Production and manufacturing scheduling optimization method based on improved genetic algorithm

A technology for improving genetic algorithms and optimization methods, applied in genetic rules, manufacturing computing systems, computing, etc., can solve the problems that genetic algorithms cannot perform global optimization and reduce optimization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Under the conditions of fierce market competition and the general trend of economic globalization, enterprises are facing more and more complex and diversified market demands. Improving production efficiency and responding to market demands in a timely manner are the core goals of modern intelligent manufacturing. An important way to improve efficiency and enhance the core competitiveness of enterprises. The manufacturing process is complicated, the processing route and the use of equipment are very flexible, and there are many changes in product design, processing demand and order quantity. In order to achieve the goal of modern intelligent manufacturing, it is necessary to optimize the production scheduling of manufacturing enterprises and arrange them reasonably Production and processing plan.

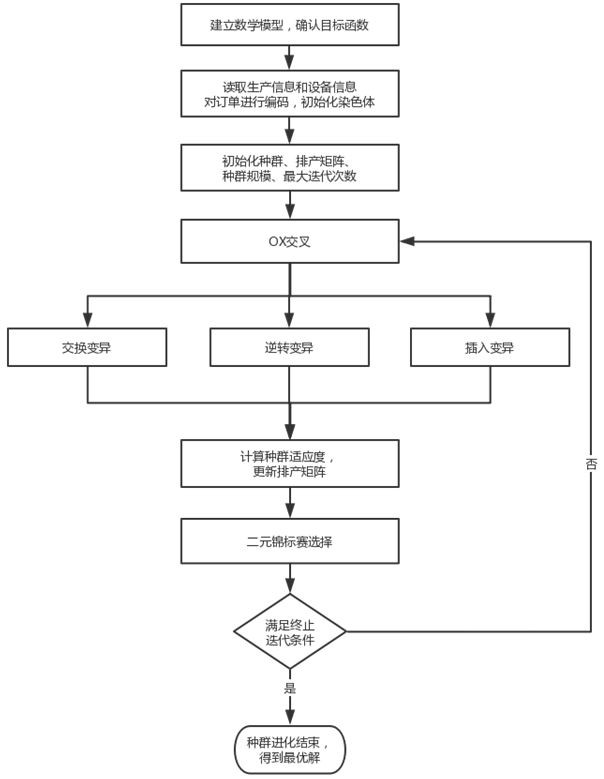

[0037] Using the genetic algorithm to solve the production scheduling optimization problem will produce coding conflicts, that is, it cannot satisfy the constraint that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com