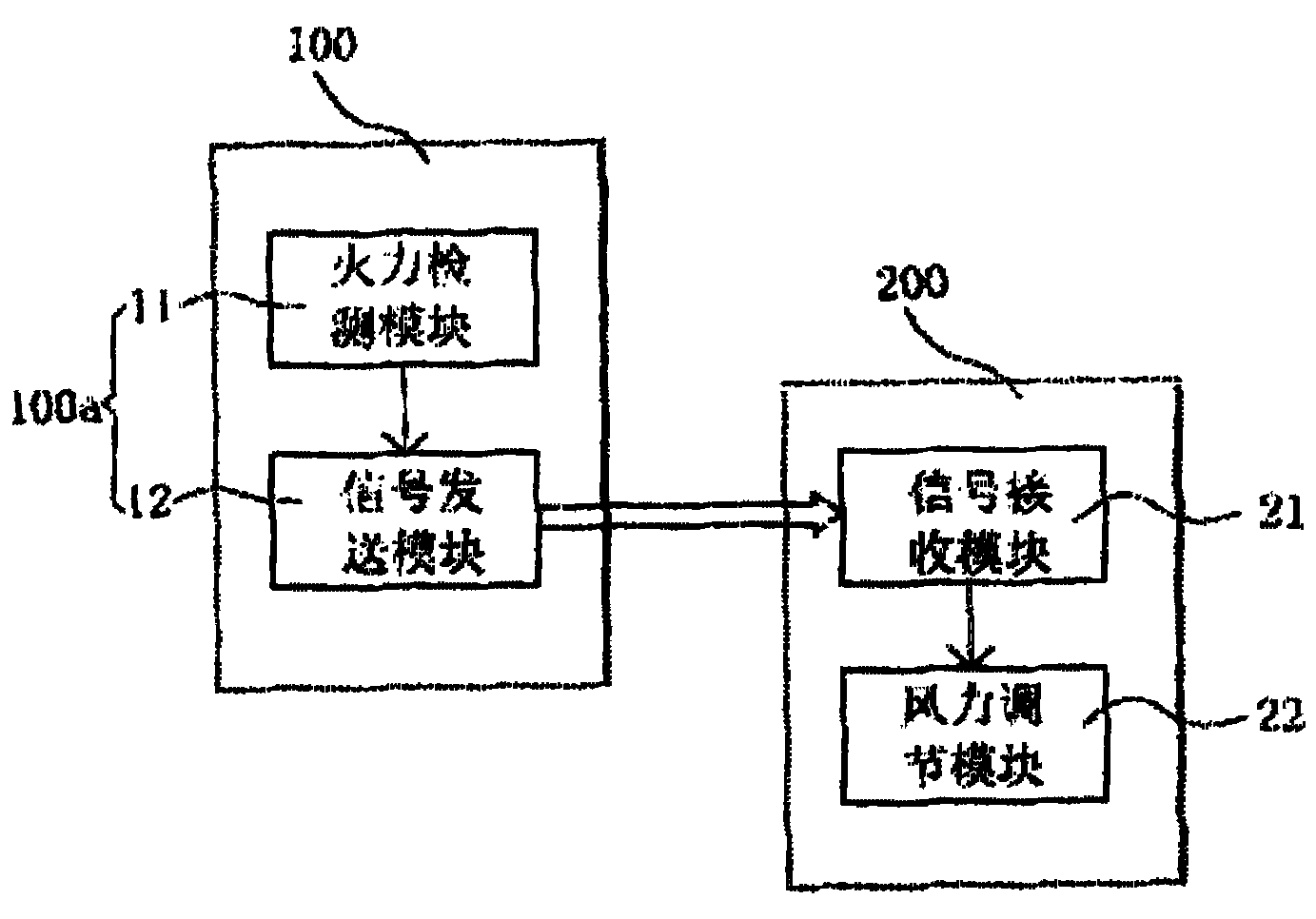

Linkage control system for kitchen range and control module thereof

InactiveCN102183979AReal-time automatic control of wind powerEasy to useAuxillary controllers with auxillary heating devicesControl systemWind power

The invention relates to a linkage control system for a kitchen range and a control module thereof. The linkage control system for a kitchen range comprises a kitchen range, a rang hood and a control module, wherein the rang hood is provided with a wind-power adjusting unit; the control module comprises a temperature sensor, a control unit, a signal emitting unit and a signal receiving unit; the control unit is respectively connected to the temperature sensor and the signal emitting unit; the control unit receives and processes a temperature signal from the temperature sensor, so as to acquire a wind-power adjusting signal; the wind-power adjusting signal is transmitted to the signal emitting unit; the signal emitting unit is correspondingly matched with the signal receiving unit; the signal emitting unit transmits the wind-power adjusting signal to the signal receiving unit; the signal receiving unit is connected to the wind-power adjusting unit; the signal receiving unit transmits the wind-power adjusting signal to the wind-power adjusting unit; and the wind-power adjusting unit adjusts the wind power of the rang hood according to the wind-power adjusting signal. The linkage control system for the kitchen range provided by the invention is conveniently used.

Owner:HAIER GRP CORP +1

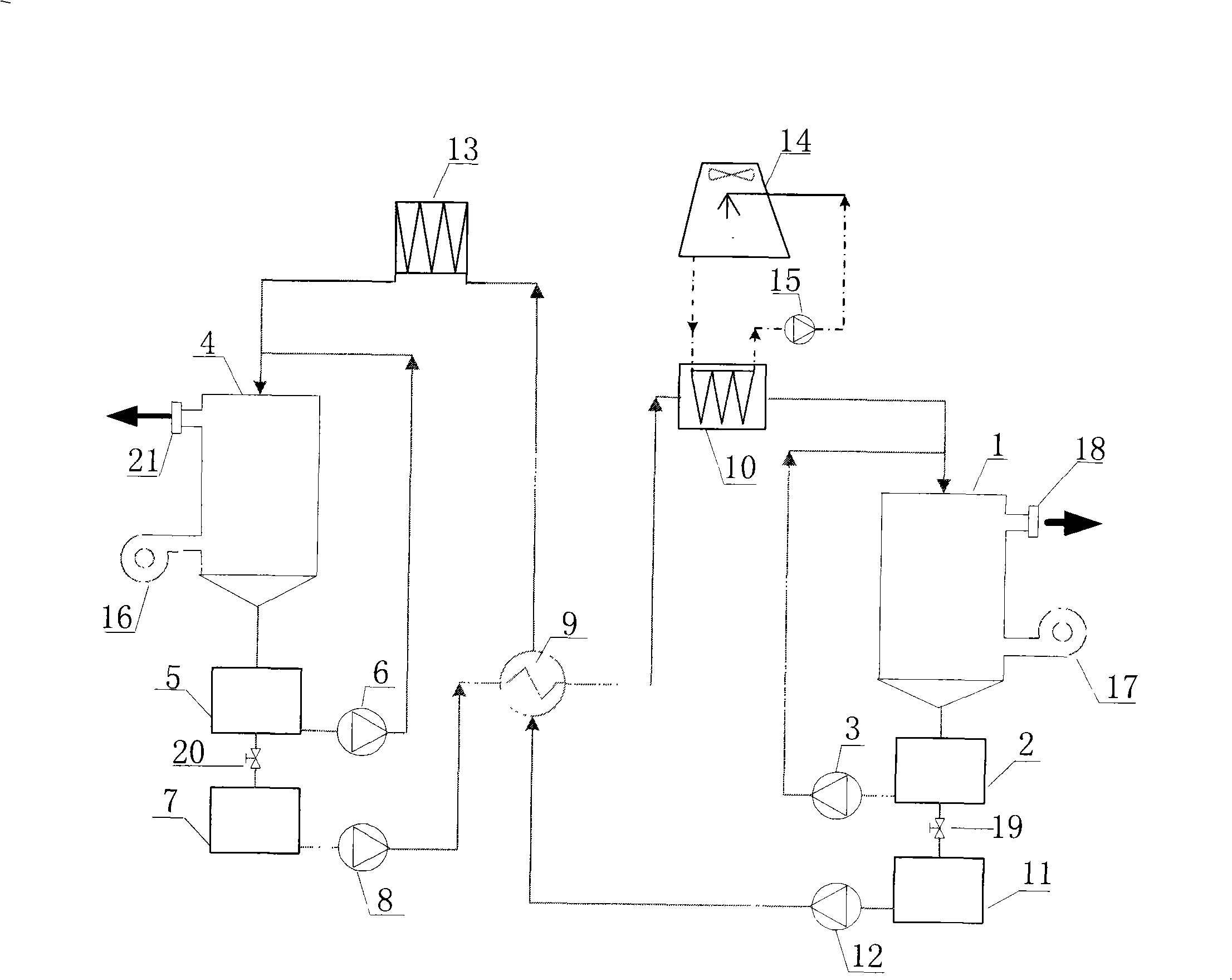

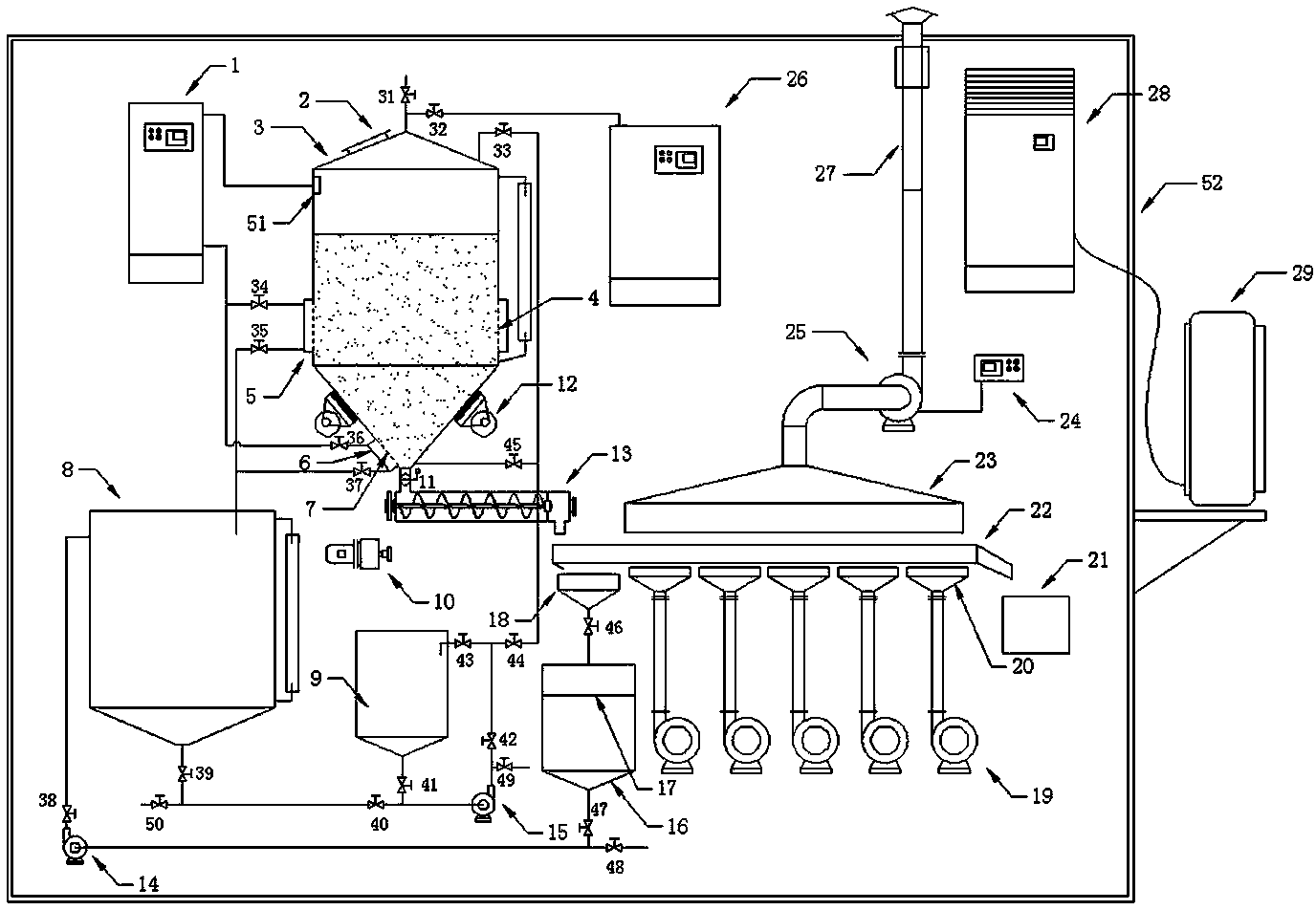

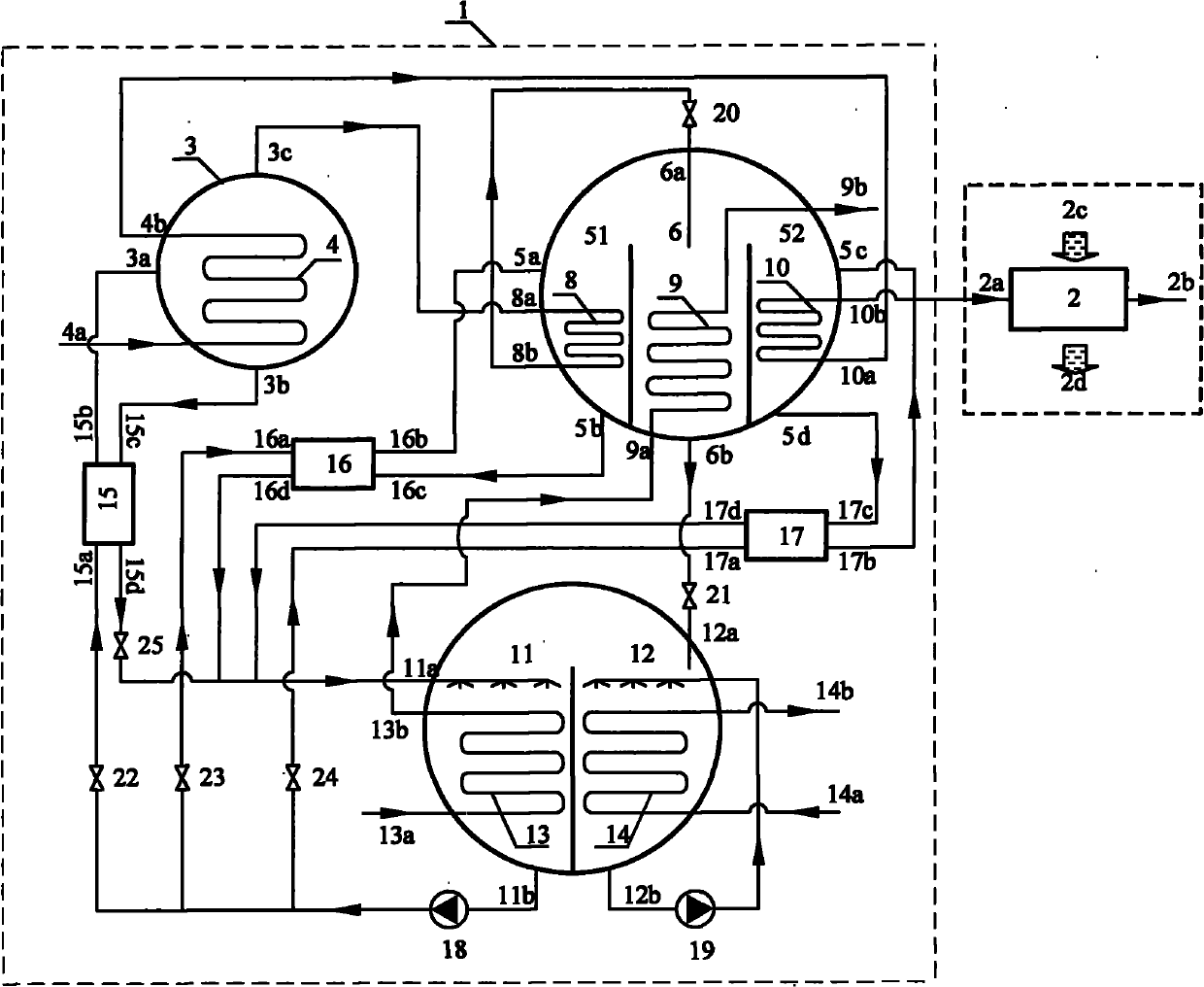

Solution dehumidification device driven by low-temperature smoke gas

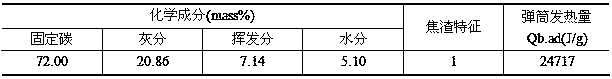

InactiveCN101537303AAddress underutilizationSave waterDispersed particle separationCooling towerMoisture absorption

The invention discloses a solution dehumidification device driven by low-temperature smoke gas, comprising a solution dehumidifier, a solution regenerator, a flue heater, a heat exchanger, a solution cooler, a concentrated solution trough, a diluted solution trough, a cooling tower, a water pump, a fan, a concentrated solution internal circulation pump, a concentrated solution external circulation pump, a diluted solution internal circulation pump, a diluted solution external circulation pump, a valve, an air inlet and an air outlet. The device takes a moisture-absorption solution as a dehumidizer to remove the water in the air; and the dehumidified air can be used for industrial combustion or used as the new air of an air conditioning system; and the device utilizes the low-temperature smoke gas exhausted by an industrial furnace as the heat source of the solution regenerator and drives the whole device to run by heating the solution with the flue heater. The device has the advantages of recovering the residual heat of the low-temperature smoke gas, saving energy resource, having high heat recovery rate and strong dehumidification capability, and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

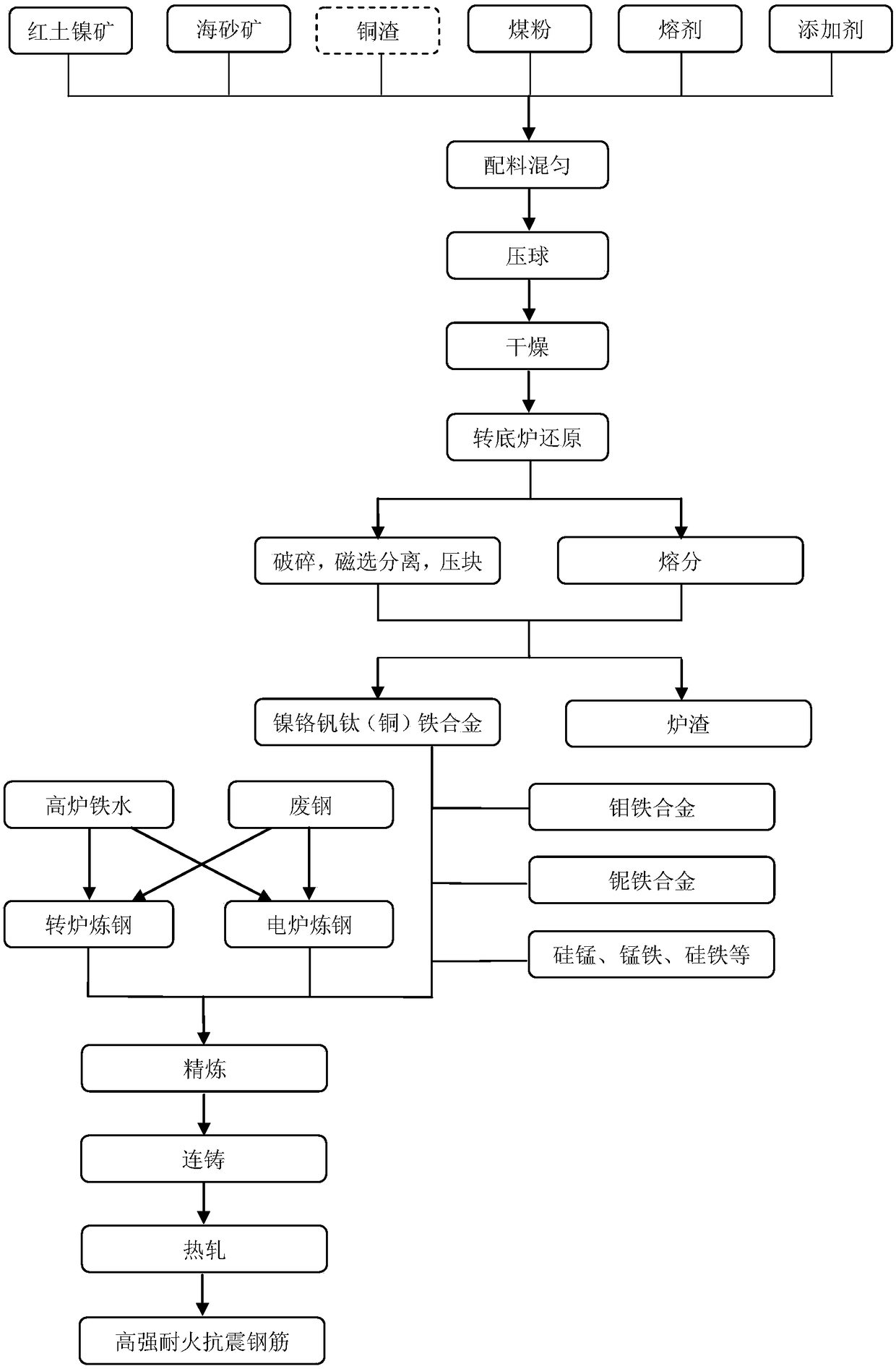

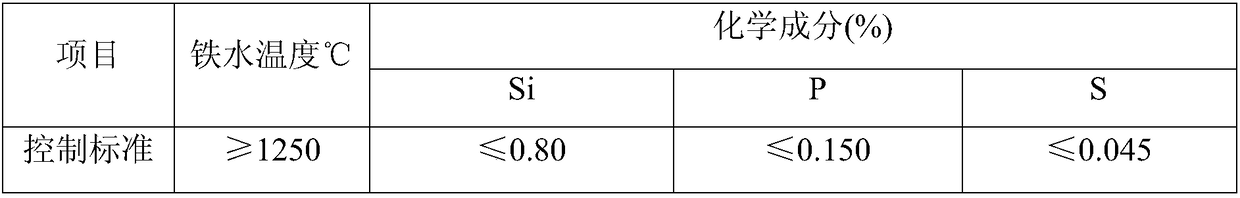

High-strength refractory anti-seismic steel bar and low-cost preparation cost thereof

The invention relates to a low-cost preparation method of a high-strength refractory anti-seismic steel bar, and further discloses the high-strength refractory anti-seismic steel bar. The low-cost preparation method comprises the steps that 1, laterite nickel ore, marine placer and pulverized coal are dried, crushed, levigated and screened to obtain mixed particles; 2, a fusing agent of slaked lime and an additive of syrup are added into the mixed particles to obtain a to-be-reacted material; 3, the to-be-reacted material is subjected to ball pressing treatment to obtain a pellet; 4, the pellet is subjected to direct reduction-magnetic separation or smelting separation treatment to obtain an alloy; and 5, the alloy and ferromolybdenum or ferrocolumbium are added into molten steel, and LF refining, continuous casting and rolling are conducted to obtain the high-strength refractory anti-seismic steel bar. According to the low-cost preparation method of the high-strength refractory anti-seismic steel bar and the high-strength refractory anti-seismic steel bar, compared with separate use of the laterite nickel ore or the marine placer or copper slag, the reduction cost is greatly reduced, and an obtained nickel chromium vanadium titanium copper iron alloy can be directly used for low-cost production of the high-strength refractory steel bar; and the laterite nickel ore, the marineplacer and the copper slag are reasonably utilized, and energy saving and emission reducing are facilitated.

Owner:钢研晟华科技股份有限公司

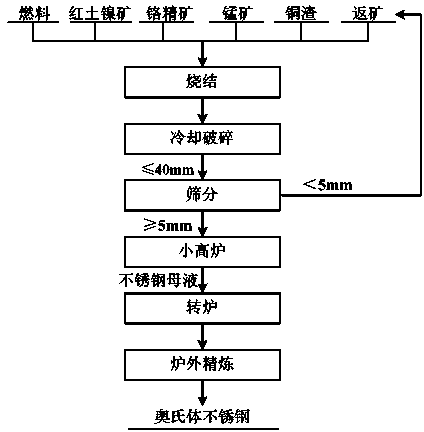

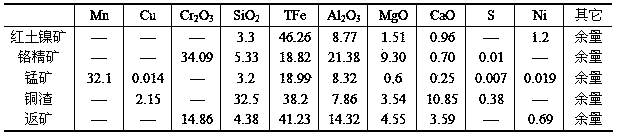

Compact production method of austenitic stainless steel

InactiveCN103866076ASimple processReduce the temperatureManufacturing convertersProduction lineManganese

The invention provides a compact production method of austenitic stainless steel. According to the method provided by the invention, the original four production lines for production of ferronickel, ferrochromium and manganese-iron alloys as well as mixed smelting steel-making are combined into one production flow, and nickel laterite, ferrochromium concentrate, manganese ore and copper slag are directly subjected to mixed sintering and smelting to produce the austenitic stainless steel, thus simplifying the process flow, reducing a sintering ignition temperature and the proportion of carbon, and reducing energy consumption and reducing production cost; and moreover, stainless steel mother solution containing chromium, nickel, manganese and copper is directly obtained by smelting, and the obtained thermal stainless steel mother solution is directly blown in a converter to produce stainless steel, thus further reducing heat loss, decreasing energy consumption, facilitating simplification of a production line of austenitic stainless steel, avoiding the problem of increase of equipment management and maintenance costs due to decentralized flow, and opening up a novel way for a production process of the austenitic stainless steel.

Owner:CHONGQING UNIV

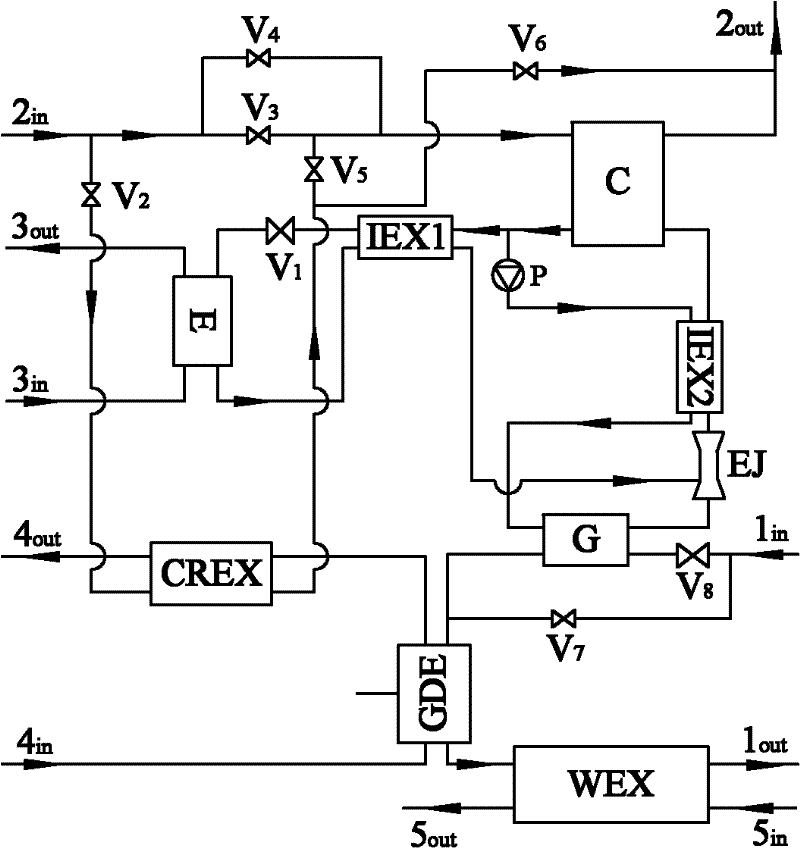

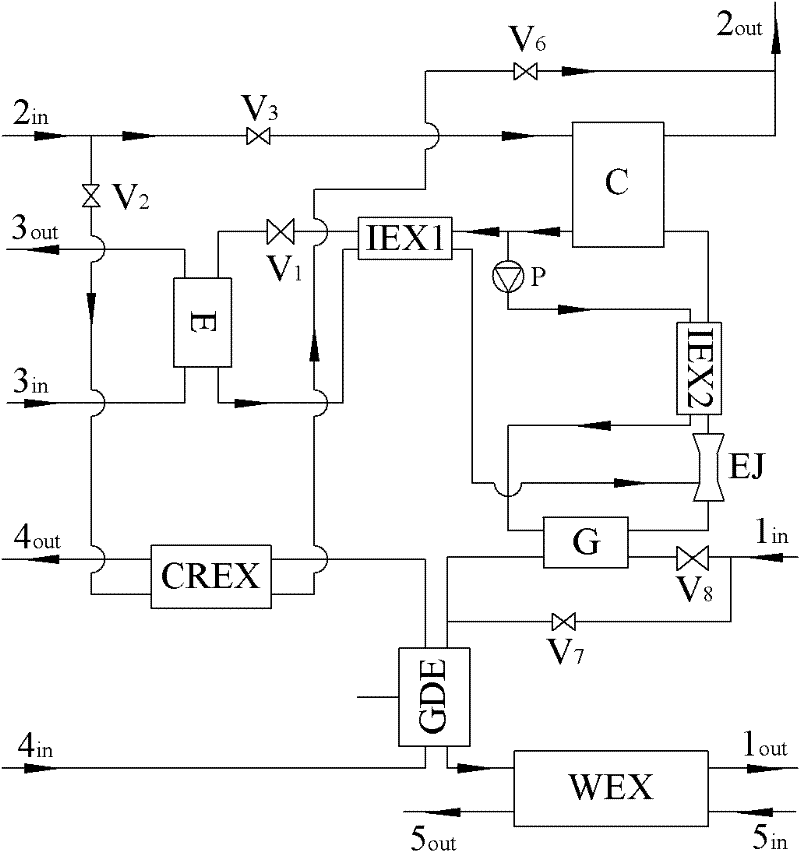

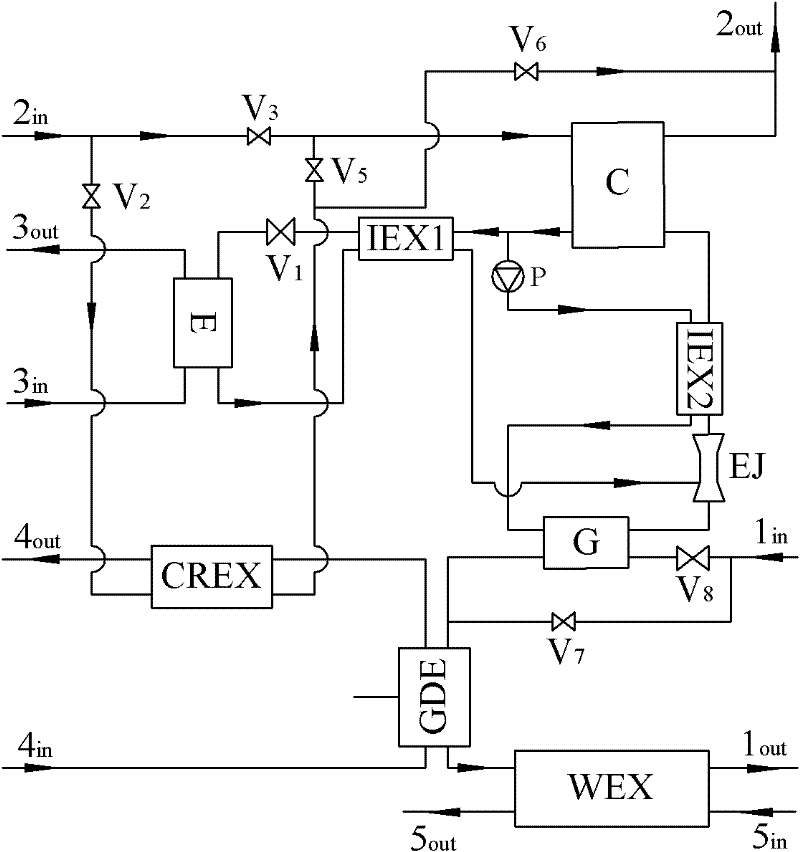

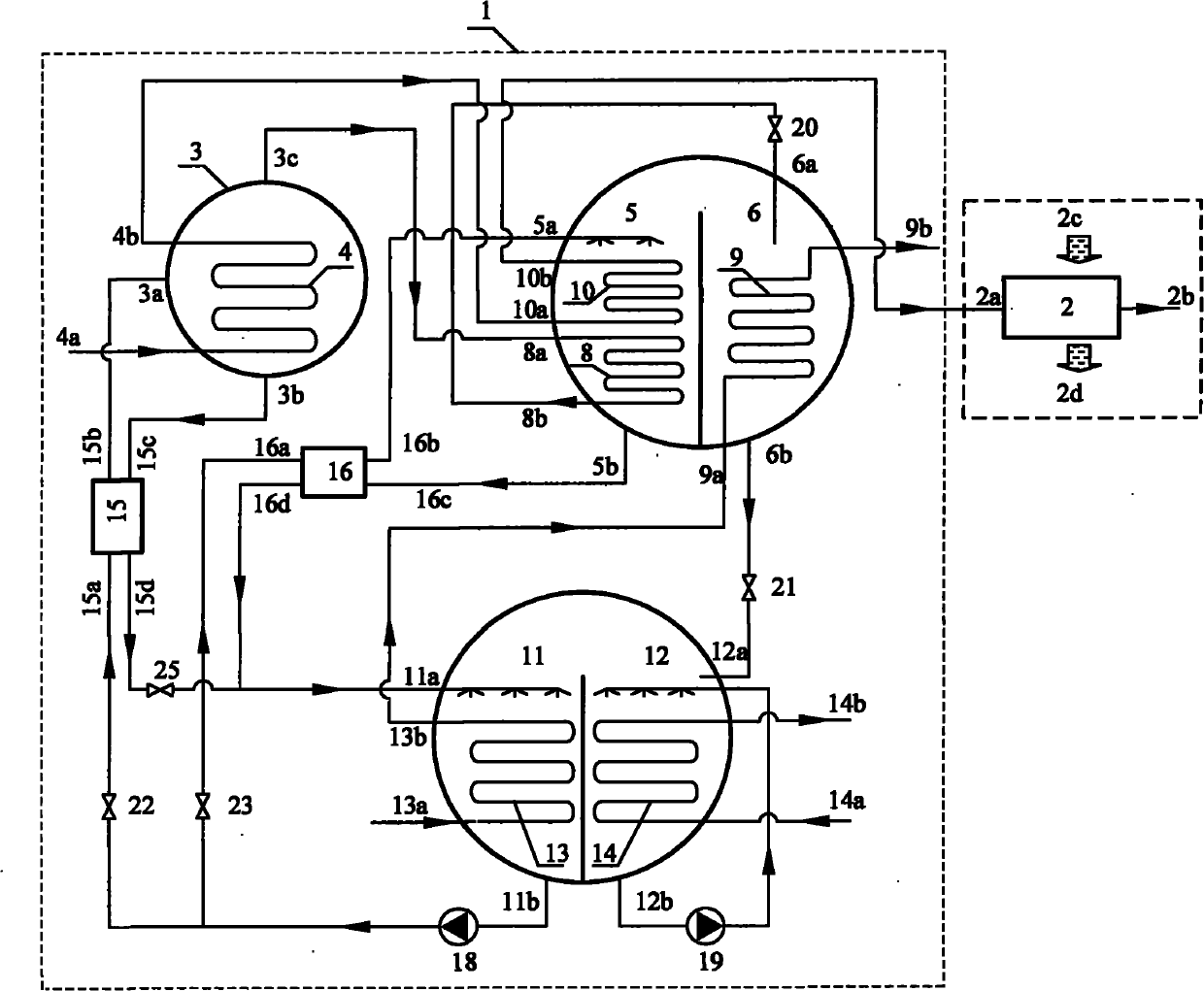

Multifunctional injection heat pump unit

InactiveCN102226601AReduce consumptionReduce peak-to-valley differenceHeat pumpsHeat recovery systemsThermal energyEngineering

The invention belongs to the technical field of energy sources and particularly relates to a multifunctional injection heat pump unit. The heat pump unit provided by the invention consists of an injection heat pump, a dehumidification solution regenerating system, a domestic hot water system, a valve and a connecting pipeline, and comprises a generator, a condenser, an evaporator, an injector, a pump, a heat regenerator, a solution generator, a solution cooler and a water-water heat exchanger; and the connecting pipeline is divided into a water system pipeline, a dehumidification solution system pipeline and a heat pump working medium system pipeline. The multifunctional injection heat pump unit provided by the invention can be used for recycling industrial waste heat, solar energy and the like, preparing chilled water and dehumidifying concentrated solution and hot water, improves the comprehensive utilization rate of heat and is beneficial to the reduction of the load peak and valley difference of a power grid in summer.

Owner:北京建筑工程学院

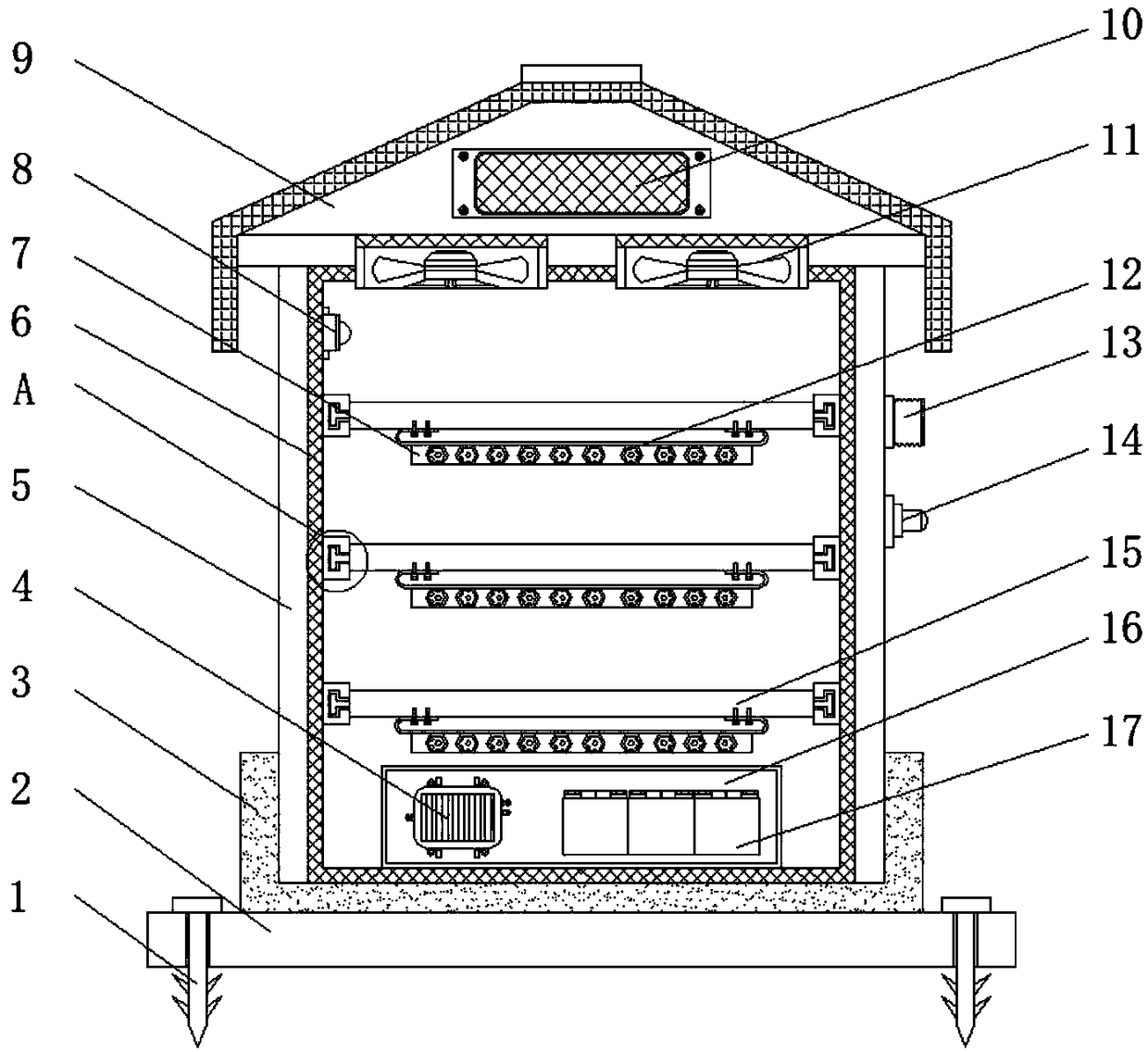

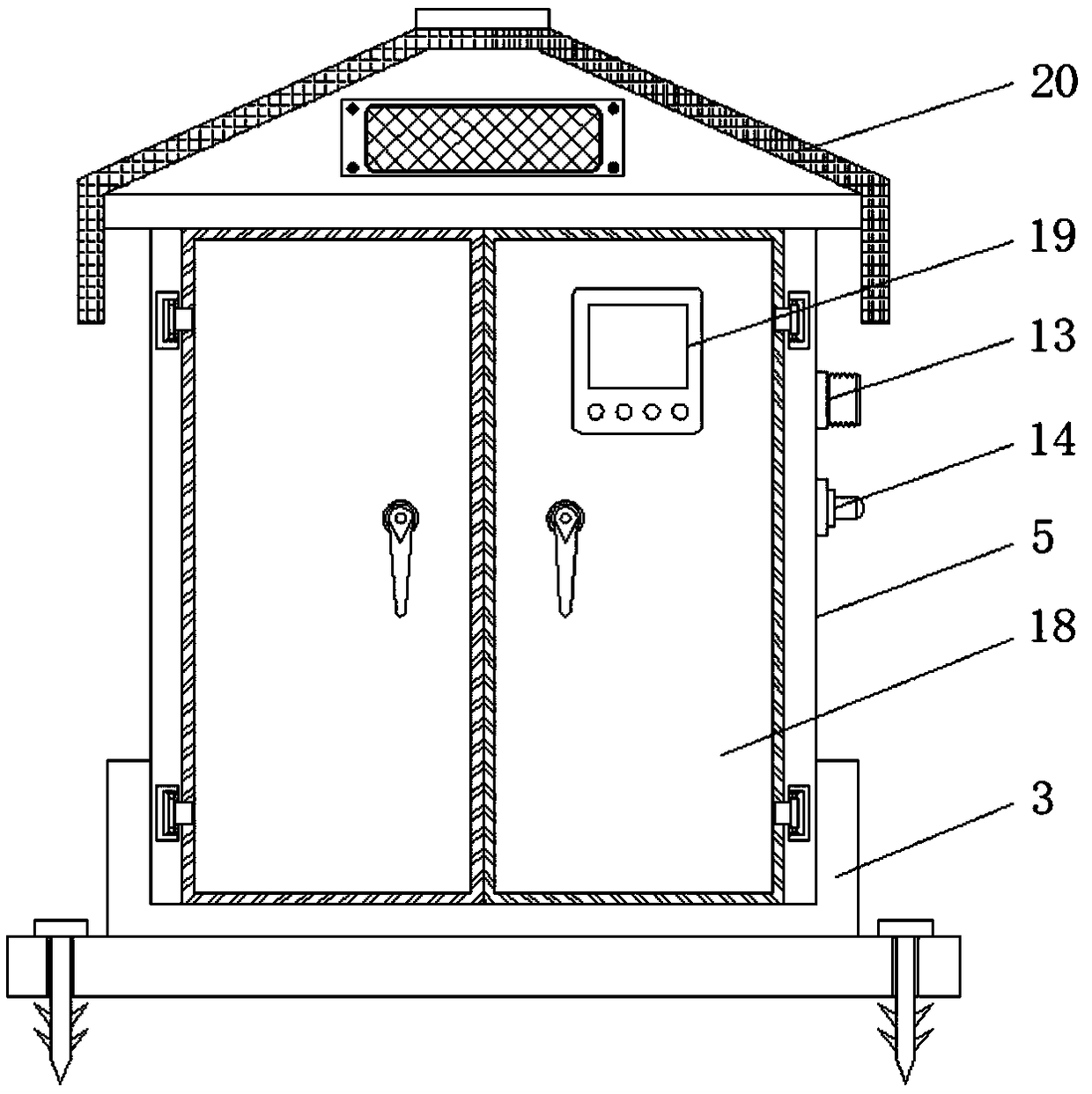

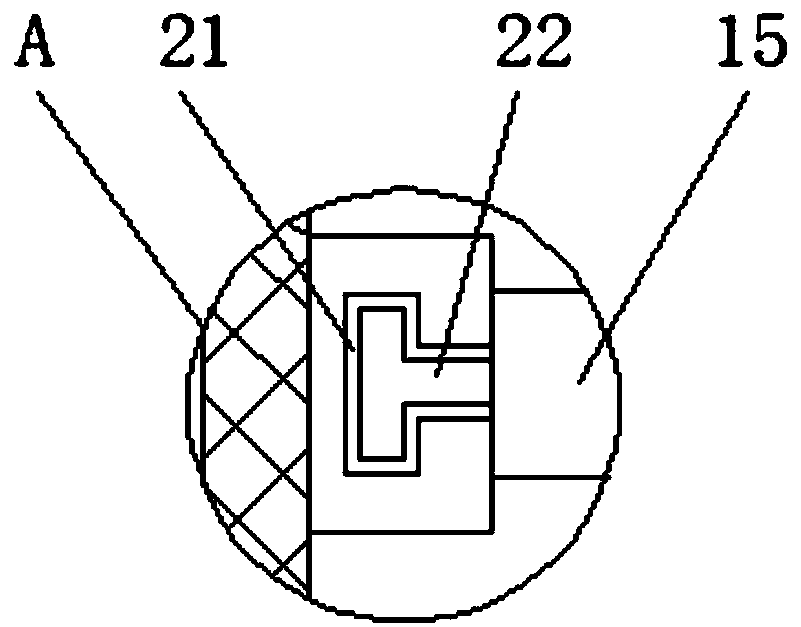

Power transformation box shielding external interference

PendingCN109494597AEasy to installImprove stabilityScreening casingsSubstation/switching arrangement cooling/ventilationMicrocomputerMicrocontroller

The invention discloses a power transformation box shielding external interference, and the box comprises a bottom plate, a box body, a placement board, and a solar cell panel. The top of the bottom plate is fixedly provided with a protection pedestal, and the interior of the protection pedestal is fixedly provided with the box body. The interior of a side wall of the box body is provided with a carbon steel reinforcing layer, and two sides of the carbon steel reinforcing layer are uniformly provided with rubber compression-resistant balls. The outer side of the box body is uniformly coated with a teflon corrosion-resistant layer, and two ends of one side of the box body are hinged to door bodies. The output ends of a temperature sensor and a current detector are electrically connected with the input end of a single-chip microcomputer through wires, and the output end of the single-chip microcomputer is electrically connected with a cooling fan and the input end of a buzzer alarm. According to the invention, the box is provided with the bottom plate and a fixing ground pile, and the fixing ground pile is uniformly provided with a barb, thereby facilitating the fixed installation ofa device. The barb enables the insertion into the ground to be deeper, thereby improving the stability of the device, and enabling the collapse to be difficult. The box is convenient and quick for use.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP

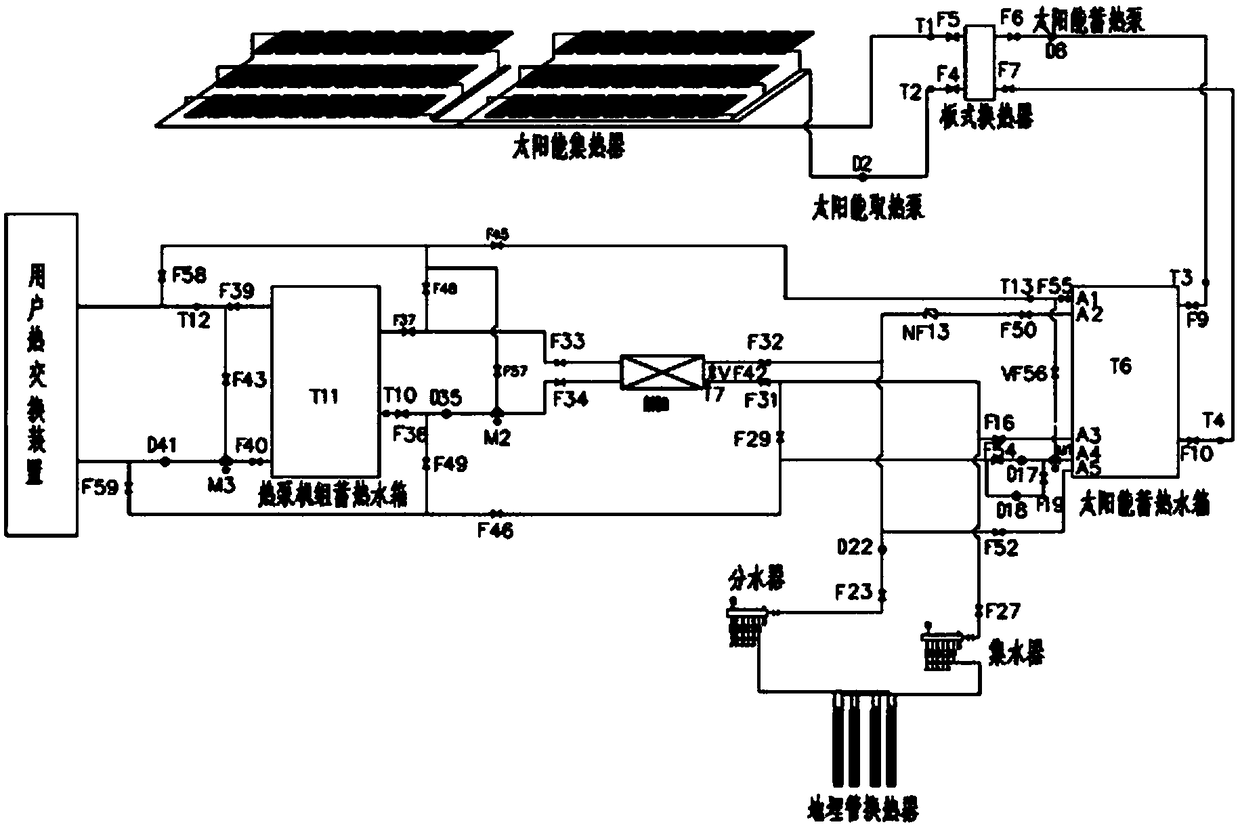

Solar assisted ground source heat pump cooling and heating system and using method thereof

ActiveCN108362036AAchieve indoor cooling effectSave powerMechanical apparatusCompression machinesAnti freezingSolenoid valve

The invention discloses a solar assisted ground source heat pump cooling and heating system and a using method thereof. The system is mainly formed by connecting a solar heat collector, a solar heat storage water tank, a ground heat exchanger, a heat pump unit, a heat pump unit heat storage water tank and a user heat exchange device through a control circulation line. The using method of the solarassisted ground source heat pump cooling and heating system comprises the steps that the direct heat supply setting value of the solar heat storage water tank, the direct supply water temperature setting value, the water inlet temperature setting value of the heat pump unit and the anti-freezing temperature setting value of the solar heat storage water tank are set; a water temperature sensor T6of the solar heat storage water tank is used for obtaining the actual temperature value of water in the solar heat storage water tank, and the direct heat supply setting value of the solar heat storage water tank is compared with the actual temperature value of water in the solar heat storage water tank; and then a solenoid valve is used for controlling a corresponding circulation path, indoor heat supply is carried out, and the beneficial effects of being various in function, saving energy, being environment-friendly and the like are achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

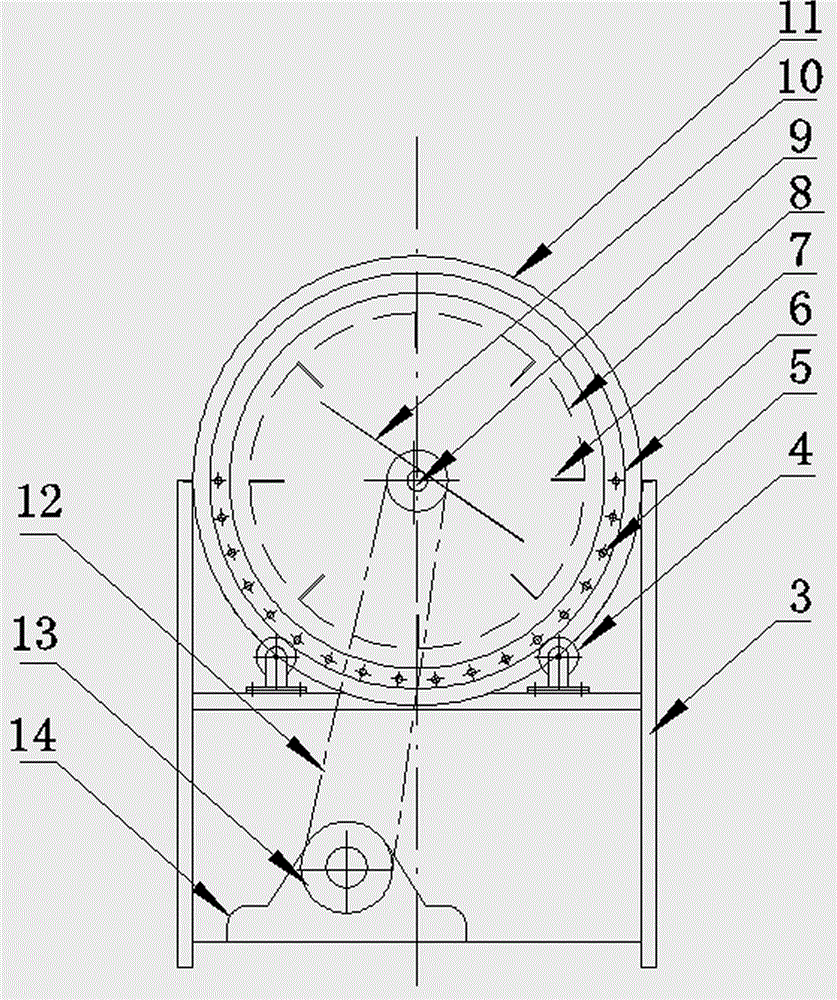

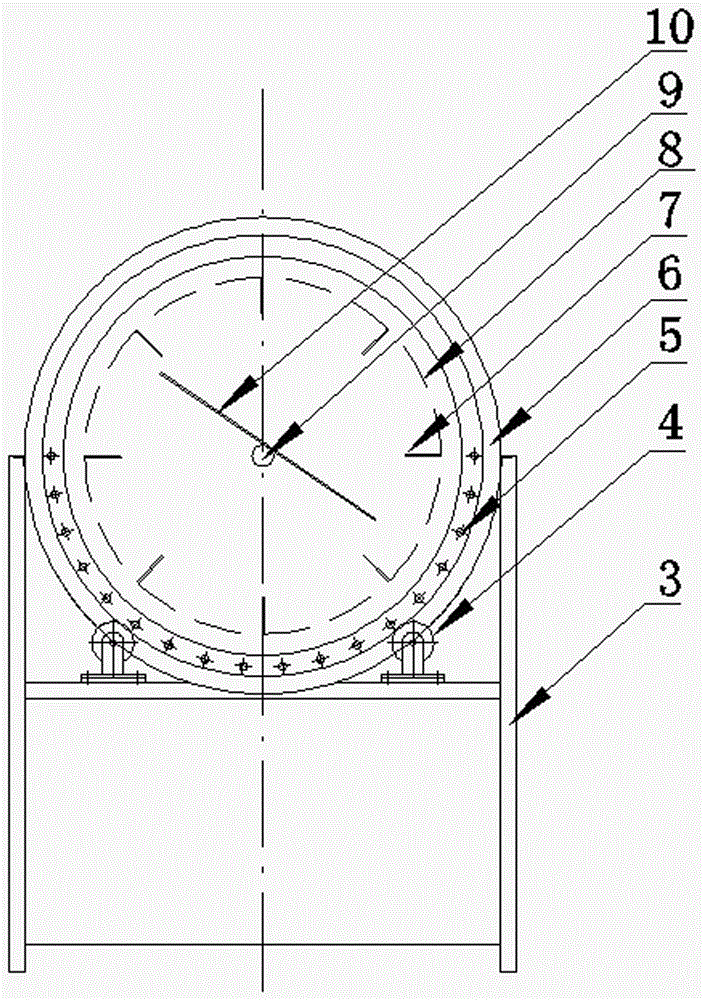

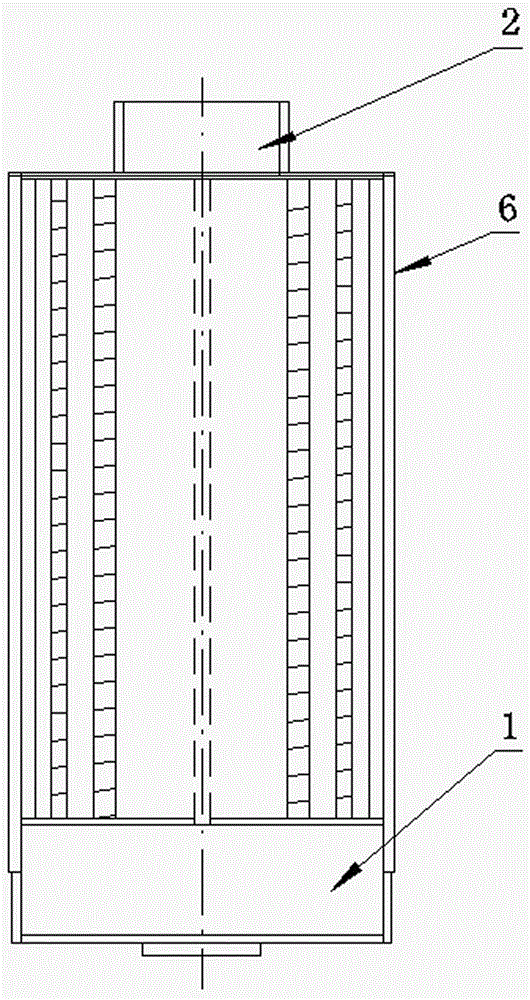

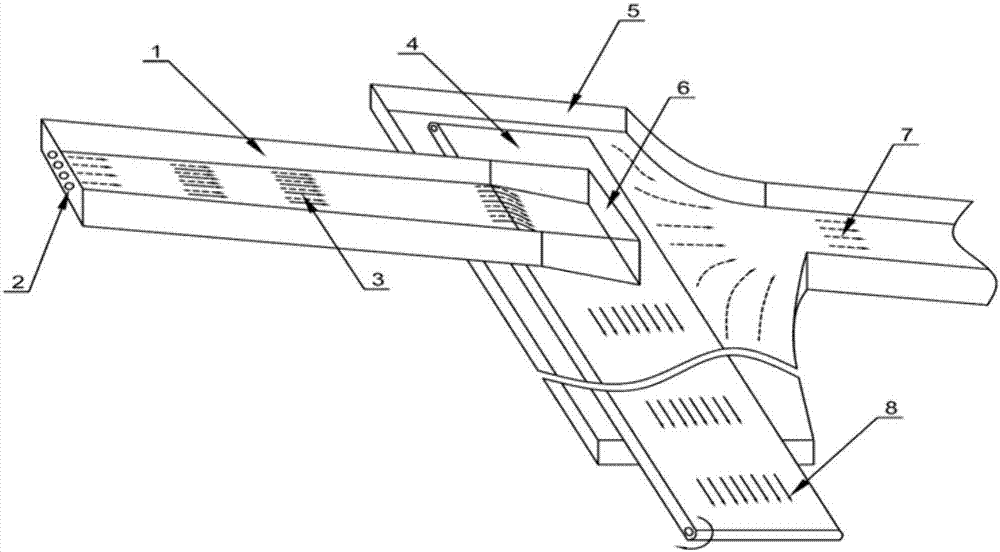

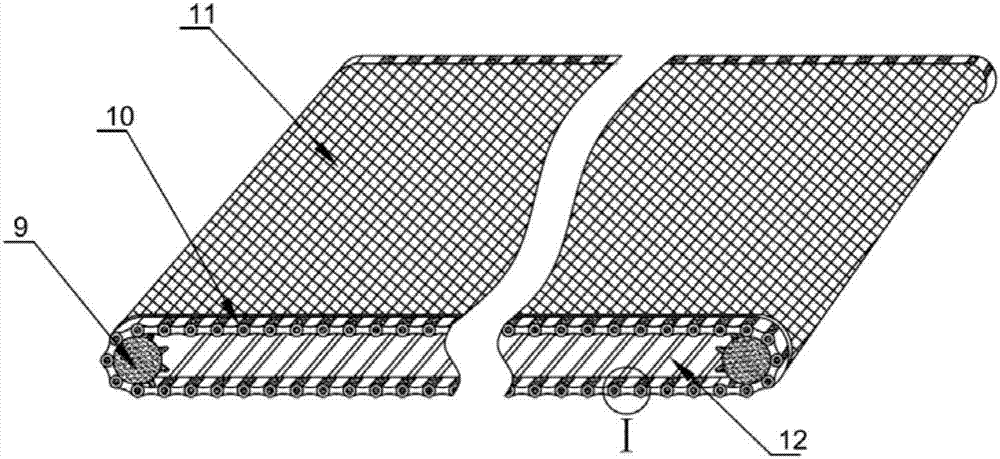

Baking apparatus and baking process for oolong tea

InactiveCN106035782AImprove baking efficiencyReduce the transfer linkPre-extraction tea treatmentThermodynamicsHeater Rod

The invention discloses a baking apparatus and baking process for oolong tea. The baking apparatus is prepared at first and is provided with a rotary drum, a rotary drum support, an electric heating rod, a motor transmission device, a plurality of stir-frying blades, a stir-frying guide plate, a helical groove, a discharge outlet, a feed inlet and a transmission mechanism driving rotation of the rotary drum. Controlling principles for baking in the invention are that a continuous baking mode of simultaneous feeding and discharging is employed and cooperated with three parameters consisting of set blanking speed, electric furnace temperature and rotating speed of the rotary drum, so rapid drying of the oolong tea is controlled, the water content of the oolong tea and optimal fire meet process requirements, the oolong tea can maintain a certain degree of dryness, and the fragrance and taste of the oolong tea are improved; so the product quality of the oolong tea is improved to a greatest extent.

Owner:福建茶叶进出口有限责任公司

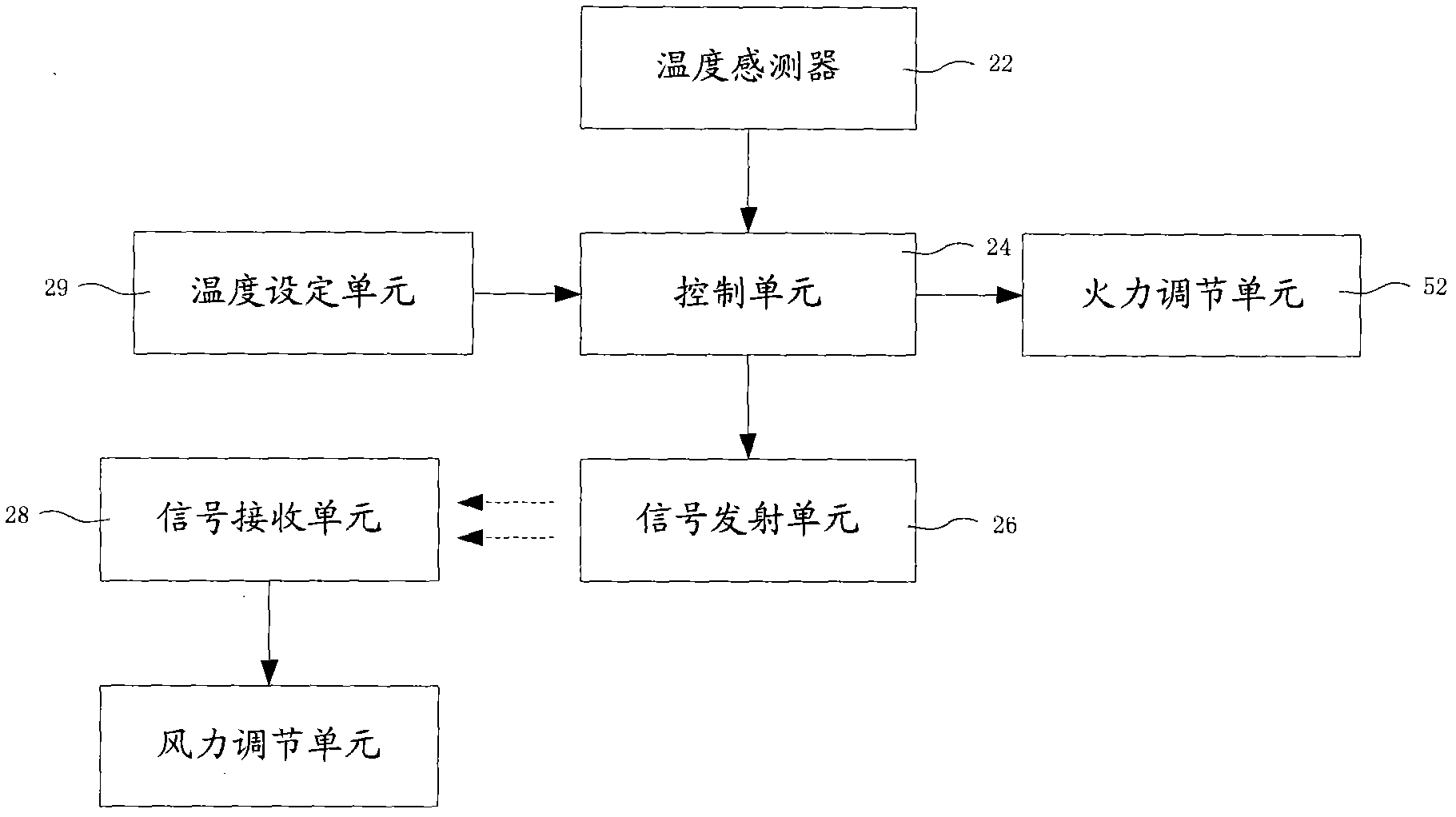

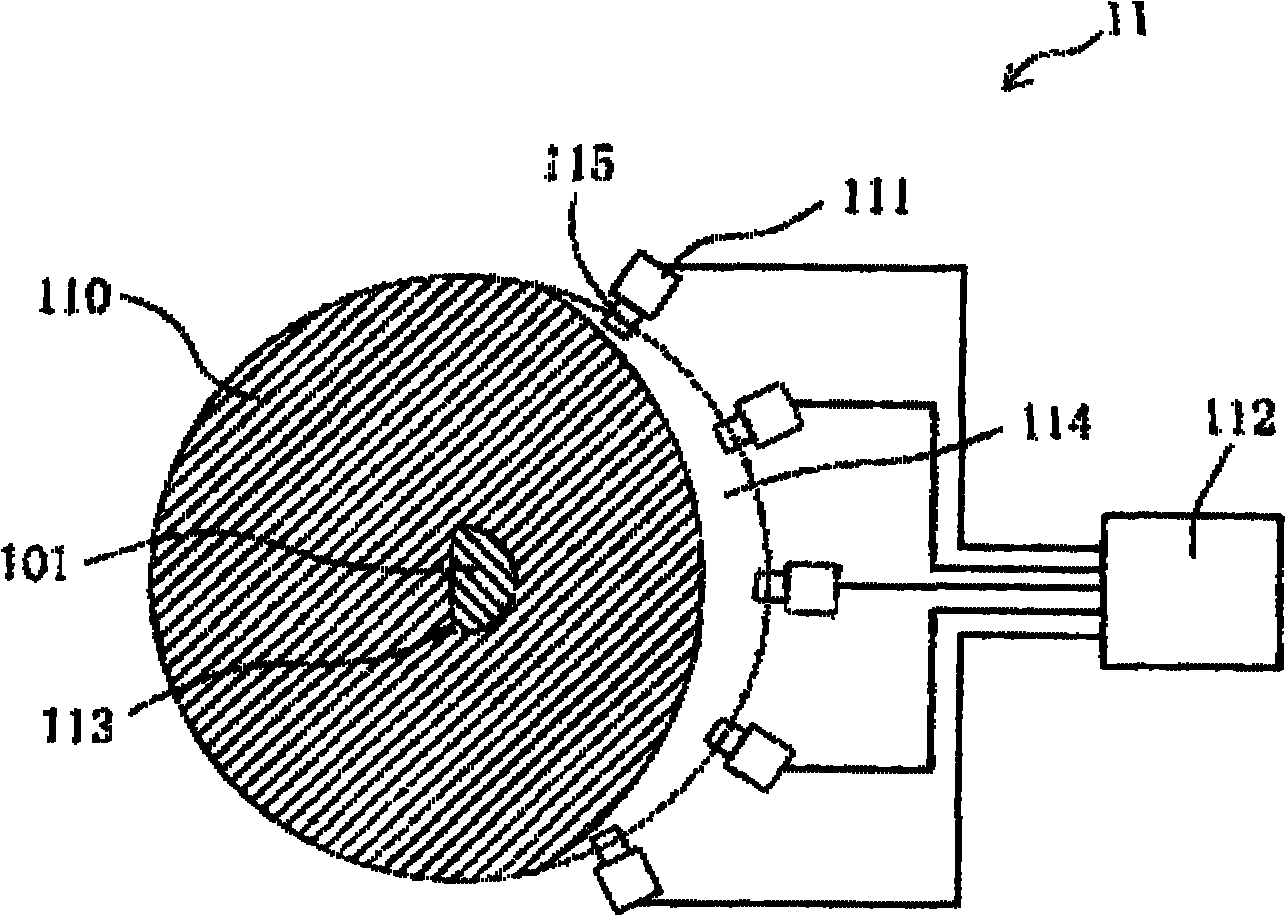

Cooking utensil controlling module, cooking utensil and cooking utensil linkage system

ActiveCN102155752AEnergy saving, emission reduction, clean and hygienicKeep clean and hygienicDomestic stoves or rangesLighting and heating apparatusValve stemEngineering

The invention relates to a cooking utensil controlling module. The cooking utensil comprises a valve for controlling firepower; the valve is provided with a rotatable valve stem; the cooking utensil controlling module comprises a firepower detecting module and a signal sending module, wherein the firepower detecting module is linked to the valve so as to detect the firepower; and the signal sending module sends the related information of the firepower to an external device. The invention also provides the cooking utensil that uses the cooking utensil controlling module and a cooking utensil linkage system. The cooking utensil controlling module has a simple structure, low cost and high reliability.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

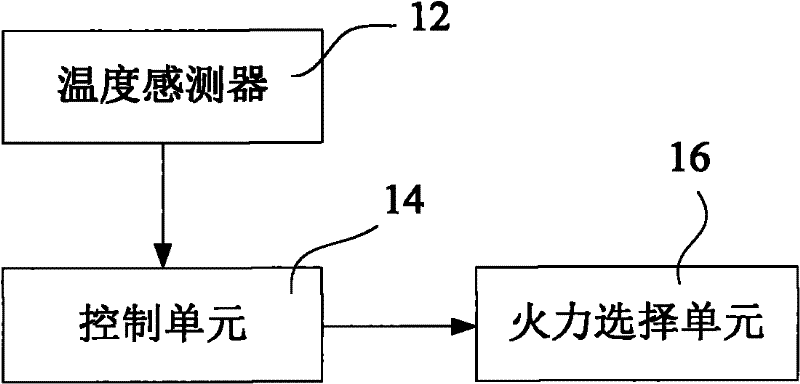

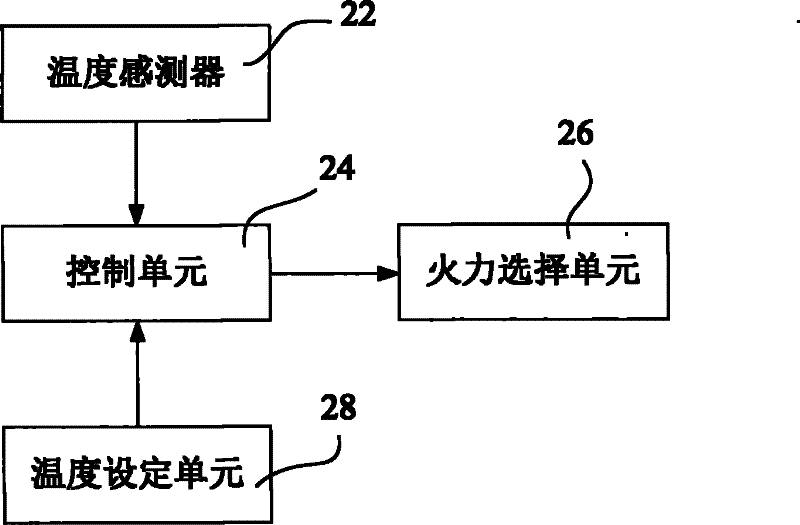

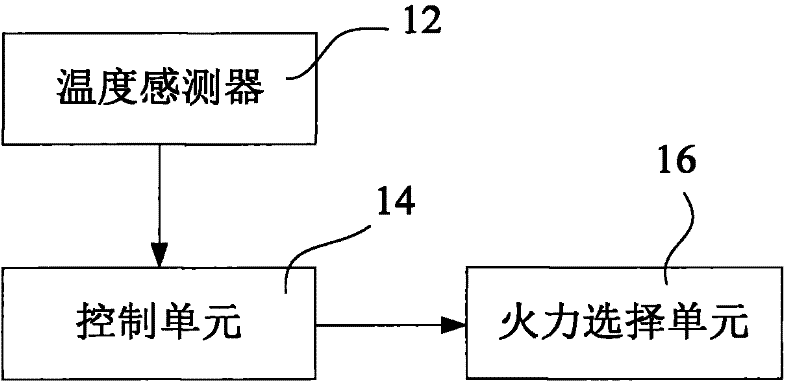

Stove and intelligent control method thereof

ActiveCN102200298AReal-time automatic control of firepowerAvoid it happening againDomestic stoves or rangesLighting and heating apparatusTemperature controlEngineering

The invention relates to a stove. The stove comprises a stove body and a control module, wherein the control module comprises a temperature sensor, a controlling unit and a firepower selecting unit. The controlling unit is connected with the temperature sensor and the firepower selecting unit; the temperature sensor is connected with the stove body, and is provided for sensing a temperature signal related to a firepower situation of the stove body. The controlling unit is provided with a preset temperature controlling range, and is provided for receiving and processing the temperature signal from the temperature sensor, and determining whether the temperature sensed through the temperature sensor is in the preset temperature controlling range to acquire a firepower adjusting signal. The firepower selecting unit is provided for receiving the firepower adjusting signal from the controlling unit, and adjusting the firepower of the stove body according to the firepower adjusting signal. The invention further provides an intelligent control method for the stove. According to the stove and the intelligent control method, cooking temperature can be controlled in a certain range.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

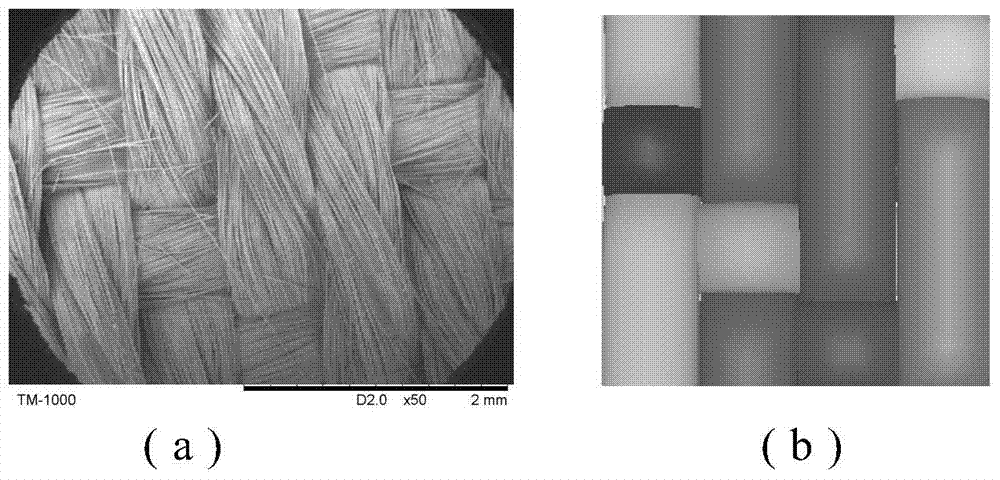

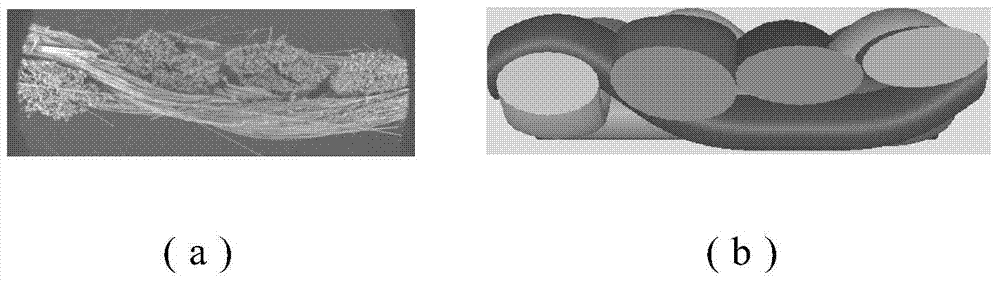

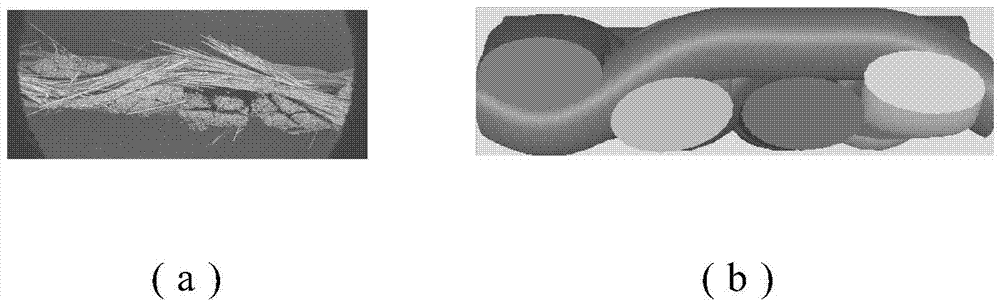

Method for predicting heat protection performance of fabric

ActiveCN104504212AThe result is accurateContribute to energy saving and emission reductionSpecial data processing applicationsYarnUnit model

The invention discloses a method for predicting heat protection performance of fabric. The method includes building a three-dimensional geometrical model of the fabric based on the geometrical structure and the interweaving route of yarns, studying the transfer process of heat in the fabric on the basis and predicting the heat protection performance of the fabric. Compared with the prior art, the heat transfer process in the fabric is studied based on the three-dimensional geometrical model of the fabric, the result is more accurate compared with the existing method that the fabric is seen as a uniform flat plate, two concepts of the fabric domain and the air domain are provided innovatively, the effect of air components in the fabric unit model on heat transfer is fully considered, and the prediction result is closer to the actual condition. By means of popularization of the method for predicting heat protection performance of the fabric, the manufacturing and evaluating of the heat protection fabric are facilitated, test flow and time can be reduced, and energy saving and emission reduction are achieved.

Owner:TIANJIN POLYTECHNIC UNIV

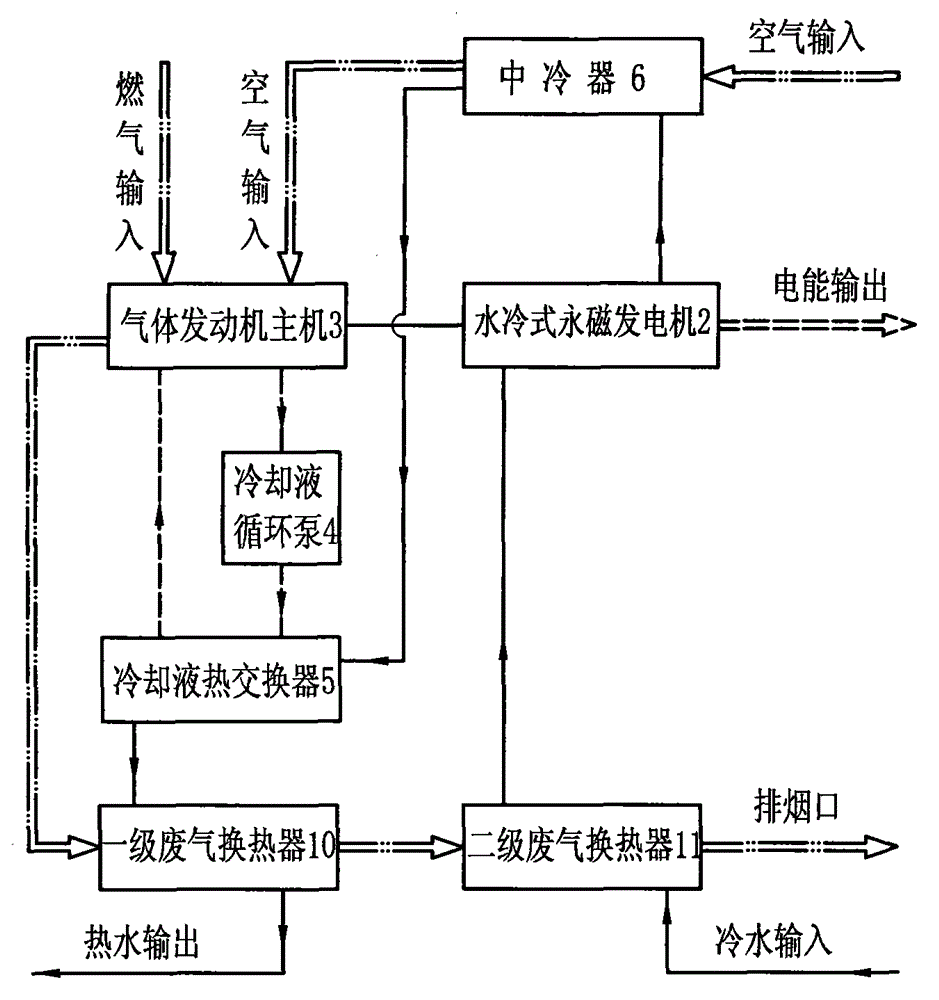

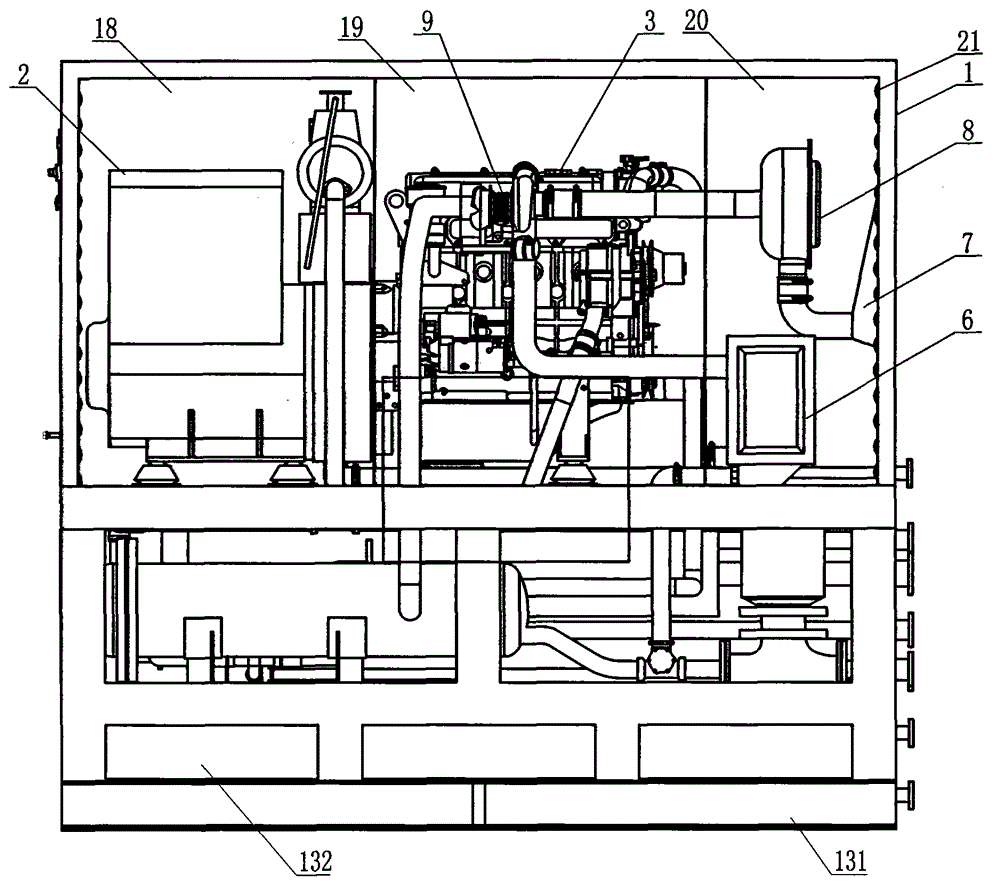

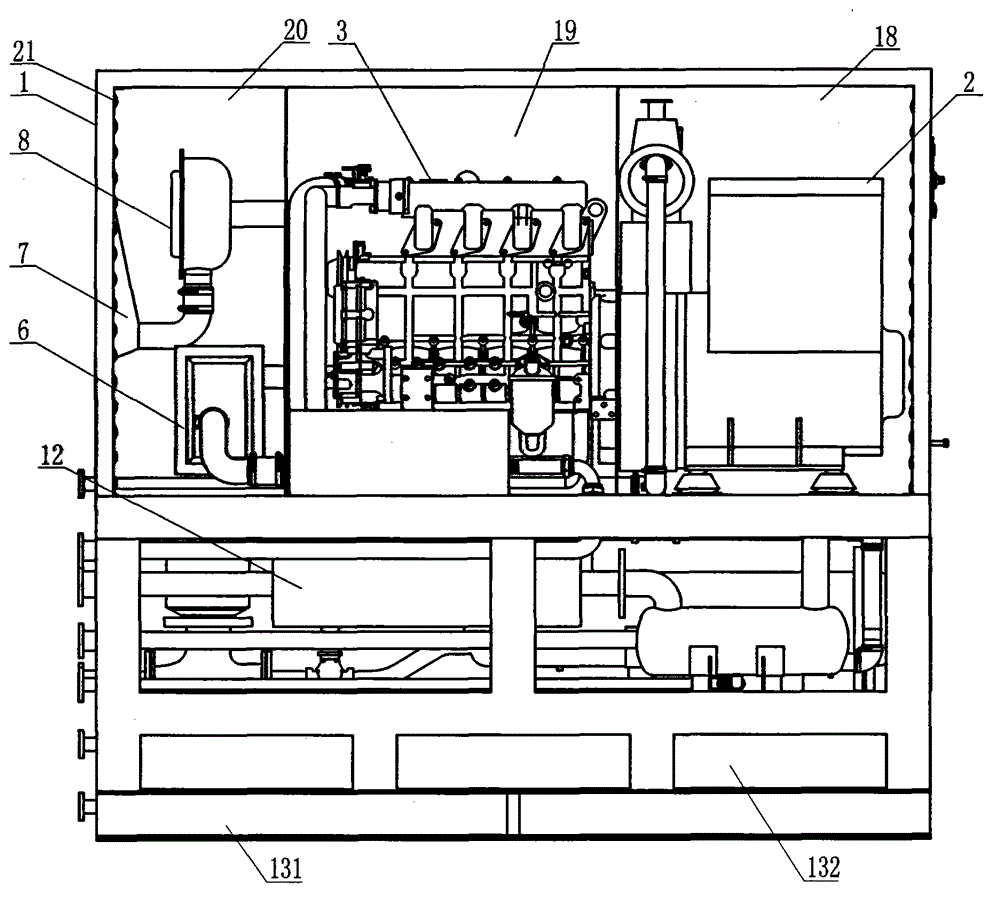

Ultra-silence efficient gas cogeneration system

ActiveCN103147852AReduce running noiseReduce noiseLiquid coolingMachine framesEnvironmental noiseThermal energy

The invention discloses an ultra-silence efficient gas cogeneration system which comprises a silence case, wherein a water-cooled permanent-magnet power generator, a gas engine, an engine flue gas waste heat recovery device, an engine lubricating oil replacement device and an external heat supply system are mounted in the silence case. All parts of the cogeneration system are mounted in the silence case, so that noise is low when the system operates, and the noise is lower than fifty-six decibels through detection, and environmental noise pollution is eliminated. In addition, the engine flue gas waste heat recovery device is used to recover a large amount of heat generated when the system operates, the heat is transferred outside by the external heat supply system, and a step-type heat recovery structure is formed, so that a heat recovery rate is high, the continuous operation time is long, and the cogeneration system is widely applied to household or working sites, can meet heating requirements of the sites, is high in utilization rate, and contributes to energy conservation and emission reduction.

Owner:WEIFANG NAIPUTE GAS GENSET

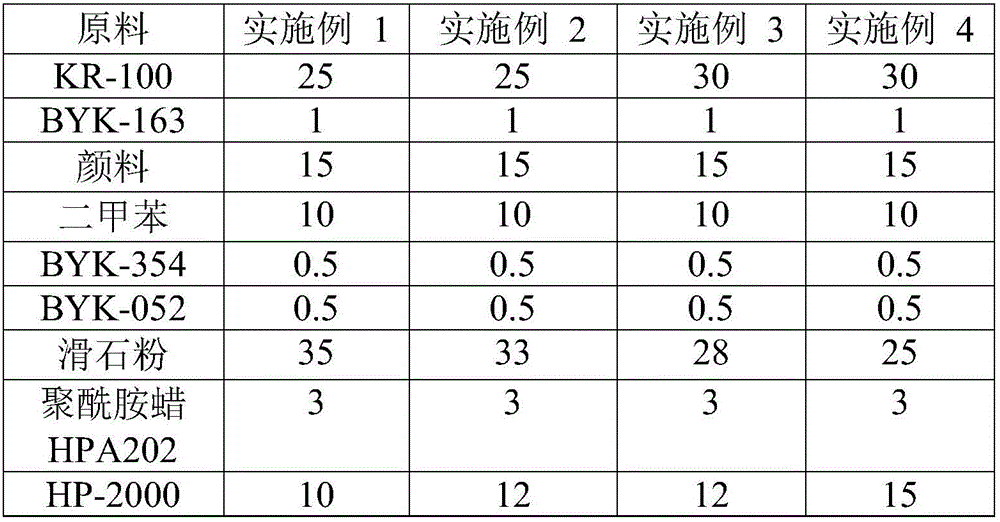

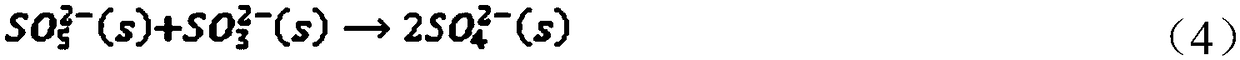

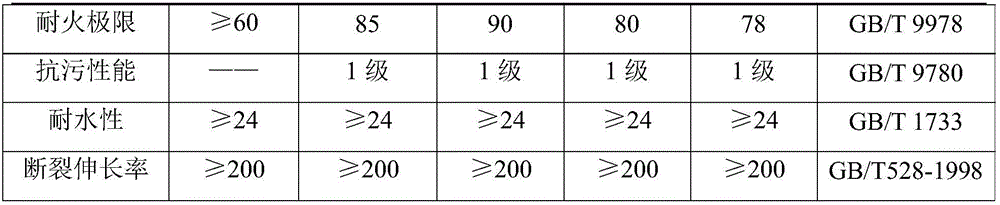

High-temperature-resistant and tough epoxy coating

InactiveCN106318120AGood electrical performanceImprove anti-corrosion performanceFireproof paintsAnti-corrosive paintsDiluentExtreme temperature

The invention provides a high-temperature-resistant and tough epoxy coating. The coating is prepared from raw materials in percentage by weight as follows: 25%-35% of epoxy resin, 5%-25% of a pigment, 15%-35% of filler, 5%-15% of a diluent, 1%-5% of aids and 10%-15% of a curing agent; the aids comprise a dispersant, a leveling agent, an antifoaming agent and a rheological aid in the mass ratio being (1-3):(0.2-0.8):(0.2-0.8):(1-5). The high-temperature-resistant and tough epoxy coating is applied to casing parts of high-voltage electrical appliances, and a coating film has the extreme temperature resistance up to 800 DEG C (instantaneous), can resist high pressure and cooking and has good toughness and corrosion resistance.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

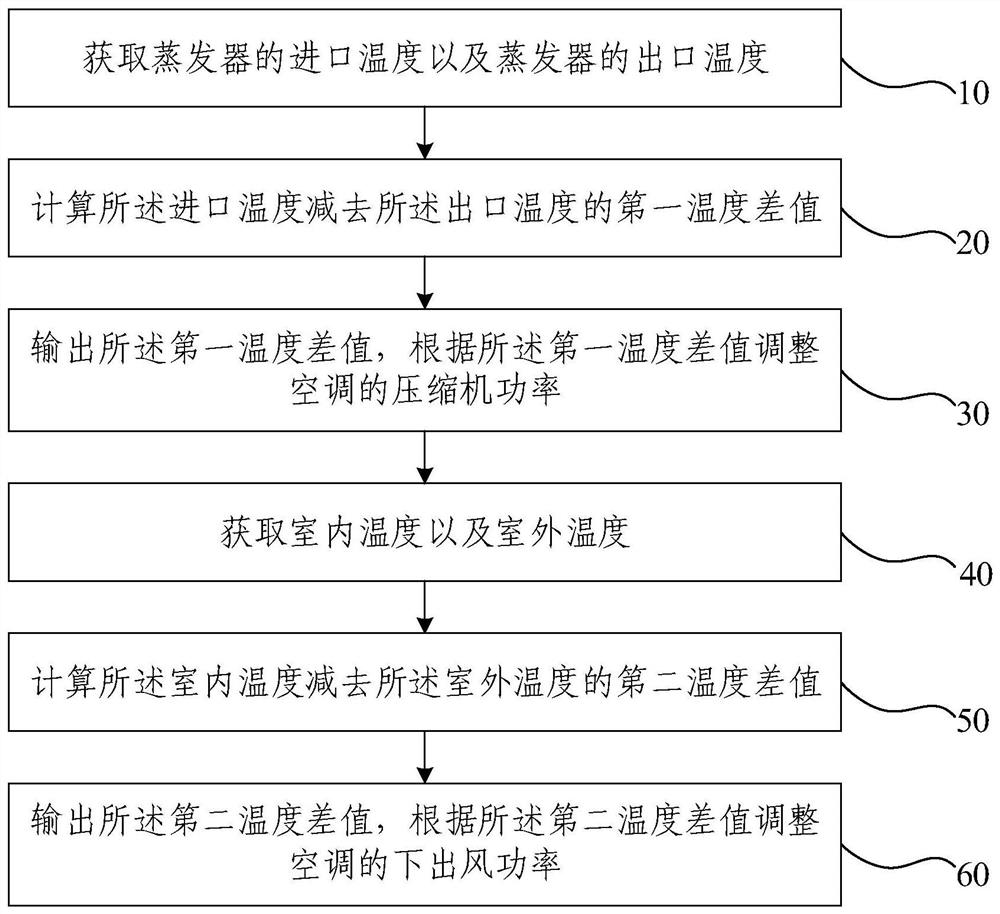

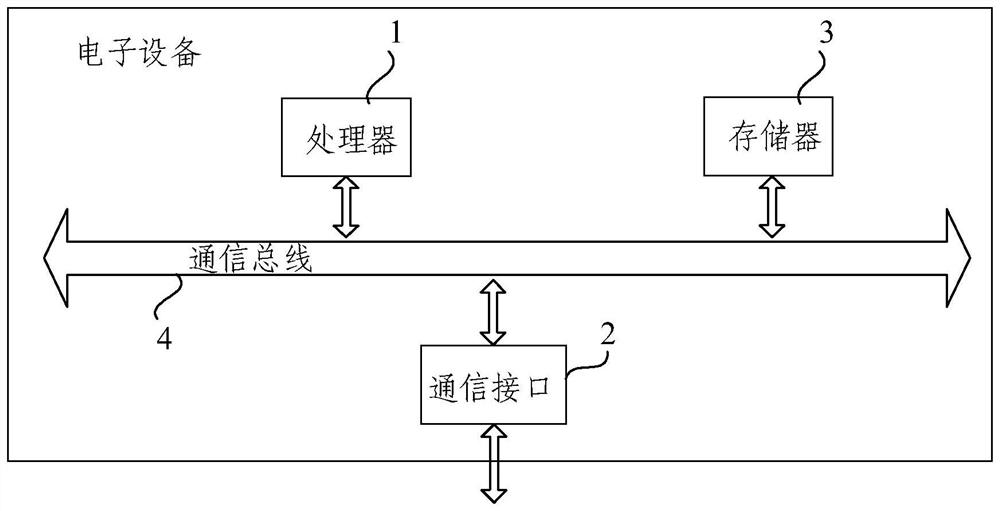

Fresh air conditioner control method and device, electronic equipment and storage medium

PendingCN113375303AAutomatically adjust working statusImprove work efficiencyMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsFresh air

The invention provides a fresh air conditioner control method and device, electronic equipment and a storage medium. The control method comprises the steps that the inlet temperature of an evaporator and the outlet temperature of the evaporator are obtained; a first temperature difference value is calculated by subtracting the outlet temperature from the inlet temperature; the first temperature difference value is output, and the compressor power of the air conditioner is adjusted according to the first temperature difference value; indoor temperature and outdoor temperature are obtained; a second temperature difference value is calculated by subtracting the outdoor temperature from the indoor temperature; and the second temperature difference value is output, and the lower air outlet power of the air conditioner is adjusted according to the second temperature difference value. The operating parameters of the air conditioner can be adjusted according to the difference values among the temperature parameters, and the air conditioner is more environmentally friendly and energy-saving while the working efficiency of the air conditioner is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Method for preparing composite plate by recycling bag type dust remover waste filter bags

InactiveCN104760365AFacilitate reuseAvoid secondary pollutionConstruction materialLaminationFiberGlass fiber

The invention discloses a method for preparing a composite plate by recycling bag type dust remover waste filter bags; the waste filter bags are successively subjected to crushing, cleaning, drying, shredding, mixing of glass fibers and the crushed opened material, acupuncture composite, high-temperature pressing, cooling and design finalizing, and finished product composite plate obtaining. Compared with the prior art, produced building templates and wall partition plates have no high requirements on a cleaning process and can be covered with cement and the like on the outside during the using process, so that no requirement exists for building remaining cement or lime compositions; with recycling of the waste filter bag resources, secondary pollution caused by landfilling, incineration and other processing methods is effectively solved, so as to contribute to resource re-utilization, energy saving, emission reduction and other works; in the high-temperature pressurization process, thermoplastic fibers are dissolved to play a bonding effect, so that a glue and other binders are replaced, and produced boards do not contain formaldehyde, the glue and other harmful substances and belong to green environmental-protection building materials.

Owner:ZHEJIANG DEWEIDE ENVIRONMENTAL PROTECTION TECH

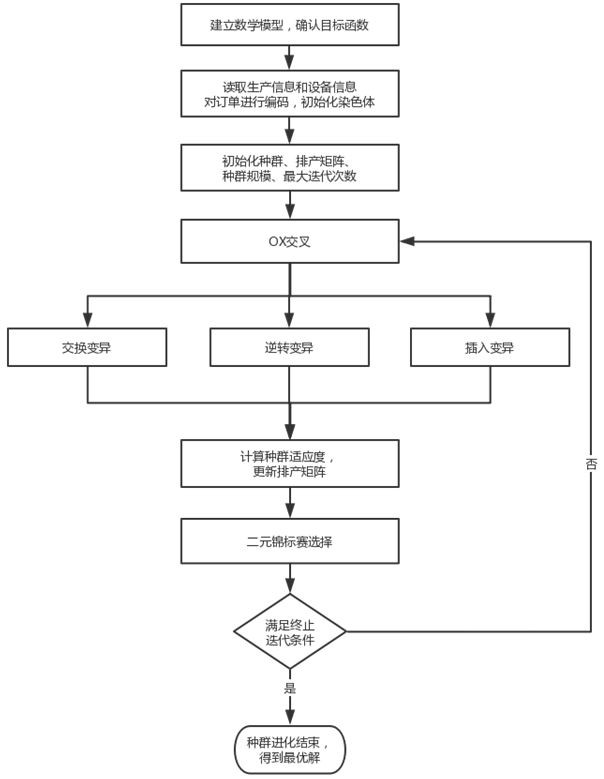

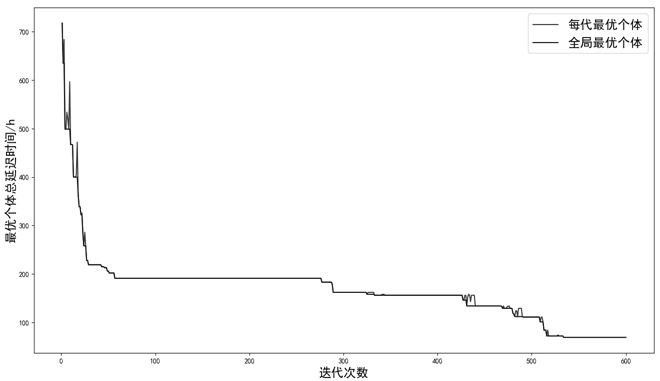

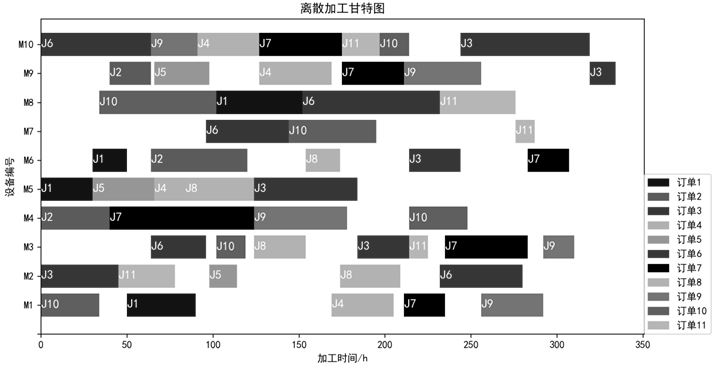

Production and manufacturing scheduling optimization method based on improved genetic algorithm

InactiveCN113379087AReduce delivery delay penalty costsImprove satisfactionReservationsManufacturing computing systemsGenetics algorithmsManufacturing scheduling

The invention discloses a production and manufacturing scheduling optimization method based on an improved genetic algorithm. The method comprises the following steps: firstly, aiming at a production scheduling optimization target, establishing a mathematical model, determining a population fitness function, reading order information and equipment information, numbering equipment, encoding an order process into a chromosome gene, initializing a population, the maximum number of iterations and a production scheduling matrix; carrying out operations such as crossover and variation on chromosomes of the population to obtain a new generation of population, arranging order procedures corresponding to chromosome genes on equipment in a conflict-free manner by combining a production scheduling matrix, and calculating a fitness function of population individuals; and finally, selecting next-generation individuals according to a binary tournament selection strategy, reserving fitness individuals to the next generation, repeating the steps until the maximum iteration frequency is reached, and decoding the individual chromosome with the highest fitness as an optimal production scheduling scheme. The global optimization can be quickly realized, and the effect is better than that of the existing optimization method.

Owner:ZHEJIANG UNIV

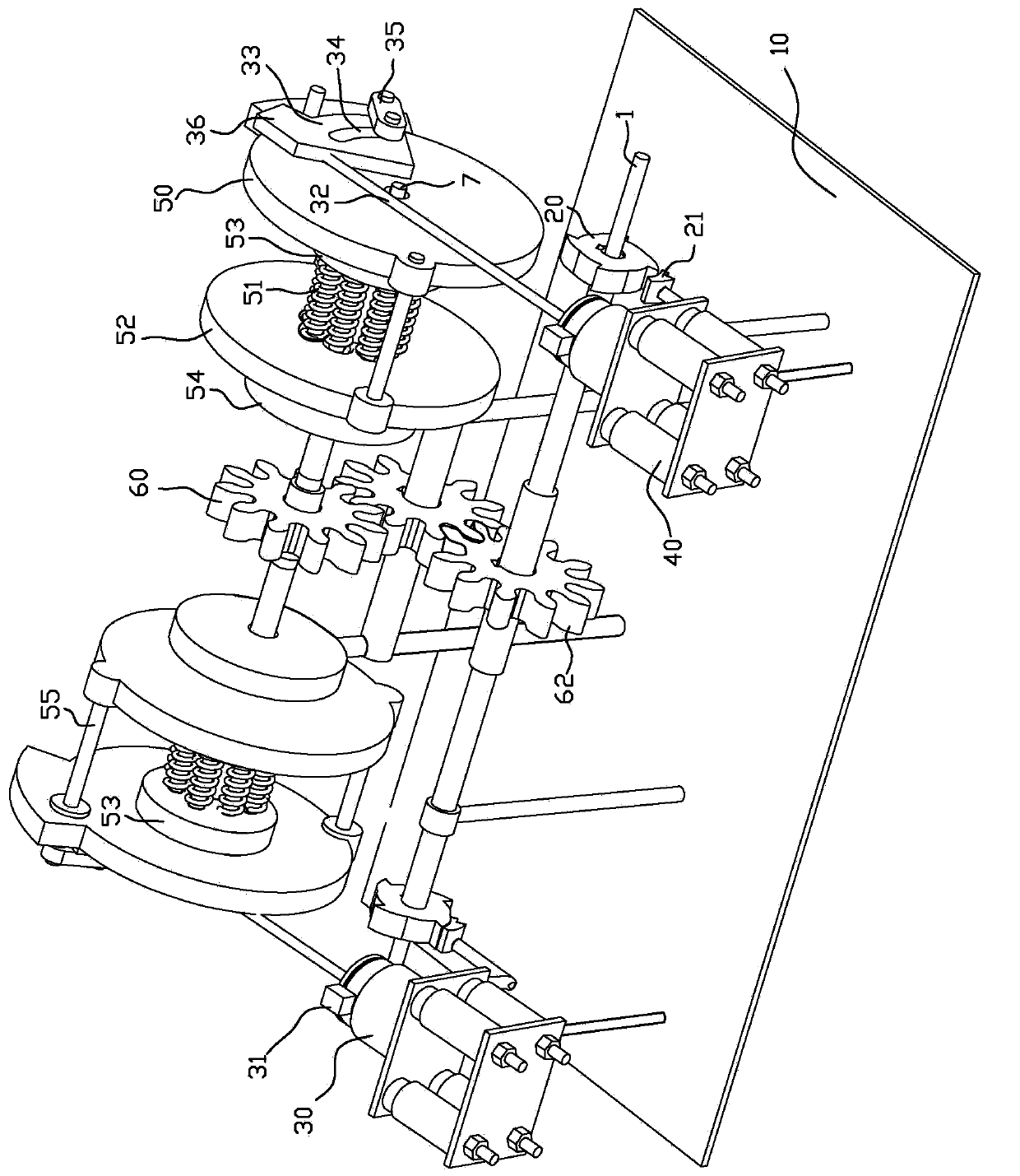

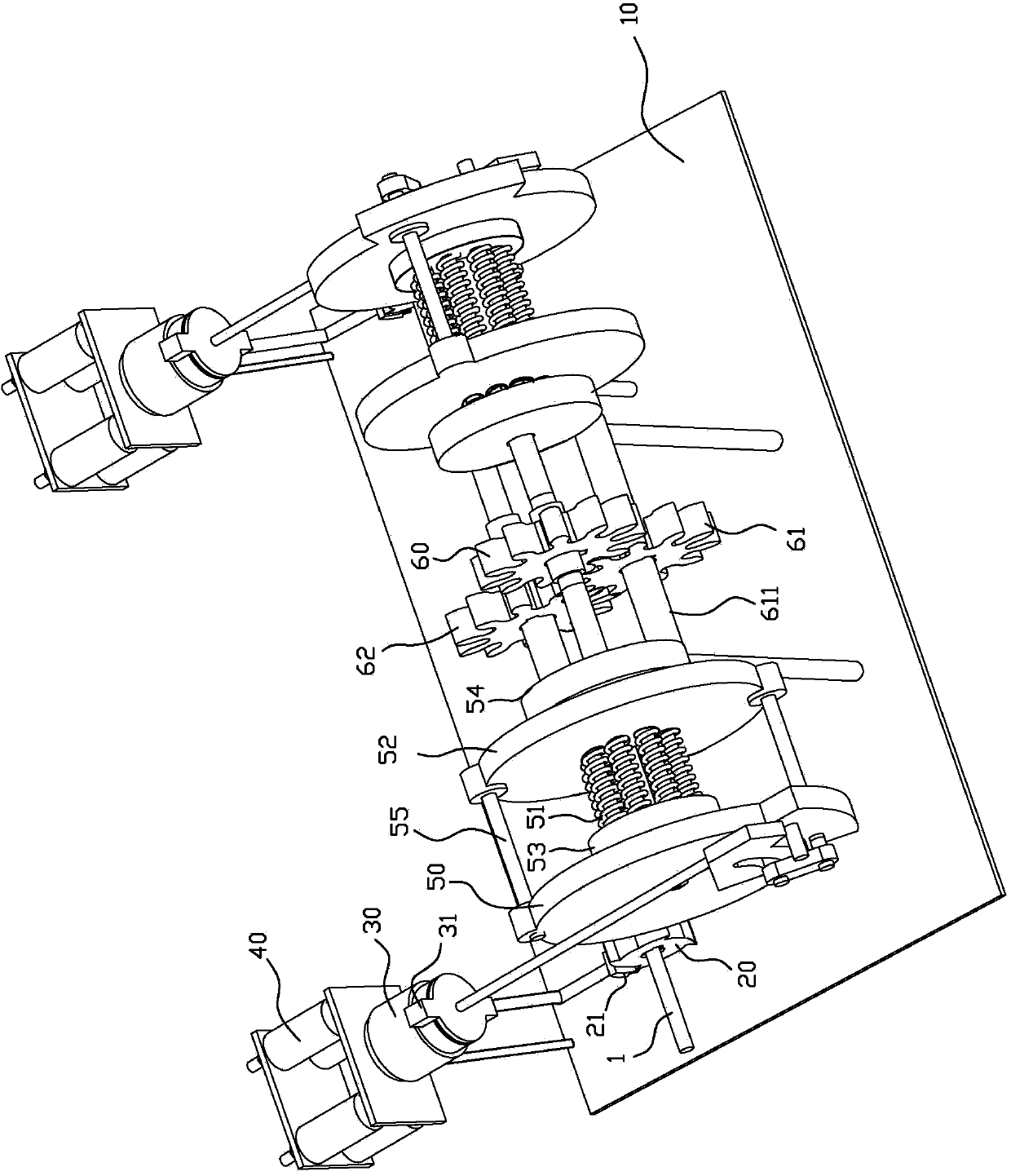

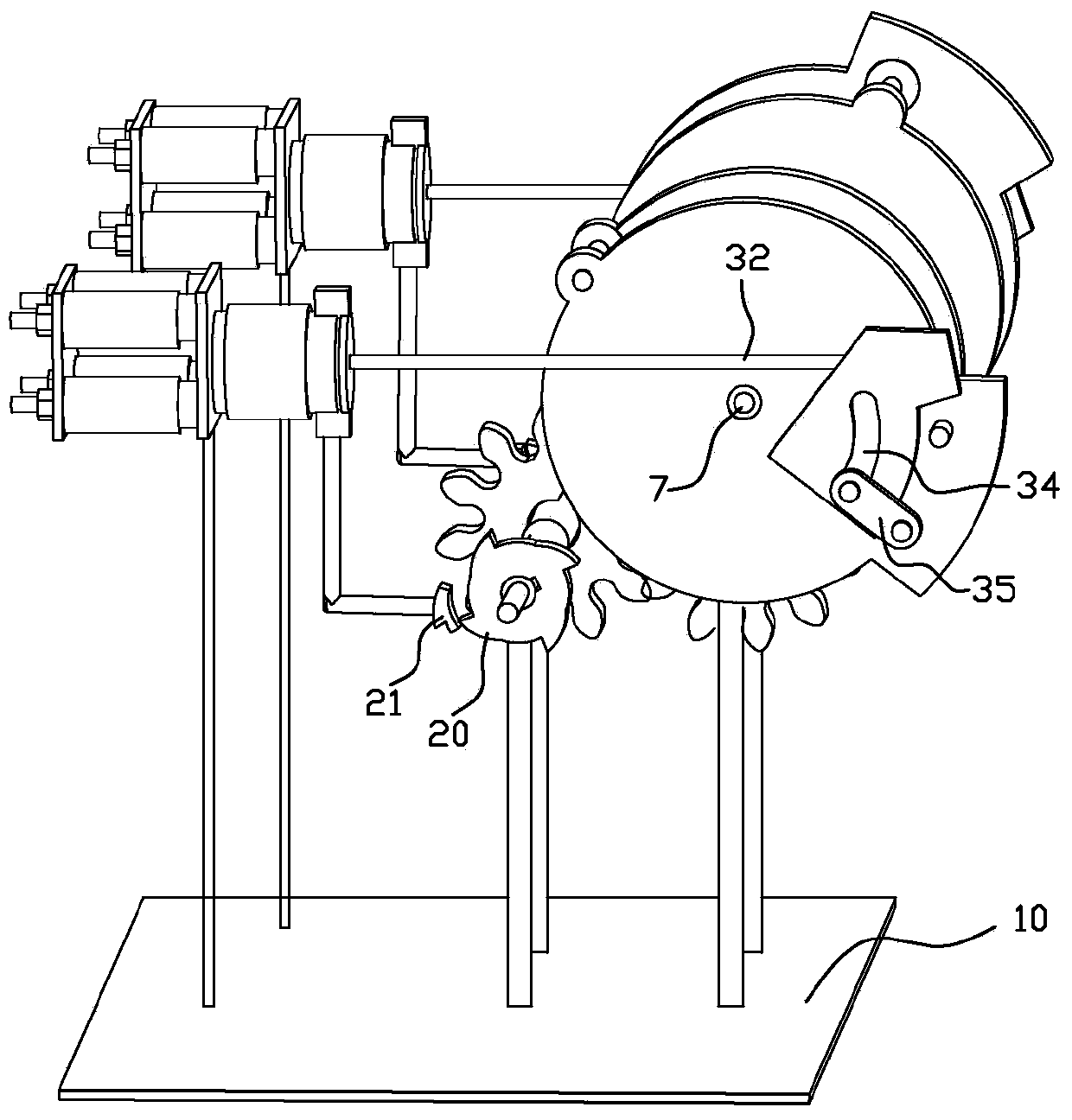

Mechanical transmission device

InactiveCN104179922ACompact designContribute to energy saving and emission reductionGearingDrive wheelTransmitted power

The invention relates to a mechanical transmission device. The device comprises a power generation mechanism, a power releasing mechanism, a power transition mechanism and a power back-transmission mechanism, wherein the power generation mechanism comprises a power device and a connecting cylinder; the power releasing mechanism comprises a power output shaft, a first gear and elastic transmission assemblies arranged on two sides of the first gear, the elastic transmission assemblies are provided with connecting rod assemblies connected with the connecting cylinder, the connecting rod assemblies can drive driving wheel assemblies to rotate on the power output shaft, and an angle between each of two push points, by which the two connecting rod assemblies are connected with the driving wheel assemblies for rotation, and the power output shaft is 45 degrees; and the power releasing mechanism transmits power through gears while releasing the power, so that one transmission block of the power back-transmission mechanism is always staggered with an arc angle of the four-angle transmission wheel arranged at the end where the transmission block is located, and performs staggered movement under the pushing of the power device for a next round of transmission. The device has the advantages of novel structure, energy saving, environment protection and improvement of power system efficiency.

Owner:邹新鹏

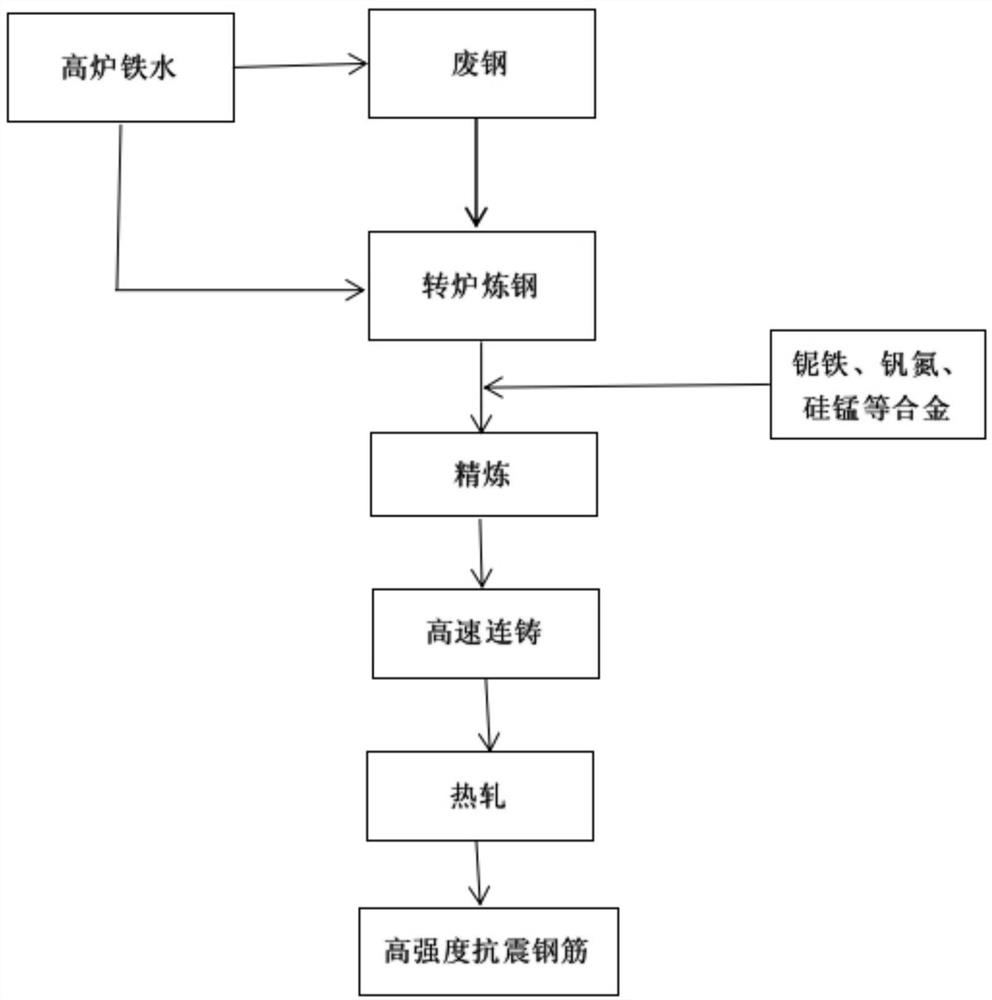

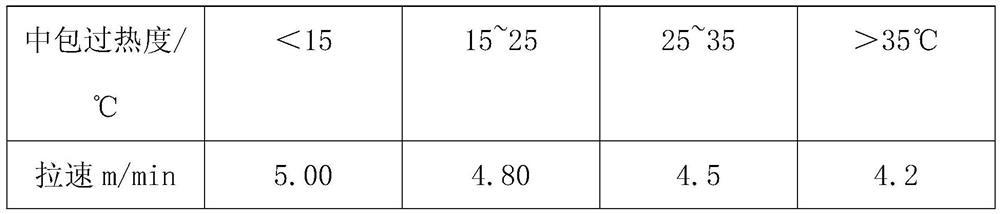

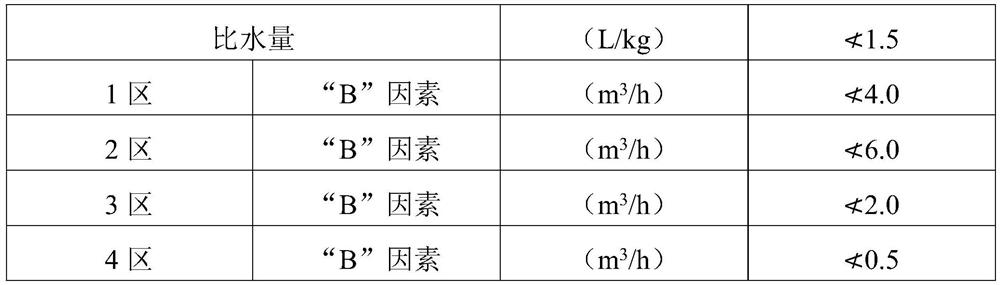

Production method of HRB600E high-strength anti-seismic reinforcing steel bar

PendingCN114058770AQuality improvementImprove applicabilityManufacturing convertersProcess efficiency improvementFerroniobiumSmelting process

The invention provides a production method of an HRB600E high-strength anti-seismic reinforcing steel bar, and relates to the technical field of reinforcing steel bar production. The method includes the following steps: melting in a blast furnace, charging in a converter, refining in an LF furnace, continuously casting and cooling and rolling to obtain a finished product; a process route of blast furnace molten iron, a converter, an LF (ladle furnace), high-pulling-speed continuous casting and a rolling mill is adopted, a converter smelting process, a microalloying process, an LF refining inclusion removal process, continuous casting electromagnetic stirring, an automatic water distribution process, hot rolling processes such as optimization of hot rolling starting temperature and controlled cooling after rolling are adopted, and a through-water cooling process is not adopted; and the high-strength anti-seismic reinforcing steel bar is produced through converter smelting and by adopting a niobium and vanadium nitrogen microalloying process, the method is similar to a common deformed steel bar smelting process, operating is easy, applicability is high, popularization is convenient, ferroniobium and vanadium nitrogen alloy is added in the tapping process, the alloy yield is high, molten steel components can be accurately controlled, and the product performance is stably controlled.

Owner:YANGCHUN NEW STEEL CO LTD

Ultra-dispersed photocatalyst and preparation method and application thereof

InactiveCN105833920AReduce maintenance costsEasy to operateNon-fuel substance addition to fuelOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholCombustion

The invention provides an ultra-dispersed photocatalyst which is prepared from 90-110 parts of an alcohol solvent, 2-6 parts of titanium dioxide and 10-14 parts of a dispersing agent. The ultra-dispersed photocatalyst is a semi-transparent solution, the primary particle size of titanium dioxide is 10-50 nm, the secondary particle size of titanium dioxide is 100 nm, and the ultra-dispersed photocatalyst is safe, free of toxin and remarkable in catalytic effect. The ultra-dispersed photocatalyst mainly has the advantages that firstly, a photocatalysis response in the ultraviolet and visible light full-spectrum range is achieved; secondly, the photocatalyst is suitable for combustion catalysis of fuel; thirdly, the photocatalyst can remarkably reduce emission and is safe and environmentally friendly. A preparation method of the ultra-dispersed photocatalyst has the advantages that high dispersing of nano titanium dioxide in the alcohol solvent is achieved; part of titanium ion self-doping features are obtained, the forbidden band width is reduced, and the photocatalysis response in the ultraviolet and visible light full-spectrum range is achieved; cost is reduced. Application of the ultra-dispersed photocatalyst is not limited to indoor environment pollution, sterilization and deodorizing, and the ultra-dispersed photocatalyst can be directly applied to combustion catalysis of fuel, particularly combustion catalysis of fuel of automobile internal-combustion engines.

Owner:天津茏怿投资有限公司

Greenhouse multi-crop ecological cultivation method for penaeus vannamei

ActiveCN106332821APrecise temperature controlTemperature controlClimate change adaptationPisciculture and aquariaGreenhouse cultivationDesalination

The invention discloses a greenhouse multi-crop ecological cultivation technology for penaeus vannamei. The technology mainly comprises the steps: (1) building a penaeus vannamei greenhouse cultivation facility; (2) preparing before putting young penaeus vannamei; (3) putting the young penaeus vannamei and performing desalination management; (4) performing water environment management; (5) throwing feed; (6) preventing and controlling diseases; (7) catching and the like. The technology can be implemented by adjusting measures to local conditions and is high in operability, and the cultivation yield of the penaeus vannamei is increased.

Owner:常熟市民意水产科技发展有限公司

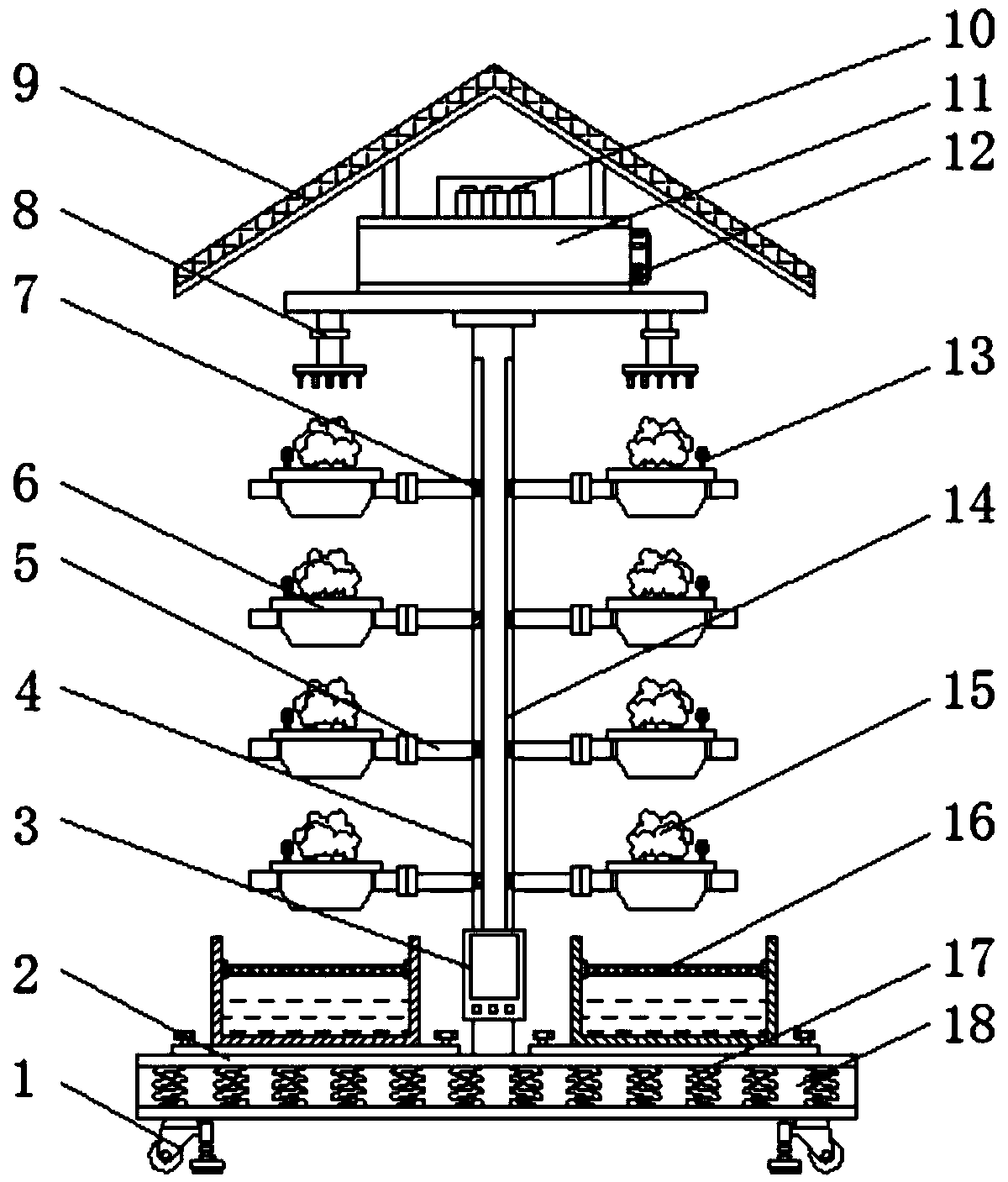

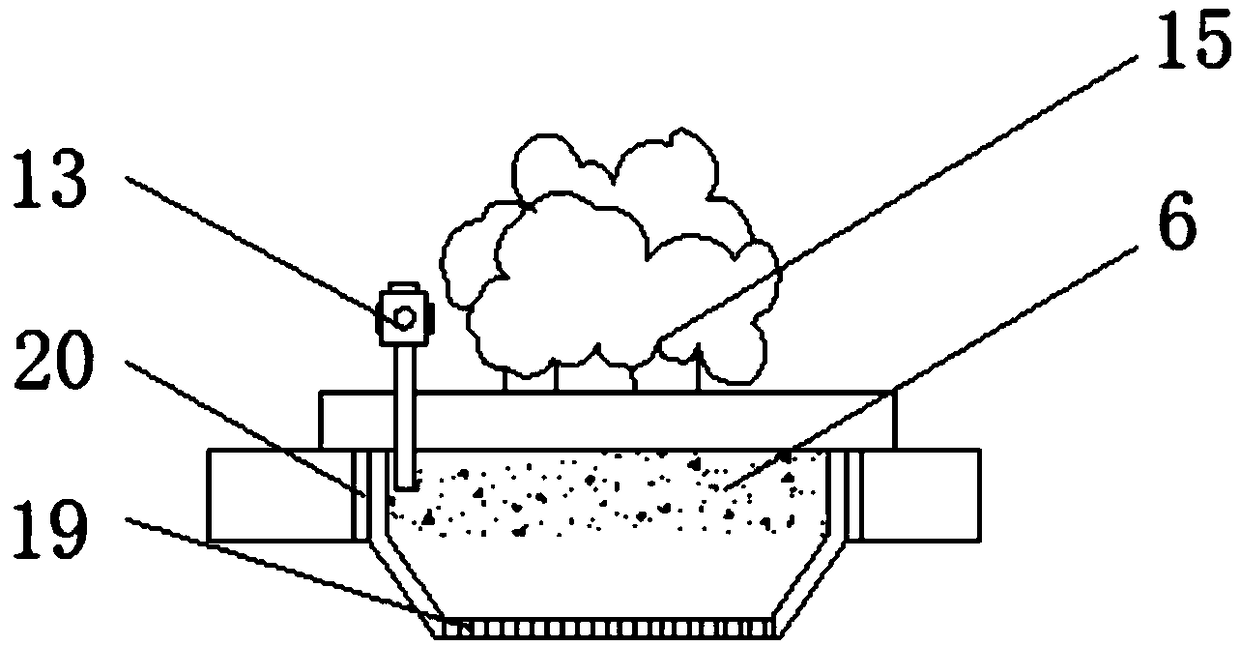

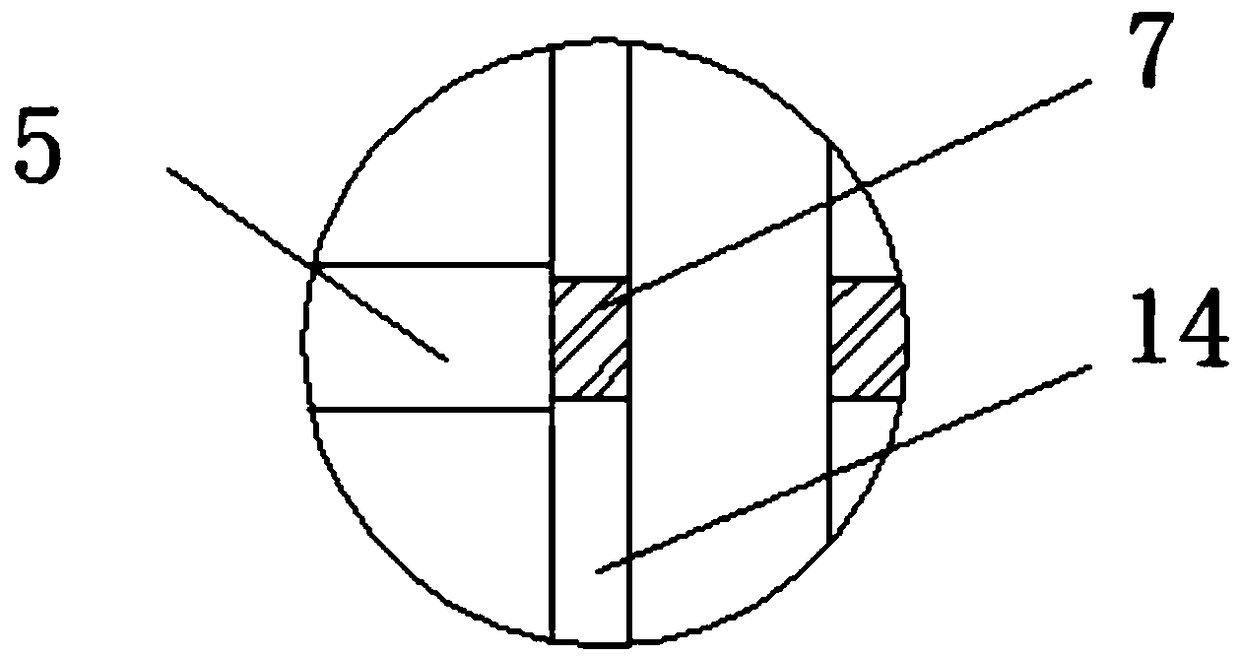

Vertical stand for conveniently planting vegetables in balcony

InactiveCN108770544AEasy plantingEasy to collectSelf-acting watering devicesCultivating equipmentsWater storage tankAgricultural engineering

The invention discloses a vertical stand for conveniently planting vegetables in a balcony. The vertical stand comprises a bottom plate, planting pots, a solar panel and water storage tanks, wherein avertical column is mounted in the center of the top of the bottom plate; a control panel is arranged at the bottom of the vertical column; cross rods are uniformly mounted on two sides of the vertical column; reserved grooves are formed in centers of the cross rods; the planting pots are fixed in the reserved grooves; the vegetables are arranged in the centers of the planting pots; a soil humidity detector is arranged in each planting pot on one side of the corresponding vegetable; outputs of the soil humidity detectors are electrically connected with an input end of the control panel; an output end of the control panel is electrically connected with an input end of a spray device. The vertical stand for conveniently planting the vegetables in the balcony is provided with the bottom plate, universal wheels are arranged at the bottom of the bottom plate, so that the vertical stand is convenient to move and can be moved at any time, and the vertical stand is convenient to use.

Owner:贵州太朴生态农业有限公司

Continuous efficient seed priming device

InactiveCN104285541AIncrease the priming speedSolve the large consumption of initiatorGerminating apparatusEngineeringSeed priming

The invention discloses a continuous efficient seed priming device which comprises a priming agent dissolution and output device and a tank, wherein the tank is provided with a tank cover, is connected with a vacuum machine and is also provided with a vacuum breaker valve and a moisture exhaust valve; a humidity sensor in the tank is connected with an air compressor; the air compressor is communicated with the tank through a cavity and a filter screen; the cavity is connected with a priming agent storage tank; the priming agent storage tank is communicated with the tank through the priming agent dissolution and output device; the bottom of the tank finally falls into a temporary seed storage barrel through a spiral conveyer and a vibrating conveying screen; and the vibrating conveying screen is communicated with the priming agent storage tank through a liquid collection hopper and a small priming agent storage tank. The continuous efficient seed priming device is capable of solving the technical difficulties that a seed priming device is slow in priming speed and low in efficiency and has a poor priming agent permeation effect, seeds are not fluidized, the priming agent consumption is large and a priming agent is difficult to recycle, and the continuous efficient seed priming device is conducive to energy conservation and emission reduction, is capable of improving the working efficiency and priming effect, has a simple and reliable system mechanism, has continuous and perfect functions, is particularly suitable for the large-scale agricultural industrial priming and seed soaking operations and has broad application prospects.

Owner:JISHOU UNIVERSITY

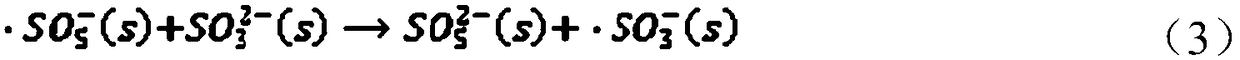

Flue gas desulfurization catalyst and application thereof to flue gas desulfurization in decomposition furnace of novel dry-process cement kiln

ActiveCN108714425AEmission reductionIncrease speedGas treatmentHeterogenous catalyst chemical elementsResource utilizationDecomposition

The invention belongs to the technical field of environmental protection, and discloses a flue gas desulfurization catalyst and the application thereof to flue gas desulfurization in a decomposition furnace of a novel dry-process cement kiln. The flue gas desulfurization catalyst comprises the following components in percent by mass: 30-60% of manganese slag, 10-42% of nickel slag, 20-40% of copper slag, 10-30% of steel slag and 0.1-0.5% of cobalt oxide, altogether 100%. The flue gas desulfurization catalyst is uniformly mixed and ground and is then added at a raw material mill, a kiln hoist or a decomposition furnace coal injection pipe, and the SO2 concentration of flue gas can meet the standard when the addition amount is only 0.01-0.1% of the mass of a cement raw material. CaO desulfurization in the decomposition furnace is fully used for achieving the flue gas desulfurization; the flue gas desulfurization catalyst is easy to produce, easy and convenient to use and low in cost, isespecially suitable for the desulfurization of cement kiln flue gas with medium and low sulfur emission, and has an important practical significance on solving the problems of resource utilization andenvironment pollution of a high-sulfur raw material in the cement industry.

Owner:广东万引科技股份有限公司

Preparing method for high-pressure-resistant tough epoxy paint

InactiveCN106280898AGood electrical performanceImprove anti-corrosion performanceFireproof paintsConjugated diene hydrocarbon coatingsSolvent freeFirming agent

The invention provides a preparing method for high-pressure-resistant tough epoxy paint. The preparing method comprises a main agent preparing method and a curing agent preparing method. The main agent preparing method comprises the following steps that firstly, epoxy resin, a thinning agent and a dispersing agent are added into a stirrer in sequence and stirred evenly under the rotating stirring speed of 800 rpm; secondly, pigment and a defoaming agent are added into the stirrer in the first step in sequence, filler is added after the mixture is sufficiently stirred evenly, the mixture is ground by a grinding miller, and ground paste is obtained; thirdly, the ground paste is put into the stirrer, a flatting agent and a rheology modifier are added in the stirring state and stirred evenly, and the wet-cured high-elasticity solvent-free epoxy paint main agent is obtained. The high-pressure-resistant tough epoxy paint is applied to paint for shells of high-voltage electrical apparatuses, the extreme temperature resistance of coatings of the product can reach 800 DEG C (instant), the coatings can be resistant to high pressure and steaming, and the paint coatings have good toughness and corrosion resistance.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

Blast furnace slag treatment method and device capable of directly obtaining high-temperature dried slag

InactiveCN106906321AReduce dosageIncrease temperatureRecycling and recovery technologiesSlagHigh pressure water

The invention discloses a blast furnace slag treatment method and device capable of directly obtaining high-temperature dried slag and belongs to the technical field of blast furnace slag treatment in steel-metallurgy industries. The blast furnace slag treatment device comprises an upper water slag groove, a high-pressure water spray head, a special net-type conveyor belt, a lower hot water collecting groove and an end slag-blocking net; liquid blast furnace slag flows into the upper water slag groove and is cooled by water sprayed by a high-pressure water nozzle, and the liquid blast furnace slag is broken into a small-granular slag-water mixture after water quenching, cooling and breaking, and the slag-water mixture flows downwards along the upper water slag groove by aid of gravity; after the temperature of granulated blast furnace slag is lowered to be 400-800 DEG C, the granulated blast furnace slag falls into the special net-type conveyor belt to quickly achieve slag-water separation, after water falls into the lower hot water collecting groove, the water is continuously used through a circulating system, and after separation, water on the surface of slag is heated and then evaporates, so that the high-temperature dried slag of 300-700 DEG C is formed; and the high-temperature dried slag is finally sent to a waste heat boiler to be subjected to waste heat using. According to the blast furnace slag treatment method and device capable of directly obtaining the high-temperature dried slag, the waste heat using rate of blast furnace slag treatment can be greatly improved, the product quality of solid slag is improved, and energy conservation and emission reduction of the steel-metallurgy industries are facilitated.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

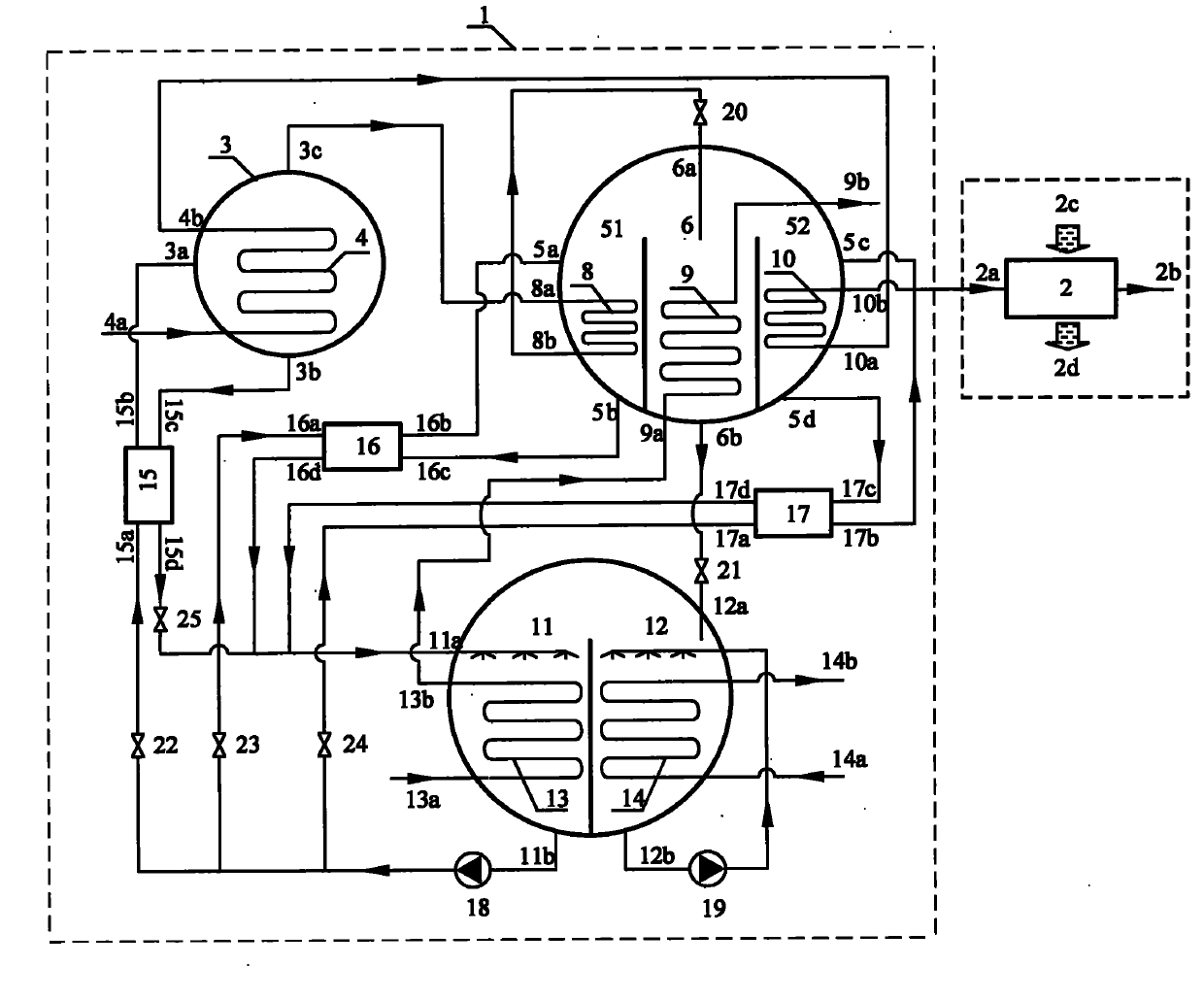

Heat-moisture treatment device driven by urban heat supply network

InactiveCN101949610AImprove energy efficiencyImprove economyDispersed particle separationSorption machinesThermal energyLow voltage

The invention discloses a heat-moisture treatment device driven by an urban heat supply network, which belongs to the technical field of heat-moisture treatment devices. The heat-moisture treatment device comprises an absorption set, a dehumidification set and connecting pipes, wherein the high-temperature water supply of the urban heat supply network is used as the driving heat sources of the absorption set and the dehumidification set so as to realize the energy-level use and graded use of hot water of the heat supply network, the absorption set is used for realizing thermal load processing, and the dehumidification set is used for realizing moisture load processing; and the absorption set comprises a high voltage generator, a low voltage generator, a condenser, an absorber, an evaporator, a plurality of solution heat exchangers, a solution pump, connecting pipelines and accessories. The invention has the greatest advantages of improving the energy utilization and economy of a thermal power plant in summer, reducing the electrical load for refrigeration in summer, alleviating the pressure on peak load regulation so as to help to ensure the normal power demands of the residents in summer, realizing the graded use of thermal energies, and improving the annual utilization rate and comprehensive energy utilization rate of the heat supply network so as to facilitate energy conservation and emission reduction.

Owner:TSINGHUA UNIV +1

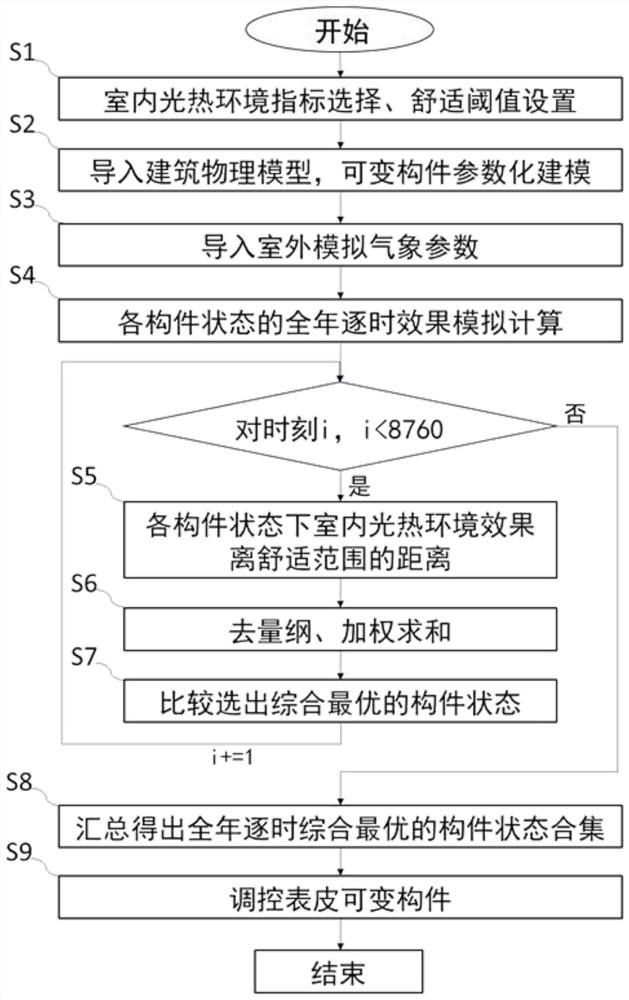

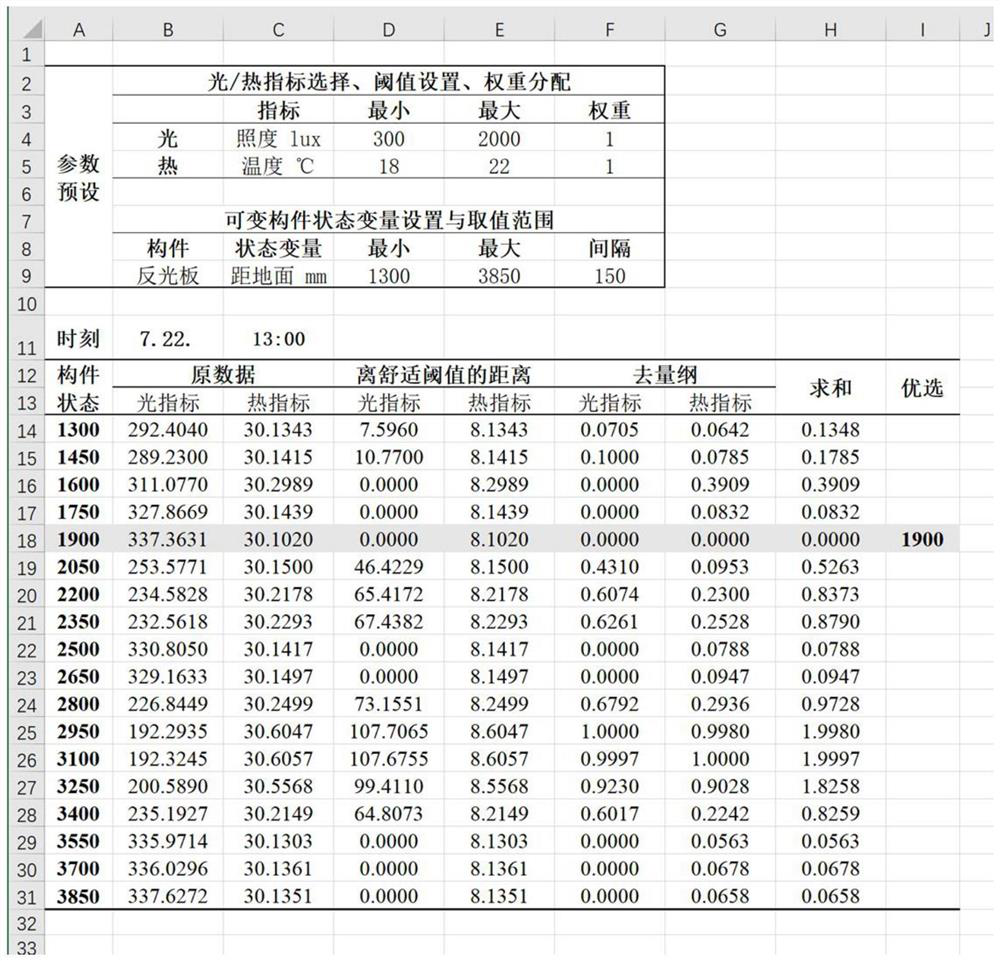

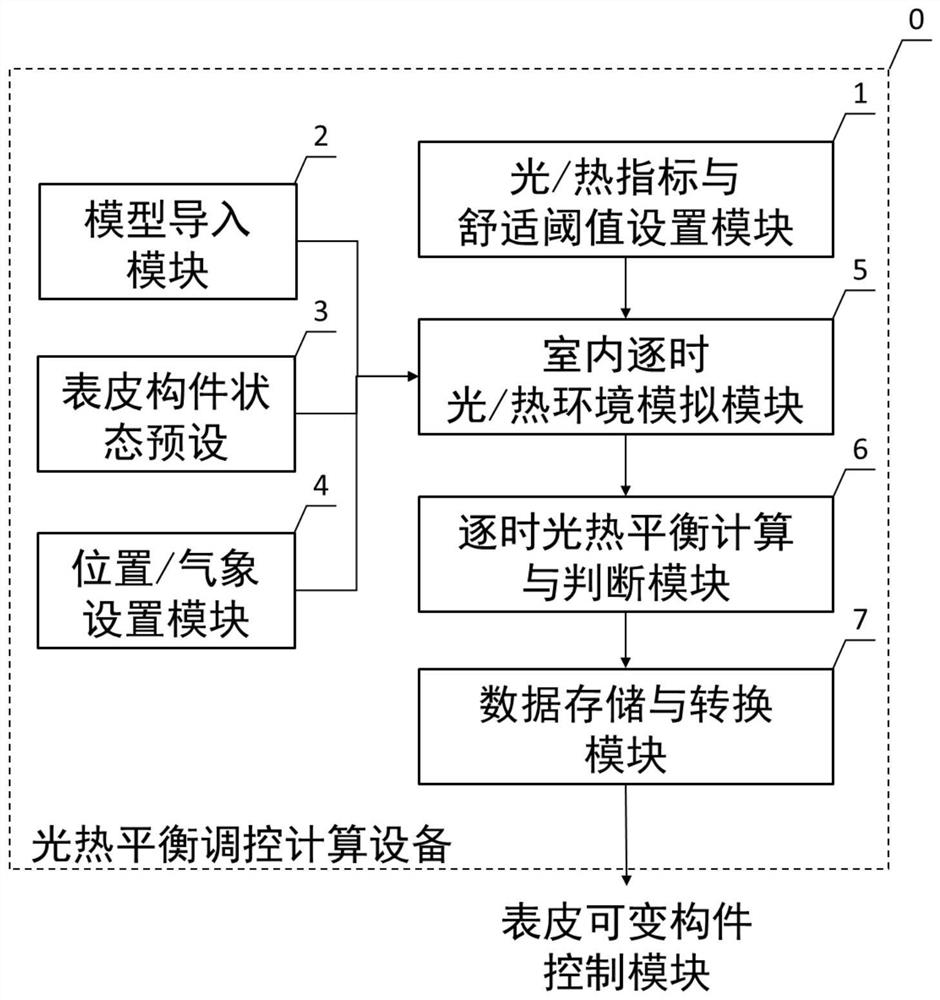

Photo-thermal dynamic balance regulation and control method for building skin variable component

PendingCN112818547ARealize dynamic balance regulationAvoid excessive solar heat radiationDesign optimisation/simulationSpecial data processing applicationsThermodynamicsControl theory

The invention discloses a photo-thermal dynamic balance regulation and control method for a building skin variable component, and belongs to the field of buildings. A photo-thermal dynamic balance regulation and control method for building skin variable components comprises the steps: determining description indexes and comfort threshold values of a photo-thermal environment; conducting parametric modeling on the building skin variable components; importing outdoor simulation meteorological parameters; conducting annual hourly effect simulation calculation analysis on the opening states of all the variable components; calculating the distance between the indoor photo-thermal environment and a preset comfort range threshold value under the opening state of each variable component at the moment i; processing the distance data between the photo-thermal environment and the preset comfort range; comparing to obtain the opening state of the variable component with the optimal comprehensive effect at the moment i; summarizing to obtain a year-round hour-by-hour comprehensive optimal variable component opening state set and automatically controlling opening of the variable component by using the set. By means of the method, the light environment and the heat environment of the building outer skin variable component are jointly optimized, and balance regulation and control between solar heat radiation and natural lighting are achieved.

Owner:SOUTHEAST UNIV

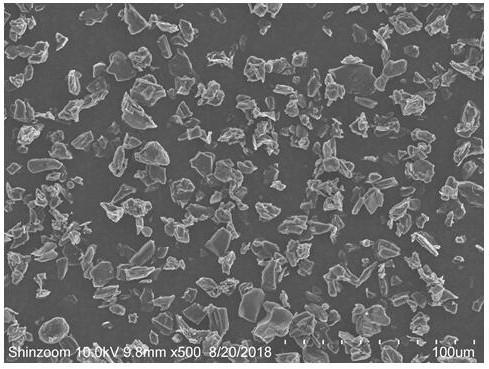

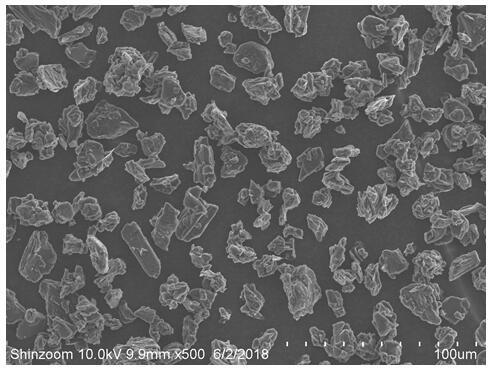

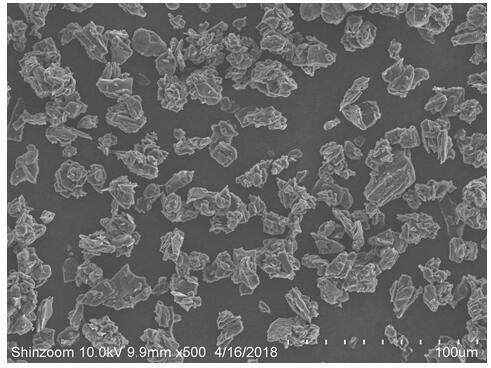

Preparation method of low-cost composite particle graphite cathode material

InactiveCN109748274AImprove charge and discharge performanceSmooth de-embeddingCarbon compoundsCell electrodesMetallurgyMixed materials

The invention provides a preparation method of a low-cost composite particle graphite cathode material. The preparation method includes the steps: mixing coke materials and asphalt powder according tothe weight ratio of 100:1 to 100:20 to obtain mixed materials; placing the mixed materials into a graphitization furnace for graphitization to obtain the composite particle graphitization materials;grading the composite particle graphitization materials to obtain graded materials; screening and demagnetizing the graded materials to obtain the composite particle graphite cathode material. A composite granulating process and a graphitization process are integrated, the cost of the composite granulating process is saved, and the charge and discharge performance of the material is improved.

Owner:HUNAN SHINZOOM TECH

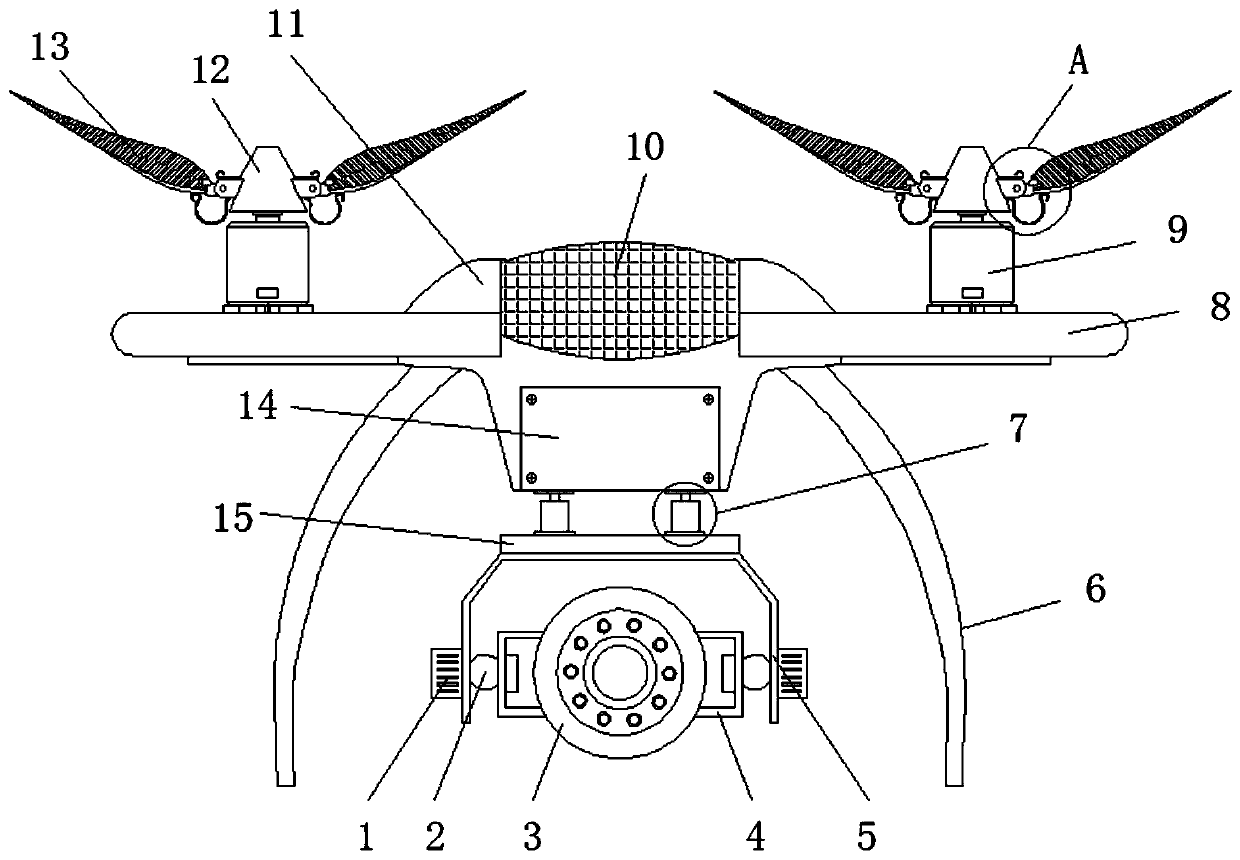

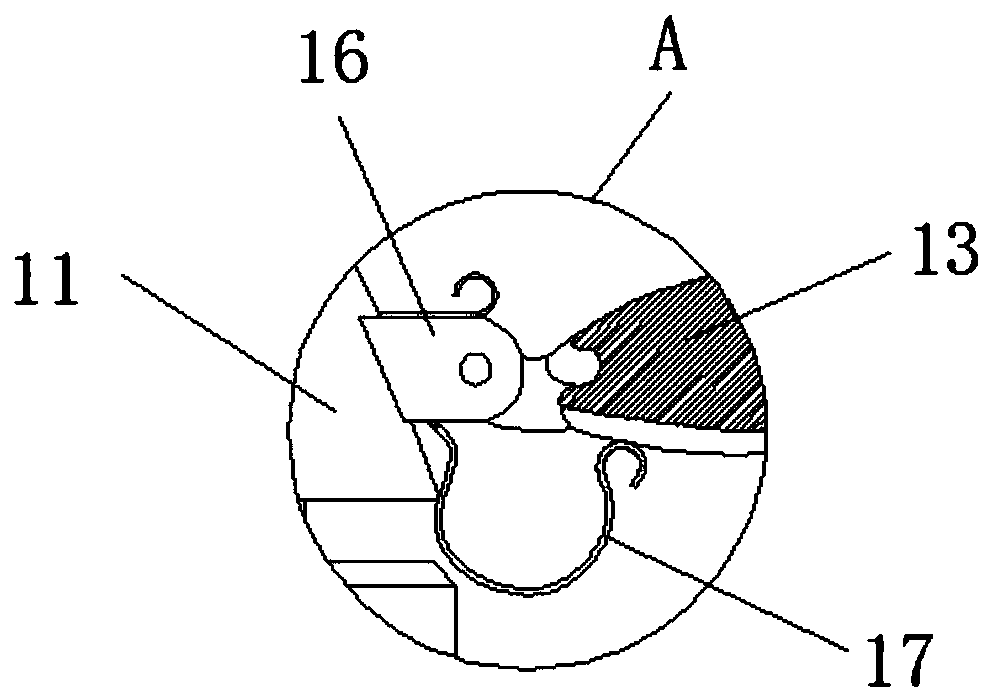

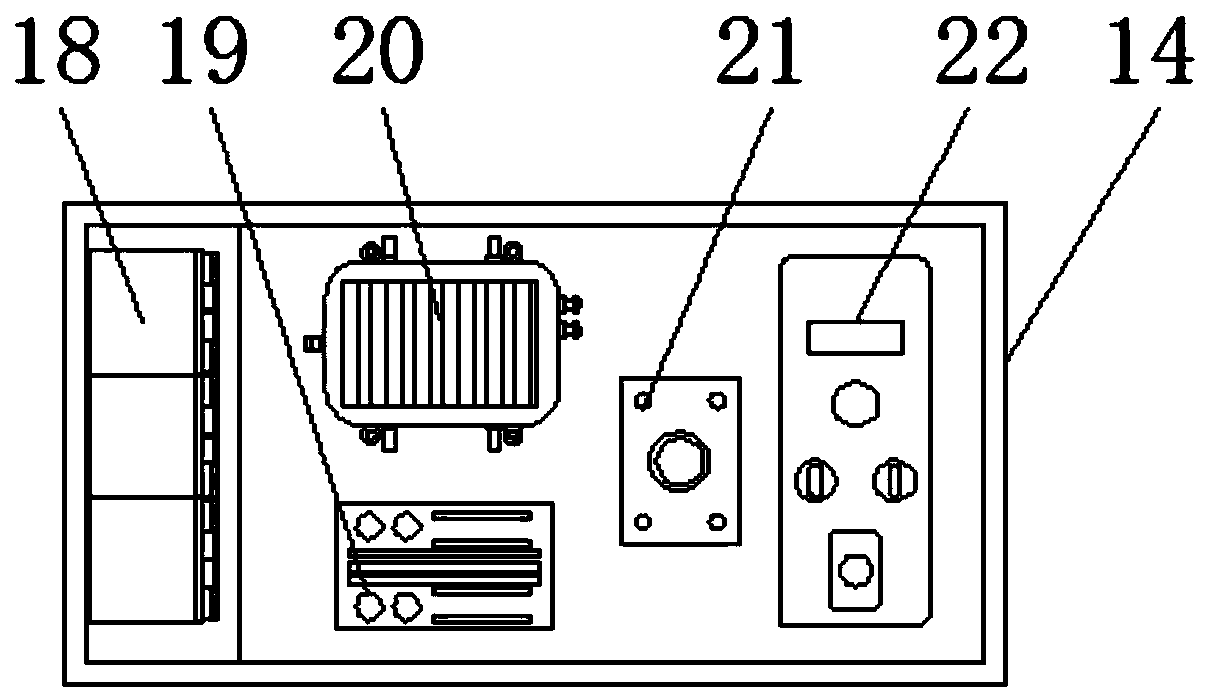

Unmanned aerial vehicle capable of automatically detecting internal and surface damage

PendingCN110254717AProtect environmentReduce impactPropellersEnergy efficient board measuresPropellerFixed frame

The invention discloses an unmanned aerial vehicle capable of automatically detecting internal and surface damage. The unmanned aerial vehicle comprises a fixing frame, an unmanned aerial vehicle body and propeller blades, wherein a solar panel is arranged on the outer side of the unmanned aerial vehicle body, a cavity is formed in the bottom end inside the unmanned aerial vehicle body, a storage battery is arranged at one end of the interior of the cavity, a central processing module is arranged in the portion, on one side of the storage battery, of the cavity a wireless communication module is arranged in the portion, below the central processing module, of the cavity, a thermal imaging camera is fixed inside the fixing frame, and landing gears are arranged at the two ends of the bottom of the unmanned aerial vehicle body. According to the unmanned aerial vehicle, the unmanned aerial vehicle body, the solar panel, the storage battery, the fixing frame, first motors, ears, rotating balls and the thermal imaging camera are installed, the two sides of the fixing frame are provided with the first motors, and the first motors are connected with the rotating balls through rotating shafts correspondingly, so that a shooting angle of the thermal imaging camera can be adjusted, and dead angles are not easy to generate.

Owner:GUIZHOU UNIV

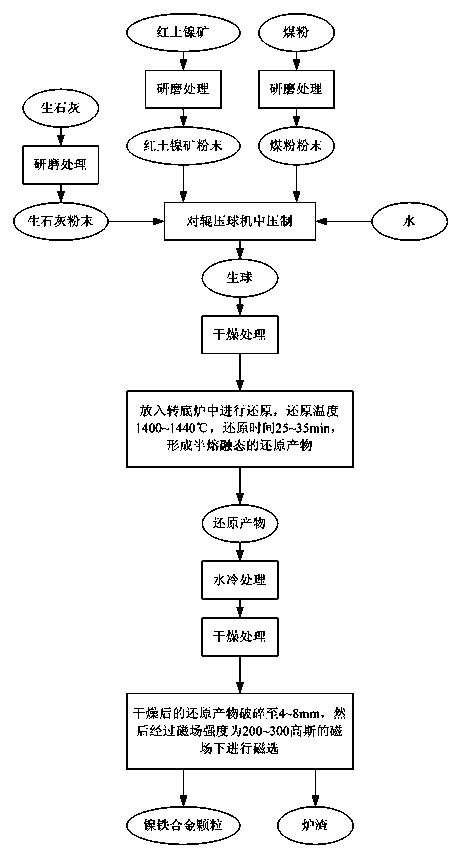

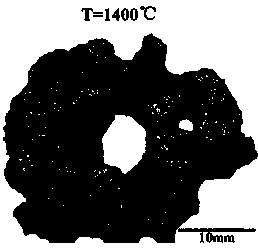

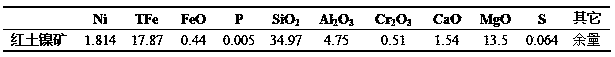

Method for producing ferro-nickel alloy from low-grade laterite-nickel ore in half-molten state

InactiveCN103695634ALow reduction temperatureShort smelting cycleMagnetic separationMolten stateSlag

The invention provides a method for producing a ferro-nickel alloy from low-grade laterite-nickel ore in a half-molten state. In the method, reduction is performed at a relatively low temperature of 1,400-1,440 DEG C, the slag in the reduction product and the reduced ferro-nickel alloy are both in a half-molten state, and then the ferro-nickel alloy is pushed by the slag and gathered by use of the phase interface acting force between the slag and ferro-nickel alloy in the half-molten state, so that the ferro-nickel alloy is mixed in the slag pores in a form of ferro-nickel alloy particles after being cooled; in follow-up steps, the slag-iron separation is performed through magnetic separation without heating the ferro-nickel alloy and slag to a full-molten state for easy flowing before separation. Therefore, the reduction temperature is relatively low, and the reduction time is only 25-35 minutes; compared with the laterite-nickel ore treatment process of the prior art needing high temperature over 1,650 DEG C and reduction time of at least one hour, the method provided by the invention has a short smelting cycle, obviously reduces the energy consumption and effectively controls the smelting cost.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com