Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Manufacturing scheduling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing Scheduling (sometimes called detailed scheduling or production scheduling) focuses on a shorter horizon than MPS. It also fixes a time and date to each operation in a continuous timeline rather than in time buckets, defining the start and completion time-frame for each process.

Real time monitoring manufacturing scheduling and control

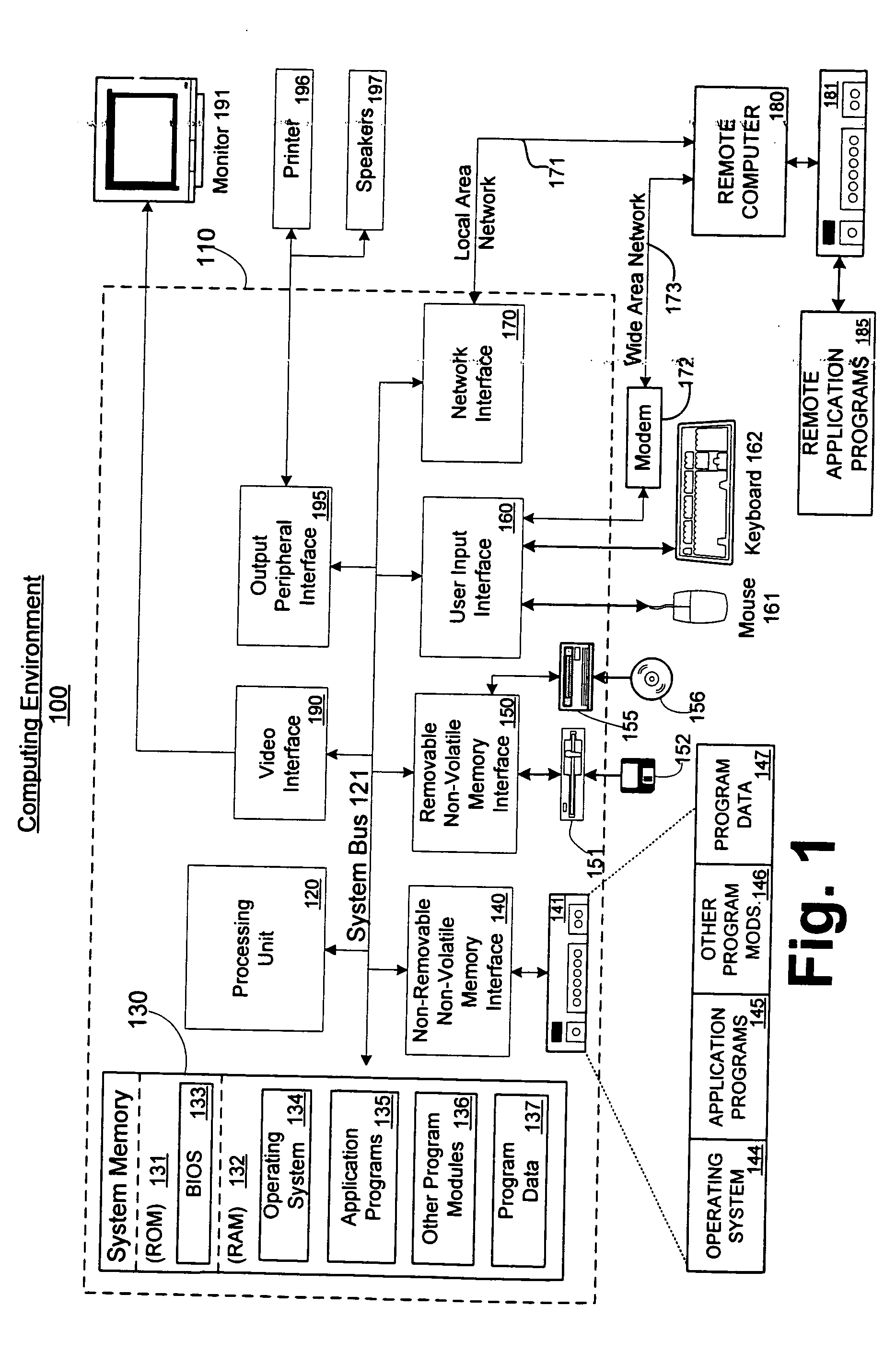

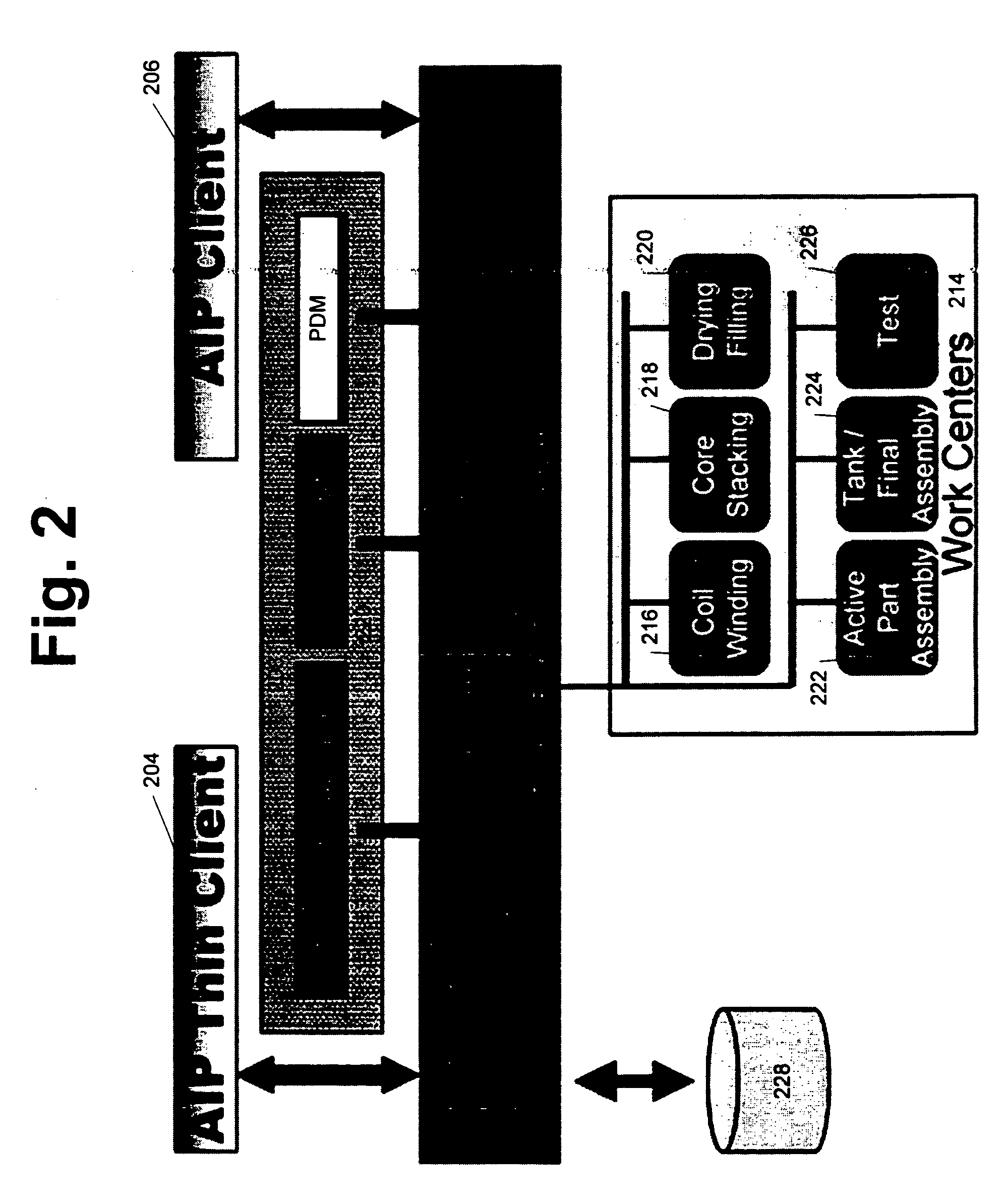

InactiveUS20060031840A1Minimize the numberMultiprogramming arrangementsMemory systemsCompletion timeBusiness management

A method and system for visually displaying real-time enterprise management information is provided. An application integration platform receives plural types of data from manufacturing and information systems within an enterprise and analyzes the plural types of data to determine key performance indicators, such as a number of tardy jobs. A process control server receives manufacturing data from at least one work center and forwards the manufacturing data to the application integration platform. A user interface that interfaces with the application integration platform provides a visual display of the number of tardy jobs in accordance with the class of user interacting therewith. The user may then reschedule the tardy jobs on alternate machines and determine how such rescheduling will affect the expected completion times of all jobs running on all machines.

Owner:ABB RES LTD

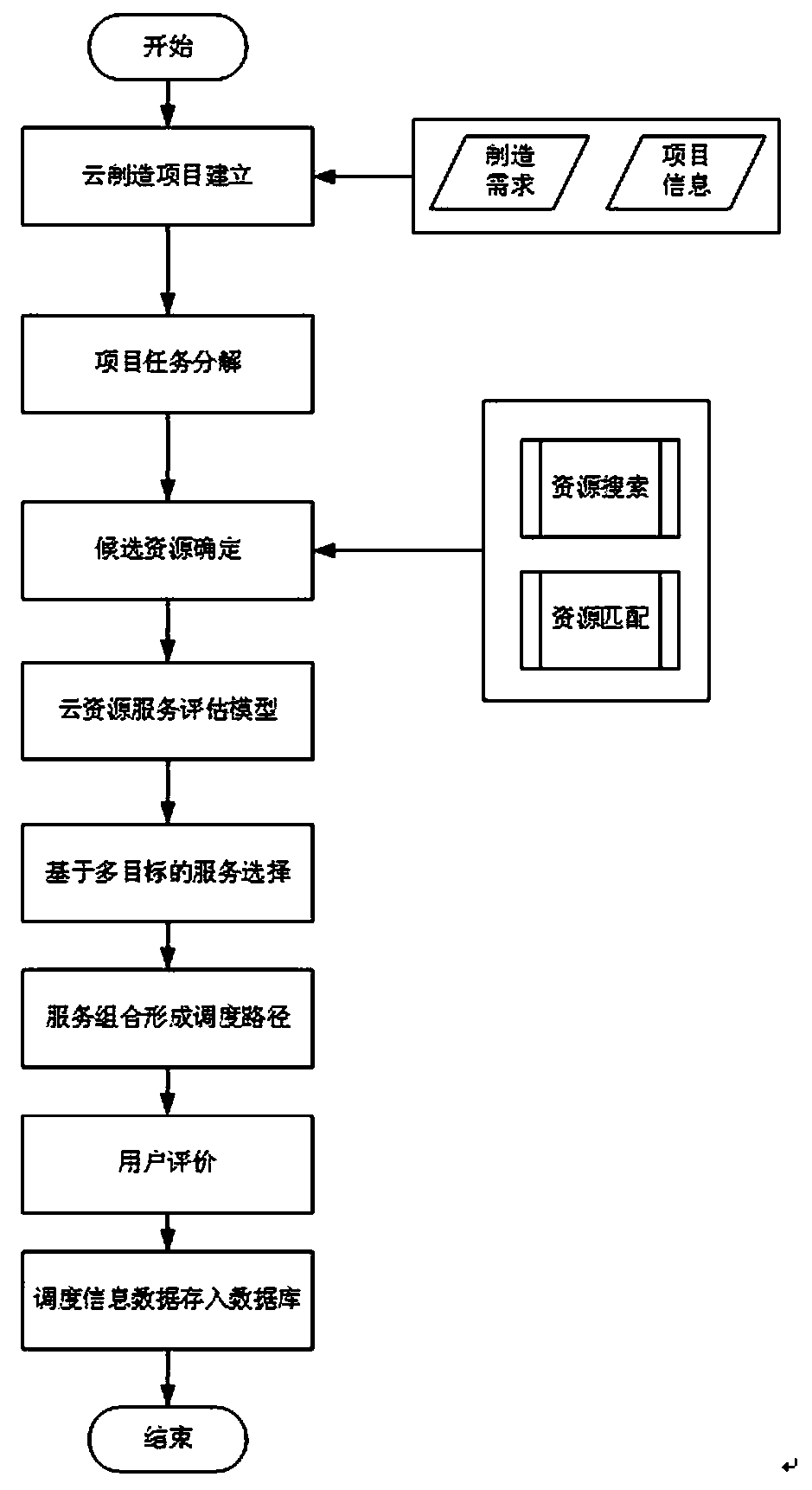

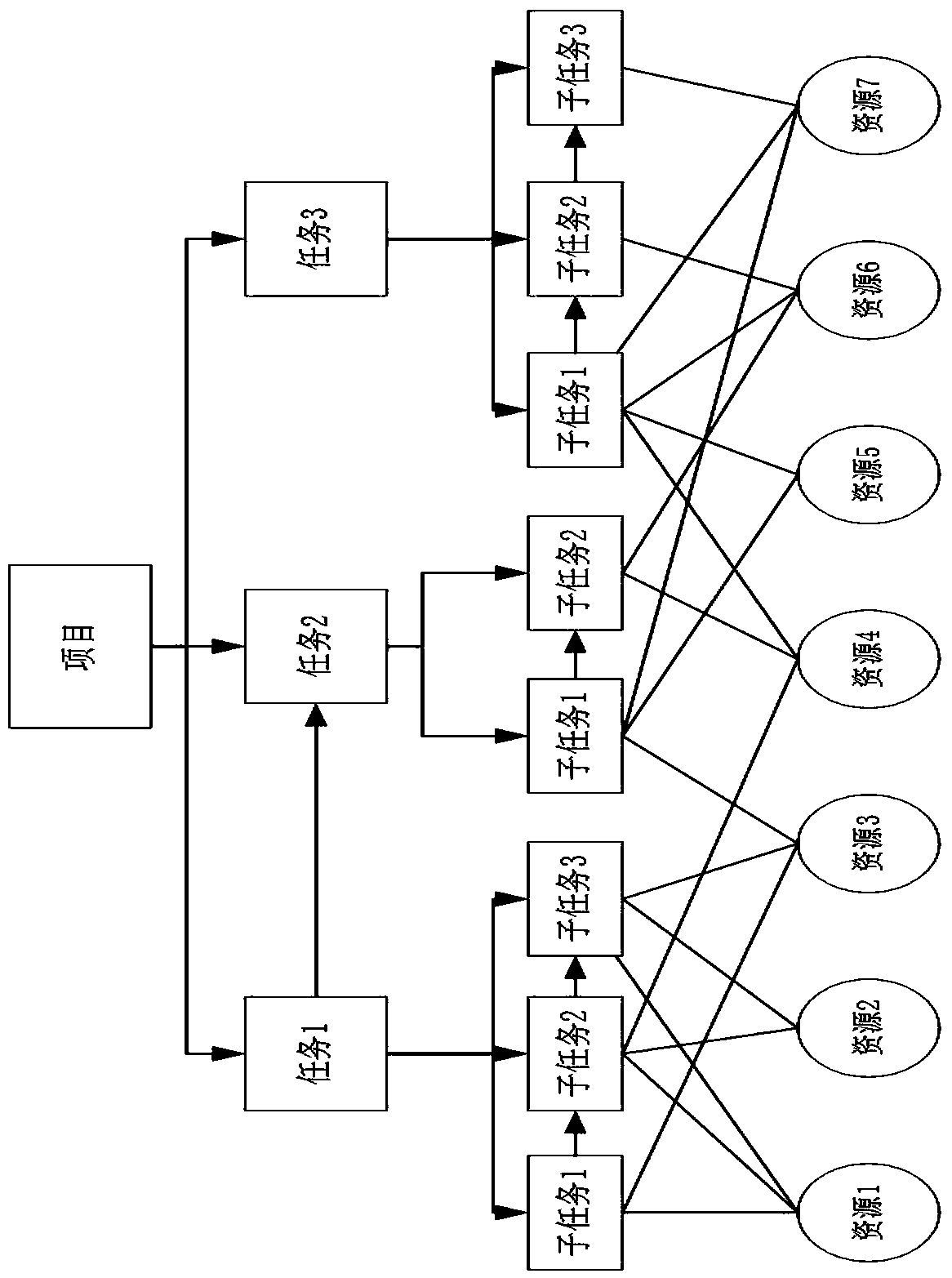

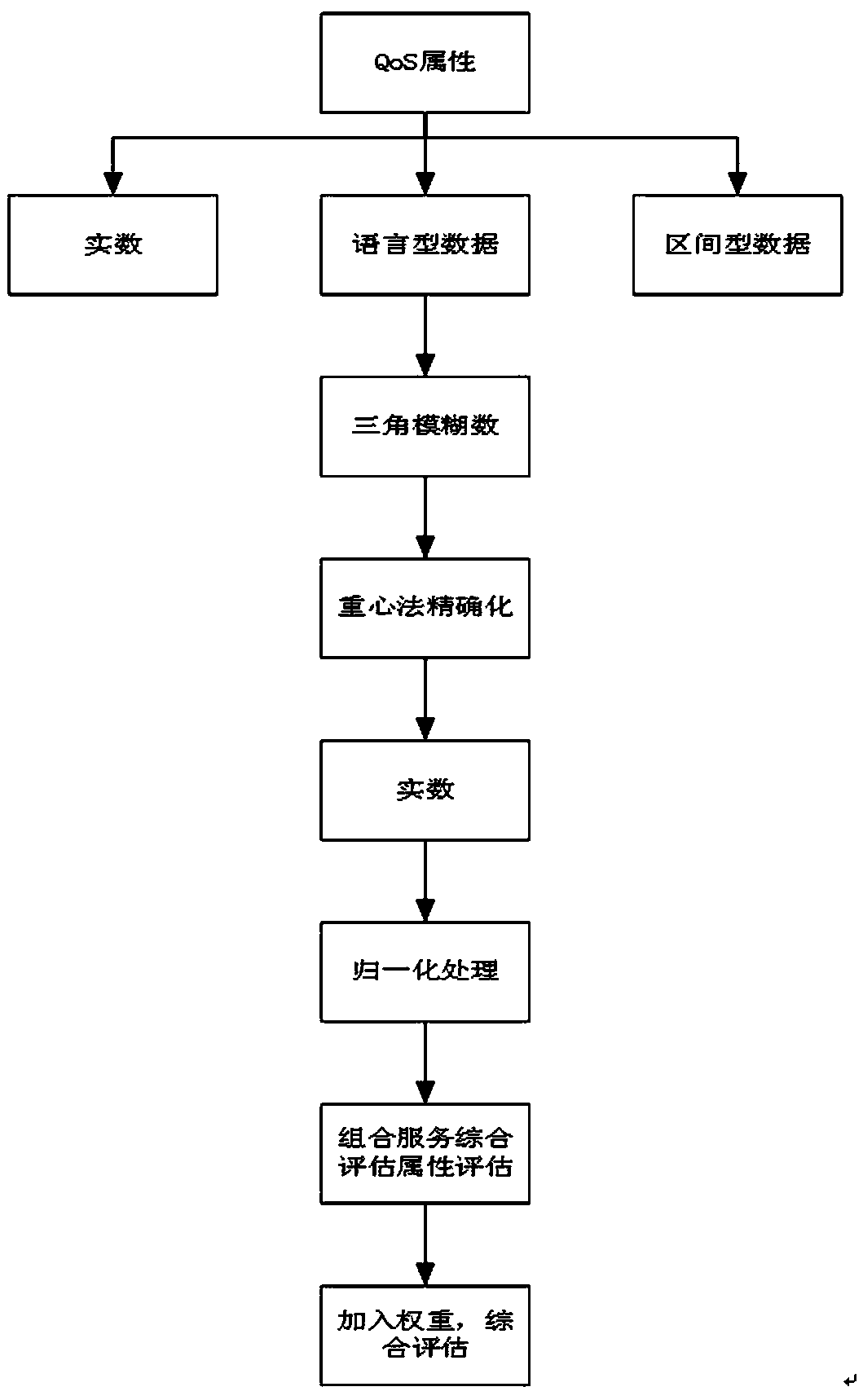

Cloud manufacturing resource service optimization scheduling method based on fuzzy multi-objective optimization

The invention provides a cloud manufacturing resource service optimization scheduling method based on fuzzy multi-objective optimization. The cloud manufacturing resource service optimization scheduling method comprises the steps that step 1, a service demander proposes project requirements; step 2, project task decomposition is performed; step 3, candidate resources are determined; step 4, cloudresource scheduling is performed; step 5, service selections are made based on a scheduling result.: corresponding services are selected according to a production scheduling scheme and operation is performed; step 6, user evaluations are made: the service demander evaluates the scheme after the task solution is executed; step 7, scheduling information is sorted into a database by storing the scheduling information and the user information into the database for next use. A fuzzification mechanism is added in the multi-objective optimization process to carry out fuzzification processing on service reliability evaluation. Therefore, the whole scheduling process finds the optimal scheduling combination scheme faster, and the technical problem that enough good service support cannot be providedfor the service demander due to narrow resource acquisition surface and opaque resources in the traditional manufacturing scheduling process is solved.

Owner:NANJING UNIV OF POSTS & TELECOMM

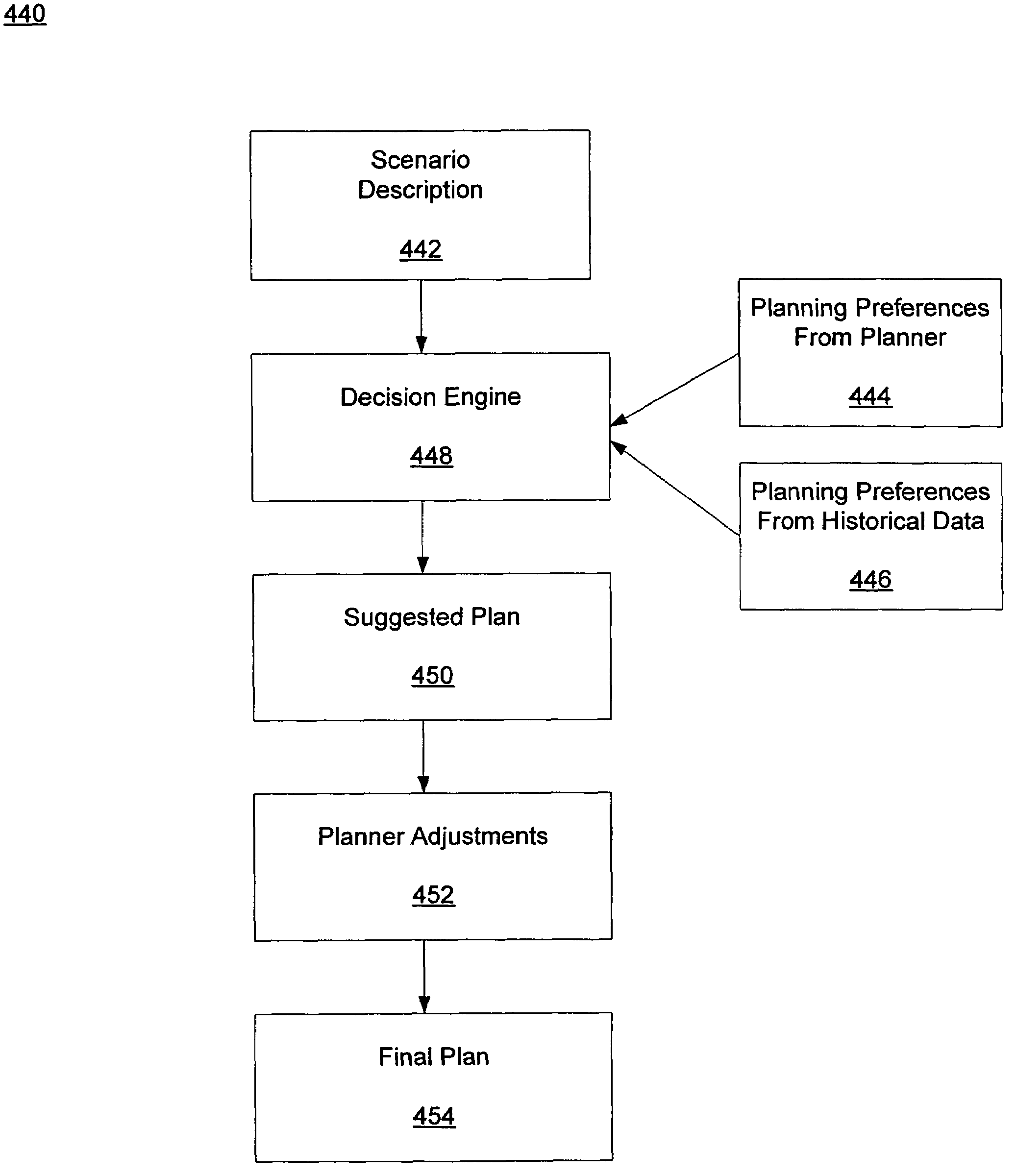

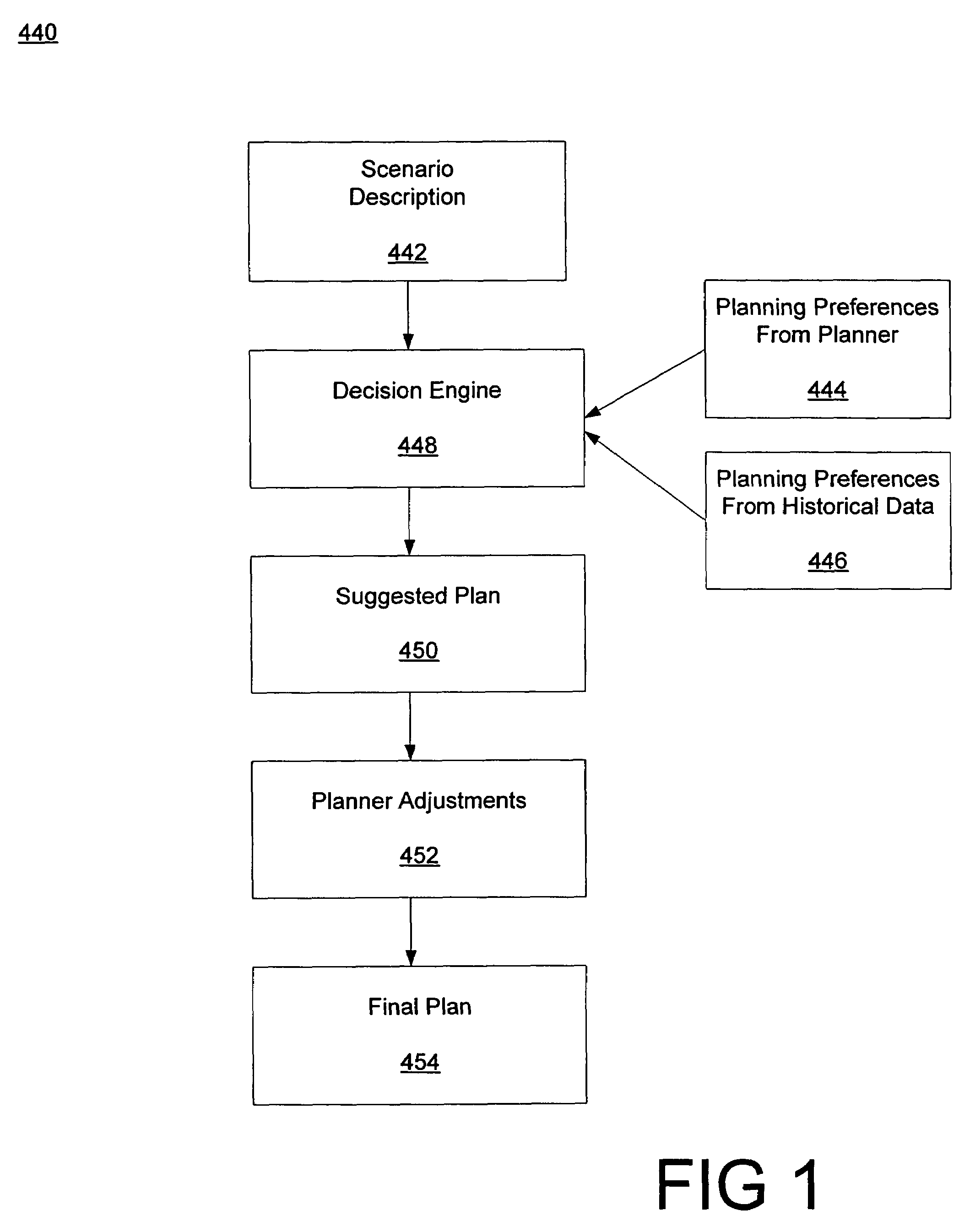

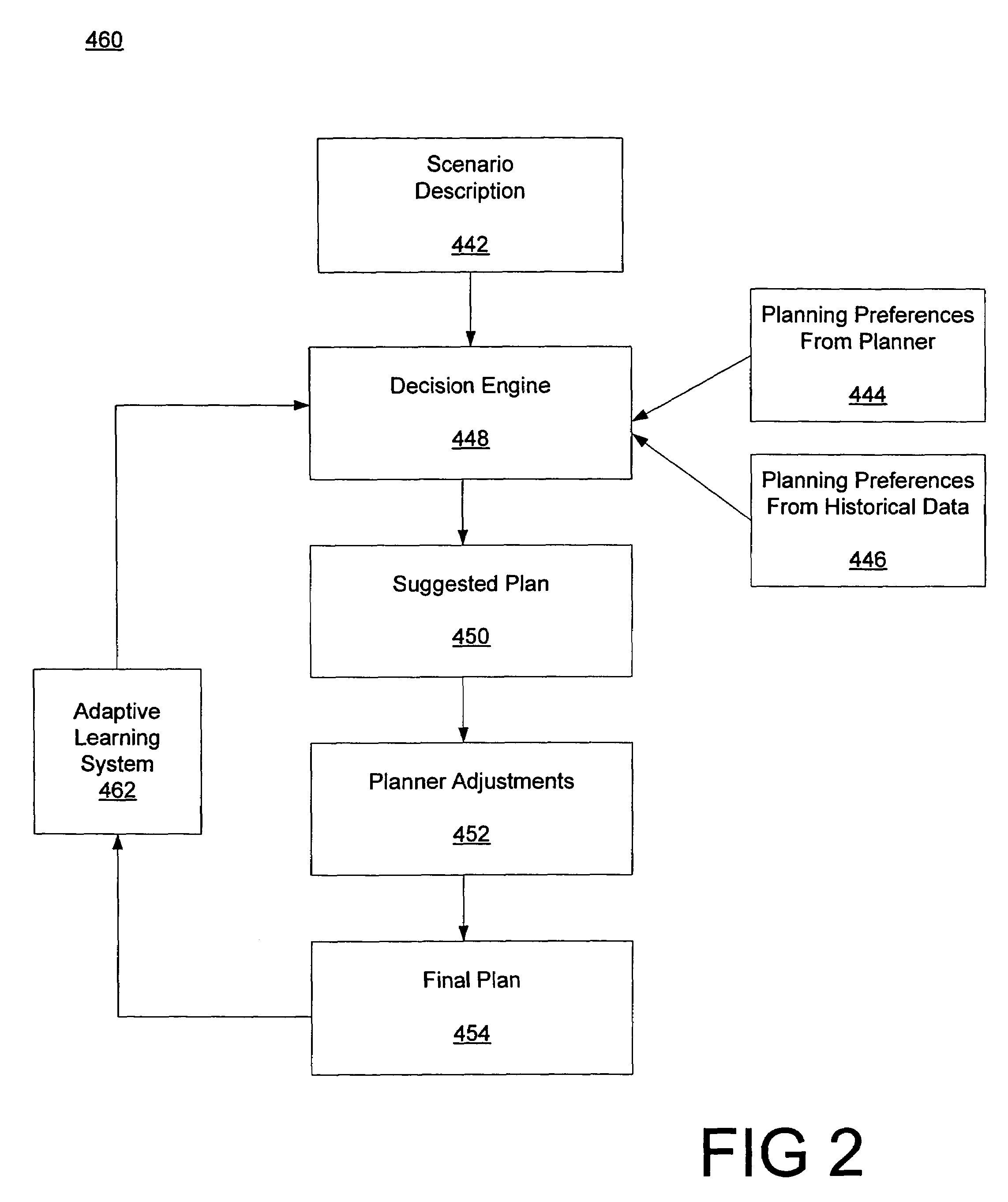

Method and apparatus for planning a manufacturing schedule using an adaptive learning process

An apparatus and method for a production planning system using a process of adaptive learning is disclosed. A production planning system receives production objects wherein each production object has at least one attribute. In one embodiment, the production objects include information relating to product to be manufactured. After receipt of production objects, multiple preference scores according to the attributes of the production objects are calculated. In one embodiment, each preference score represents desirability of transition from manufacturing a first object to a second object. The system subsequently identifies a suggested production plan which includes a sequence order of two or more objects in response to the preference scores. In one embodiment, the planning preferences are updated or modified by an adaptive learning system in response to adjustments of the suggested production plant by a planner.

Owner:E2E PROCESSING INC +1

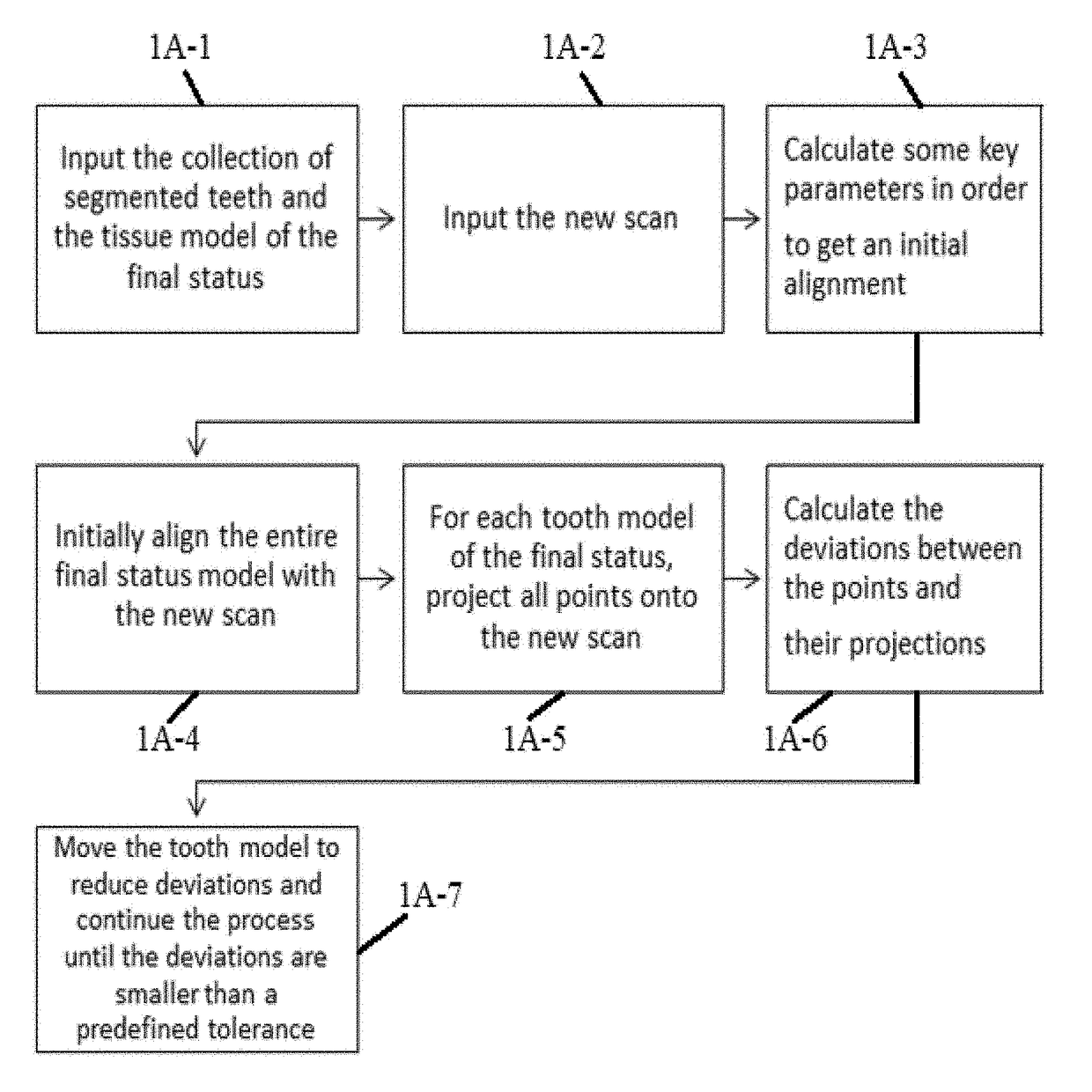

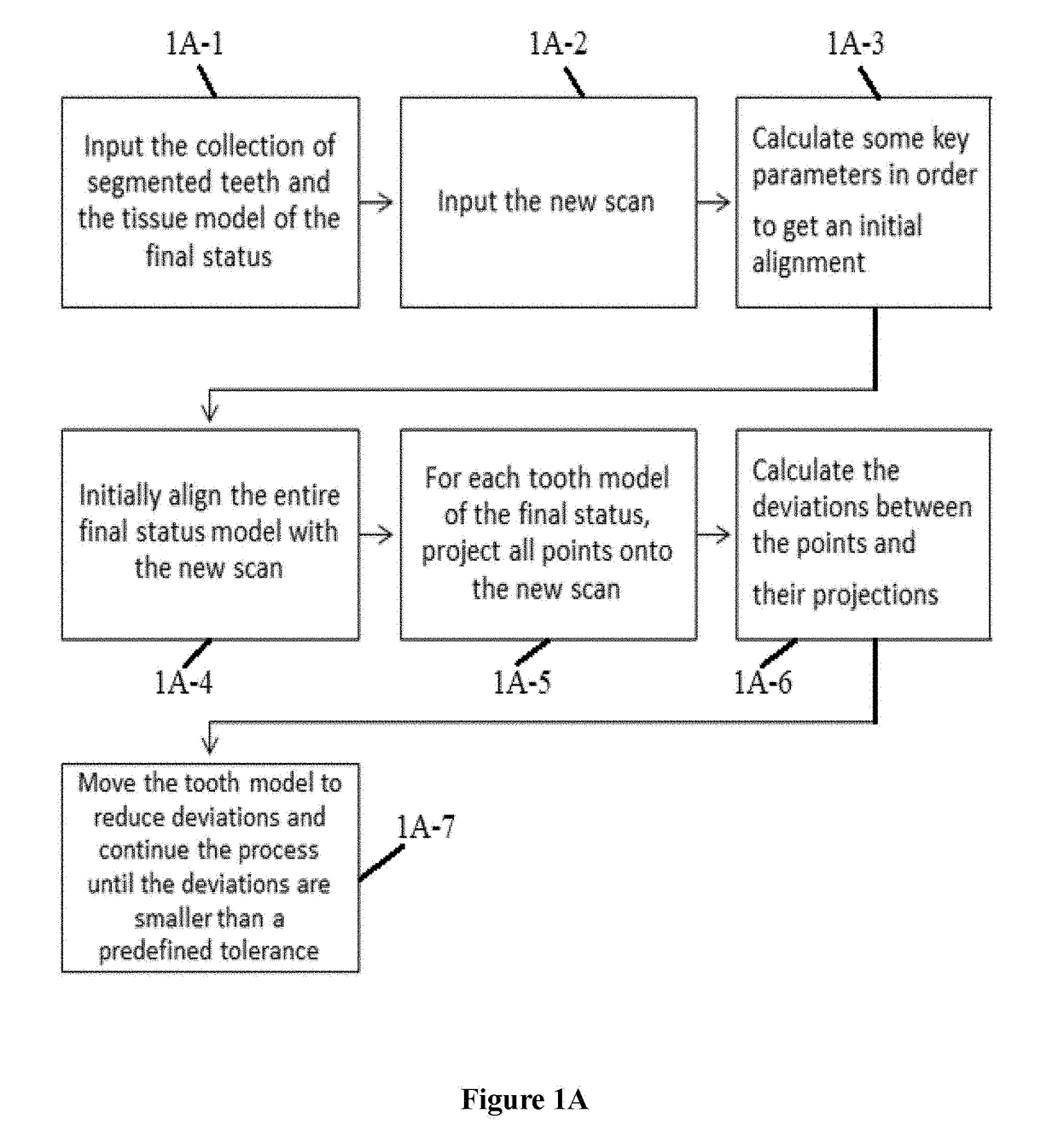

Orthodontic process with dynamic planning and incremental implementation

The present invention provides an orthodontic process phased into two or more sub-processes for repositioning a patient's teeth. In each sub-process, a complete treatment plan is established, but not all (i.e. only some) appliances in the plan are fabricated to move the teeth, out of the expectation that teeth movement may not completely follow the full course as planned. The entire orthodontic process is thus featured with dynamic planning and incremental implementation of the plans, to address ever-changing treatment profile.

Owner:GUIDEMIA TECH INC

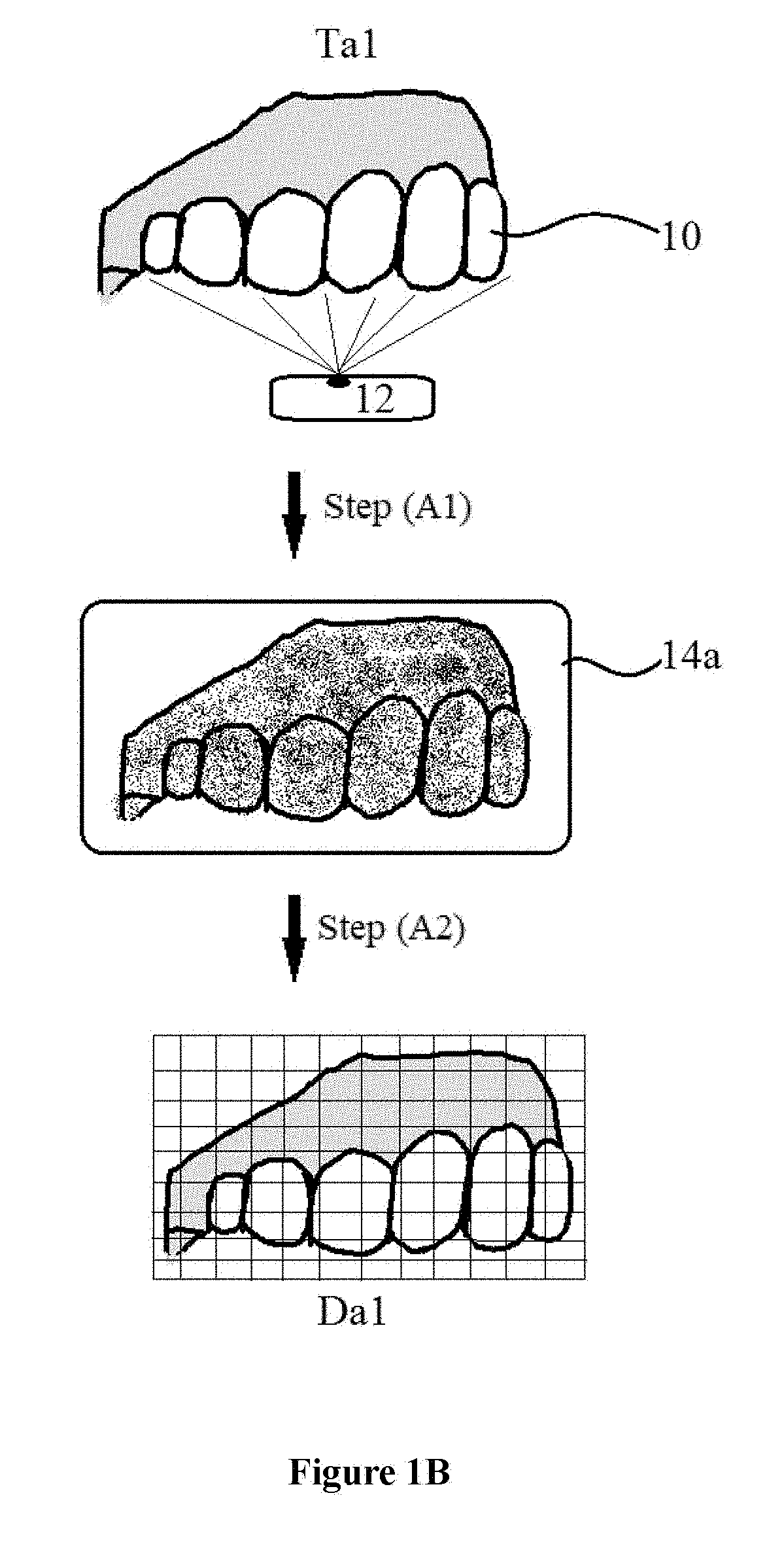

Method for process-driven bill of material

ActiveUS7321804B2ResourcesSpecial data processing applicationsBill of materialsManufacturing planning

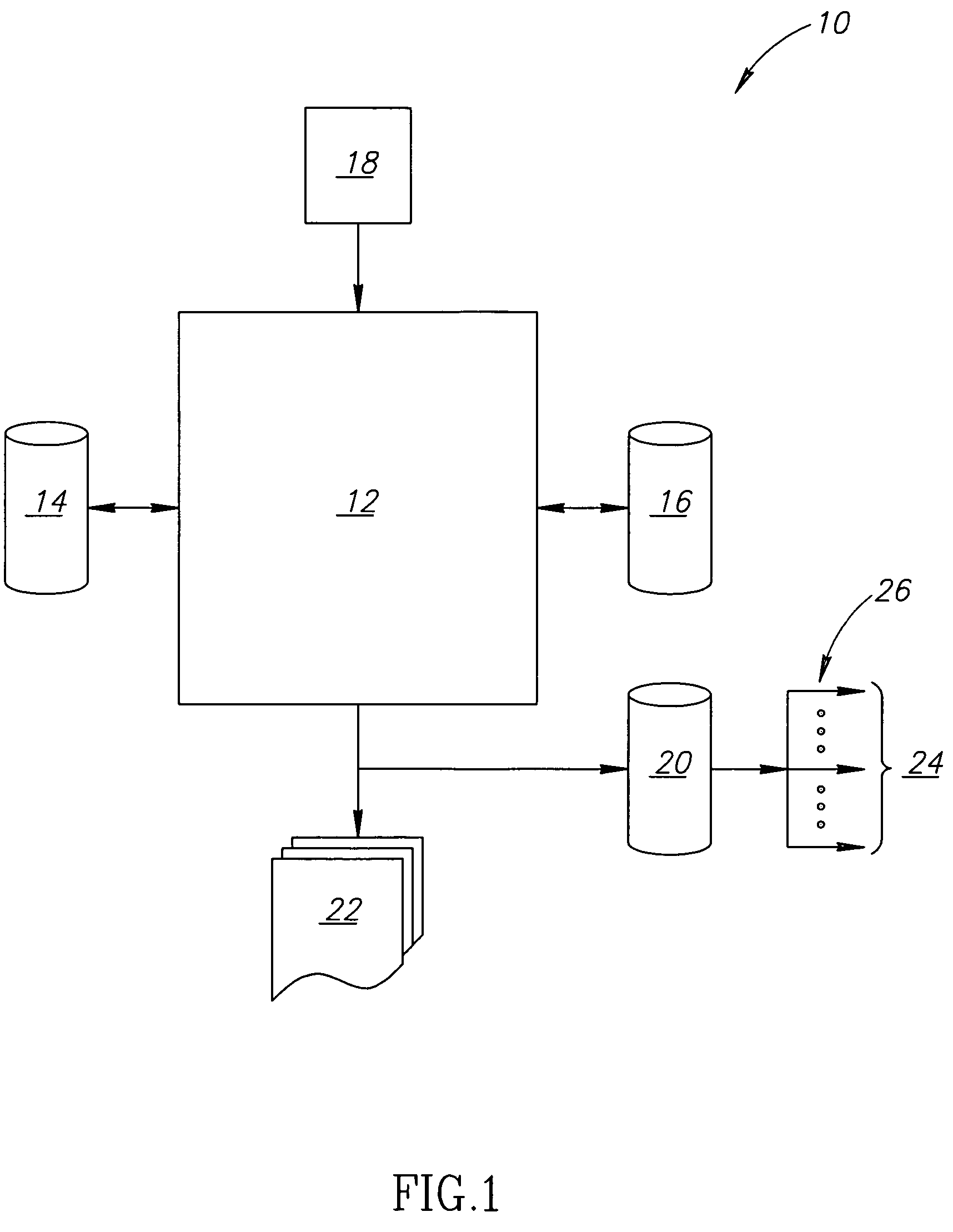

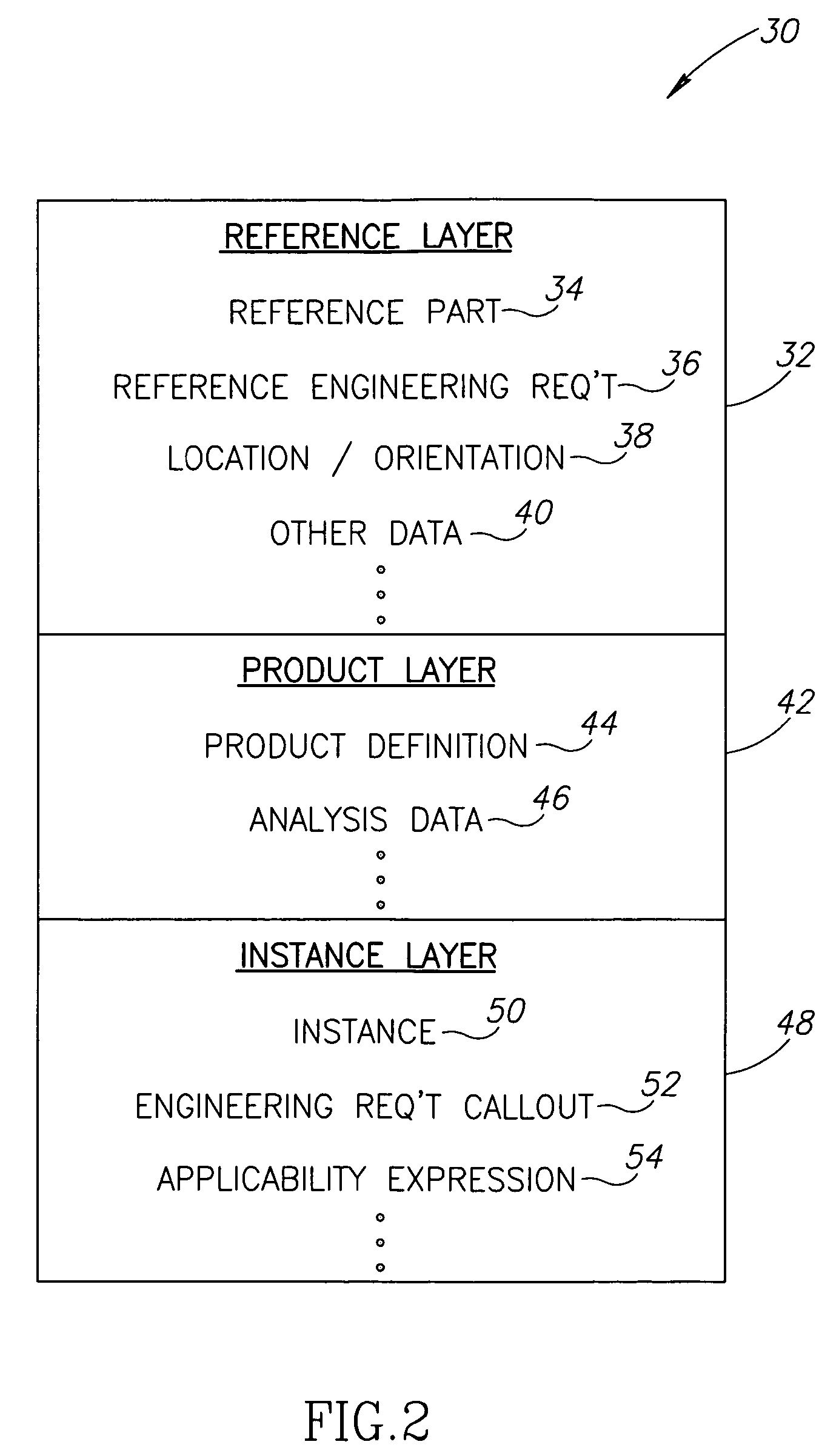

The present invention is directed to systems and methods for compiling production and planning information. In one embodiment, a system for planning the production of a product includes at least one database configured to store engineering information related to the product, and further configured to store process information related to the product, and a processor coupled to the at least one database to combine selected information from the at least one database to generate a manufacturing planning document that defines the product. In another embodiment, a method of generating a manufacturing bill of material for a selected product includes compiling a process data structure from the process information, compiling a product data structure from the engineering information, and generating a manufacturing bill of material by combining the process data structure and the product data structure.

Owner:THE BOEING CO

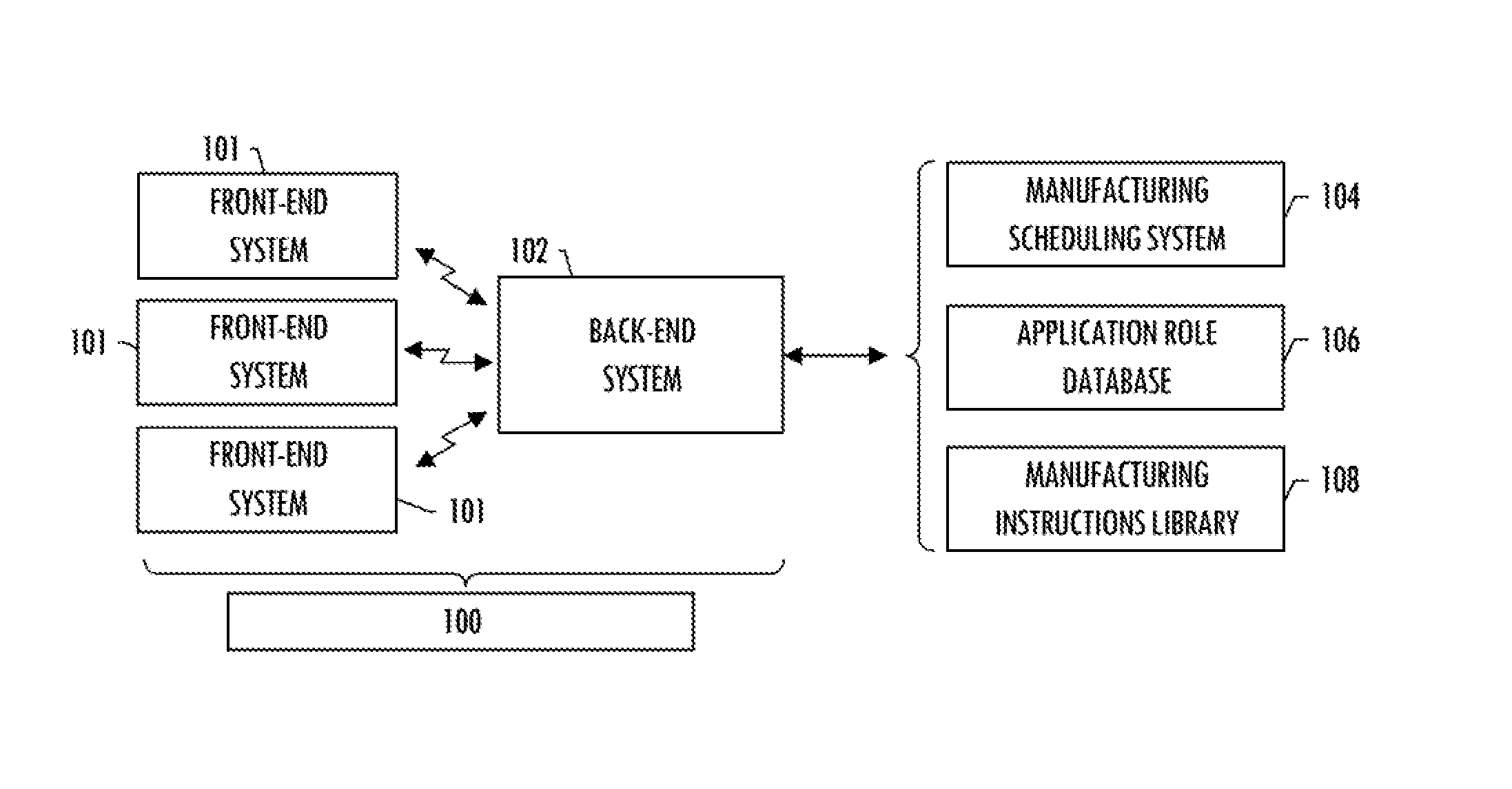

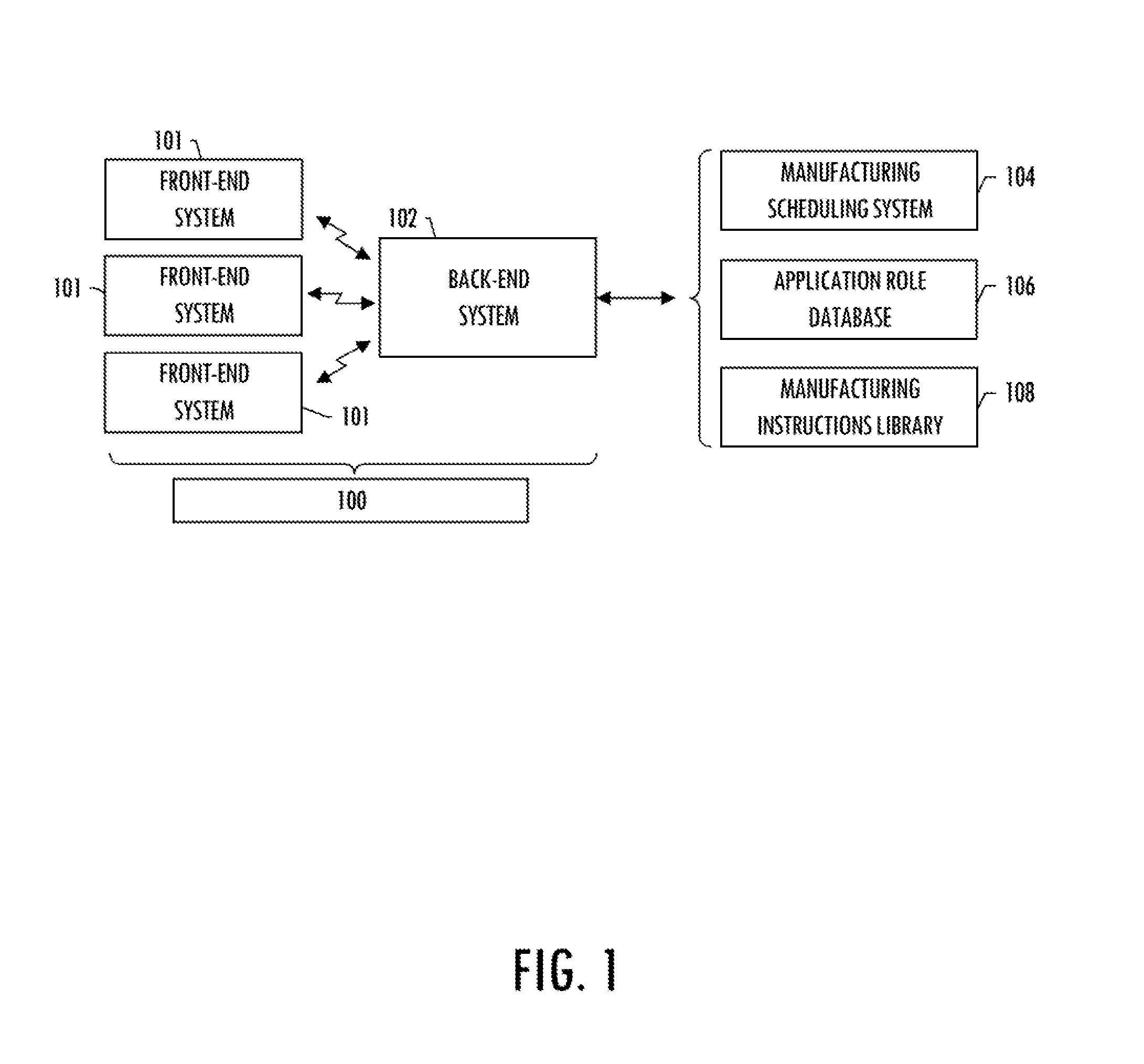

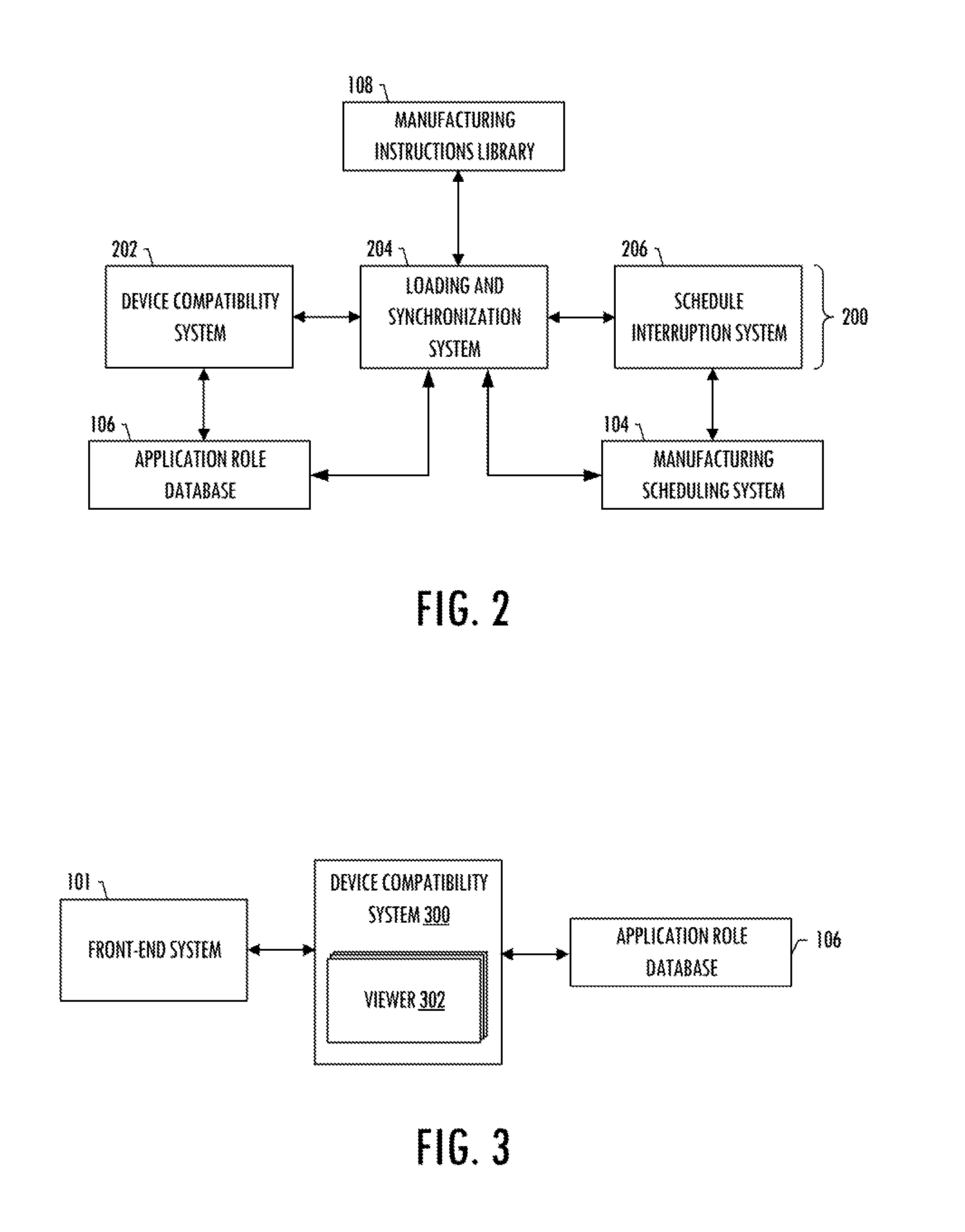

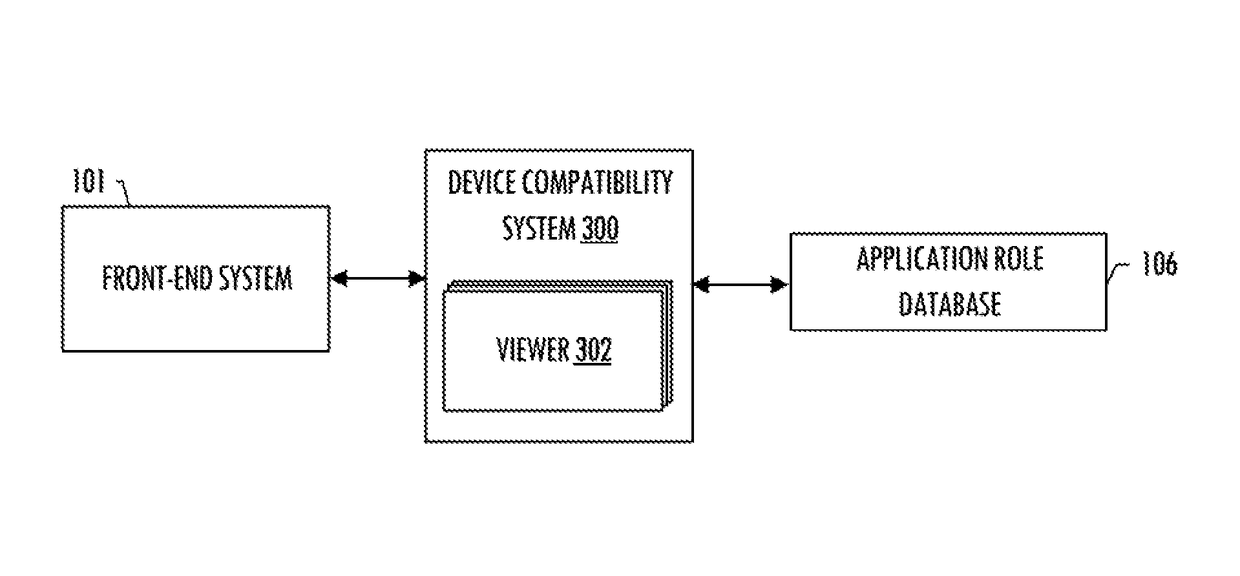

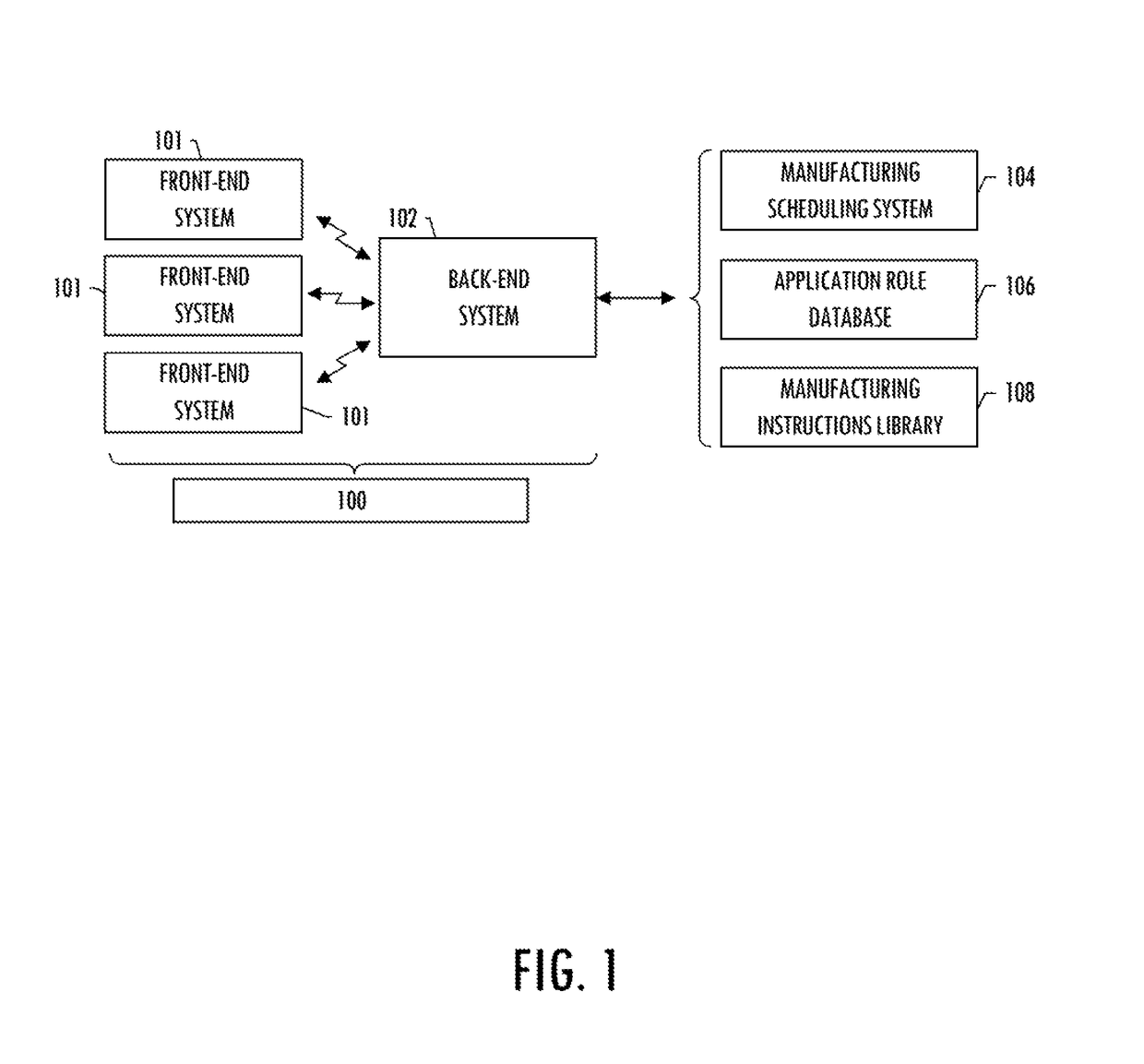

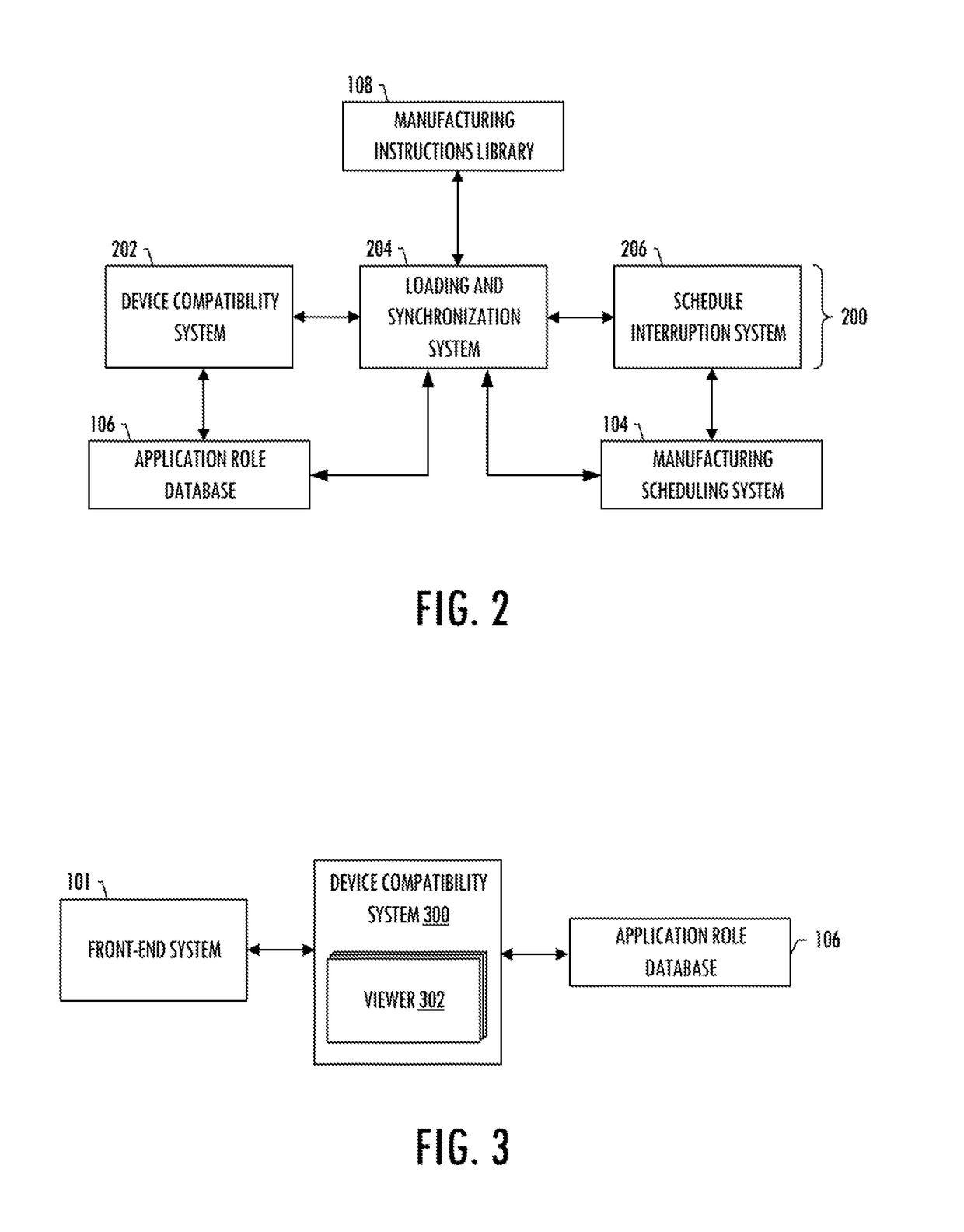

Point-of-use-toolkit

An apparatus is provided for implementation of back-end system for providing point-of-use toolkits. The apparatus may receive an assignment of work tasks assigned to a technician for manufacture of a tangible product. In response, the apparatus may compile a point-of-use toolkit including comprehensive information regarding the work tasks, and transmit the point-of-use toolkit to a front-end system associated with the technician. The apparatus may determine an occurrence of a delay associated with the schedule that impacts the assignment of the one or more work tasks, and transmit information associated with the delay to the manufacturing scheduling system. In response to receiving an update to the assignment of the tasks from the manufacturing scheduling system, the apparatus may compile an update of the point-of-use toolkit, and transmit the update of the point-of-use toolkit to the front-end system.

Owner:THE BOEING CO

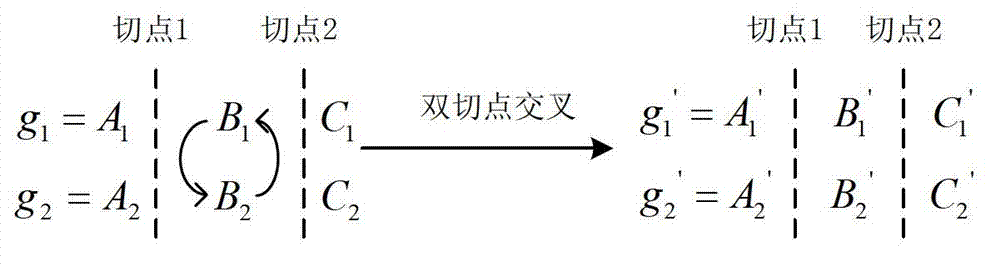

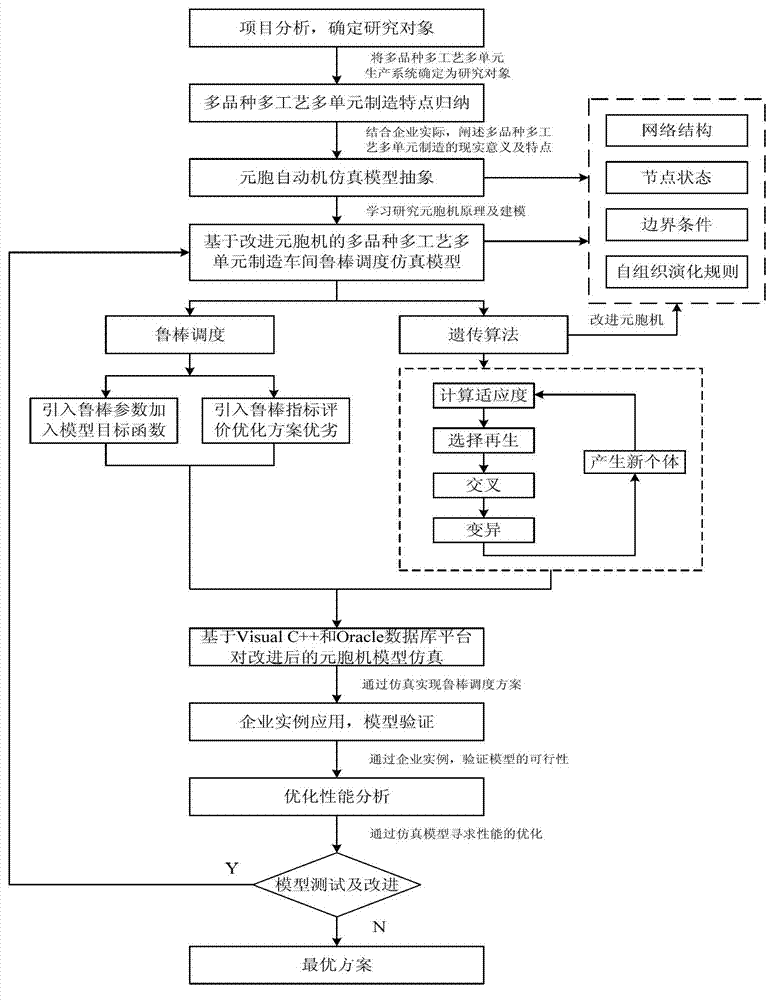

Multi-species multi-process multi-unit manufacturing scheduling method based on improved cellular machine

The invention provides a multi-species multi-process multi-unit manufacturing scheduling method based on an improved cellular machine. The method includes: 1) building a cellular automaton model of a workshop scheduling system: a) each workpiece is processed according to a certain process sequence, and the workpiece enters a next station to be processed only after a front process is completed; (b) each machine can only process one workpiece at a time period simultaneously, and a next workpiece can be processed only after processing of one workpiece is completed; and (c) the processing of the workpiece on the machine cannot be interrupted until the process is completed; and 2) building a multi-objective function: the condition is that: 2.1) maximum completion time of all processes of the workpiece is shortest; 2.2) maximum delay of the workpiece is smallest; and 2.3) balance ratio of each workpiece device is high. A scheduling general objective function of each discrete unit in each time step of a cellular automaton is obtained through a weighting method. The multi-species multi-process multi-unit manufacturing scheduling method achieves dynamic monitoring and is good in robustness.

Owner:ZHEJIANG UNIV OF TECH

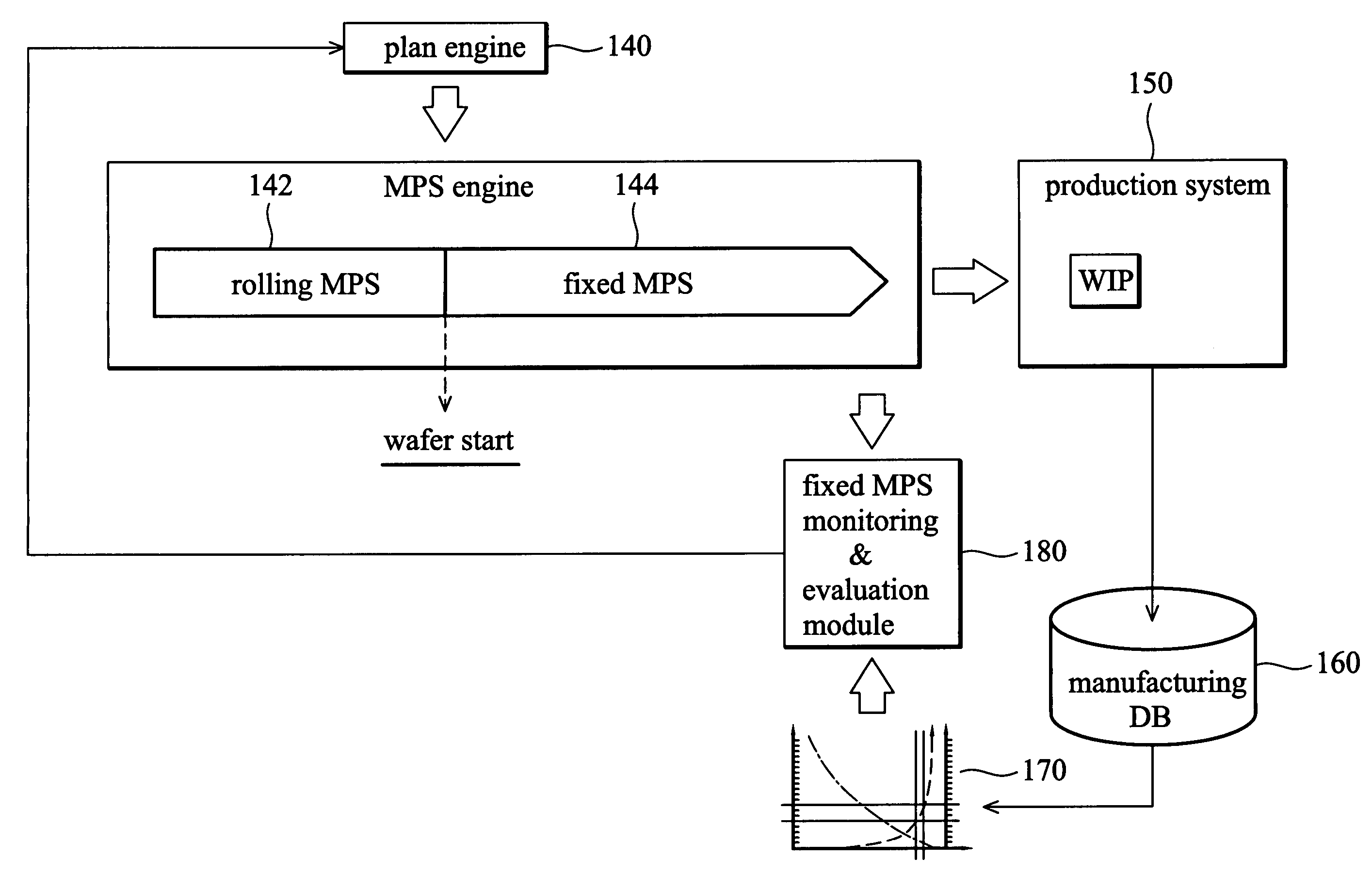

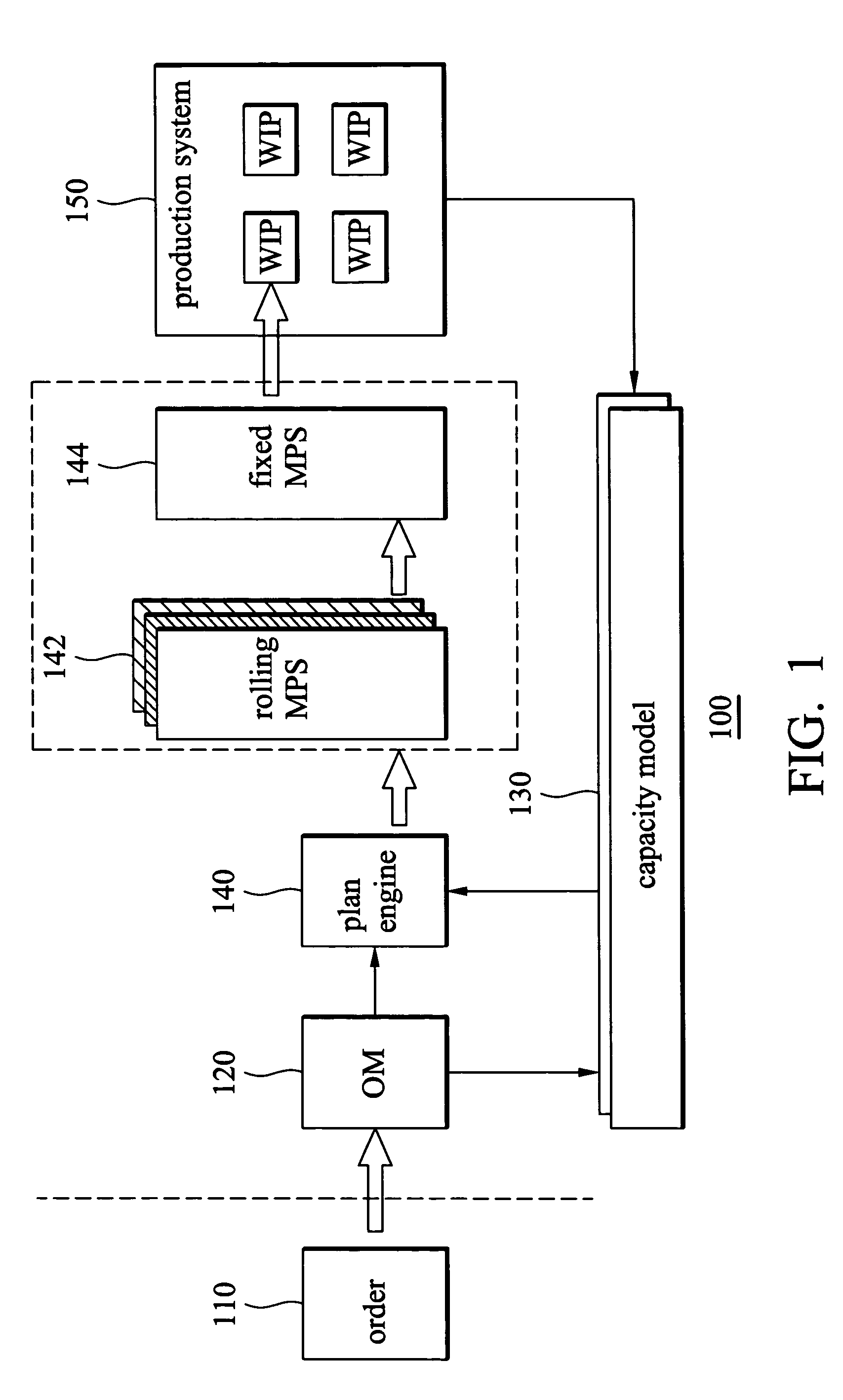

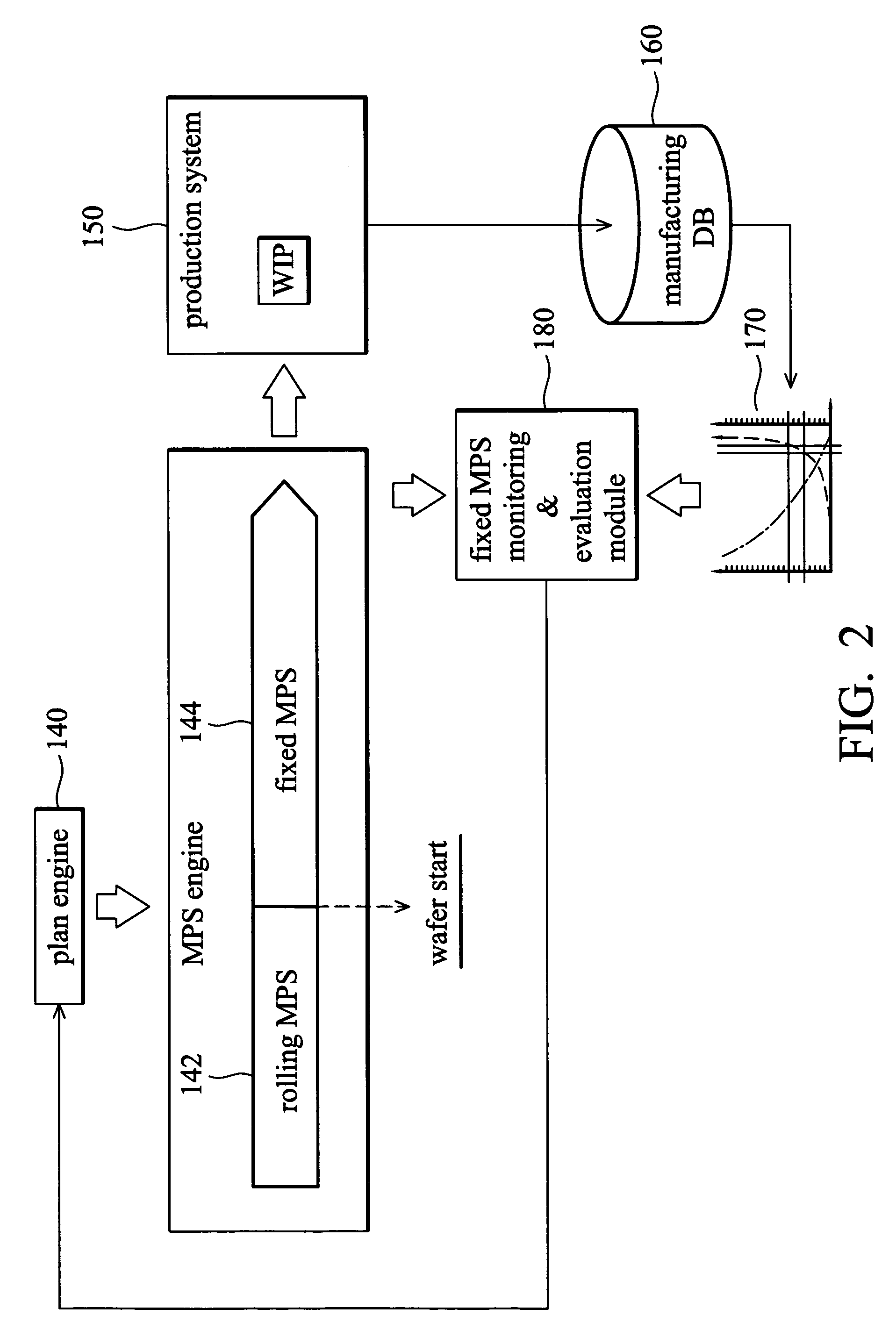

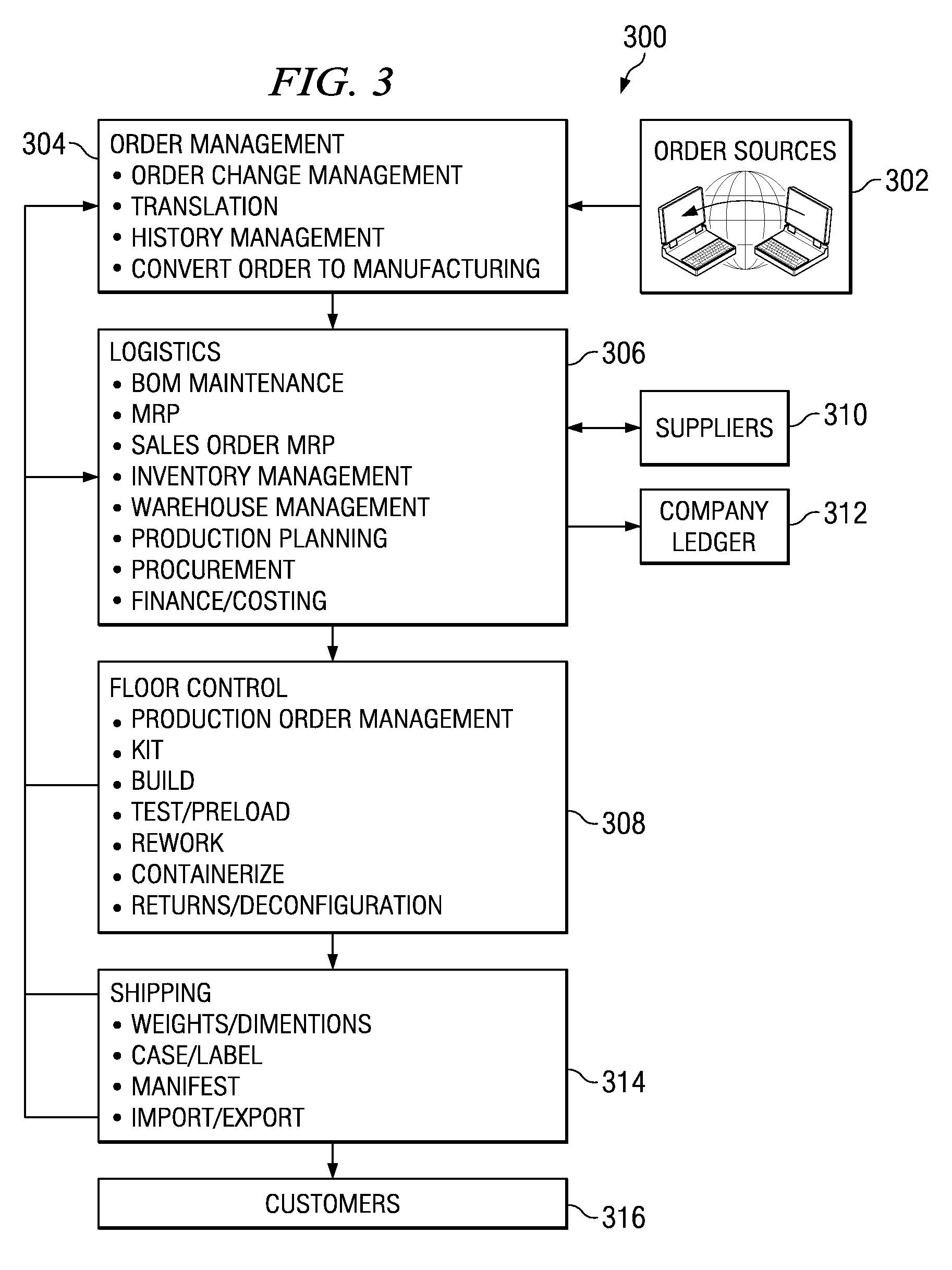

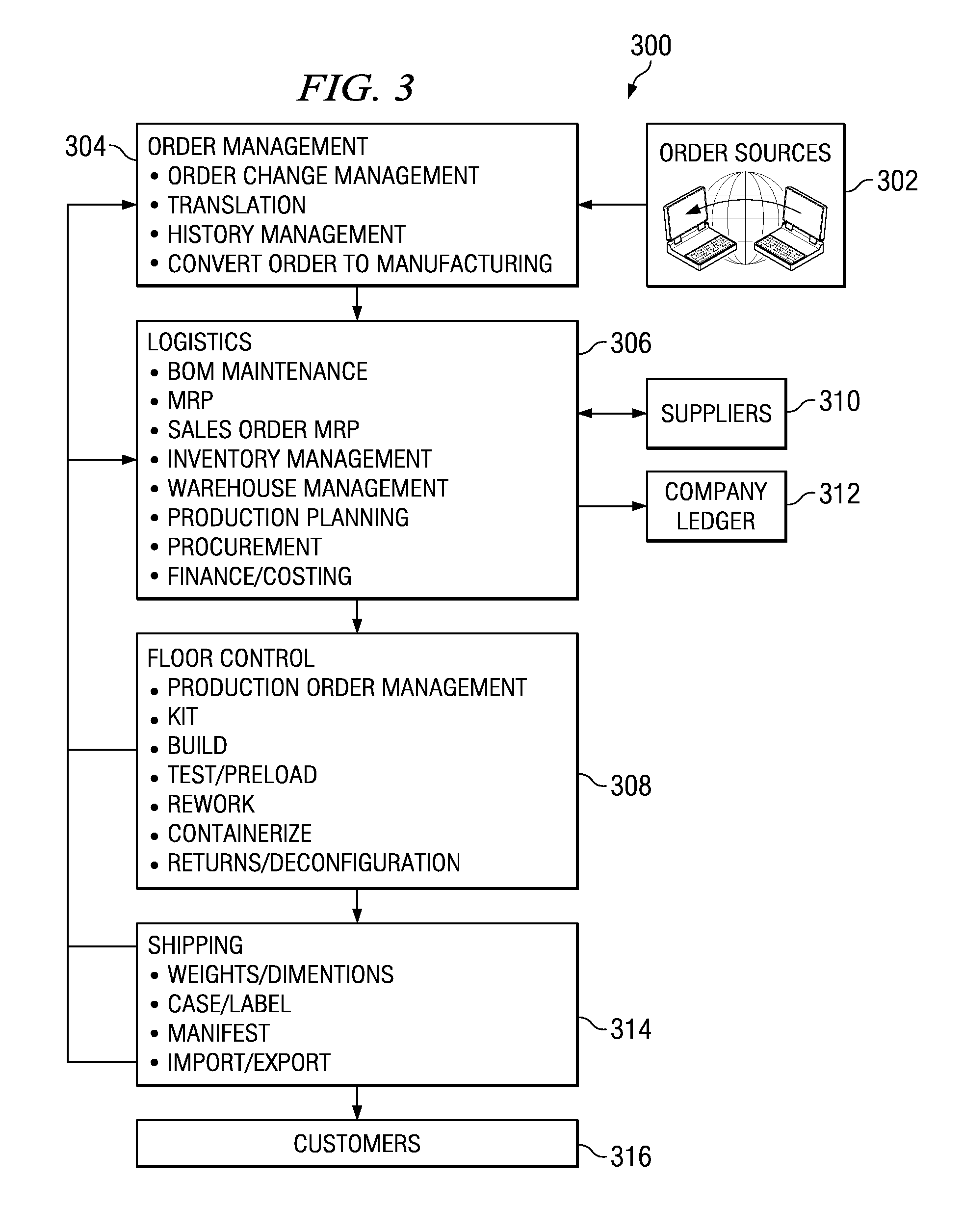

System and method for manufacturing planning and control

InactiveUS7130707B2Total factory controlSpecial data processing applicationsControl systemProgram planning

A customer-orientated manufacturing planning and controlling system. An order management module is programmed to receive an order for a product and reserve a capacity for the order based on a capacity model that considers a plurality of capacity vectors in a production system. A plan engine generates a fixed production schedule for the order based on the capacity model. A priority management engine provides a priority for the order. A production schedule monitor and evaluation module determines whether the order in process conforms to the fixed production schedule by statistical process control (SPC) and whether to adjust the fixed production schedule and to adjust the priority based on a dynamic achievement model of historical fixed production schedules, based on historical production information in a production database storing production information of the production system.

Owner:TAIWAN SEMICON MFG CO LTD

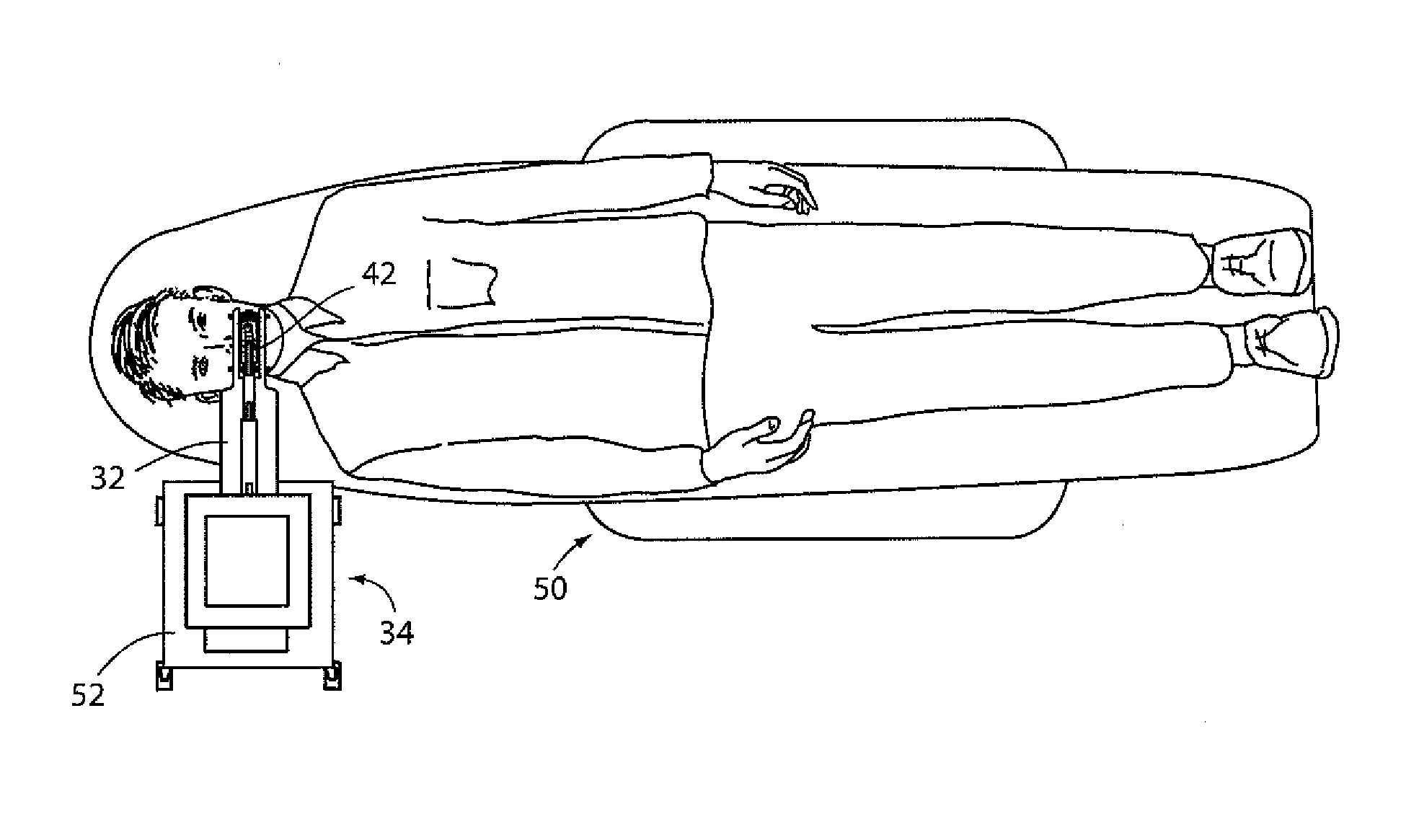

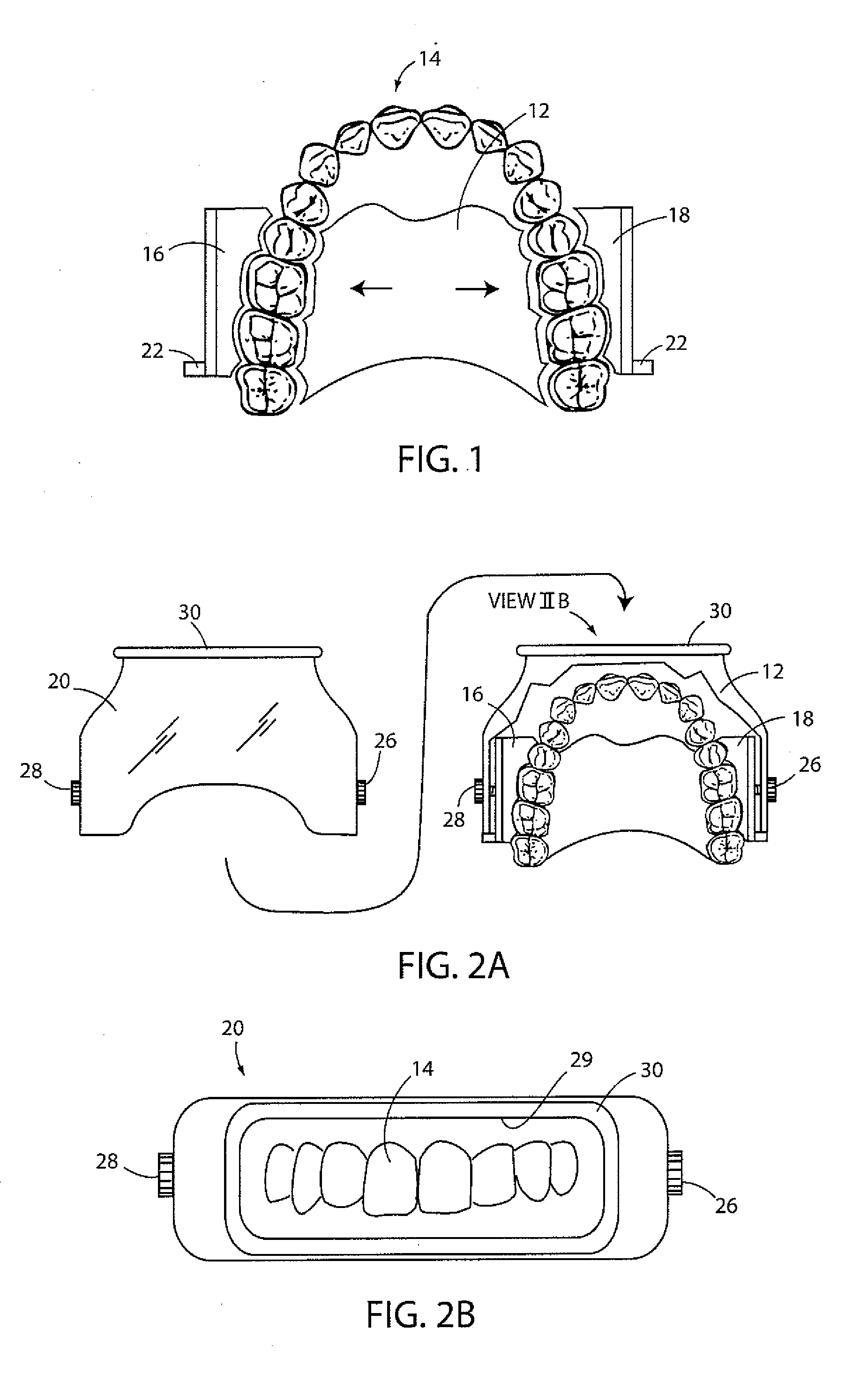

In-situ dental restoration process and apparatus

ActiveUS20150140517A1Short timeReduce embarrassmentImpression capsTeeth fillingEngineeringManufacturing scheduling

A dental restoration method that eliminates time-consuming, labor-intensive steps conventionally needed to fabricate molds, and thereby facilitates dental restorations in a shorter time, while reducing the discomfort and embarrassment sometimes associated with provisional restorations involves scanning an existing dental structure to generate a three-dimensional digital model of the existing dental structure, generating a three-dimensional digital model corresponding with a planned dental structure, and using an additive manufacturing process and apparatus (e.g., a 3-D printer) to fabricate the planned dental structure directly on the existing dental structure.

Owner:VUILLEMOT WILLIAM C

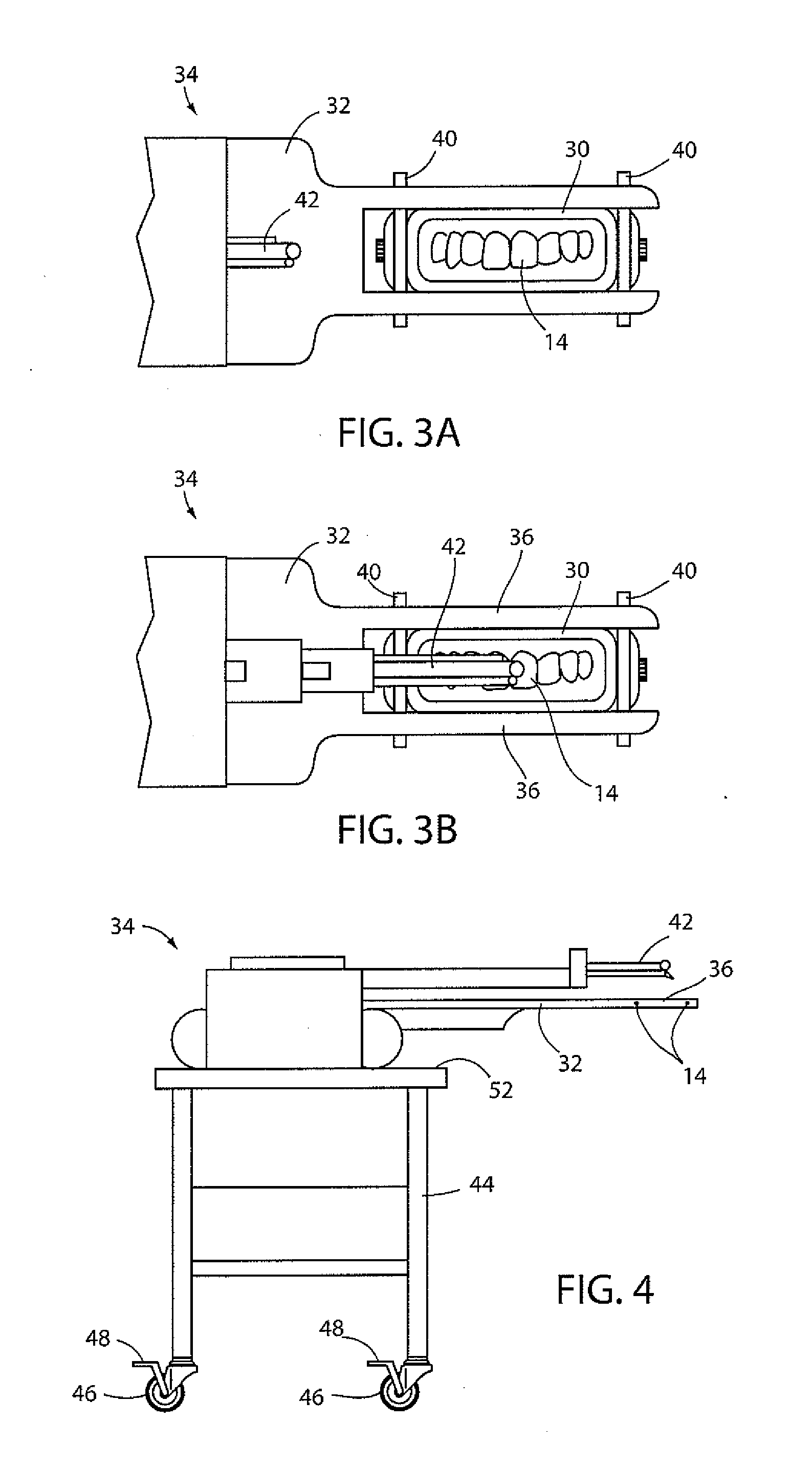

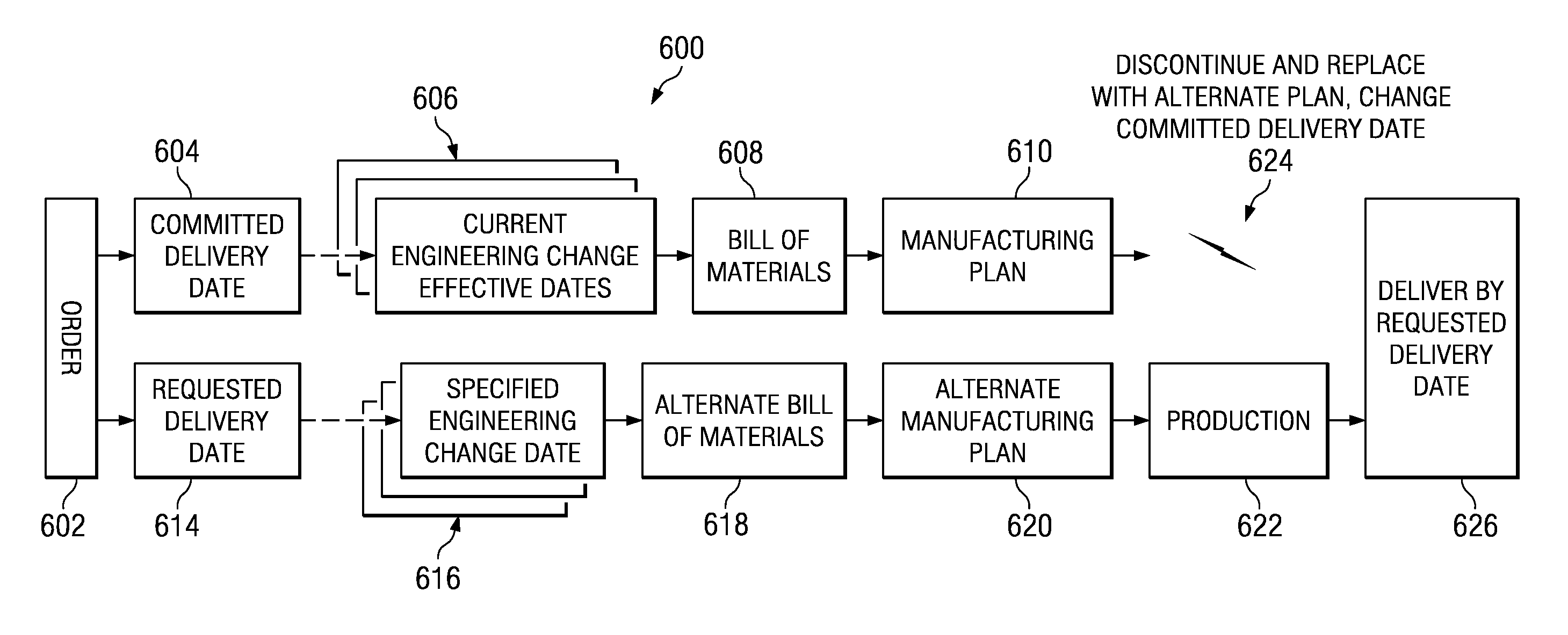

Method for manufacturing with engineering change override

The illustrative embodiments provide a computer implemented method, apparatus, and computer usable program code for processing orders. A request for delivery by a requested delivery date is received for an order having an original delivery date. The ordered product is broken down into one or more materials required for manufacturing the ordered product. For at least one material required for manufacturing the ordered product, a date when an engineering change becomes effective for the material is specified. An alternate bill of materials is created based on the specified date when the engineering change becomes effective for the material. An alternate manufacturing plan based on the alternate bill of materials is created. Manufacturing is initiated based on the alternate manufacturing plan. If manufacturing can be completed in time for delivery by the requested delivery date, the original delivery date of the order is replaced with the requested delivery date.

Owner:IBM CORP

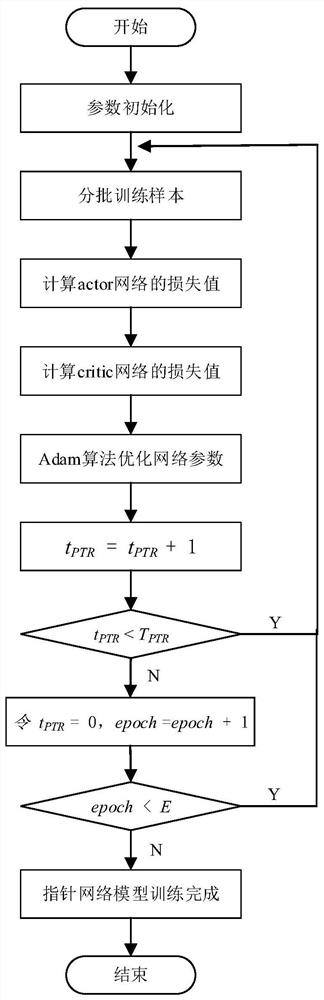

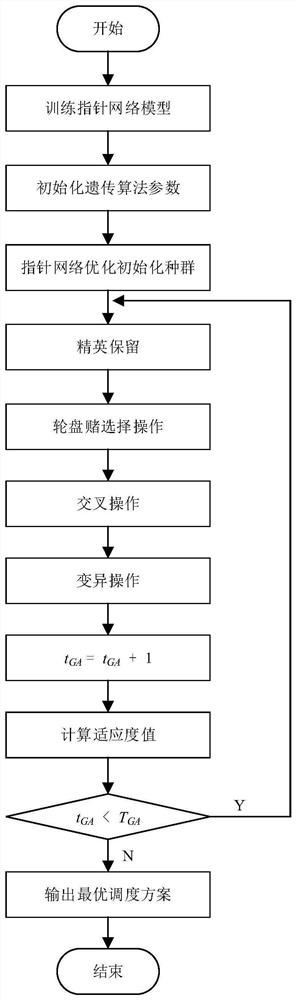

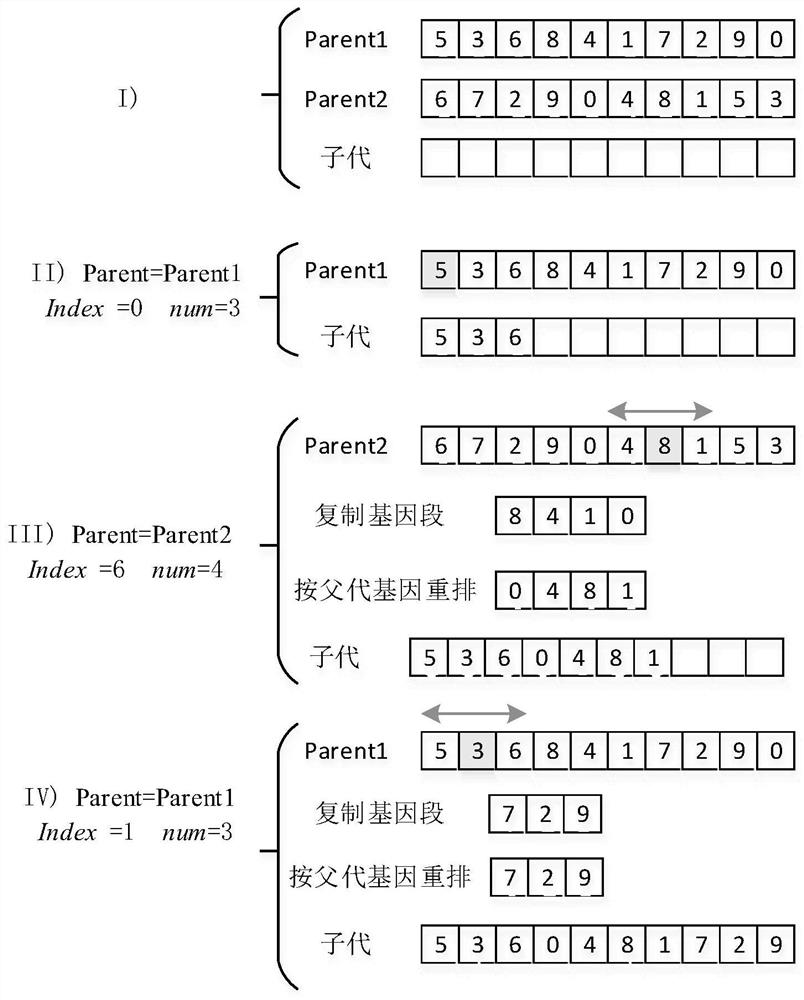

Batch scheduling optimization method based on deep reinforcement learning and genetic algorithm

ActiveCN112488315AQuality improvementImprove generalization abilityForecastingCharacter and pattern recognitionAlgorithmBatch machine

The invention belongs to the field of production and manufacturing scheduling, and discloses a batch scheduling optimization method based on deep reinforcement learning and a genetic algorithm, and the method comprises the steps: building a mathematic model of a difference workpiece batch scheduling problem; establishing a strategy model of the problem by adopting a pointer network; training a pointer network model by using an actor-critic algorithm; defining and initializing parameters of a genetic algorithm; optimizing the initial population of the genetic algorithm by using the trained pointer network; further optimizing the scheduling scheme by adopting a genetic algorithm; and the optimal scheme obtained by the genetic algorithm being used as a production scheme for processing workpieces by the batch processor. Compared with a traditional heuristic algorithm, the pointer network can obtain a better solution; in addition, in the crossover operation of the genetic algorithm, a novelcrossover mode is provided, and the performance of the scheme can be further improved by improving the optimization capability of the genetic algorithm on the basis of the scheduling scheme obtainedby the pointer network.

Owner:HEFEI UNIV OF TECH

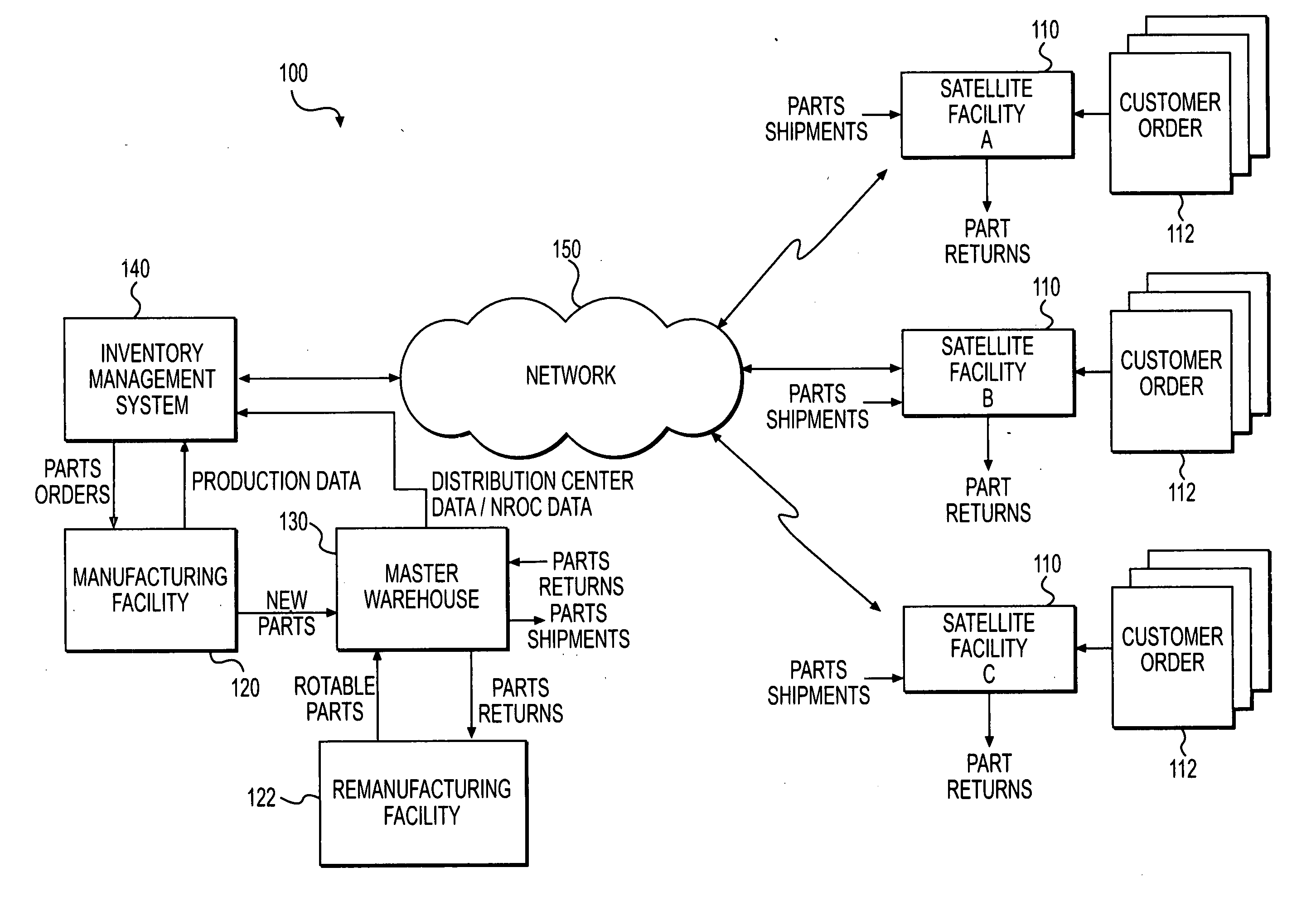

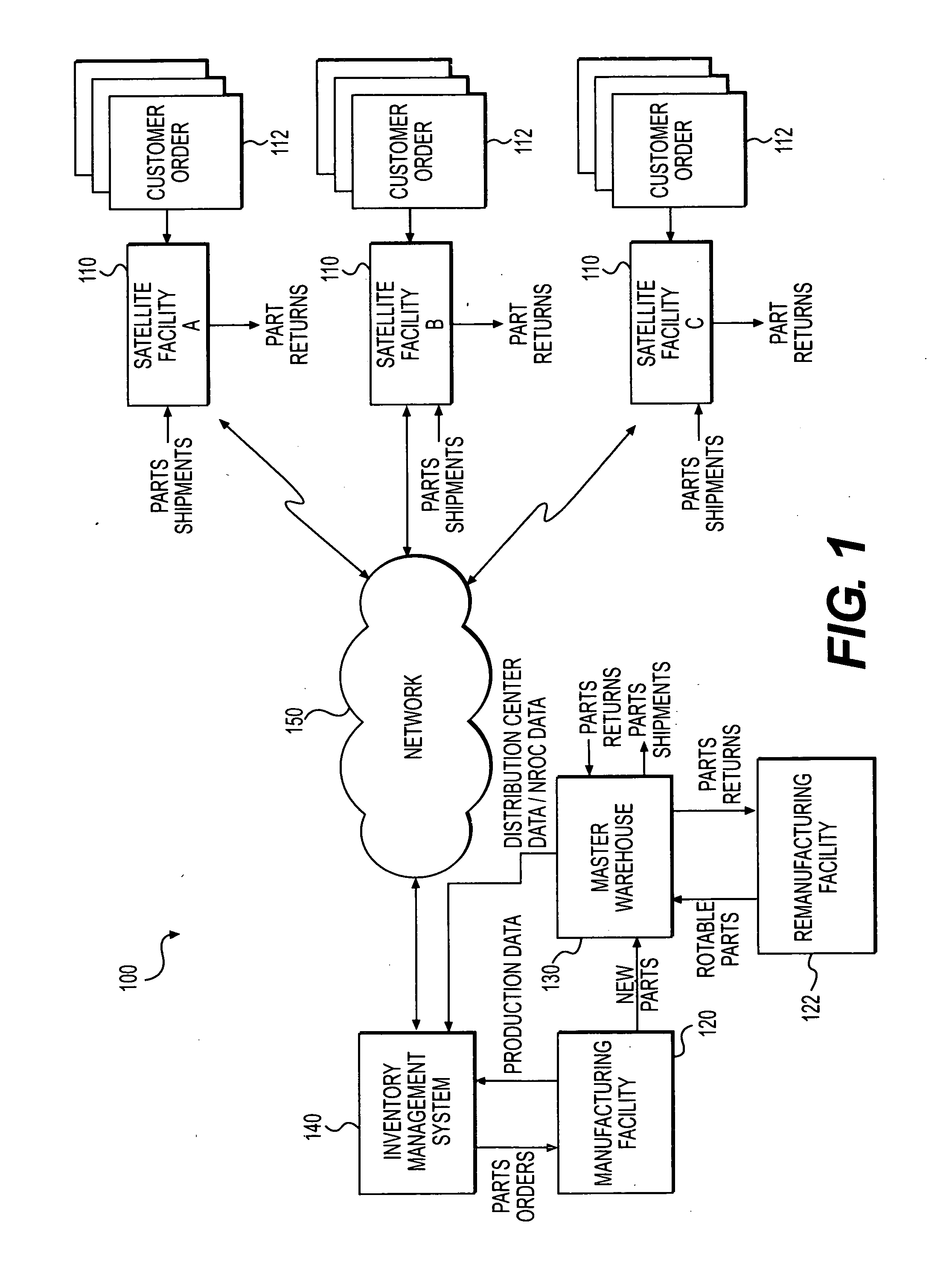

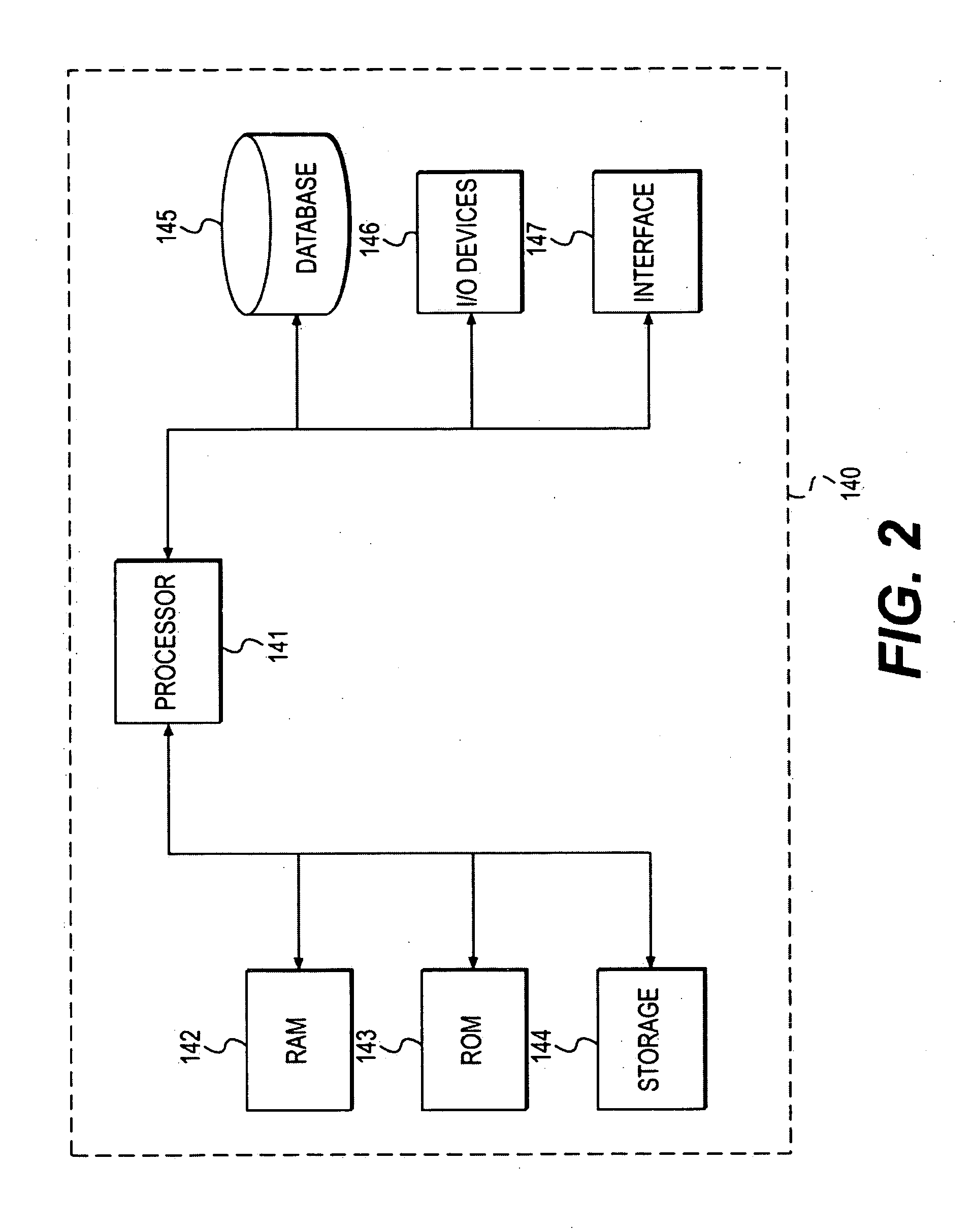

Method and system for forecasting demand of rotable parts

A method for forecasting a demand for rotable parts includes collecting demand data for one or more rotable parts associated with a product inventory. A demand pattern associated with the demand data is identified for each of the one or more rotable parts. A future demand associated with the one or more rotable parts is forecasted for at least one future demand period based on the identified demand pattern. An inventory level associated with each of the one or more rotable parts is established, for the at least one future demand period, a based on the future demand and a predetermined customer service level. The method also includes adjusting a manufacturing schedule associated with the one or more rotable parts based on the established inventory level.

Owner:CATERPILLAR INC

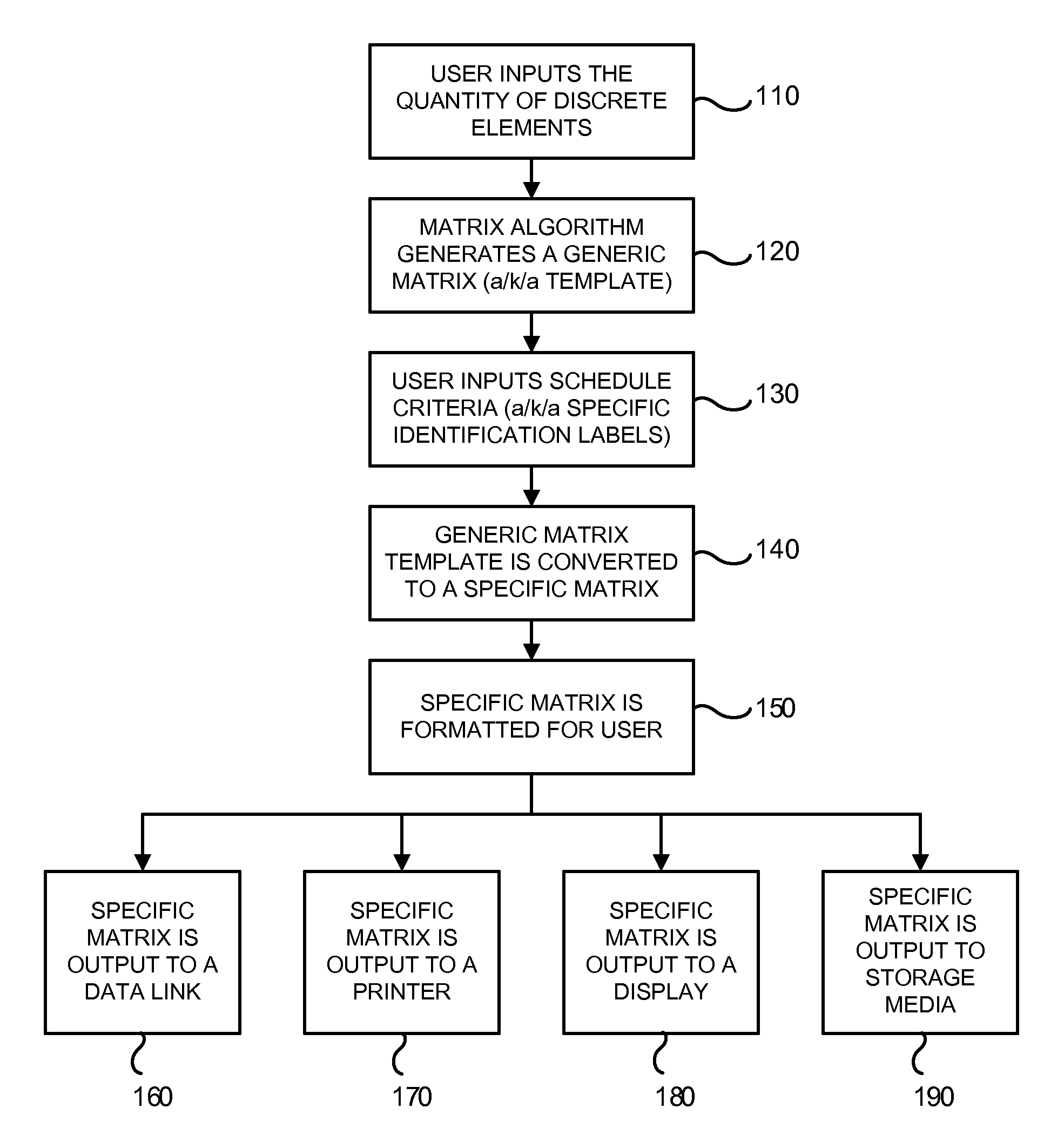

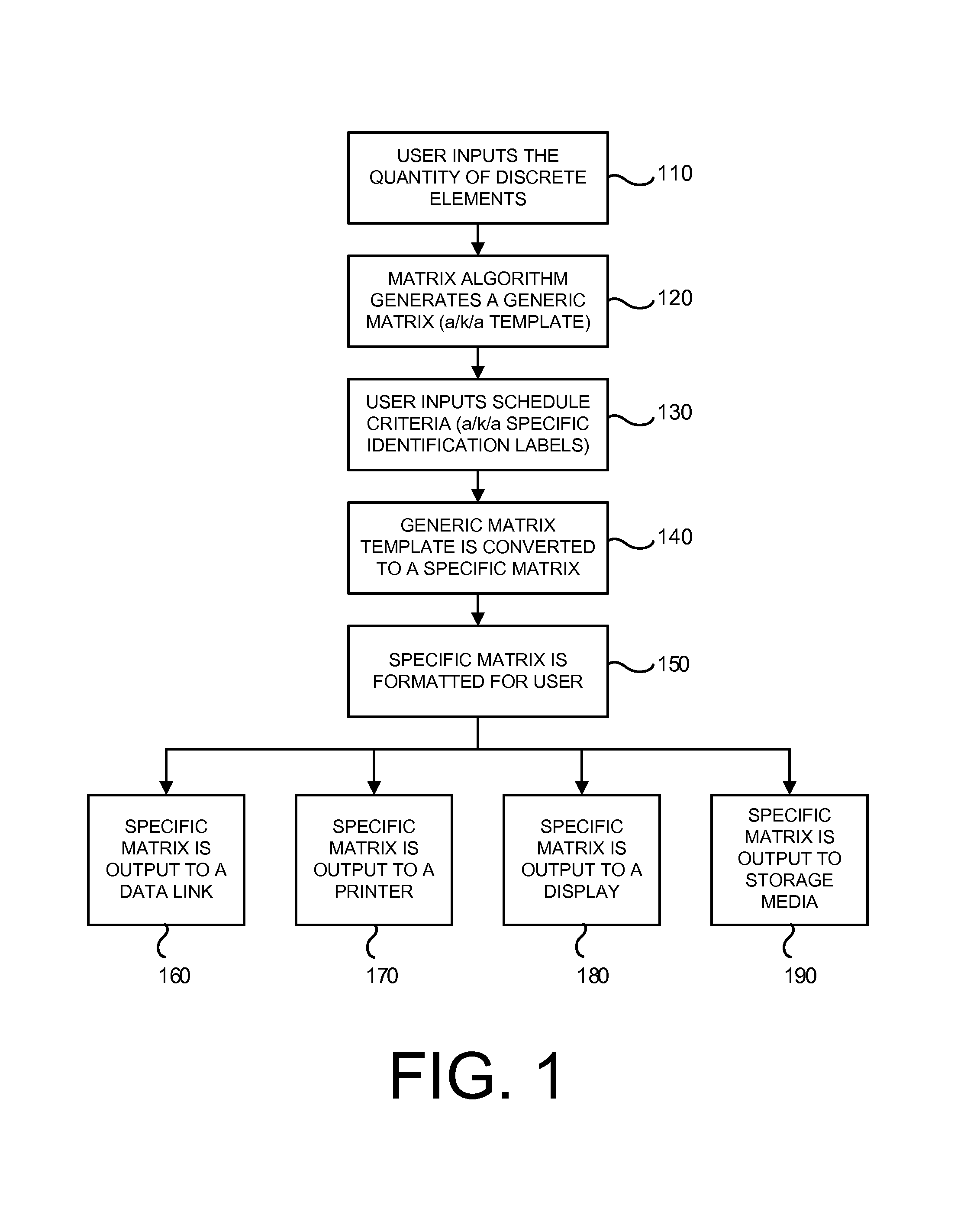

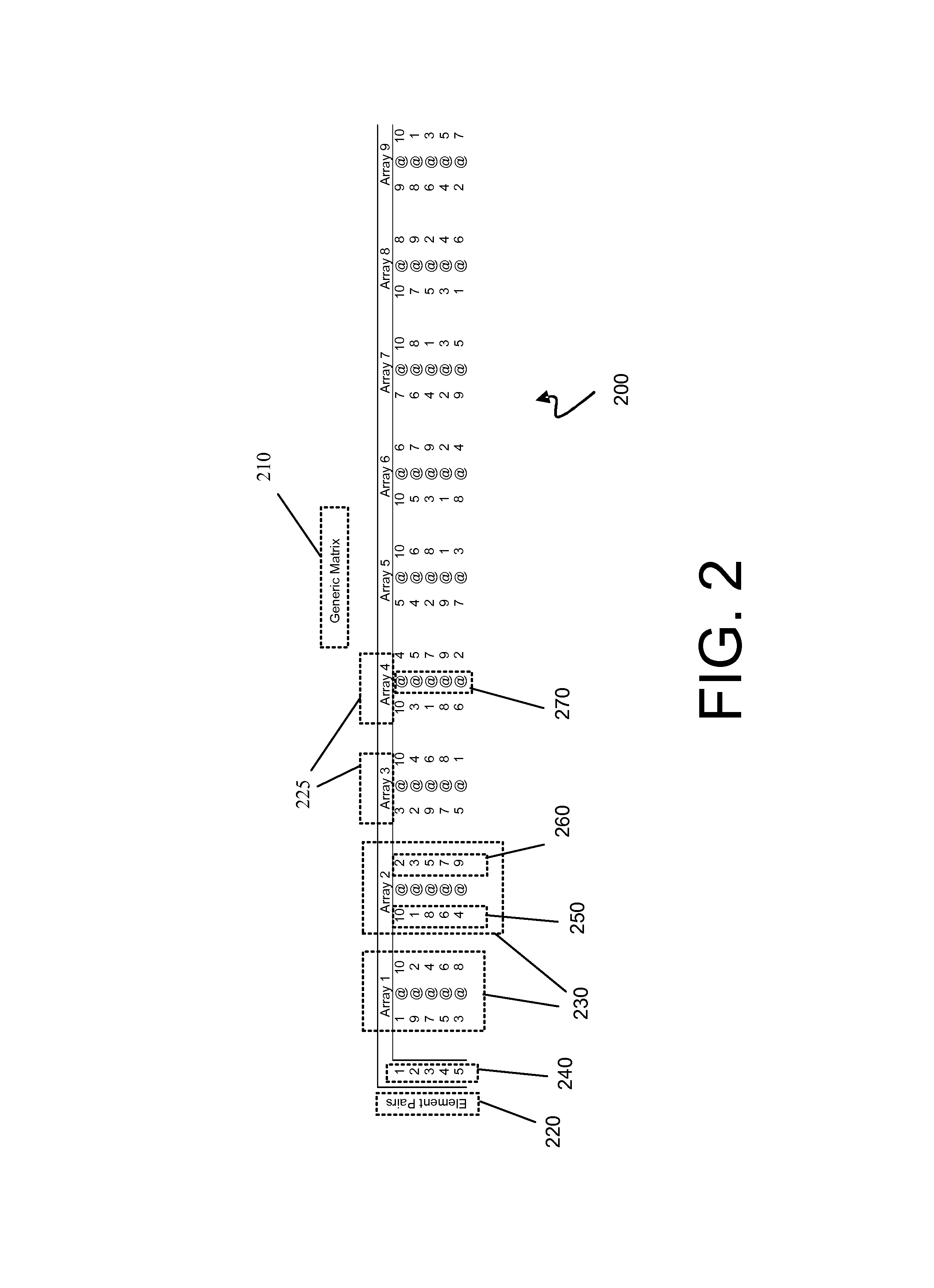

System and method for scheduling

A method and system for scheduling is disclosed. A computer generated generic matrix is provided allowing for creation of discrete pairs of discrete elements in combination, permutation, and the like. Applications of the method and system include, but are not limited to, sports scheduling, labor scheduling, manufacturing scheduling, laboratory experiments scheduling, sales performance scheduling.

Owner:ROOKS DENNIS BRIAN

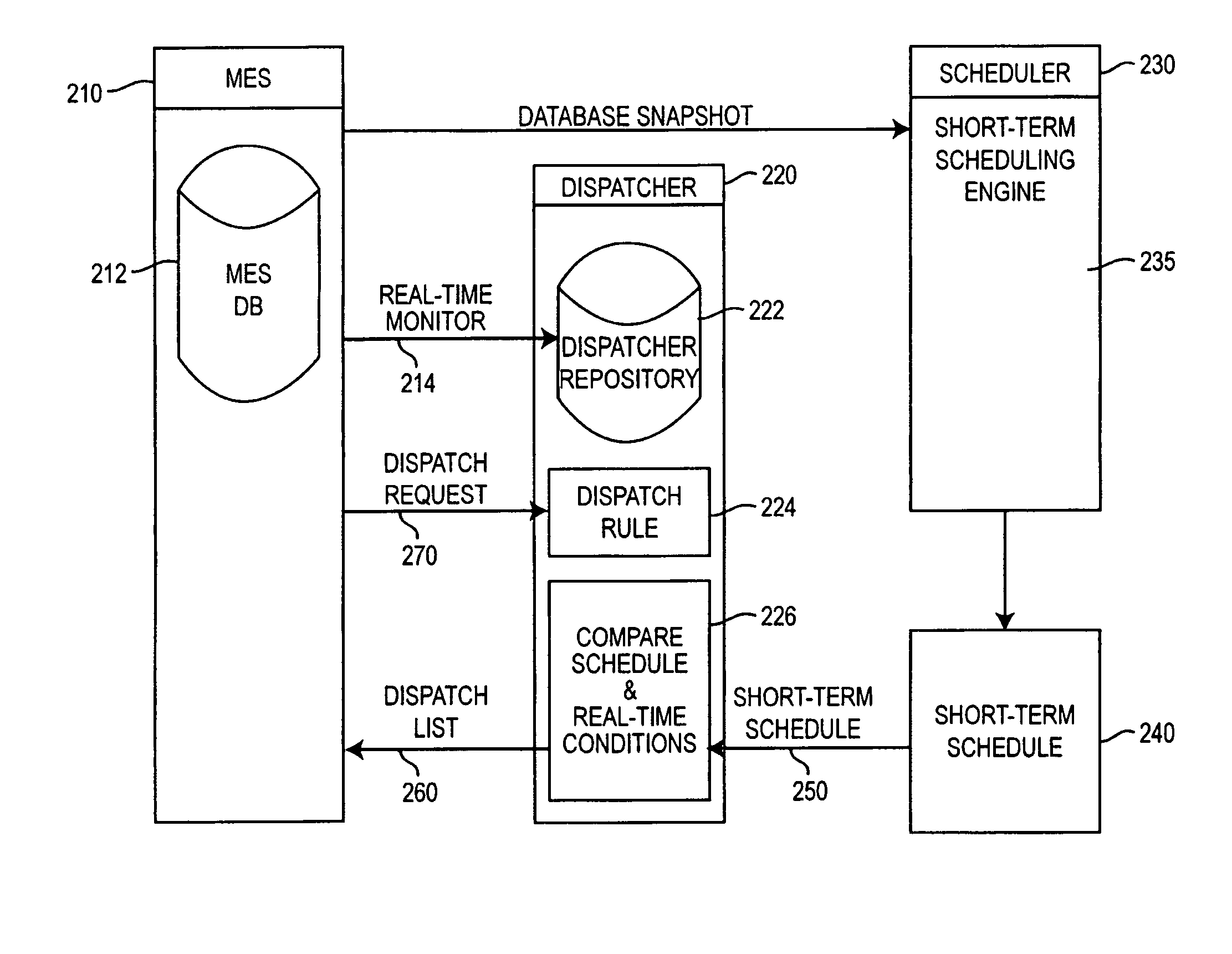

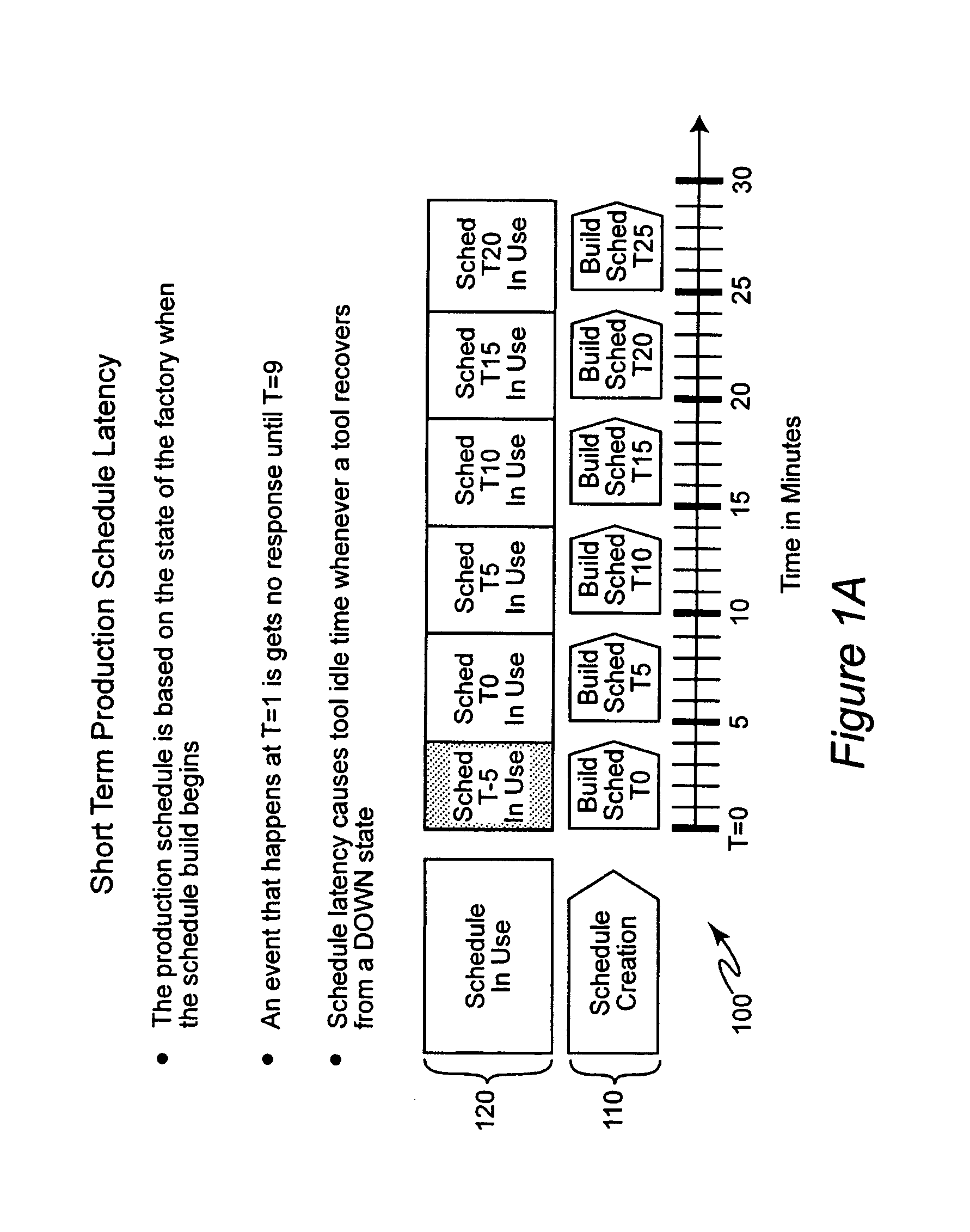

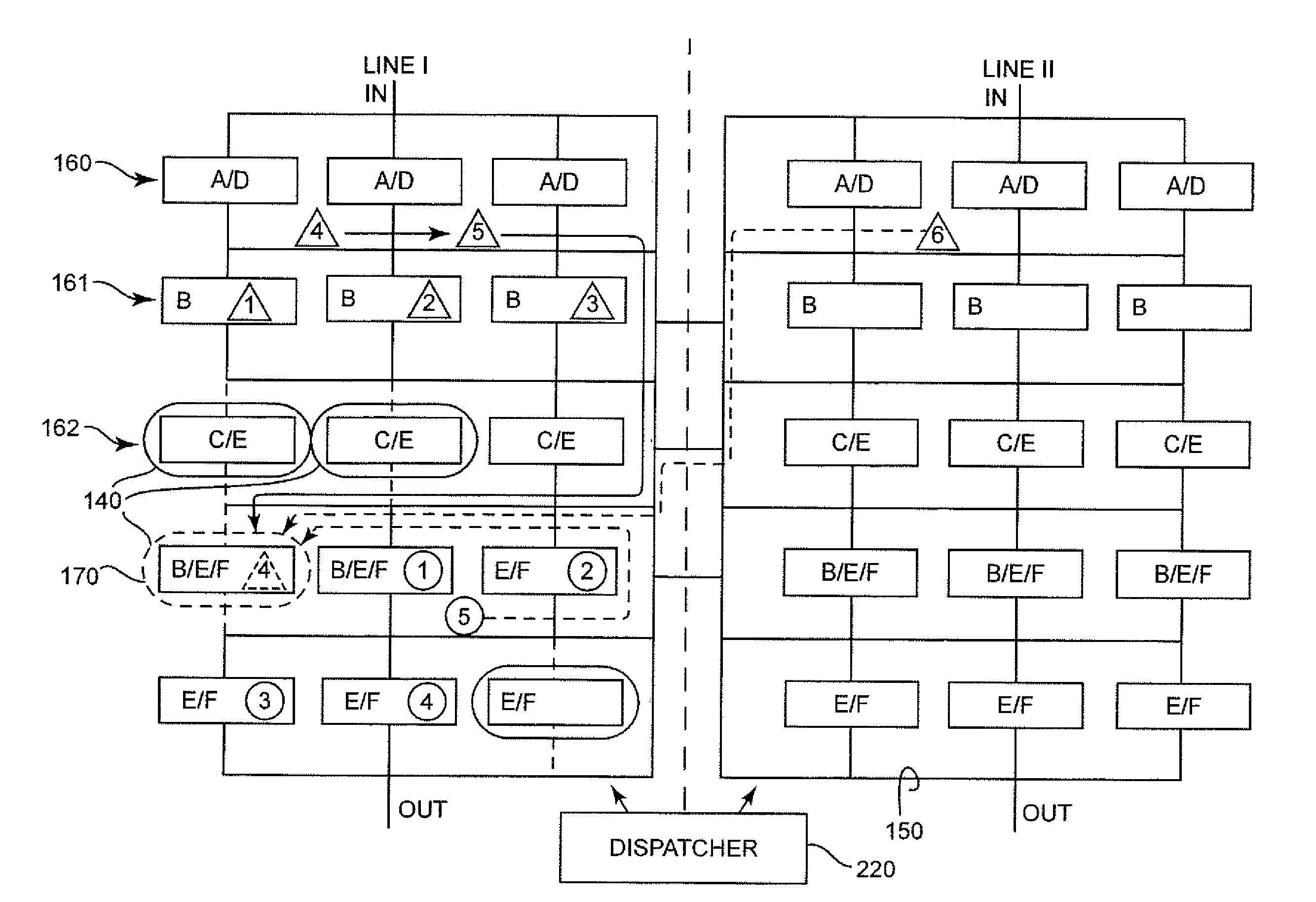

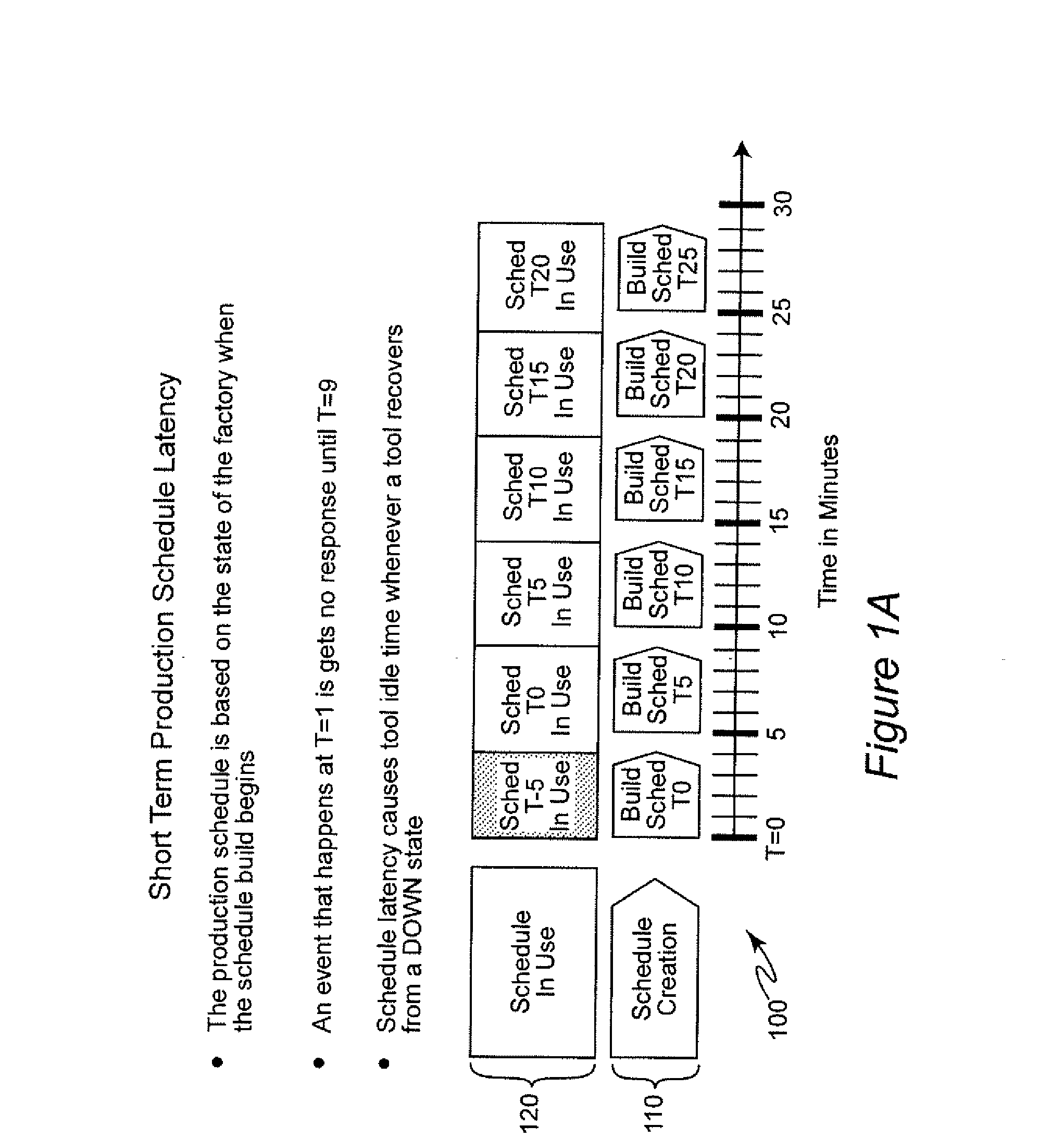

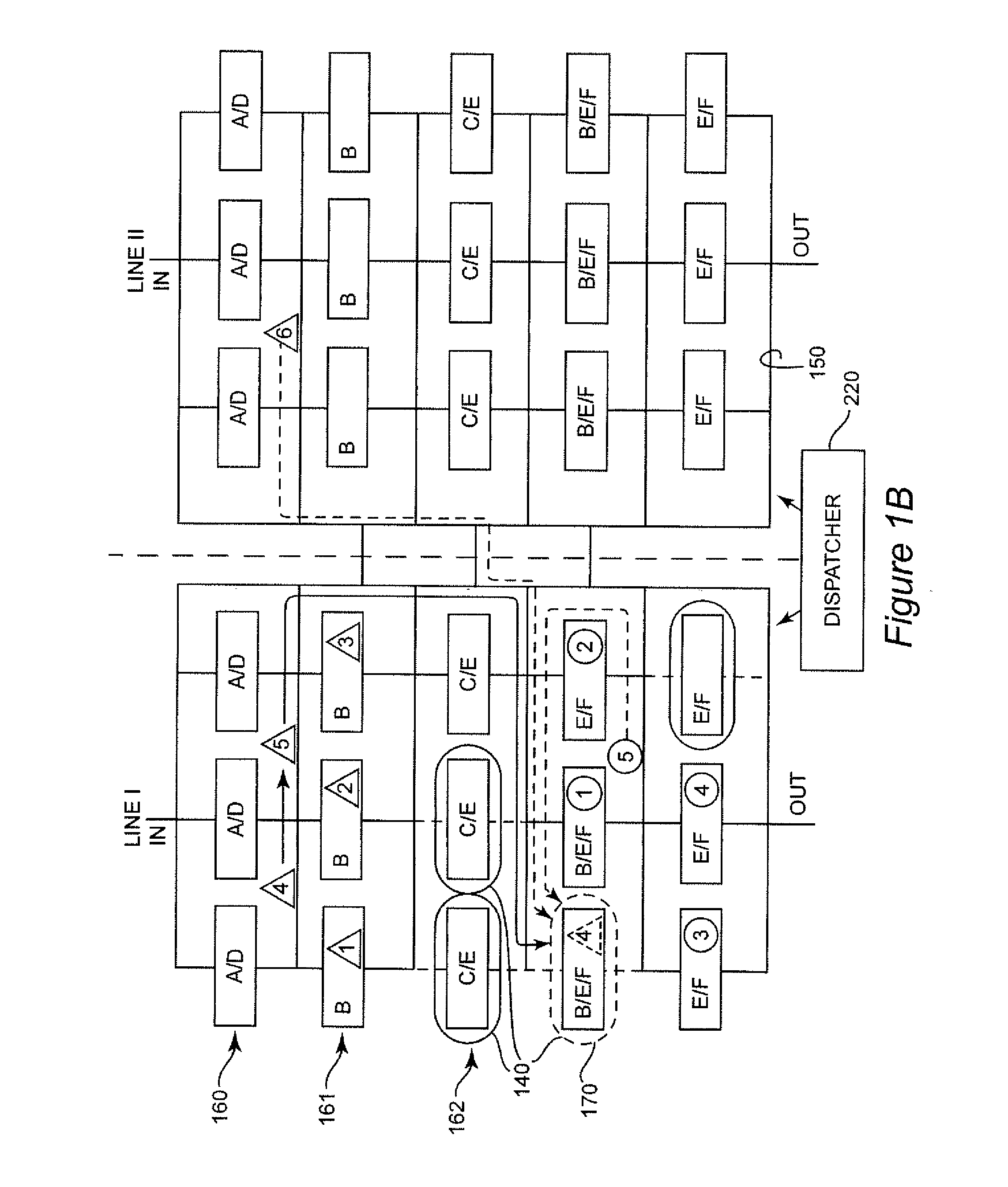

Method for minimizing productivity loss while using a manufacturing scheduler

InactiveUS20090299510A1Maximize utilizationResourcesSpecial data processing applicationsProduction rateManufacturing scheduling

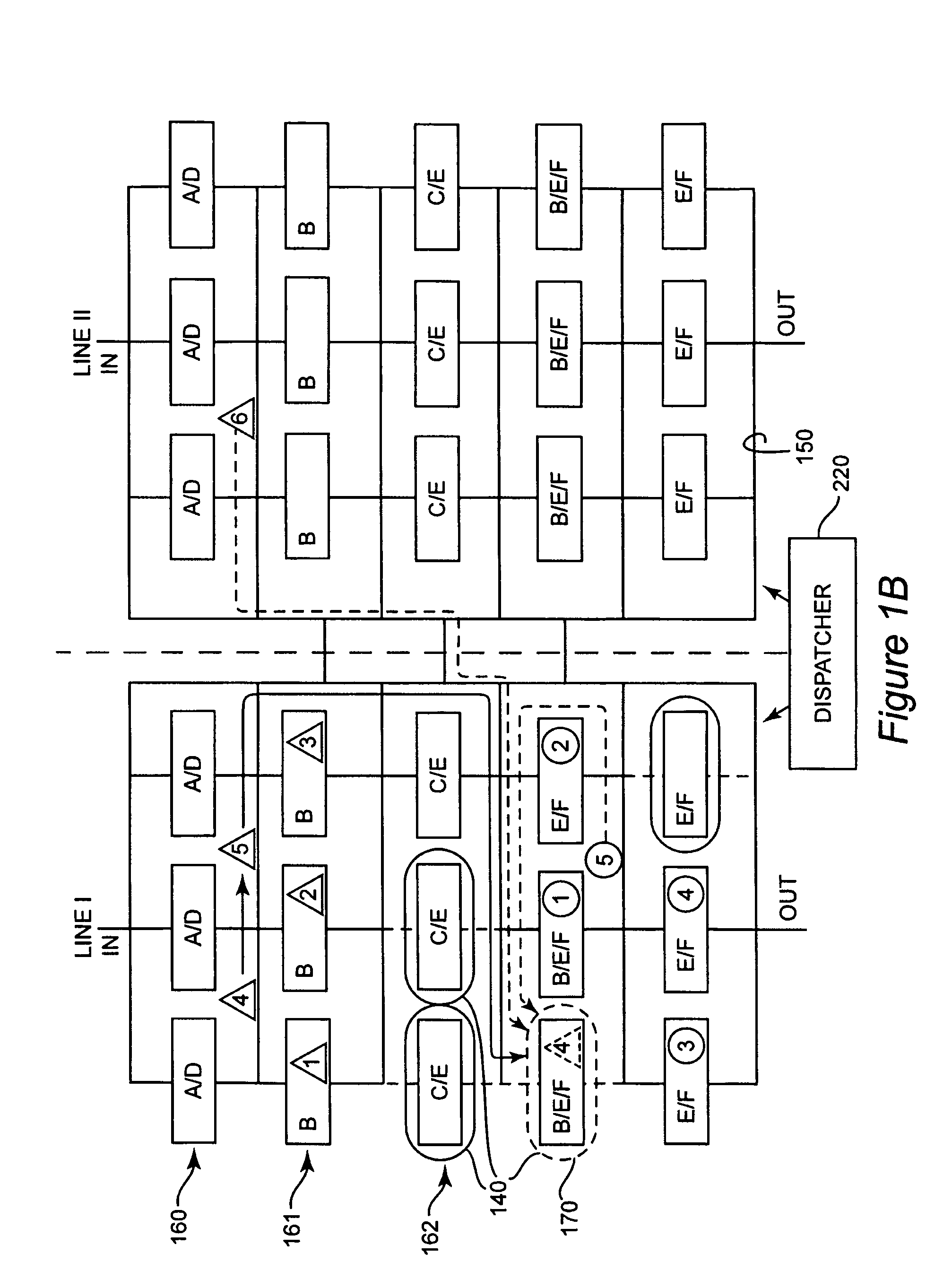

Tools and / or resources which newly become available to a re-entrant flow manufacturing line, data processing pipeline or the like are allocated in substantially real time to processing operations independent of and consistent with a scheduling segment previously generated by dispatching items such as workpieces or data to tools and / or resources of a manufacturing line until the newly available tool or resource can be conveniently included in a subsequently generated schedule segment in order to avoid productivity loss due to schedule latency. Items can be dispatched in a priority order to accelerate completion of processing. A schedule segment including the newly available tool or resource can be facilitated by merging allocations of a real time dispatch list with allocations of a dispatch list corresponding to a previously generated schedule segment.

Owner:GLOBALFOUNDRIES INC

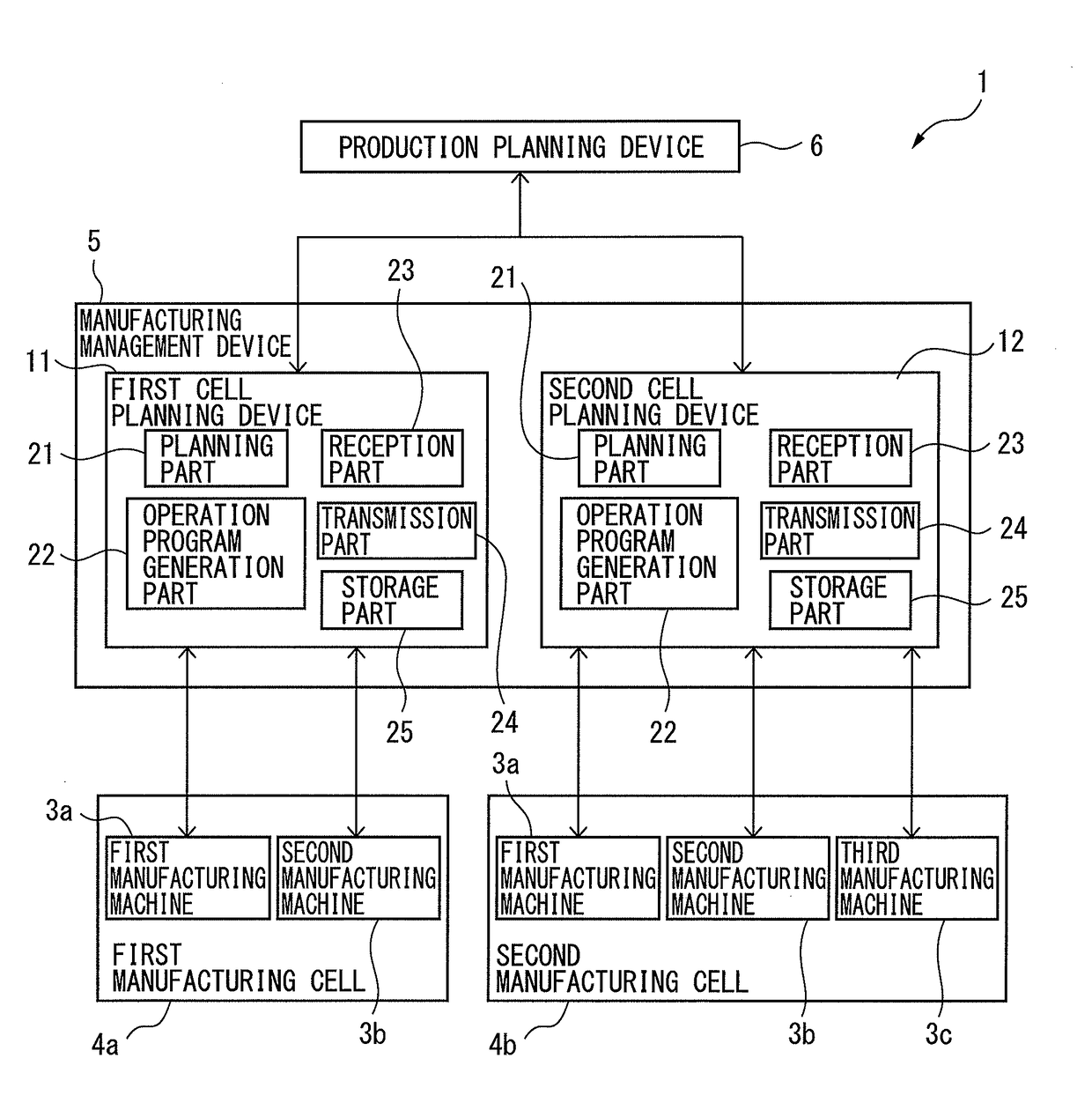

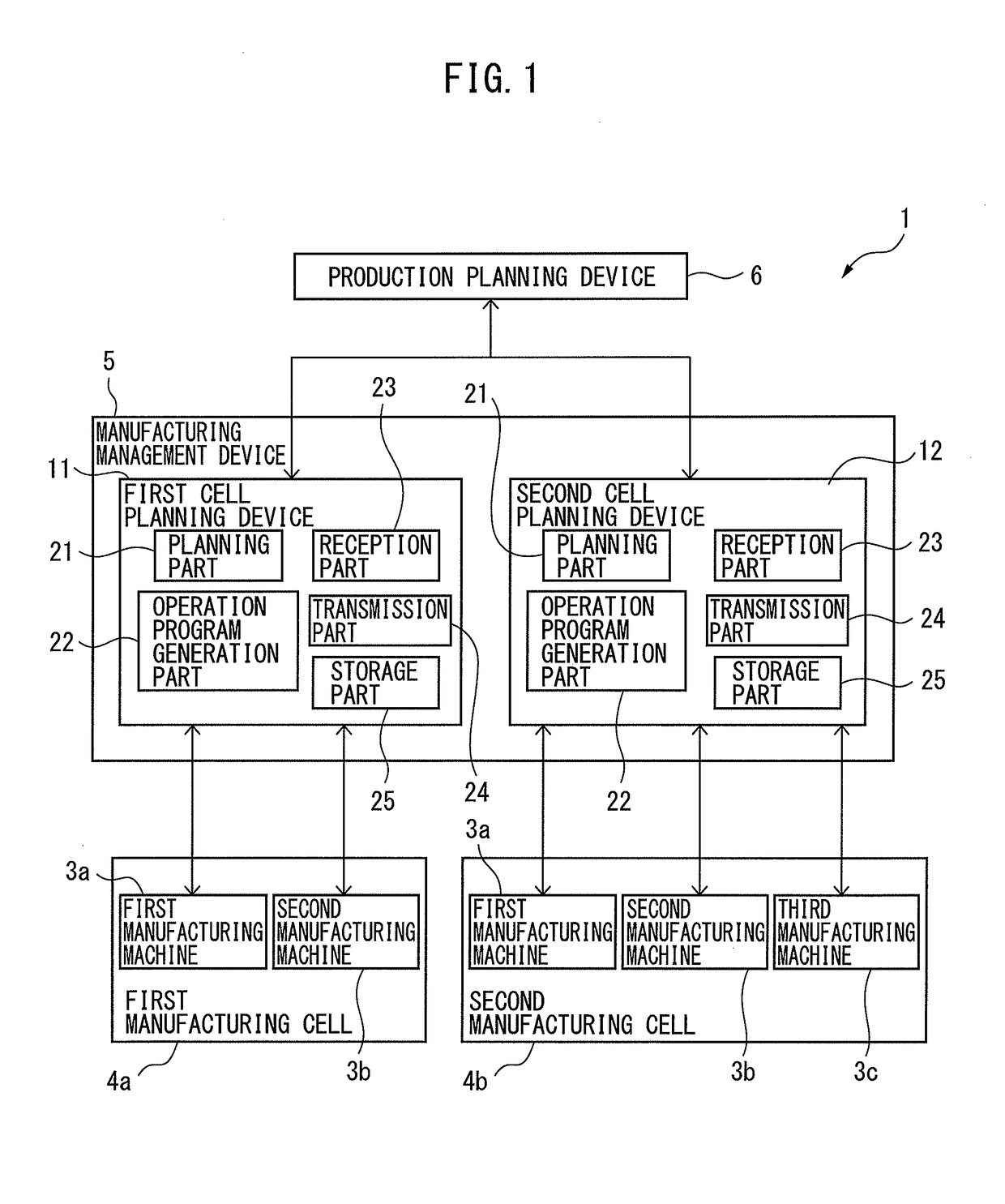

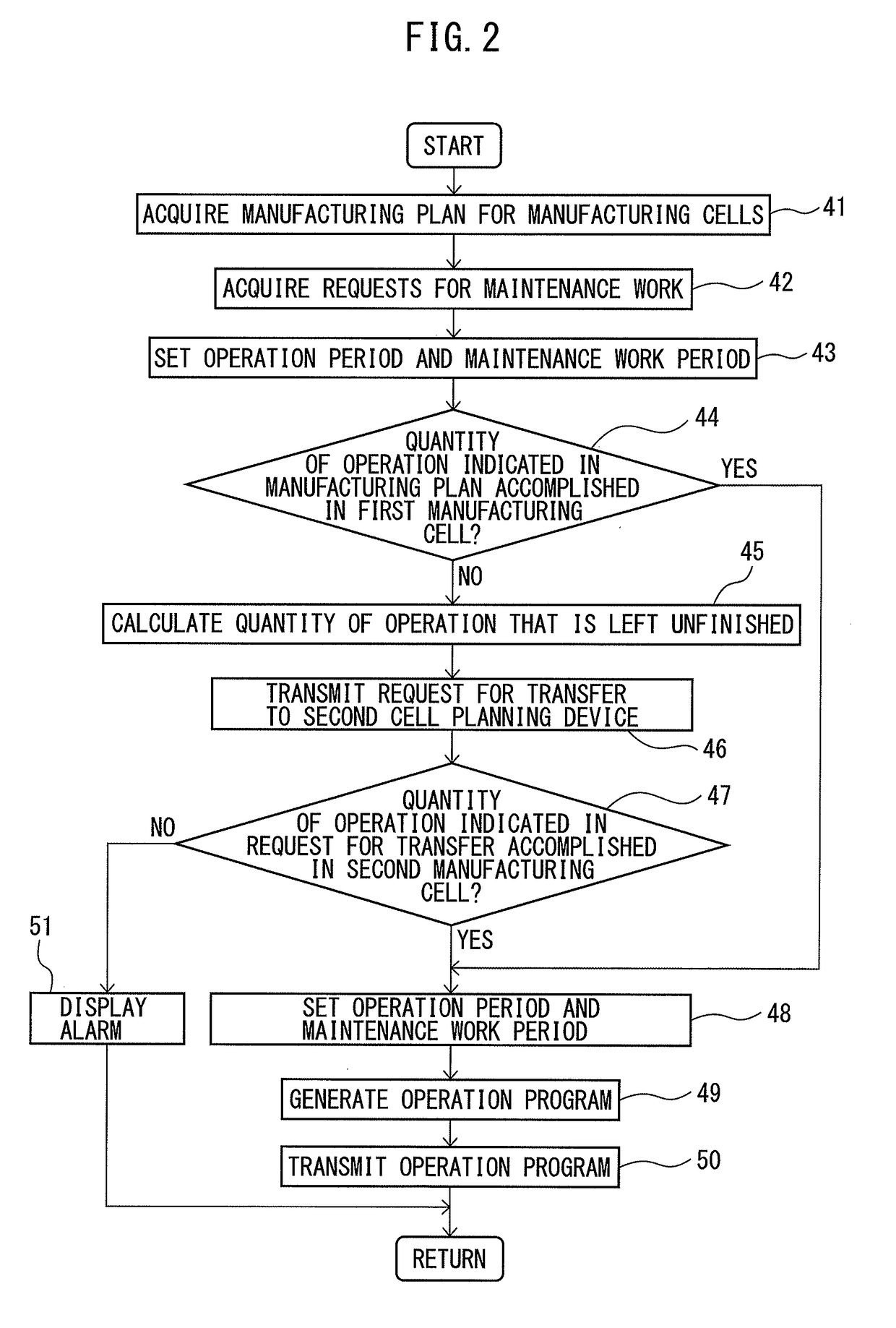

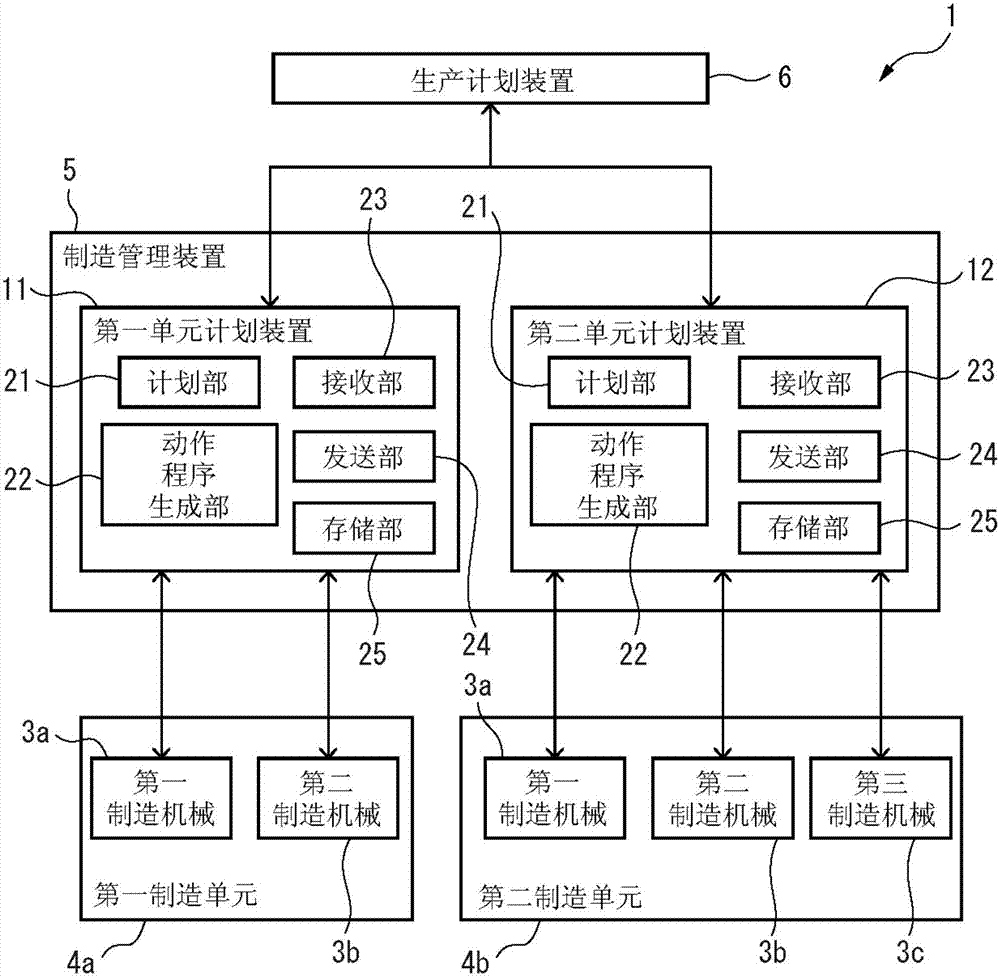

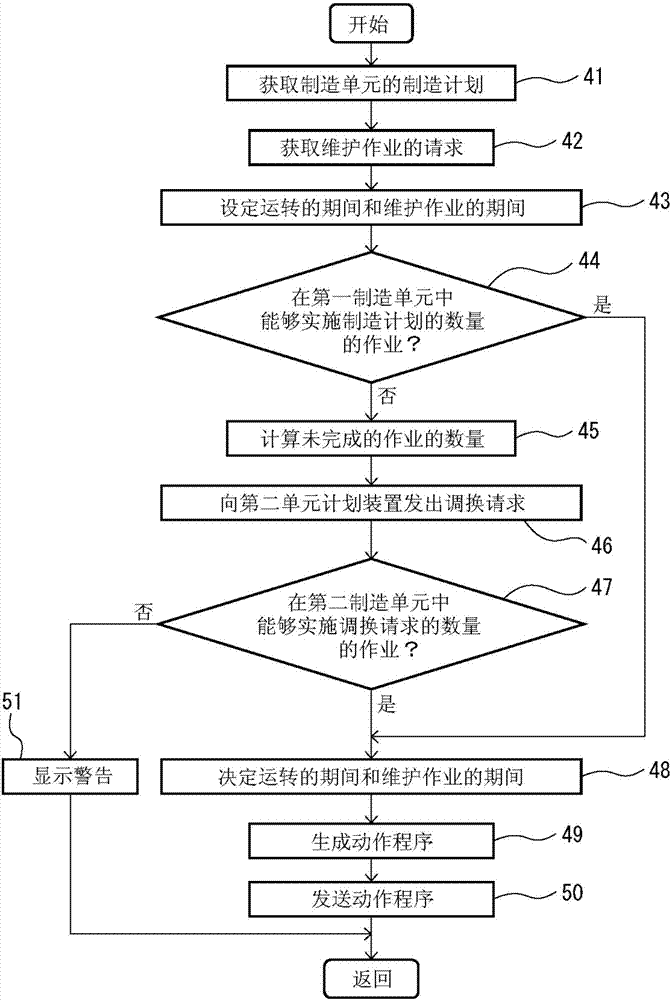

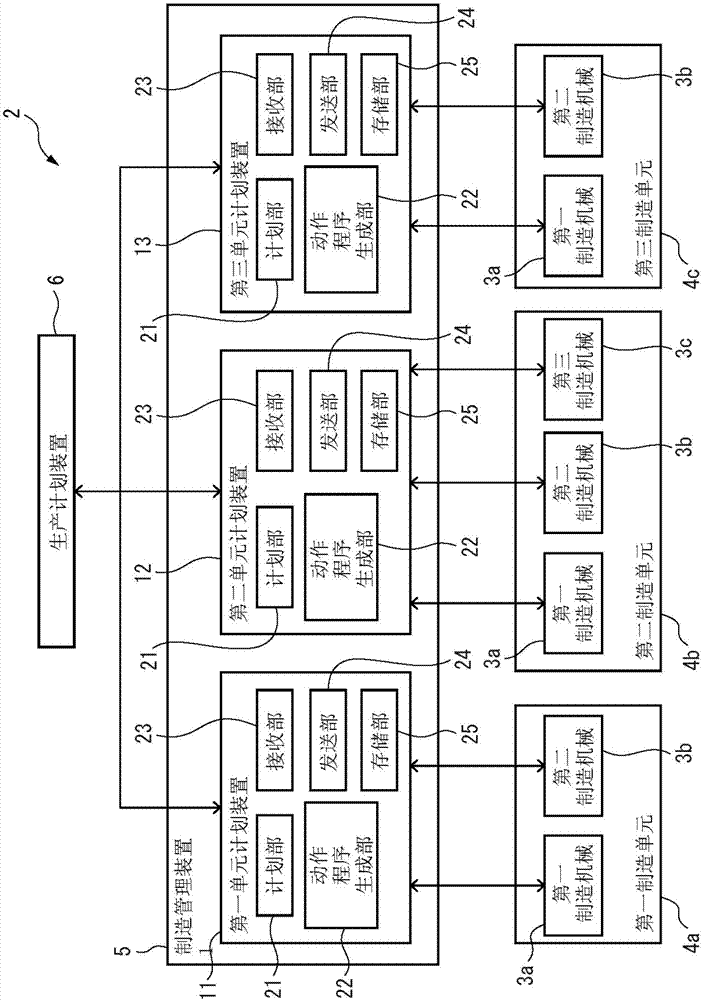

Manufacturing management device for controlling manufacturing cells in which maintenance work is conducted

InactiveUS20170343994A1Productivity is deterioratedDeterioration in operation rateTechnology managementResourcesManufacturing schedulingManufacturing management

A manufacturing management device includes first cell planning device connected to the manufacturing machine of first manufacturing cell, and second cell planning device connected to the manufacturing machine of second manufacturing cell. The planning part of the first cell planning device calculates quantity of operation that would be left unfinished with respect to the quantity stipulated in a manufacturing plan. The first cell planning device transmits a request for transfer including information on the quantity of operation that would be left unfinished to the second cell planning device. The second cell planning device modifies at least one of the operation period and the period of maintenance work of the manufacturing machine in the second manufacturing cell so as to increase the quantity of operation during the predetermined period.

Owner:FANUC LTD

Method for minimizing productivity loss while using a manufacturing scheduler

InactiveUS20120203367A1Maximize utilizationResourcesSpecial data processing applicationsManufacturing schedulingMajorization minimization

Tools and / or resources which newly become available to a re-entrant flow manufacturing line, data processing pipeline or the like are allocated in substantially real time to processing operations independent of and consistent with a scheduling segment previously generated by dispatching items such as workpieces or data to tools and / or resources of a manufacturing line until the newly available tool or resource can be conveniently included in a subsequently generated schedule segment in order to avoid productivity loss due to schedule latency. Items can be dispatched in a priority order to accelerate completion of processing. A schedule segment including the newly available tool or resource can be facilitated by merging allocations of a real time dispatch list with allocations of a dispatch list corresponding to a previously generated schedule segment.

Owner:GLOBALFOUNDRIES INC

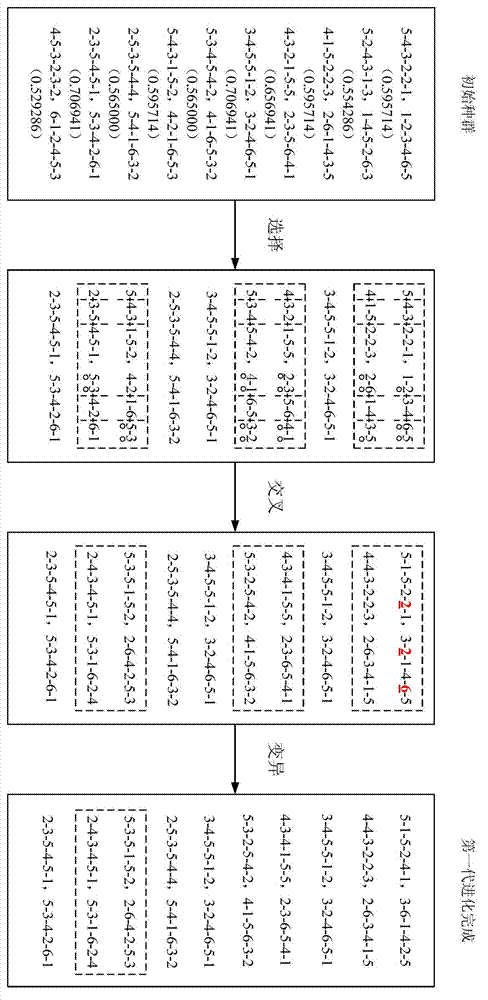

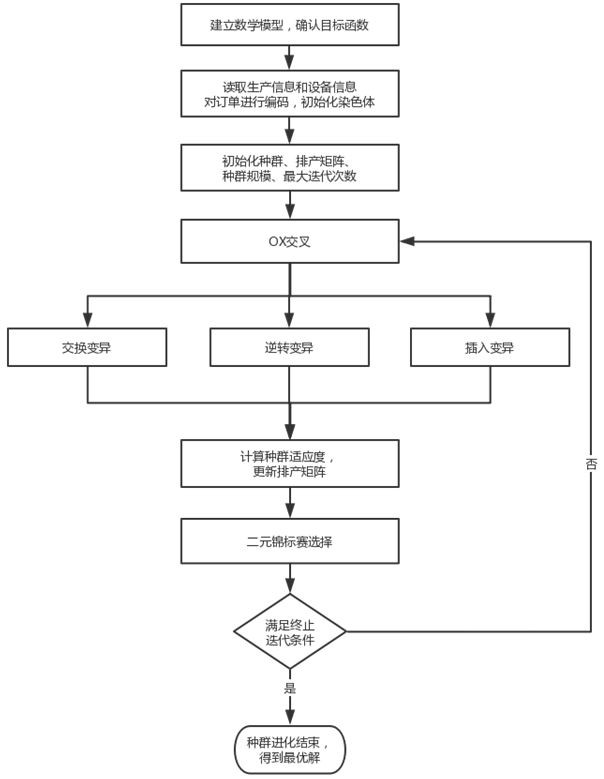

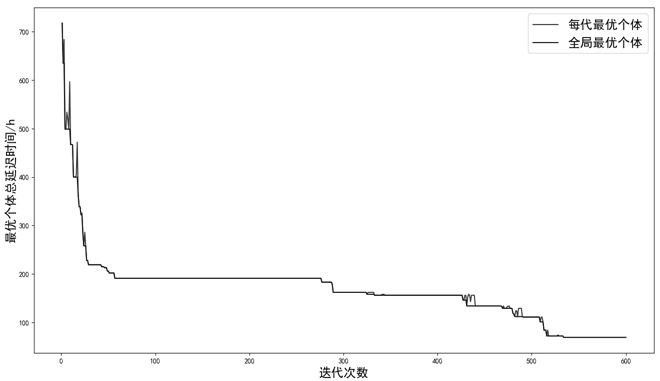

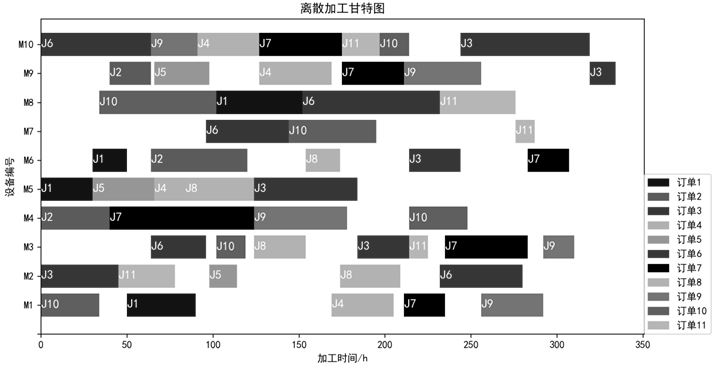

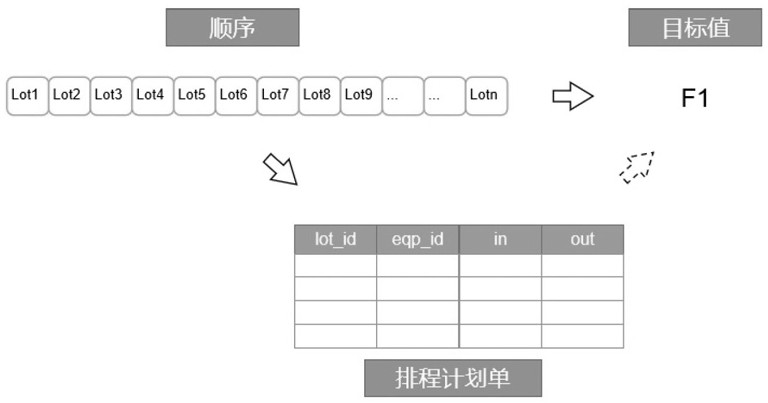

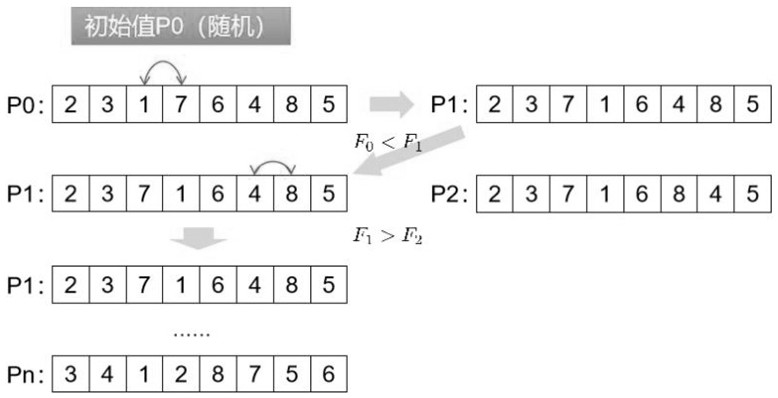

Production and manufacturing scheduling optimization method based on improved genetic algorithm

InactiveCN113379087AReduce delivery delay penalty costsImprove satisfactionReservationsManufacturing computing systemsGenetics algorithmsManufacturing scheduling

The invention discloses a production and manufacturing scheduling optimization method based on an improved genetic algorithm. The method comprises the following steps: firstly, aiming at a production scheduling optimization target, establishing a mathematical model, determining a population fitness function, reading order information and equipment information, numbering equipment, encoding an order process into a chromosome gene, initializing a population, the maximum number of iterations and a production scheduling matrix; carrying out operations such as crossover and variation on chromosomes of the population to obtain a new generation of population, arranging order procedures corresponding to chromosome genes on equipment in a conflict-free manner by combining a production scheduling matrix, and calculating a fitness function of population individuals; and finally, selecting next-generation individuals according to a binary tournament selection strategy, reserving fitness individuals to the next generation, repeating the steps until the maximum iteration frequency is reached, and decoding the individual chromosome with the highest fitness as an optimal production scheduling scheme. The global optimization can be quickly realized, and the effect is better than that of the existing optimization method.

Owner:ZHEJIANG UNIV

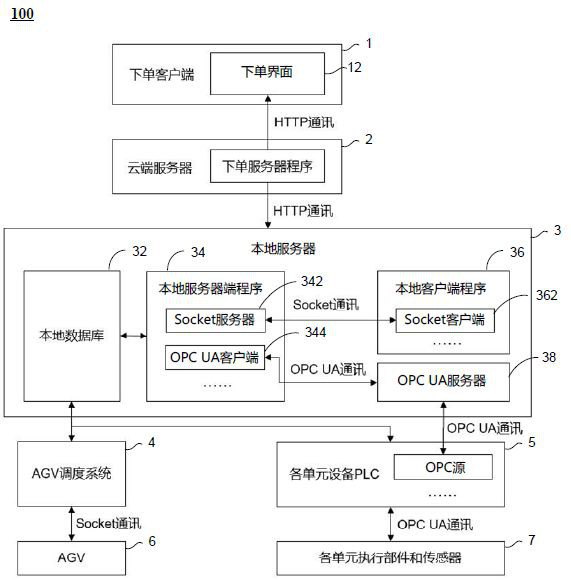

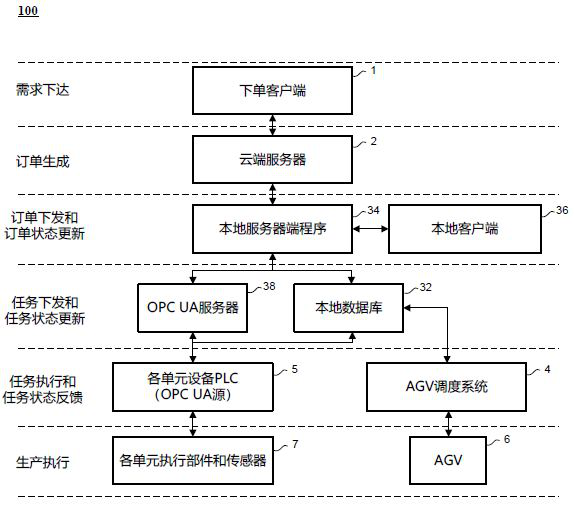

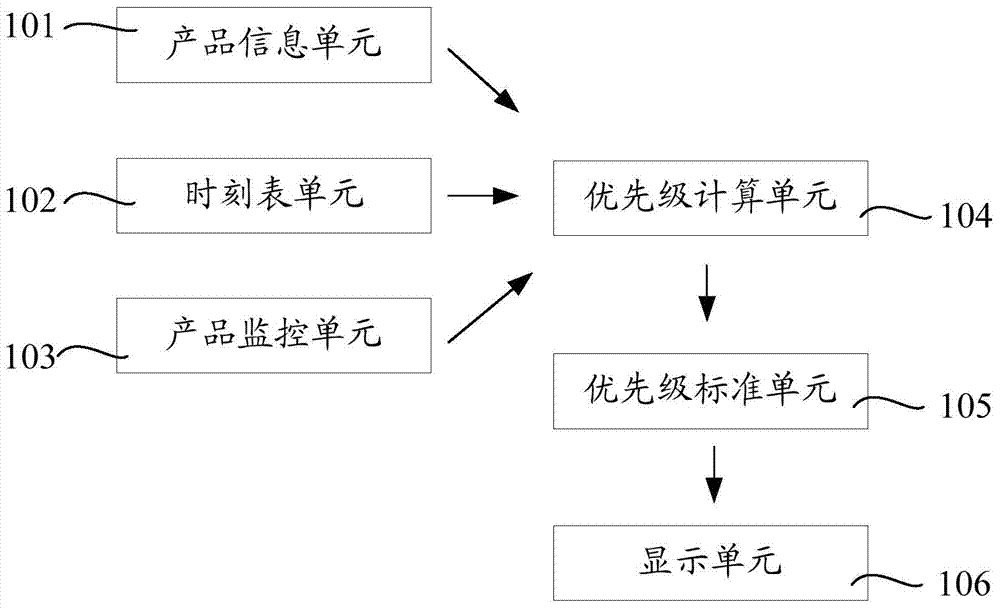

Flexible manufacturing scheduling system and manufacturing system comprising same

ActiveCN112099462ATotal factory controlProgramme total factory controlManufacturing schedulingManufacturing systems

The invention provides a flexible manufacturing scheduling system and a manufacturing system comprising the flexible manufacturing scheduling system. The flexible manufacturing scheduling system is incommunication connection with at least one controller, and each controller is used for controlling at least one actuator. The flexible manufacturing scheduling system may include a processor. The processor may be configured to receive order information, and control one or more of the at least one controller based on a pre-programmed scheduling logic corresponding to the order information to makethe controller control an action of the at least one actuator to fulfill the order task, wherein the scheduling logic is an instruction set required to fulfill the order task and recognizable and executable by the controller.

Owner:PHOENIX CONTACT NANJING R&D ENG CENT

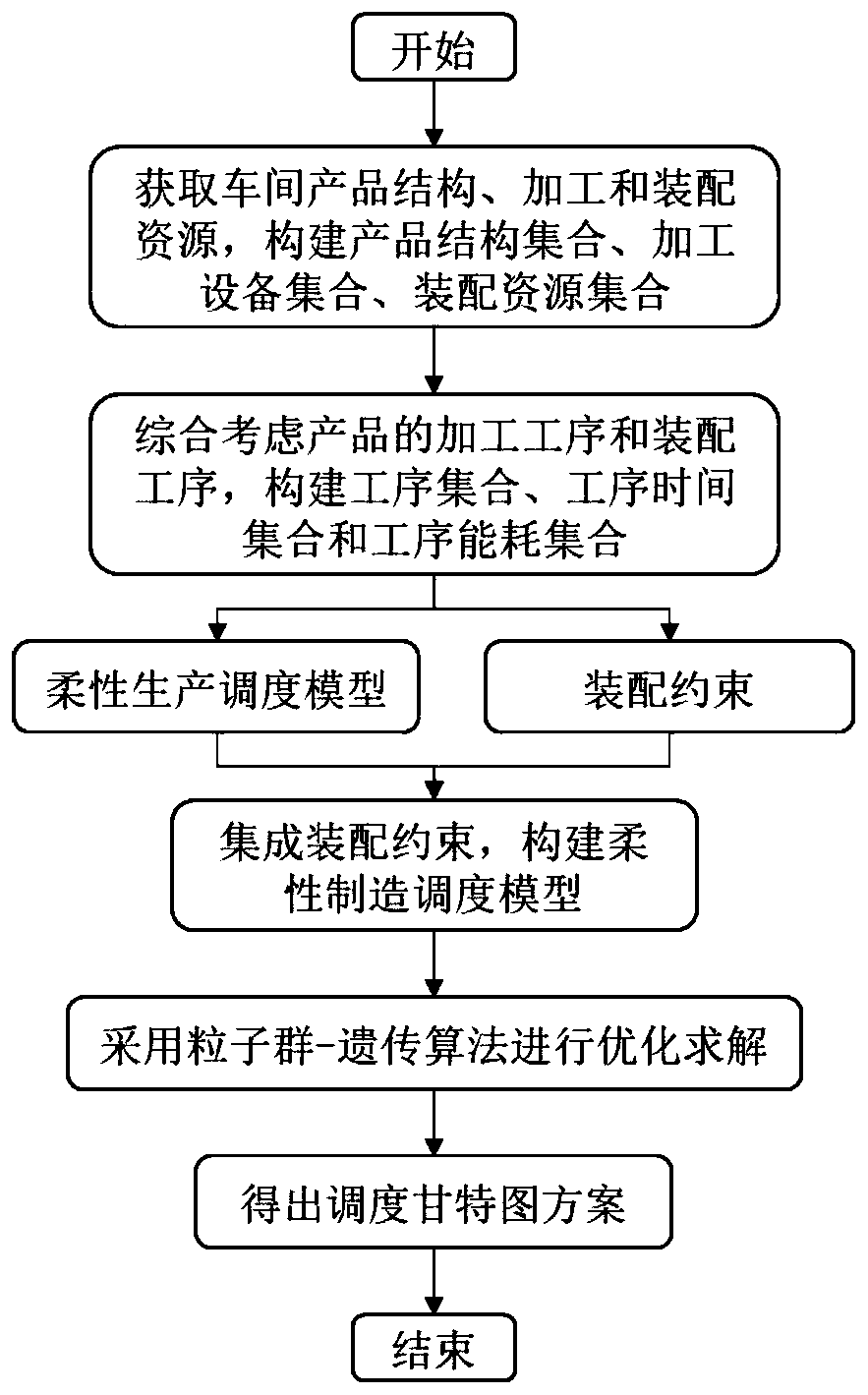

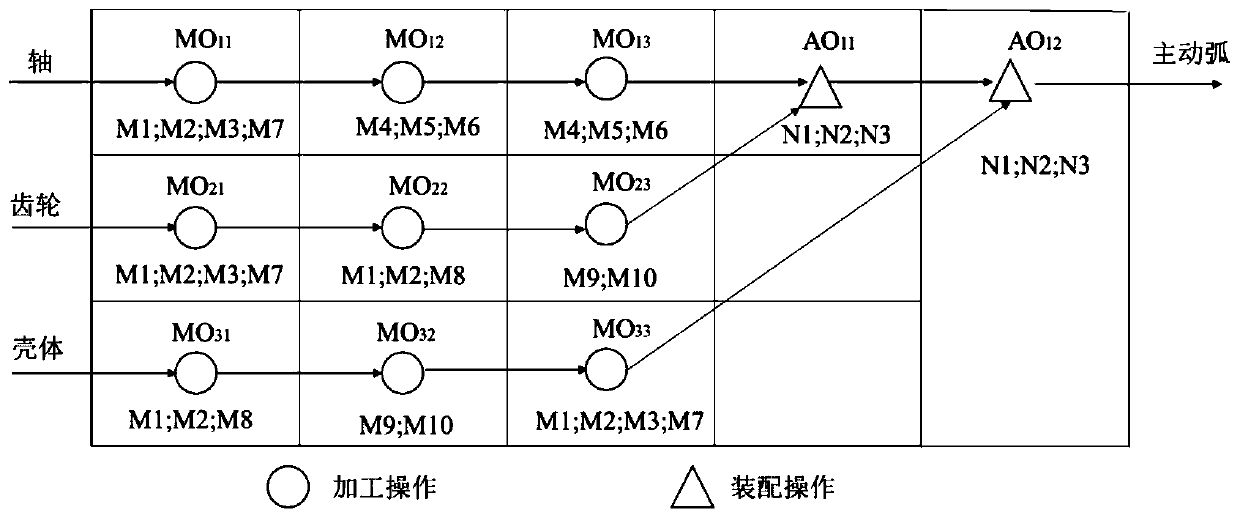

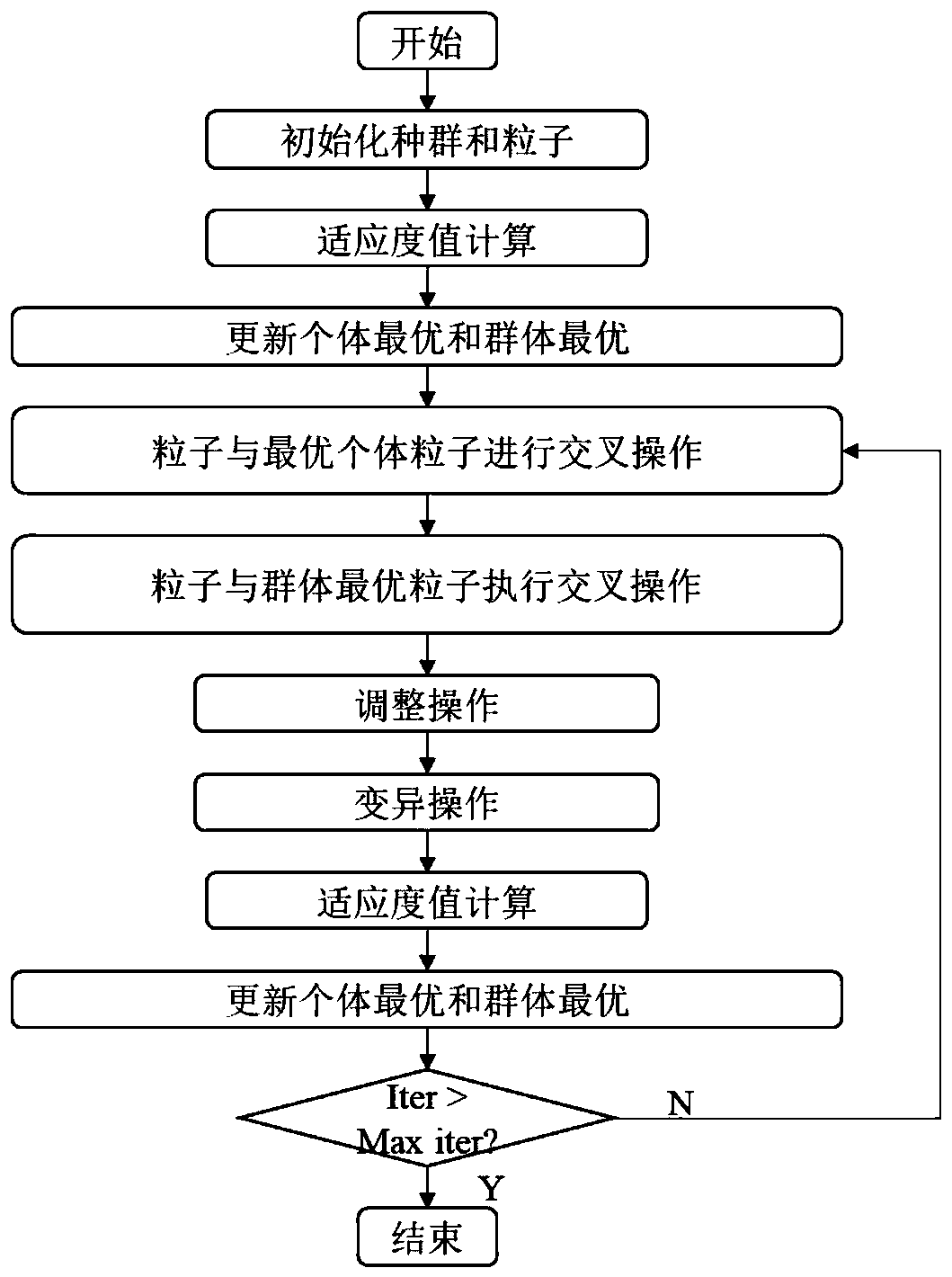

Product energy-saving scheduling optimization method for flexible manufacturing system

ActiveCN111290358AIncrease profitShorten completion timeEnergy industryTotal factory controlFlexible manufacturing systemStart time

The invention discloses a product energy-saving scheduling optimization method for a flexible manufacturing system, which belongs to the technical field of production scheduling. The implementation method comprises the steps: workshop product structures and machining and assembling resources are obtained, and a product structure set and a production resource set are constructed; a process set, a process time set and an energy consumption set are constructed; aiming at the assembly process, the process with the maximum start time of each assembly process is selected as an actual completion process to form an assembly constraint, and the assembly constraint is fused into the flexible production scheduling model to construct a flexible manufacturing scheduling model; and the flexible manufacturing scheduling model is optimized through an improved multi-target particle swarm-genetic algorithm. The optimization speed can be guaranteed, the algorithm convergence can be improved, a flexible manufacturing system scheduling scheme with a better target function is obtained, the scheduling scheme can integrally consider the production process and the assembly process of a product and is moresuitable for existing production and assembly working conditions, and therefore the production time of the product is shortened, and energy consumption in the production process of the product is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

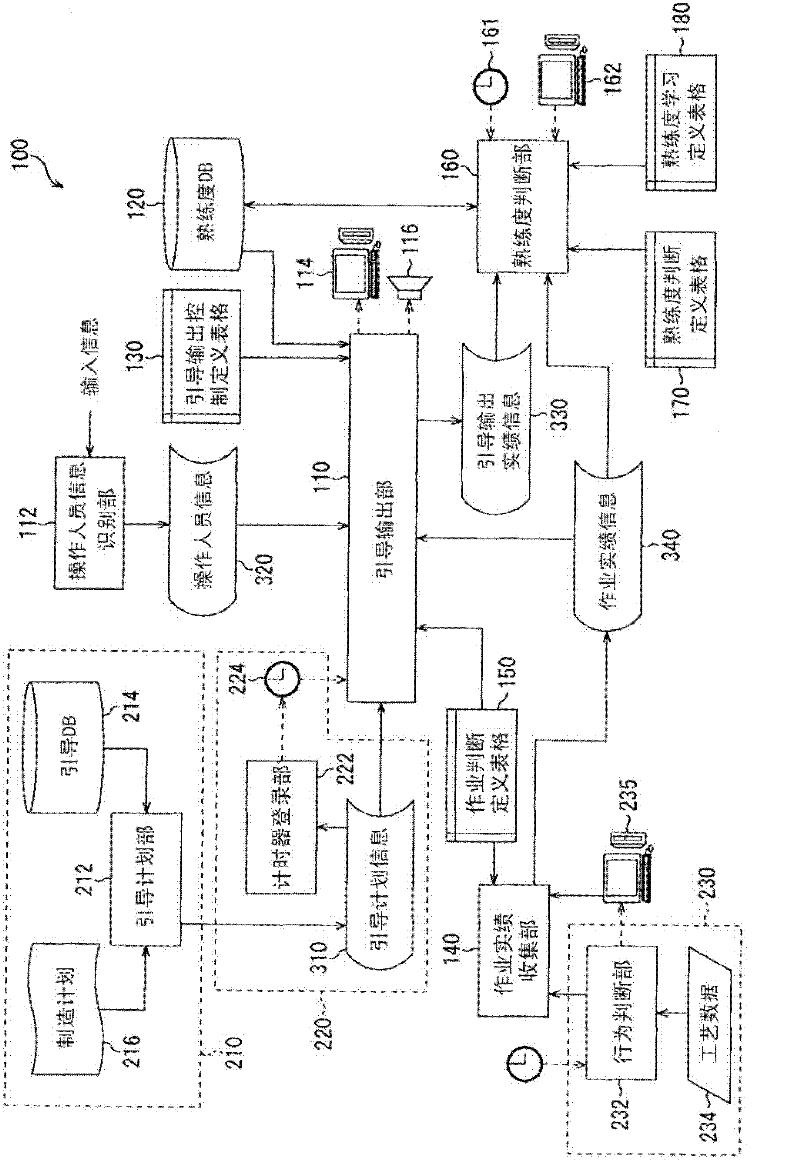

Operation support device, operation support method, and computer program

InactiveCN102301294AData processing applicationsClimate change adaptationProgram planningGuidance control

For each of tasks performed in an operation of manufacturing equipment, a proficiency of a worker with respect to a task to be performed is obtained from a proficiency DB (120) storing proficiencies of workers with respect to the tasks. A guidance base time (314) determined based on a manufacturing schedule is controlled corresponding to the proficiency of the worker, a guidance control time (334) corresponding to the proficiency of the worker is determined, and guidance is outputted at the guidance control time (334). The proficiency of the worker with respect to the task is corrected based on task record information (340) including a task content and a task time of a task performed by the worker and on the guidance control time (334), and the proficiency of the worker with respect to the task stored in the proficiency DB (120) is updated.

Owner:NIPPON STEEL CORP

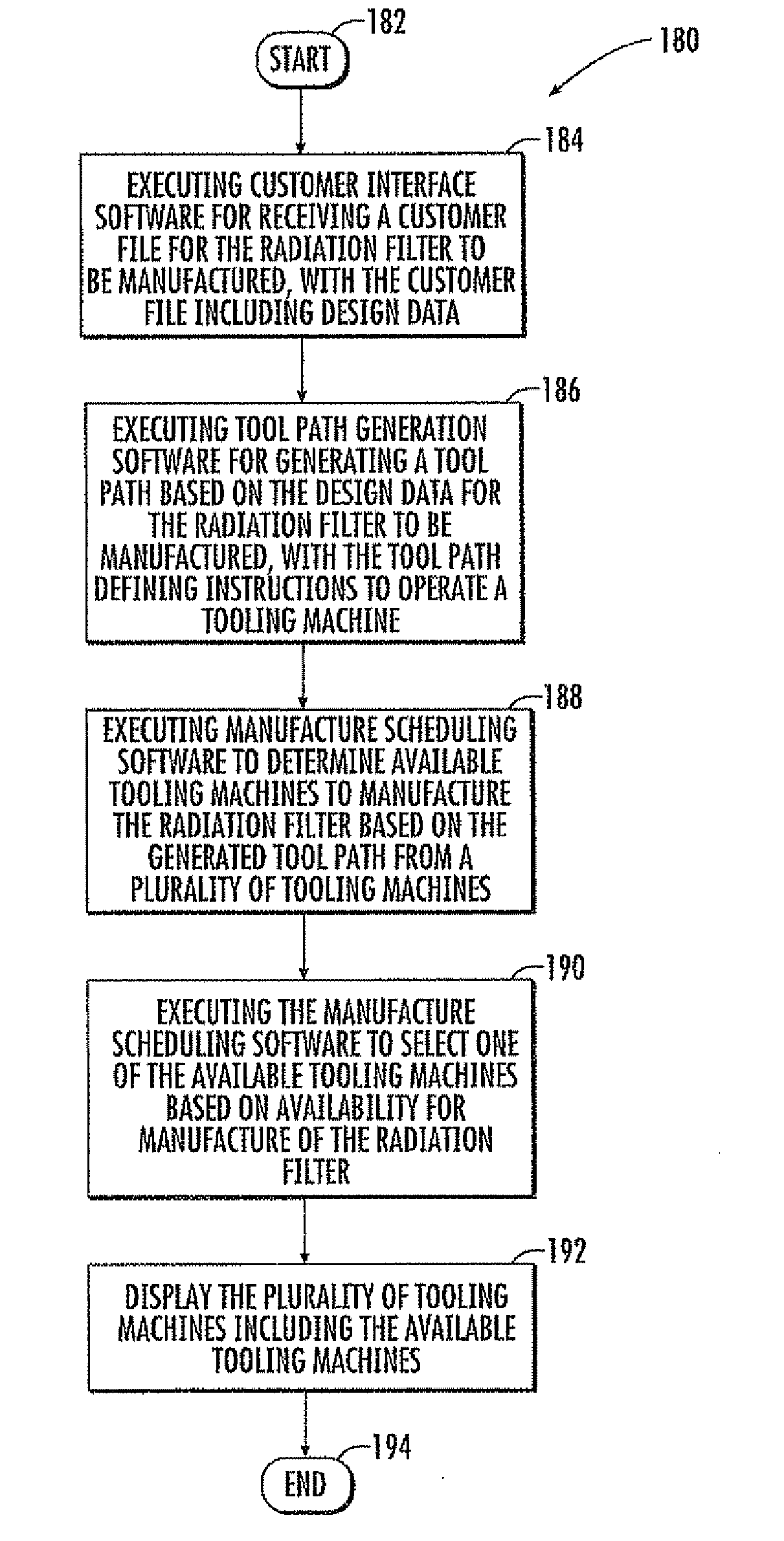

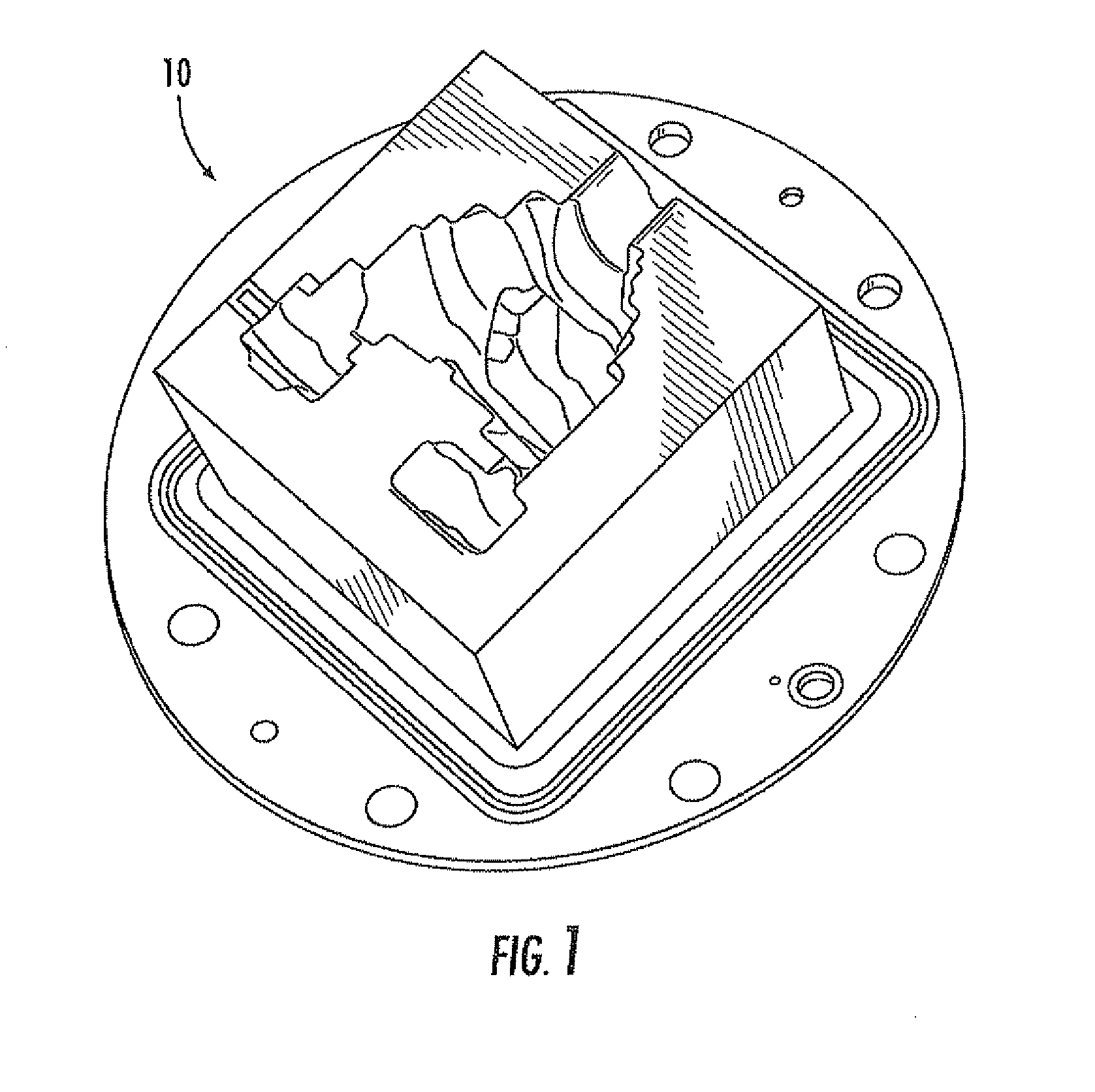

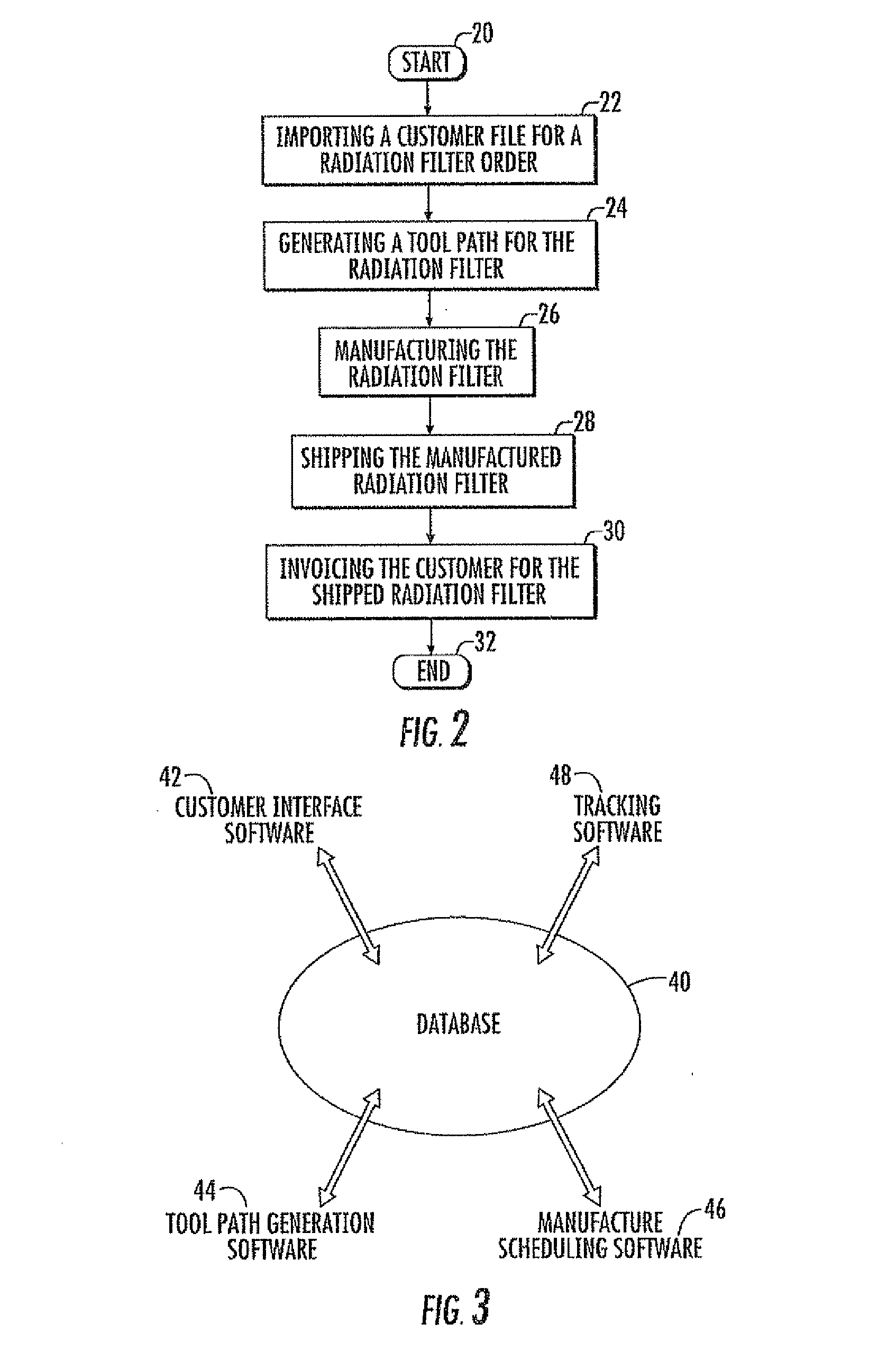

Automated process for manufacturing radiation filters for radiation treatment machines including manufacture scheduling

Automating the process for providing a radiation filter is based on different software programs executed by a computer system. The software programs include customer interface software, tool path generation software and manufacture scheduling software. Each software program performs a specific function for automating the process. The manufacture scheduling software determines available tooling machines to manufacture the radiation filter based on the generated tool path from a plurality of tooling machines, and selects one of the available tooling machines based on availability for manufacture of the radiation filter. The manufactured radiation filter is shipped, and the customer is then invoiced for the order.

Owner:DECIMAL

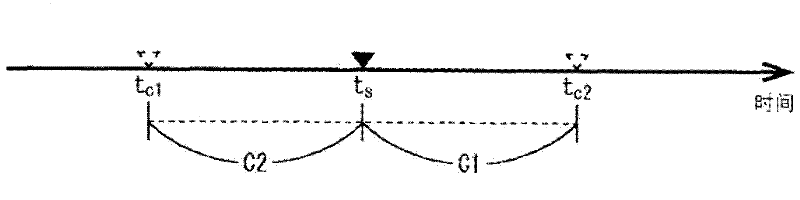

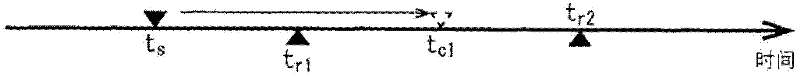

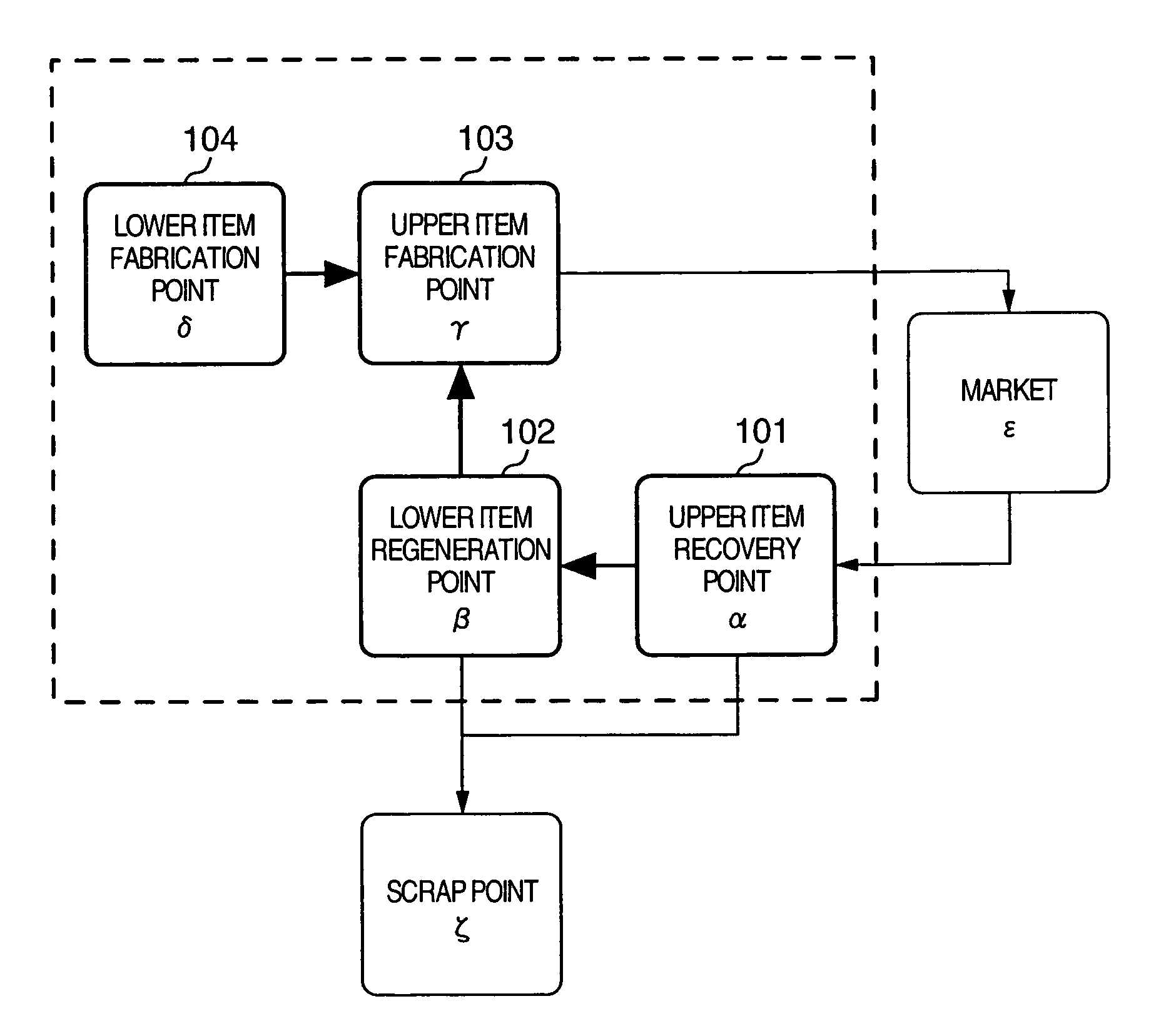

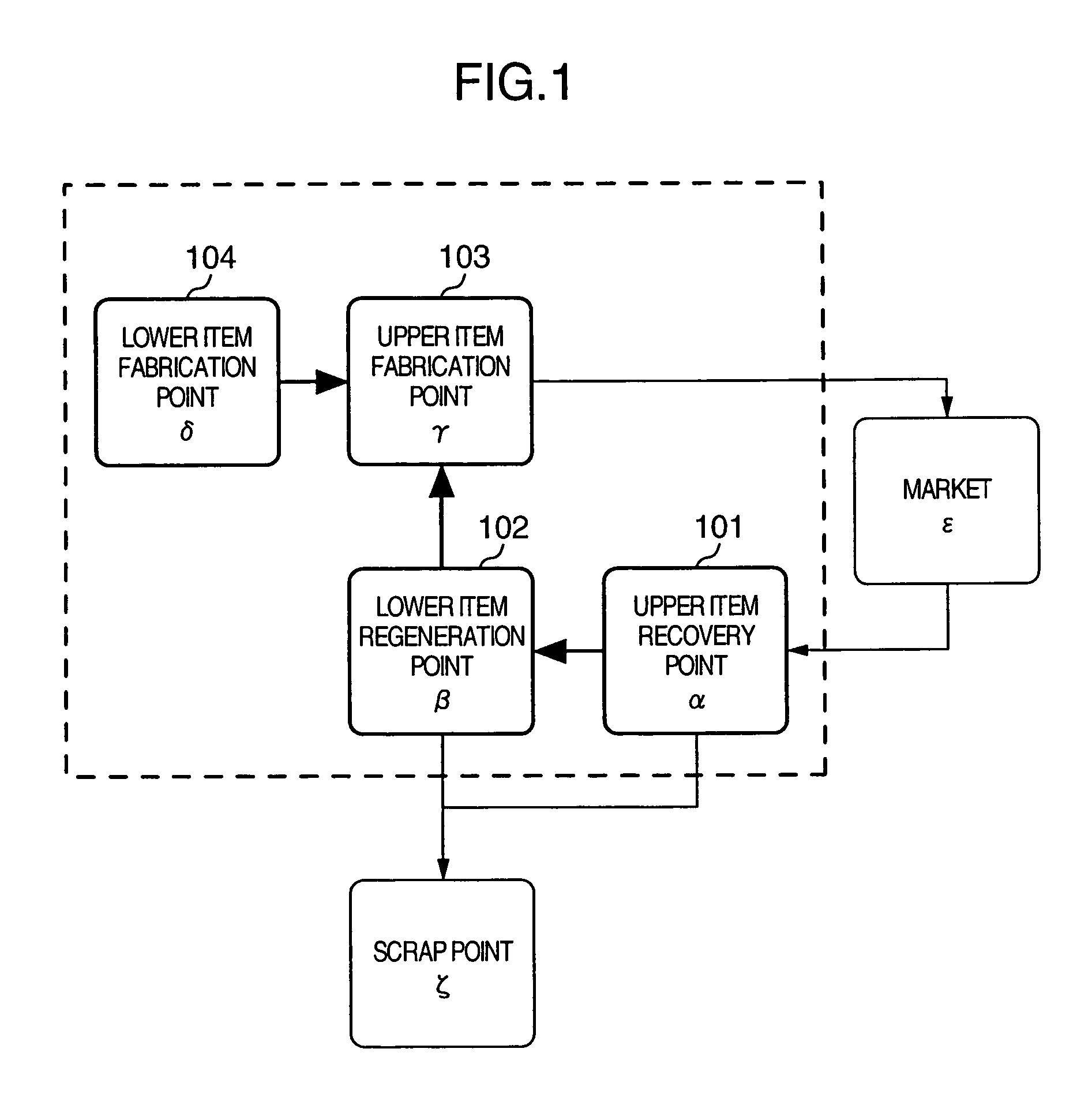

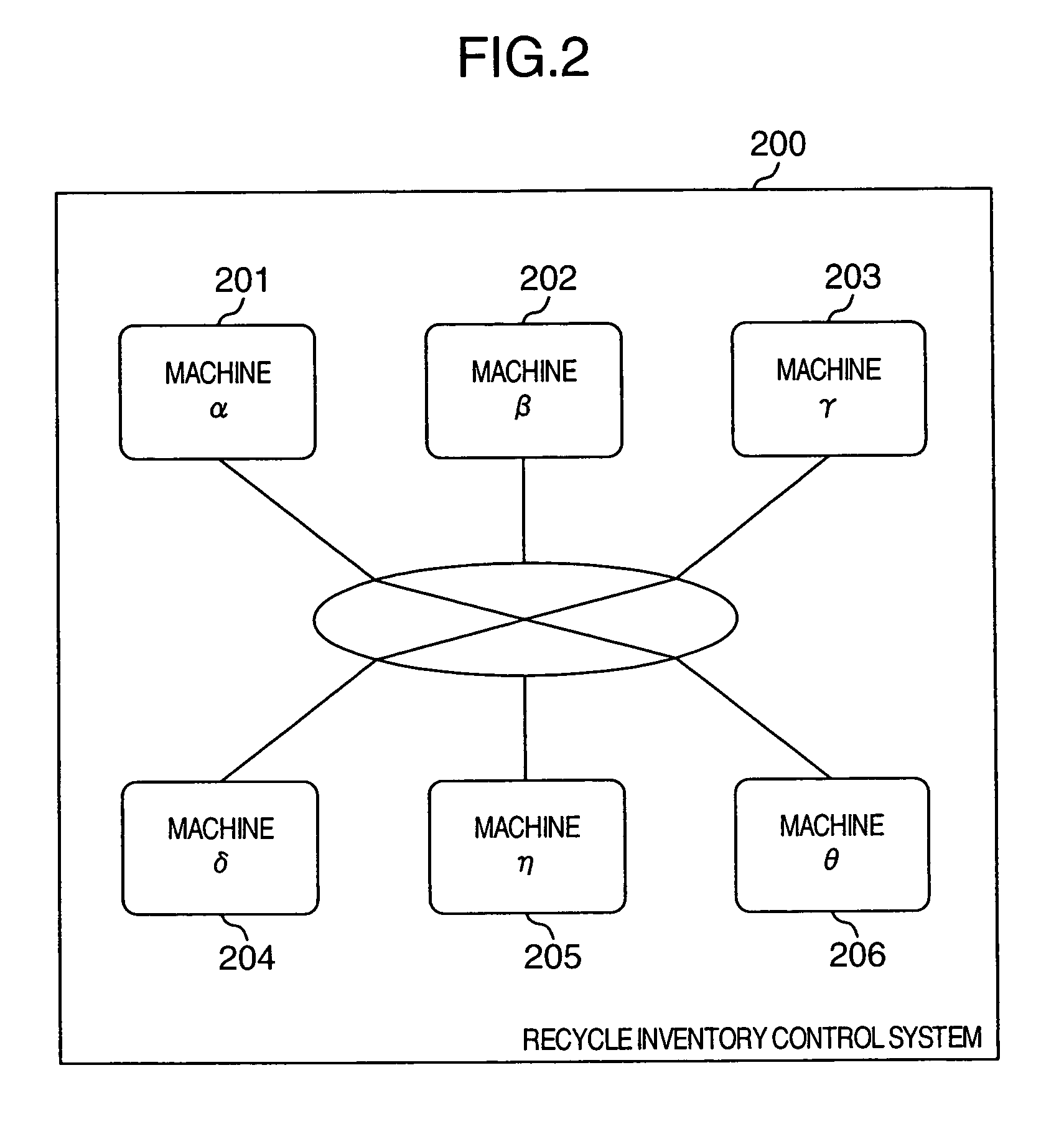

Inventory control system and method in recycle-oriented society

InactiveUS7624043B2Achieve synchronizationReduce excessSustainable waste treatmentHand manipulated computer devicesManufacturing planningControl system

In a physical distribution model of the circulation type, synchronization is established between a reuse plan and a delivery / fabrication plan to thereby reasonably reduce the excess and deficiency of inventory articles at a confluence point of regenerated reusable articles and newly delivered component parts. With regard to newly delivered lower-level items, predict a variation or fluctuation of stock quantity based on at least a delivery schedule of them and a present stock amount along with usage plans in manufacturing processes. As for lower-level items of regenerated articles, predict a delivery due date and an expected number of such regenerated lower-level items based on at least a stock quantity of recovered items collected for reuse purposes and a lead time for taking regenerated lower-level items out of the collected items, thereby controlling, based on the both prediction results, the stock quantity of the lower-level items in manufacturing processes.

Owner:HITACHI LTD

Manufacturing management device

InactiveCN107450485AA large amountTechnology managementResourcesManufacturing schedulingManufacturing cell

Owner:FANUC LTD

Point-of-use-toolkit

An apparatus is provided for implementation of back-end system for providing point-of-use toolkits. The apparatus may receive an assignment of work tasks assigned to a technician for manufacture of a tangible product. In response, the apparatus may compile a point-of-use toolkit including comprehensive information regarding the work tasks, and transmit the point-of-use toolkit to a front-end system associated with the technician. The apparatus may determine an occurrence of a delay associated with the schedule that impacts the assignment of the one or more work tasks, and transmit information associated with the delay to the manufacturing scheduling system. In response to receiving an update to the assignment of the tasks from the manufacturing scheduling system, the apparatus may compile an update of the point-of-use toolkit, and transmit the update of the point-of-use toolkit to the front-end system.

Owner:THE BOEING CO

Cloud manufacturing scheduling method based on Grover quantum search algorithm

ActiveCN110309921AImprove search speedQuantum computersProgram initiation/switchingQuantum search algorithmOptimal scheduling

The invention relates to a cloud manufacturing scheduling method based on a Grover quantum search algorithm. The cloud manufacturing scheduling method includes the steps: initializing quantum registerstates, setting a cost consumption function and a tensor product; taking a state register as an initial value; and taking M state registers from the N states by using an improved quantum Grover search algorithm, and carrying out minimum search, wherein if the cost consumption function of any new state register is smaller than the initial cost consumption function, the current state register is ascheduling optimal solution, and the scheduling state matrix corresponding to the current state register is taken as an optimal scheduling matrix, otherwise, the optimal scheduling matrix is taken asan initial scheduling state matrix, and an optimal scheduling matrix is output. According to the cloud manufacturing scheduling method, the task allocation planning speed in the cloud manufacturing scheduling problem is increased, and the quantum Grover algorithm is used for conducting hierarchical screening firstly, and most of non-optimal scheduling solutions can be filtered out to change the situation that a plurality of solutions need to be traversed originally into the situation that only a few solutions need to be traversed, and therefore the original problem is simplified, and the search speed is increased.

Owner:ZHEJIANG UNIV OF TECH

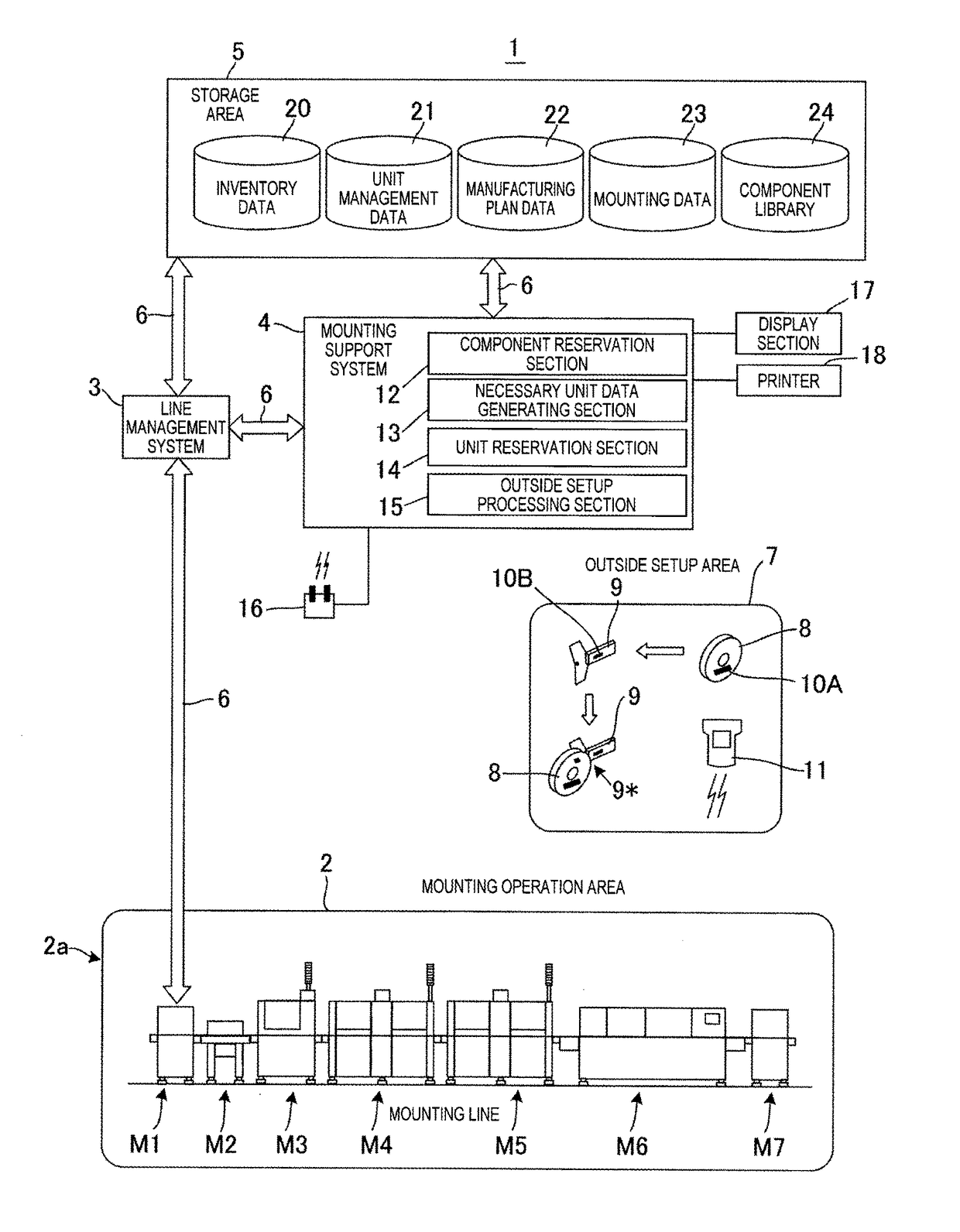

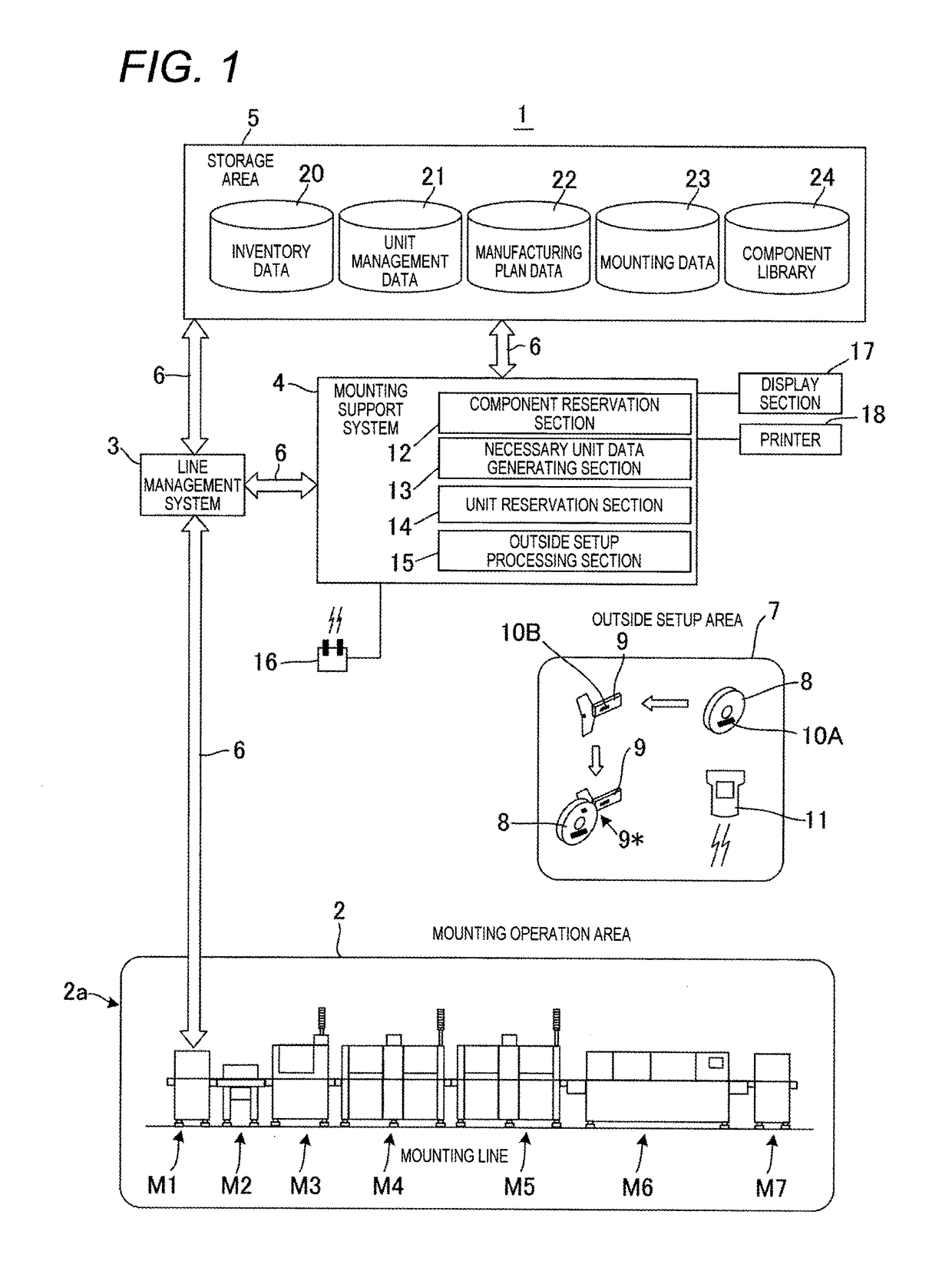

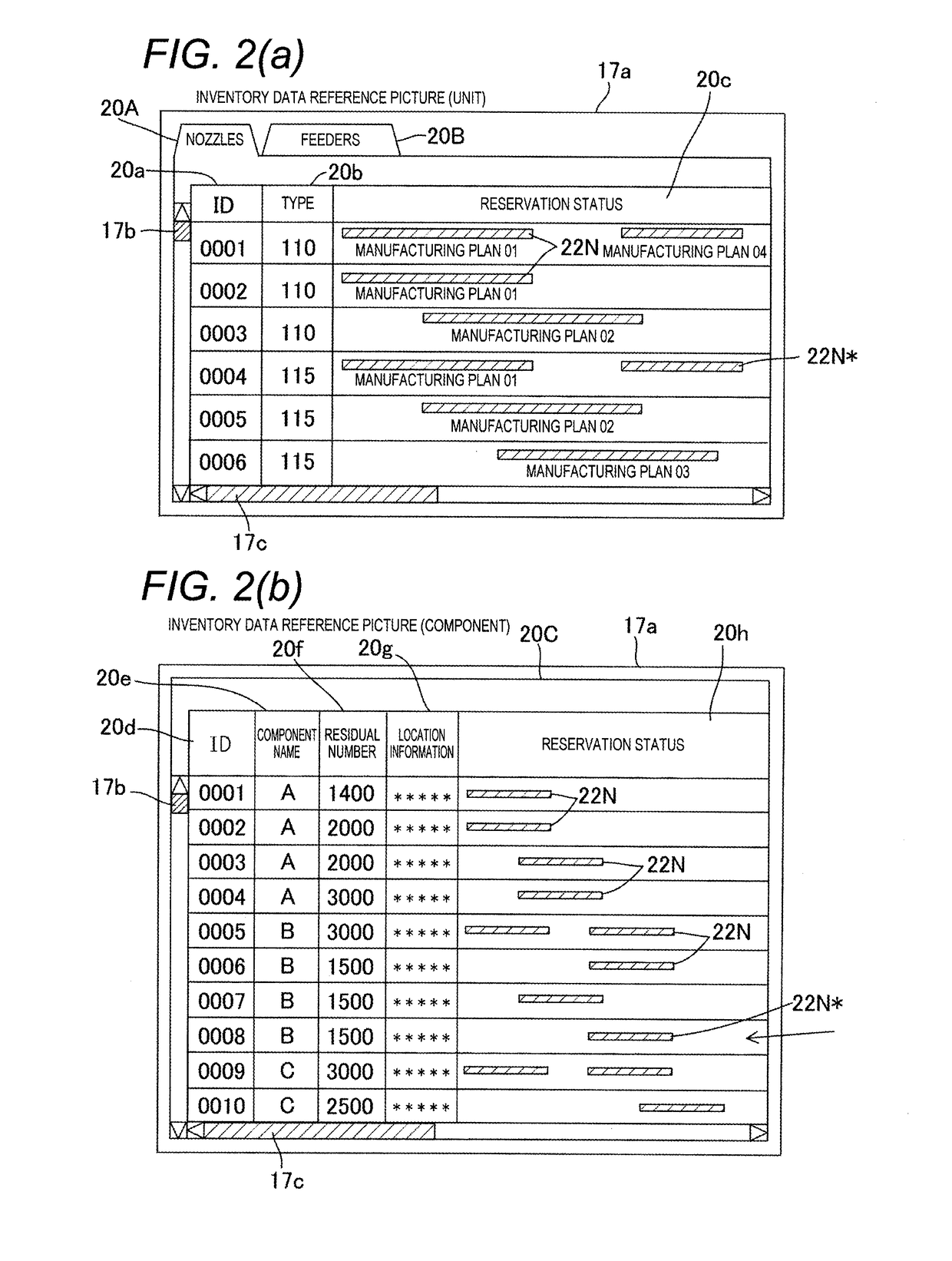

Electronic component mounting system and equipment unit management method for electronic component mounting system

ActiveUS9781837B2Reduce stepsImprove productivityPrinted circuit assemblingTechnology managementExecution unitManufacturing scheduling

An electronic component mounting system stores: manufacturing plan data for each manufacturing lot; unit management data including use permission information indicating a use permission status of an equipment unit; and inventory data indicating a stock status of the equipment units. In a unit reservation processing, new allocation processing is performed for allocating an equipment unit necessary for manufacture of a new manufacturing lot to an equipment unit for a new manufacturing lot, and an allocation result is registered. The system determines whether an equipment unit of an allocation subject in the new allocation processing can be allocated to an equipment unit for the new manufacturing lot by referring to use permission information of the equipment unit, and if the equipment unit is determined as being usable, the unit reservation processing is performed.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for Manufacturing With Engineering Change Override

The illustrative embodiments provide a computer implemented method, apparatus, and computer usable program code for processing orders. A request for delivery by a requested delivery date is received for an order having an original delivery date. The ordered product is broken down into one or more materials required for manufacturing the ordered product. For at least one material required for manufacturing the ordered product, a date when an engineering change becomes effective for the material is specified. An alternate bill of materials is created based on the specified date when the engineering change becomes effective for the material. An alternate manufacturing plan based on the alternate bill of materials is created. Manufacturing is initiated based on the alternate manufacturing plan. If manufacturing can be completed in time for delivery by the requested delivery date, the original delivery date of the order is replaced with the requested delivery date.

Owner:INT BUSINESS MASCH CORP

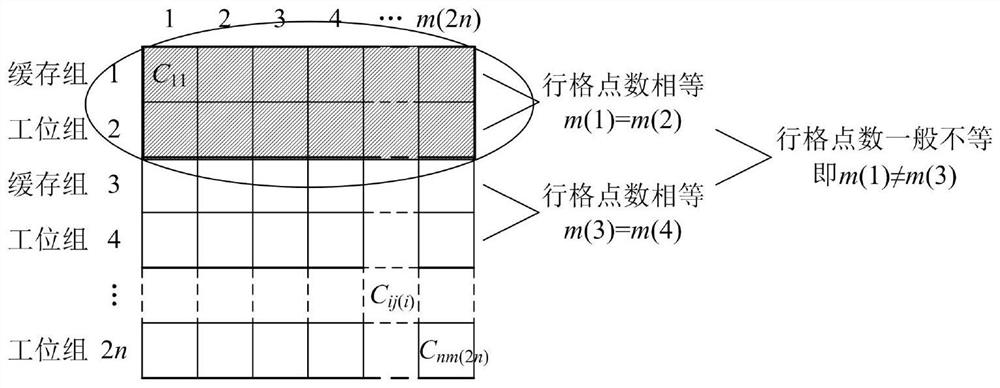

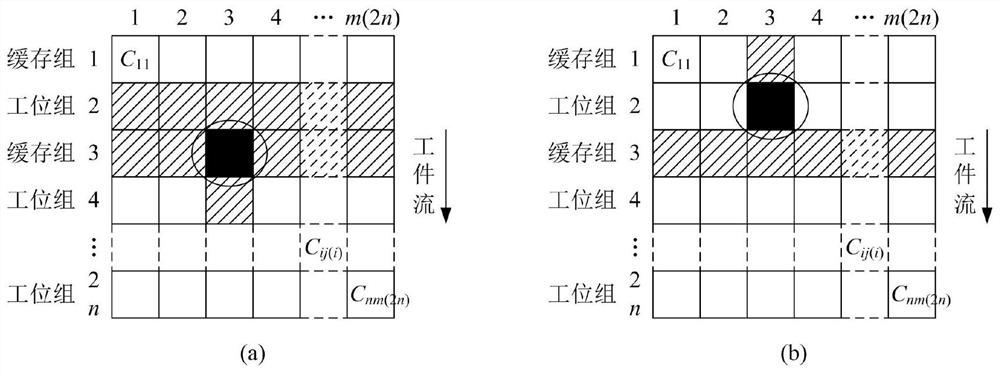

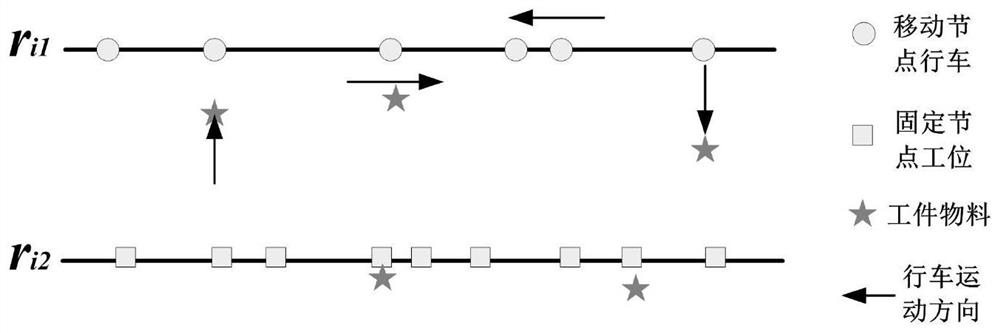

Cell plane cooperative scheduling method for large equipment manufacturing and driving system

The invention discloses a cellular machine collaborative scheduling method for a large equipment manufacturing and driving system. The method mainly comprises the following steps: (1) constructing a grid model of a production scheduling cellular machine, describing a cellular state, setting initial conditions and boundary conditions of a production scheduling cellular machine model, and setting an evolution rule; (2) optimizing an evolution rule of the production scheduling cellular machine model; (3) constructing a grid model of the driving scheduling cellular machine according to the actual driving operation condition, describing the cellular state, setting the boundary condition of the driving scheduling cellular machine model, and setting an evolution rule; (4) optimizing the driving scheduling evolution rule by means of a genetic algorithm; (5) designing a large equipment manufacturing production and driving collaborative scheduling simulation system interface. According to the production scheduling and driving scheduling collaborative modeling method based on the cellular machine, a new method and thought are provided for large equipment manufacturing scheduling.

Owner:ZHEJIANG UNIV OF TECH

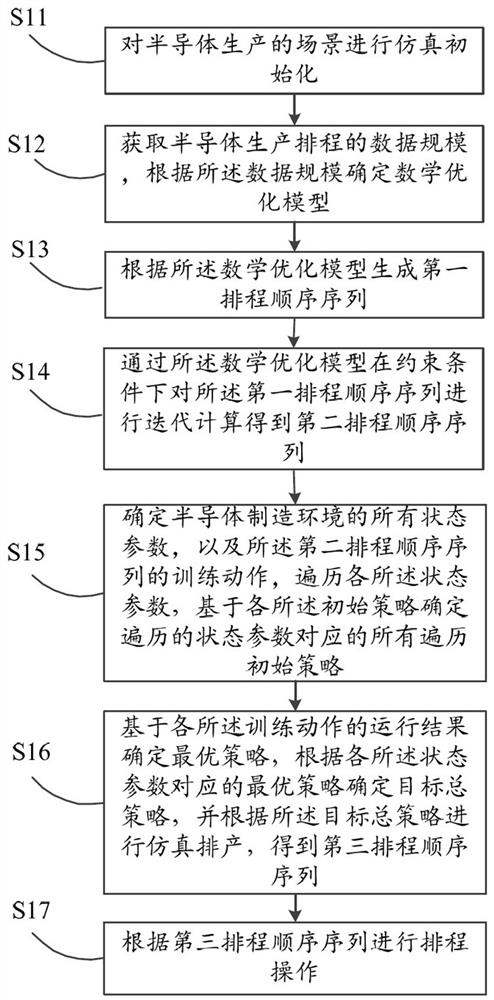

Semiconductor manufacturing scheduling method and system and computer readable storage medium

PendingCN114462772AReasonable allocation of production capacityImprove resource utilizationResourcesManufacturing computing systemsManufacturing schedulingSemiconductor

The invention discloses a semiconductor manufacturing scheduling method and system and a computer readable storage medium. The method comprises the following steps: determining a mathematical optimization model according to a data scale; generating a first scheduling sequence according to the mathematical optimization model, and performing iterative calculation on the first scheduling sequence through the mathematical optimization model under a constraint condition to obtain a second scheduling sequence; determining an optimal strategy based on an operation result of each training action, determining a target total strategy according to the optimal strategy corresponding to each state parameter, and performing simulation scheduling according to the target total strategy to obtain a third scheduling sequence; and performing scheduling operation according to the third scheduling sequence. According to the method, rapid target optimization of semiconductor manufacturing scheduling is realized, the production capacity is effectively and reasonably distributed, the resource utilization rate is improved, and the production cost is reduced.

Owner:埃克斯工业有限公司

Wafer manufacturing scheduling method and scheduling system in semiconductor integrated circuit production

ActiveCN104423331BIncrease productivityIncrease success rateSemiconductor/solid-state device manufacturingTotal factory controlProduction lineApplication computers

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com