Solution dehumidification device driven by low-temperature smoke gas

A solution dehumidification device, low-temperature flue gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient use of dehumidification solution, waste of water resources, low regeneration efficiency, etc., to achieve environmental protection, The effect of saving energy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

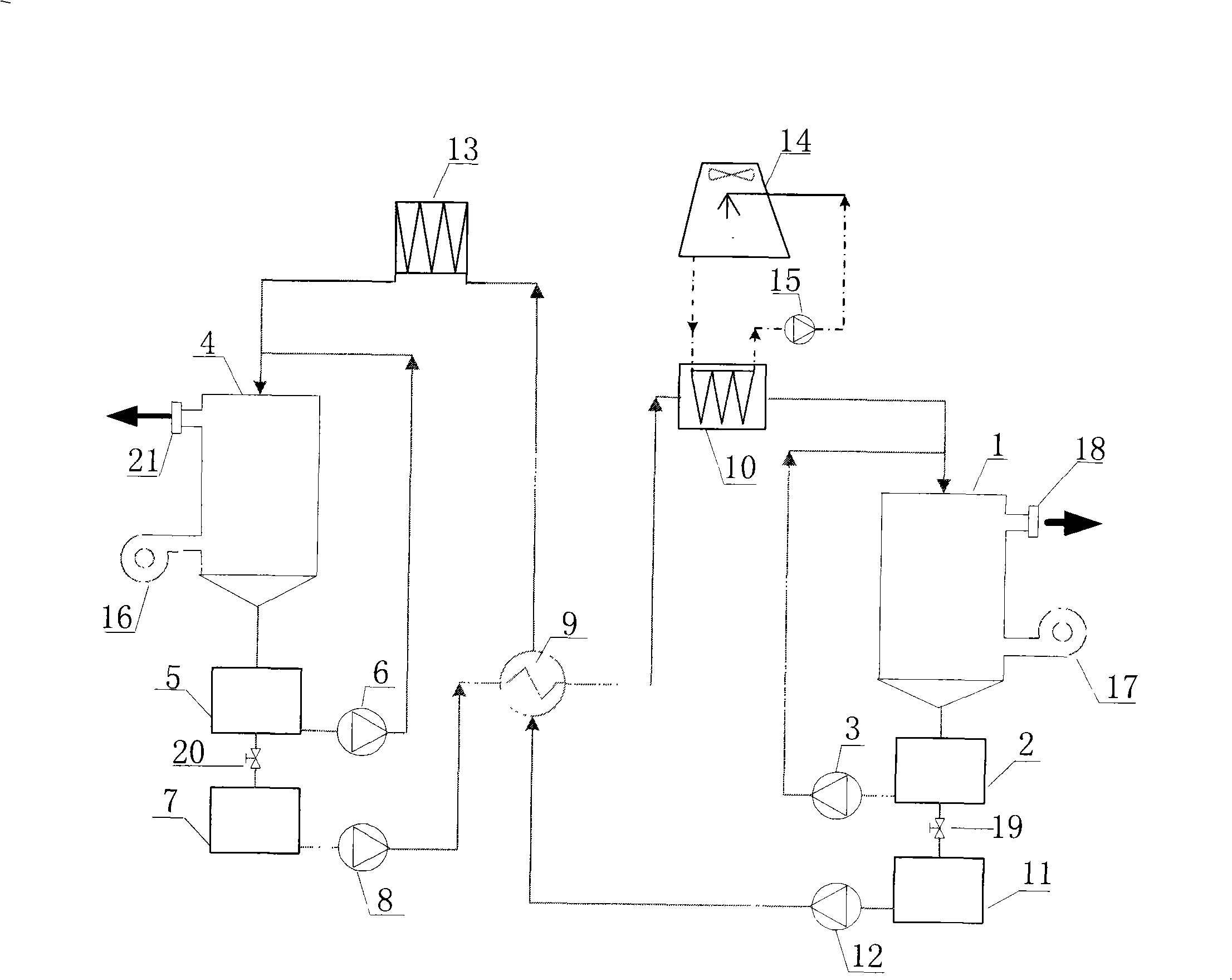

[0015] Embodiment 1: The gas consumption of a certain heating furnace is 30000m 3 / h, the air consumption is 69000m 3 / h, the flue gas temperature is about 300°C. Using 50% LiBr solution as the dehumidifier, in the dehumidification internal circulation, the solution mass flow rate is 11.2kg / s, the solution temperature is 30°C, the wet air mass flow rate is 25.08kg / s, and the wet air temperature is 28°C. In the regeneration internal circulation, the solution flow rate is 12.17kg / s, the air mass flow rate is 25.08kg / s; the heat exchange area of the flue heater is 120m 2 , the cooling area of the solution cooler is 50m 2 . The air humidity after treatment is from 25g / m 3 Reduced to 10g / m 3 , using the treated air for heating furnace combustion can save gas by 2.16%, which is equivalent to saving 1772 tons of standard coal per year.

[0016] In addition, the treated air can reduce the power consumption of the fan, reduce the oxidation atmosphere of the atmosphere in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com