Internal combustion engine system

A technology of internal combustion engine and circulatory system, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of limited working capacity of power turbine, unrecoverable energy, complicated matching between two-stage supercharging system and internal combustion engine, etc. The effect of high energy utilization rate and improved recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

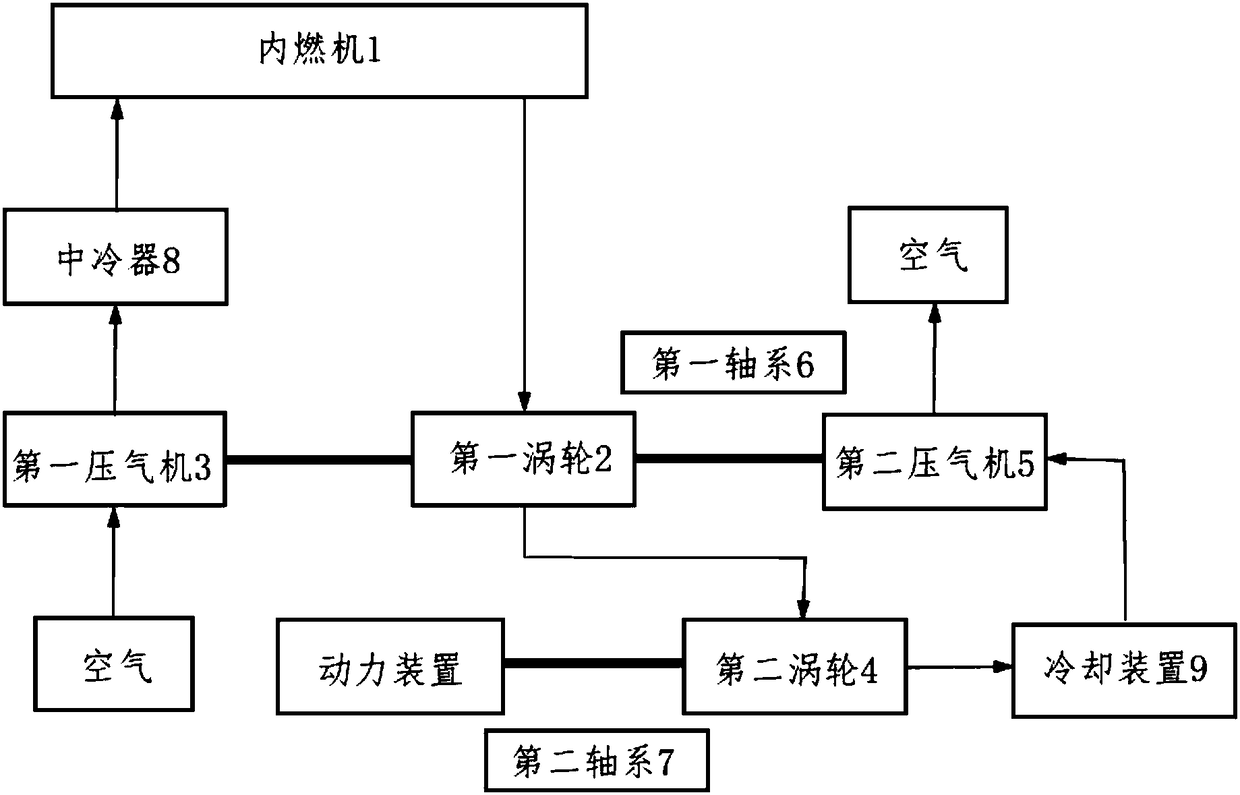

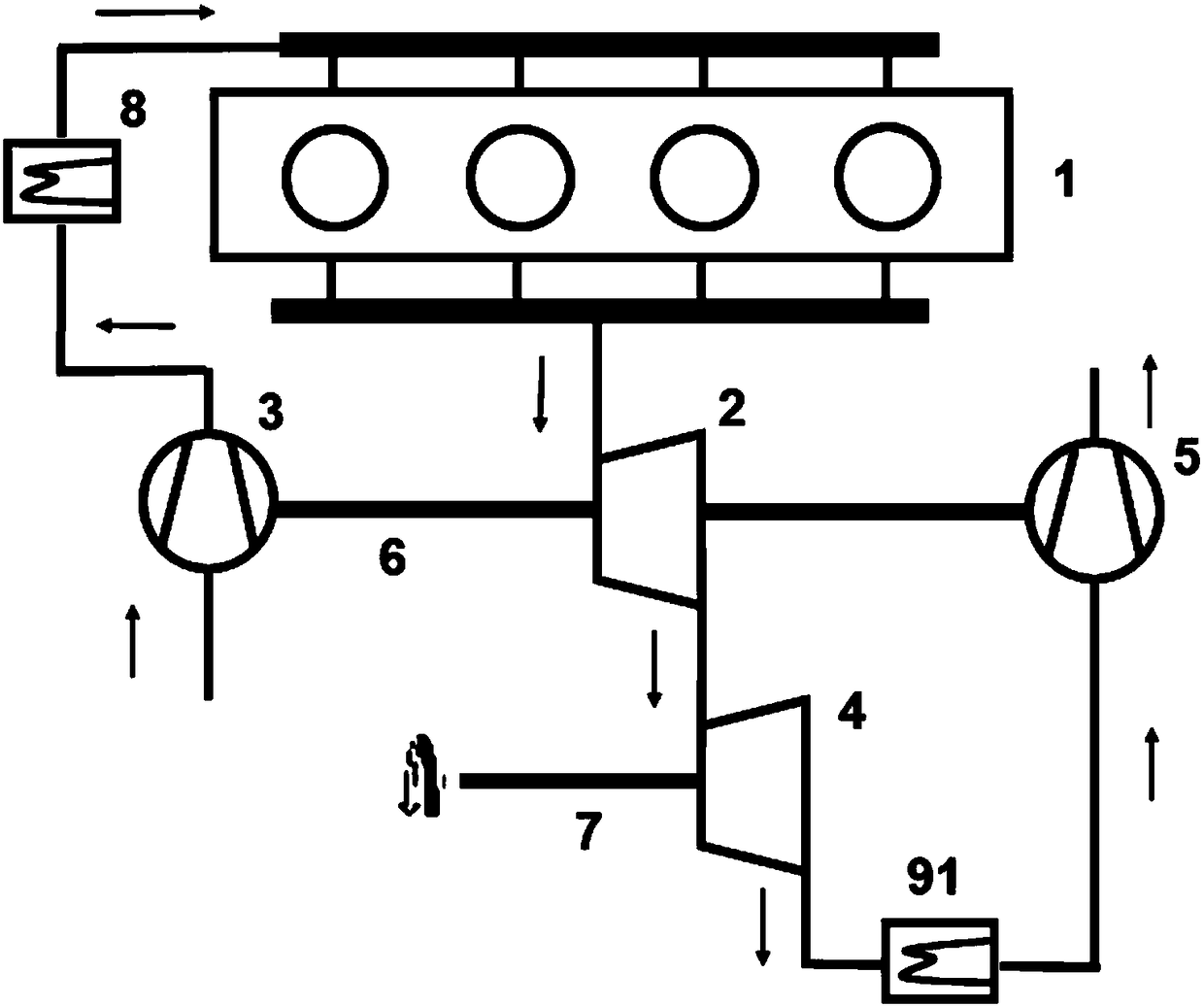

[0038] figure 2 It is a schematic composition diagram of the internal combustion engine system provided by Embodiment 1 of the present invention.

[0039] image 3 It is a schematic structural diagram of the internal combustion engine system provided by Embodiment 1 of the present invention.

[0040] Please refer to figure 2 , image 3 , The present invention provides an internal combustion engine system, comprising: an internal combustion engine 1 , a turbine 2 , a first compressor 3 , a second turbine 4 , a second compressor 5 , a first shafting 6 and a first shafting 7 .

[0041] An internal combustion engine 1 is provided with an intake port and an exhaust port. The internal combustion engine 1 is a kind of power machine, which burns fuel inside and directly converts the heat energy released by the fuel combustion into a heat engine for power.

[0042]The inlet of the first turbine 2 is connected to the exhaust port of the internal combustion engine 1 , and the outl...

Embodiment 2

[0059] Please refer to Figure 4 The difference between this embodiment and the first embodiment is that the cooling device 9 uses a thermoelectric conversion component 92 instead of the first heat exchange component 91 .

[0060] The inlet of the thermoelectric conversion component 92 is connected to the outlet of the second turbine 4 , and the outlet is connected to the inlet of the second compressor 5 for cooling the gas discharged from the second turbine 4 and converting the absorbed heat energy into electrical energy for output.

[0061] Optionally, the material of the thermoelectric conversion component 92 is a thermoelectric material, which is a material that can convert thermal energy into electrical energy.

[0062] Specifically, after the exhaust gas discharged from the internal combustion engine 1 is expanded to perform work by the second turbine 4, it still has a relatively high temperature, and there is room for waste heat recovery and utilization. The exhaust ga...

Embodiment 3

[0065] Because in the technical solution of Embodiment 1, the first heat exchange component 91 absorbs the heat of the exhaust gas, the purpose of reducing the temperature of the exhaust gas can be achieved, but no matter whether the first heat exchange component 91 adopts an air-cooled or water-cooled heat exchanger, This part of the heat is not recycled, but dissipated into the atmosphere. Therefore, in this embodiment, the Rankine cycle system is used to replace the first heat exchange component 91 , and the heat absorbed by the second heat exchange component 93 is further recycled to improve the utilization rate of energy.

[0066] Please refer to Figure 5 , In this embodiment, the Rankine cycle system includes a second heat exchange component 93 , a steam turbine 94 , a third heat exchange component 95 , a pump 96 and a third shaft system 97 .

[0067] The first inlet of the second heat exchange component 93 is connected to the outlet of the second turbine 4 , and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com