Product energy-saving scheduling optimization method for flexible manufacturing system

A technology of flexible manufacturing system and optimization method, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of ignoring process flexibility and assembly process, reducing production time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

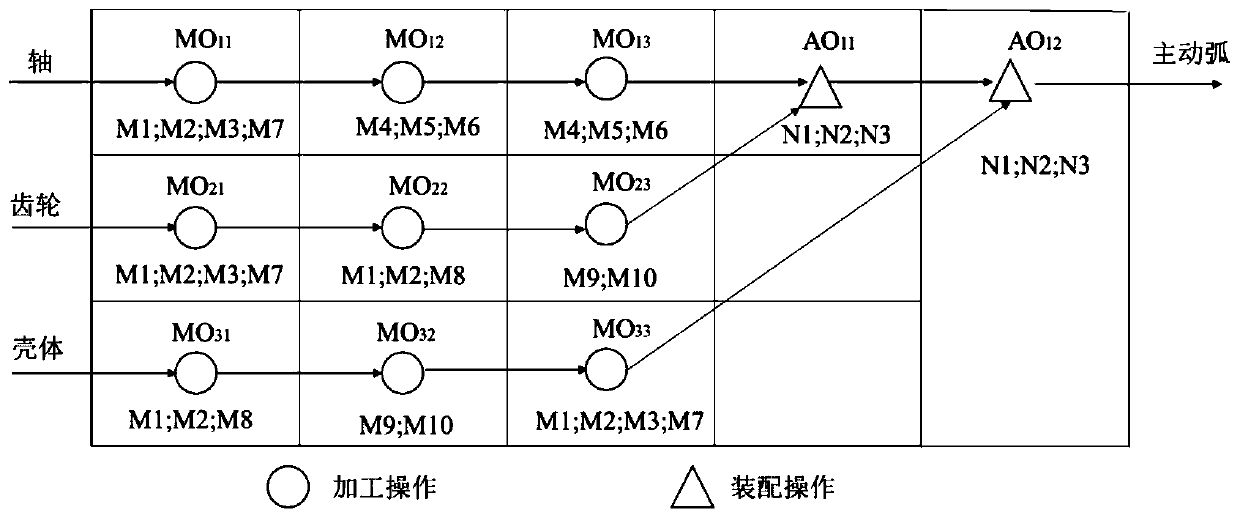

[0066] Embodiment: Take the parts production and assembly process of a tractor parts manufacturing company as an example. At present, the enterprise is mainly engaged in the processing and assembly of tractor active arcs, differentials, lifters and other product components. The manufacturing process of active arcs is shown in the attached figure 2 shown.

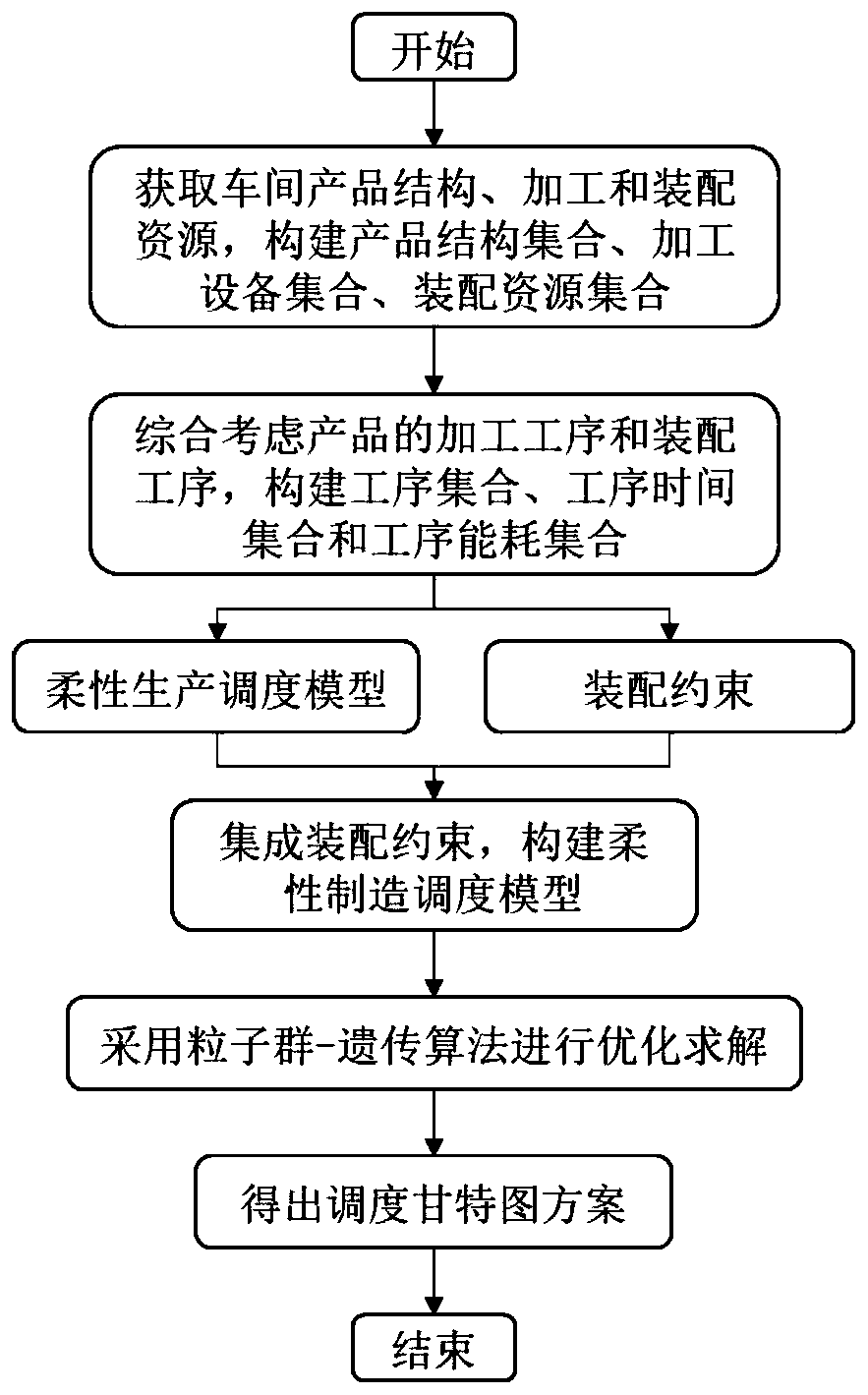

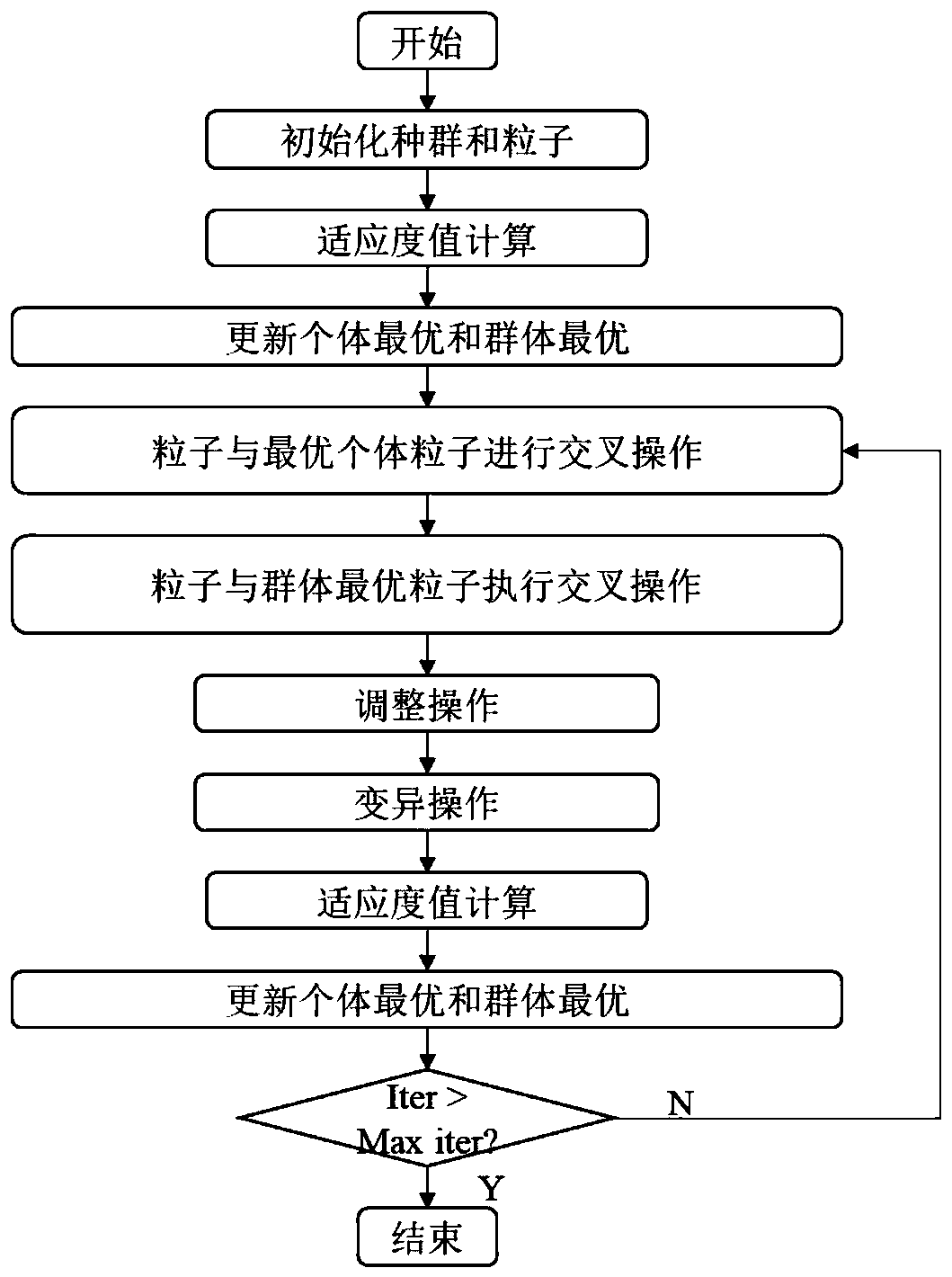

[0067] Such as figure 1 As shown, this embodiment discloses a flexible manufacturing system-oriented product energy-saving scheduling optimization method, and the specific implementation steps are as follows:

[0068] Step 1. Obtain the product structure, processing and assembly resources of the workshop, and construct a product structure set, a processing equipment set, and an assembly resource set.

[0069] Step 1.1: The manufacturing system needs to complete 3 products, and build a product set P={P 1 ,P 2 ,P 3}, where P 1 Indicates the active arc, P 2 Indicates the differential, P 3 Indicates a lifter. Build a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com