Blast furnace slag treatment method and device capable of directly obtaining high-temperature dried slag

A technology of a treatment device and a treatment method, applied in the direction of recycling technology, etc., can solve the problems of difficult purification of industrial wastewater, white pollution of the environment, waste of water resources, etc., and achieve the effects of improving energy utilization, reducing pollution, and reducing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

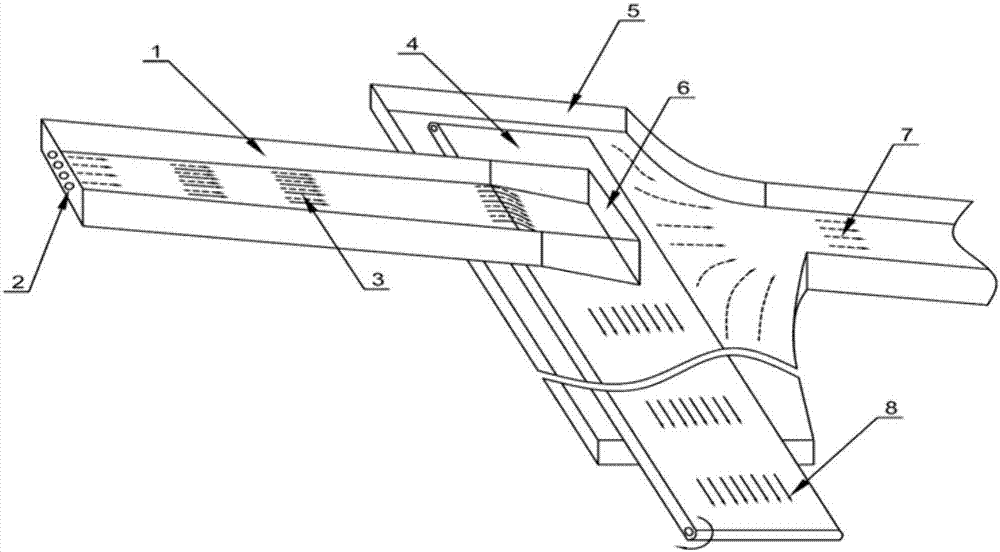

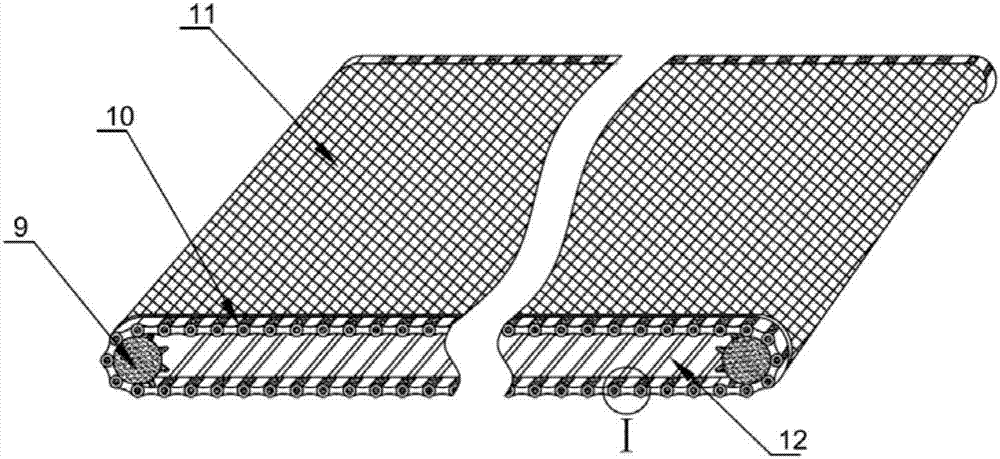

[0028] A method for treating blast furnace slag that can directly obtain high-temperature dry slag provided by the present invention is as follows: liquid blast furnace slag flows into the upper water slag tank 1, and the liquid blast furnace slag is washed and cooled by water sprayed from high-pressure water nozzles. Due to thermal stress, the slag is The slag-water mixture 3 is broken into small particles of about 4 mm, and the slag-water mixture 3 flows down along the upper slag tank 1 by gravity; during the flow, the granulated blast furnace slag in the slag-water mixture 3 exchanges heat with water, After the temperature drops to 400-800°C, it falls on the special mesh conveyor belt 4, and the end of the upper water slag tank 1 is equipped with a terminal slag retaining net 6 to ensure that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com