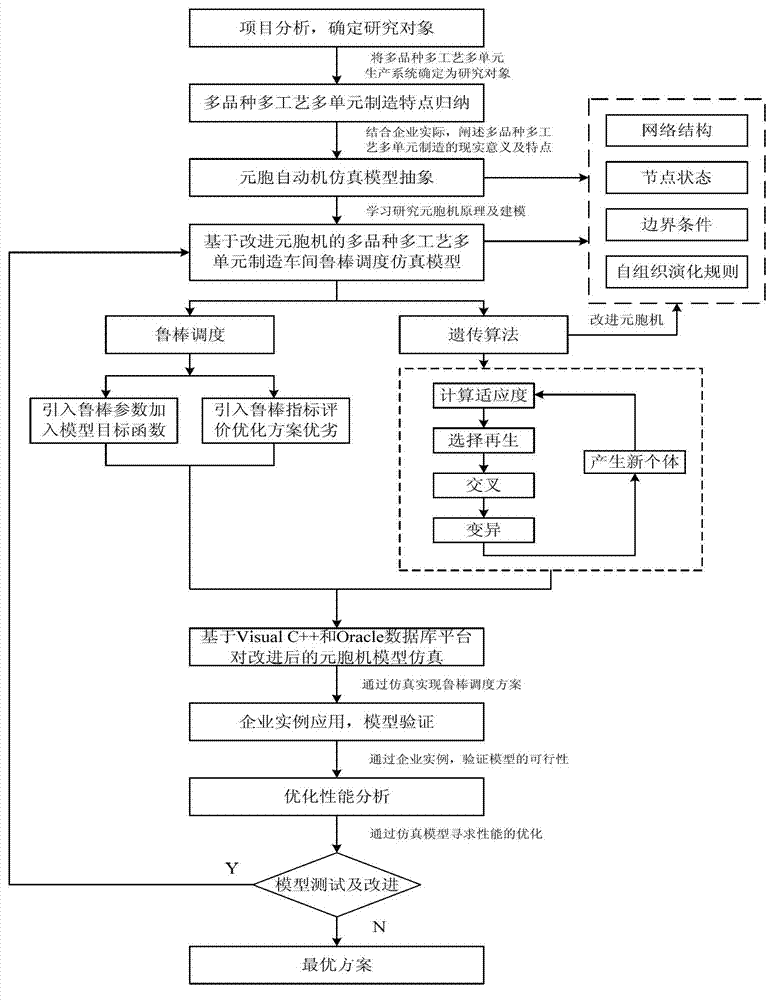

Multi-species multi-process multi-unit manufacturing scheduling method based on improved cellular machine

A scheduling method and multi-process technology, applied in control/regulation systems, adaptive control, general control systems, etc., can solve the problems of weak robustness and inability to dynamically monitor the scheduling scheme, and achieve the effect of high balance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

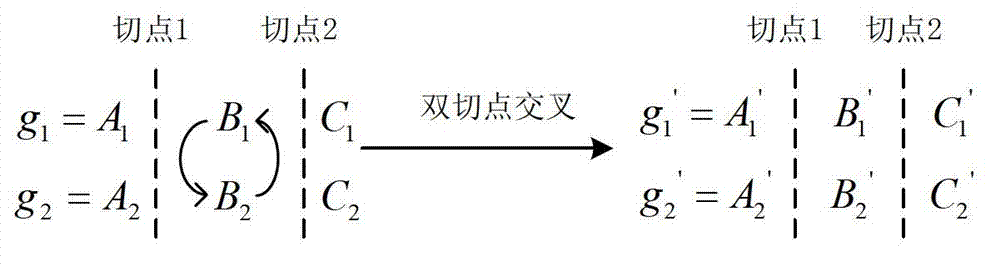

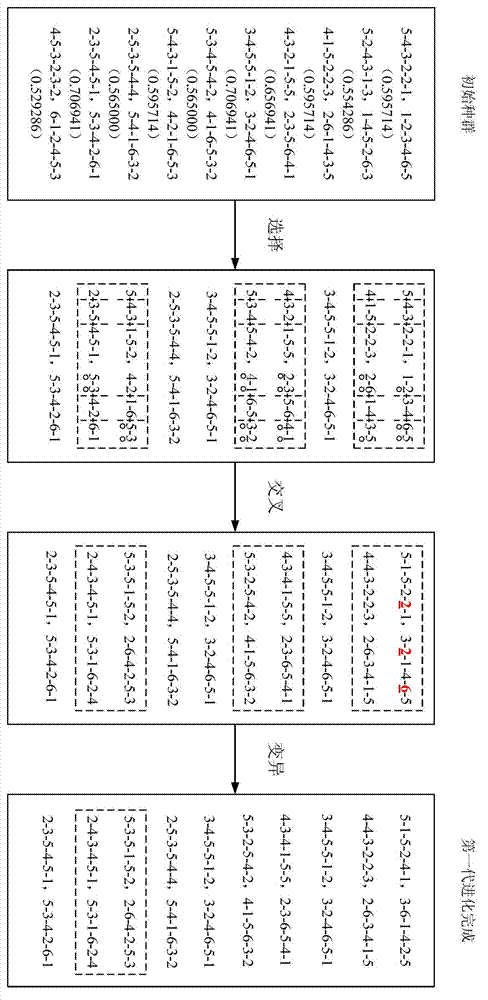

Method used

Image

Examples

example

[0125] Example: Research on the workshop part of the second factory of a certain electric tool manufacturer. This part mainly produces various types of battery packs. Table 5-1 shows the order status of battery packs in a certain quarter.

[0126] The battery pack wire produces 43 products with different structures, such as 1604335786 and 1604335333. The following 4 digits of the product model represent these 10 products. The order quantity of some models is small, and only one batch is produced in a year. Therefore, in the quarter studied in this paper, there are 39 types of products. Table 2 shows the demand for 39 battery packs in the first quarter, that is, the order quantity. Among them, the production volume in July is the normal order, and the orders in August and September are the later insertion workpieces. Table 2 is the product order information:

[0127]

[0128] Table 2

[0129] The following are the state attribute values of the station cells and workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com